Droplet Digital PCR (ddPCR)

The science of microfluidic liquid handling for droplet digital PCR (ddPCR)

- Higher accuracy

- Higher sensitivity

- Absolute quantitation

What is digital PCR (dPCR)?

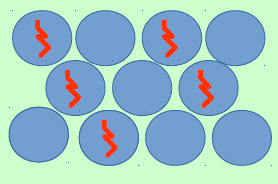

During the last decade digital-PCR (dPCR) has become one of the most prominent assays for analytical methods. dPCR carries out a single reaction within a sample as standard PCR, however, the sample is separated into a large number of partitions, and the reaction is carried out in each partition individually.

What is droplet digital PCR (ddPCR) and how does it work?

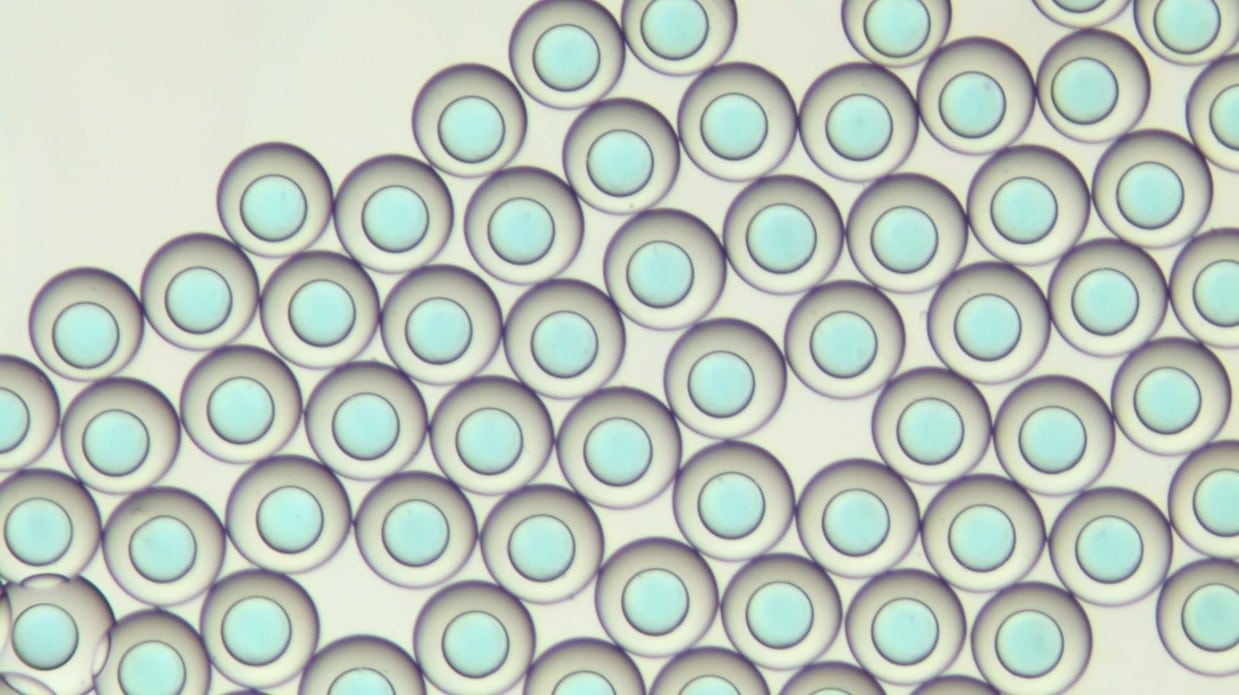

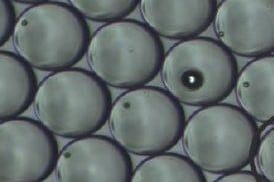

Droplet digital PCR relies on the partitioning of the tested sample into thousands of single samples thanks to the generation of droplets. For performing the assay, the sample volume is split in such a way that each droplet contains either one or none of the target DNA molecules. The droplets act as laboratory wells, each containing a sample, and being able to host a PCR reaction in within. Due to the small droplet volume, the PCR reaction runs very efficiently even from a single molecule. During amplification, a fluorescent dye is formed or activated. The positive droplets become fluorescent. Absolute quantitation of the number of target molecules is simplified to the count of fluorescence active droplets in the generated droplet collection. ddPCR is an excellent example of a transition of a microfluidic system from the academic field to industry.

What are the advantages of ddPCR?

The major advantage of droplet digital PCR is the possibility to perform absolute quantitation of the number of target molecules, which is simplified to the count of fluorescence active droplets in the generated droplet partition. The separation allows for more reliable collection and sensitive measurement of nucleic acid amounts. Precision is drastically enhanced [1], and no standard curves or calibration standards are necessary to assess the quantity of the sample of interest. The separation in multiple droplets containing nanoliters of reagent drastically reduces the time and reagents needed to perform a classical PCR reaction. This allows to reduce consumable and reagent costs, which makes it a one-of-a-kind cost effective method.

Main applications using droplet digital PCR technology

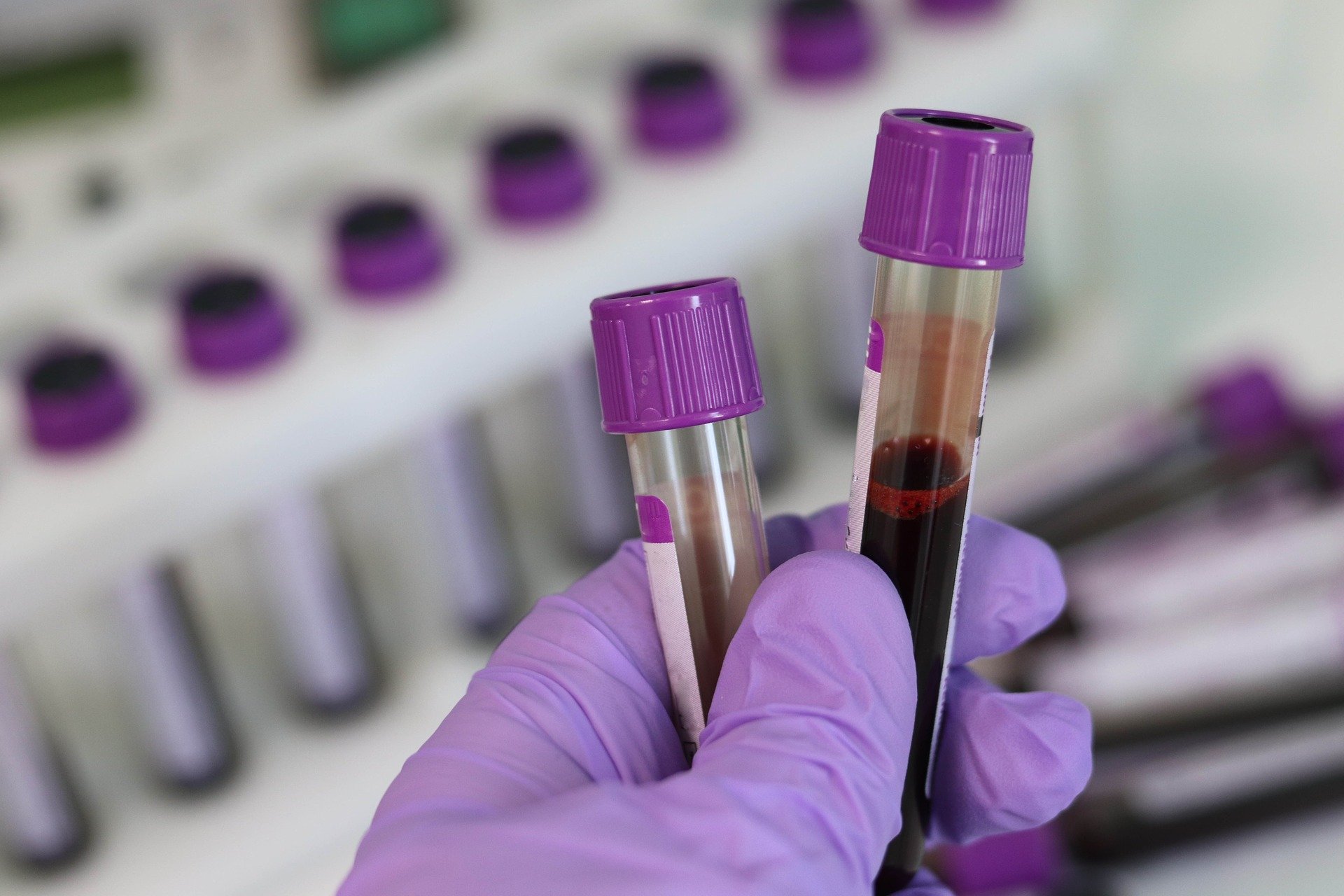

Liquid biopsy

Liquid biopsies are non-invasive tests performed on blood samples to detect cancer cells circulating in the blood (circulating tumor cells, CTCs) or pieces of DNA from tumor cells in the blood. This technique is increasingly used for cancer detection and monitoring, as it is low risk for the patient and helps doctors understand what kind of molecular changes are taking place in the tumor. Droplet Digital PCR (ddPC) provides the level of sensitivity required for liquid biopsy.

Copy number variation

A key measurement challenge in diagnostic research involves identifying small changes in nucleic acid sequence that are commonly associated with genetic diseases. Changes in the genomic DNA leading to an abnormal copy of a DNA sequence are called copy number variations (CNVs). They are present in complex diseases such as Down’s Syndrome and many cancers.

Pathogen Detection and Microbiome Analysis

Droplet digital PCR is extensively used in microbiology.. Digital PCR’s ability to amplify low concentration targets in complex backgrounds and show higher sensitivity than standard PCR makes it the technology choice for microbiome analysis.

Resources

-

Microfluidics Case Studies OEM Case Study: Microfluidic Drug Screening Read more

-

Expert Reviews: Basics of Microfluidics Microfluidics for vaccine development Read more

-

Microfluidic Application Notes High-throughput cell DNA screening using digital PCR Read more

-

Microfluidic Application Notes Analysis of a commercial surfactant for digital PCR assay Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

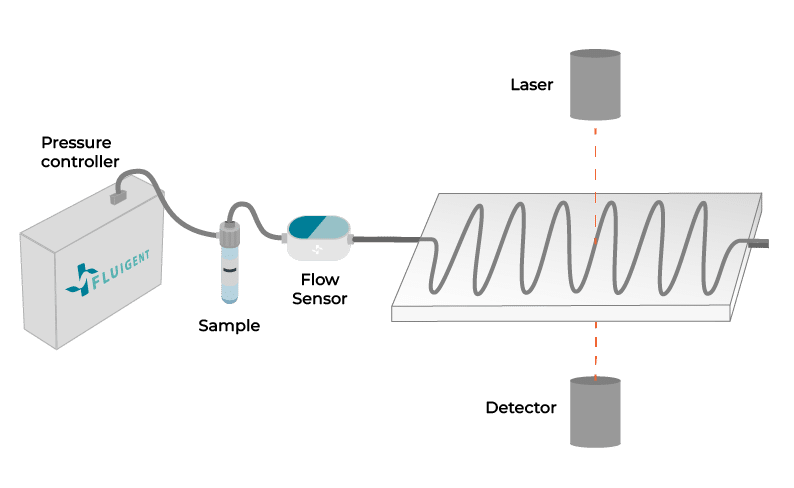

Importance of fluid handling for droplet digital PCR applications

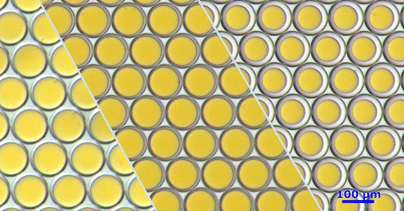

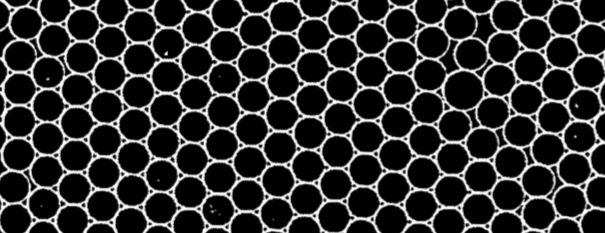

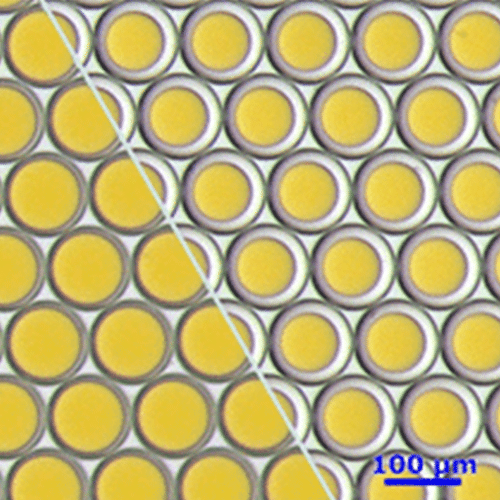

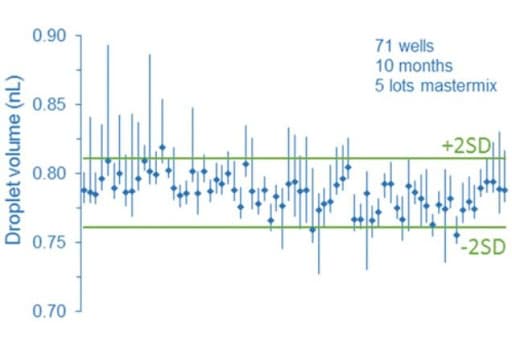

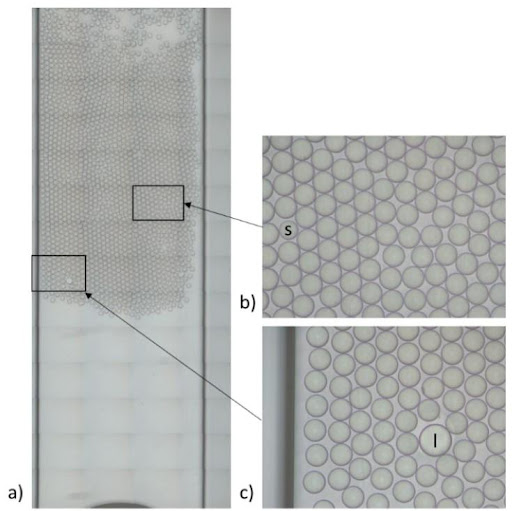

Droplet digital PCR relies on random distribution of dPCR mix containing target molecules on the partition of equivalent volumes (here, the droplets). In this way, some partitions contain no target molecules, while the remaining partitions contain at least one molecule. Partitions are next categorized and counted as positive or negative depending on their fluorescence intensity. The calculations are derived from a Poisson model, which can be impacted by partition volume since the model assumes the partition to be monodisperse. As a consequence, a heterogeneous droplet population can affect the droplet digital PCR process. In fact, several groups demonstrated through different studies that partition droplet volume variability can cause a bias on the accuracy of the measurements.

More information can be found in the paper written by Emslie et al.: Droplet Volume Variability and Impact on Digital PCR Copy Number Concentration Measurements The impact of flow rate on droplet size using a microfluidic system is today well described in the literature. Thus, to avoid heterogeneous droplet populations that can affect the droplet digital PCR process, one should consider using a precise flow controller.

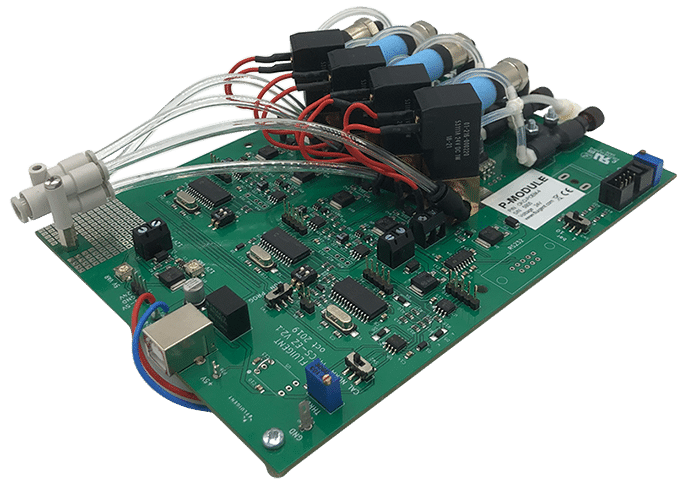

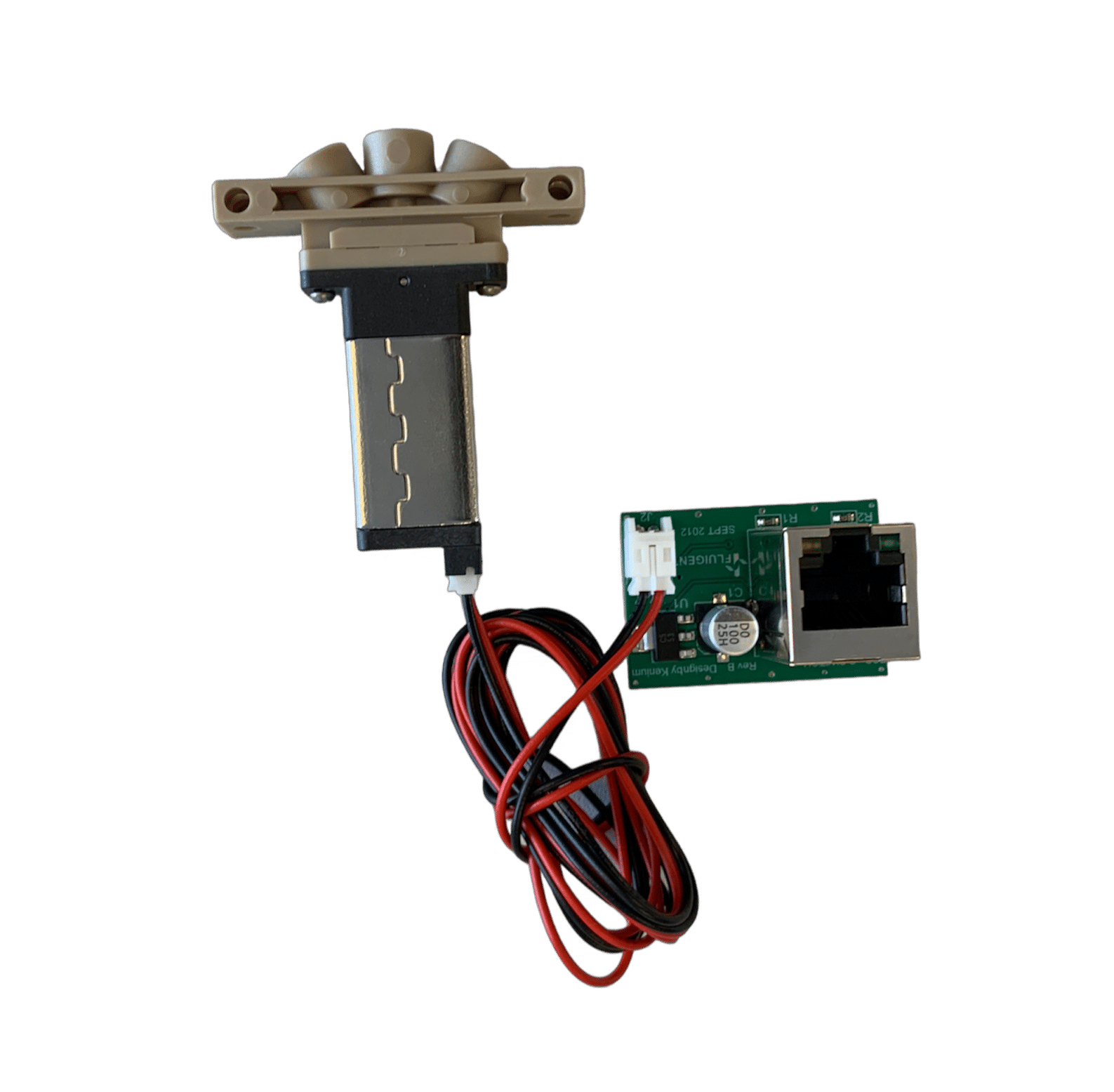

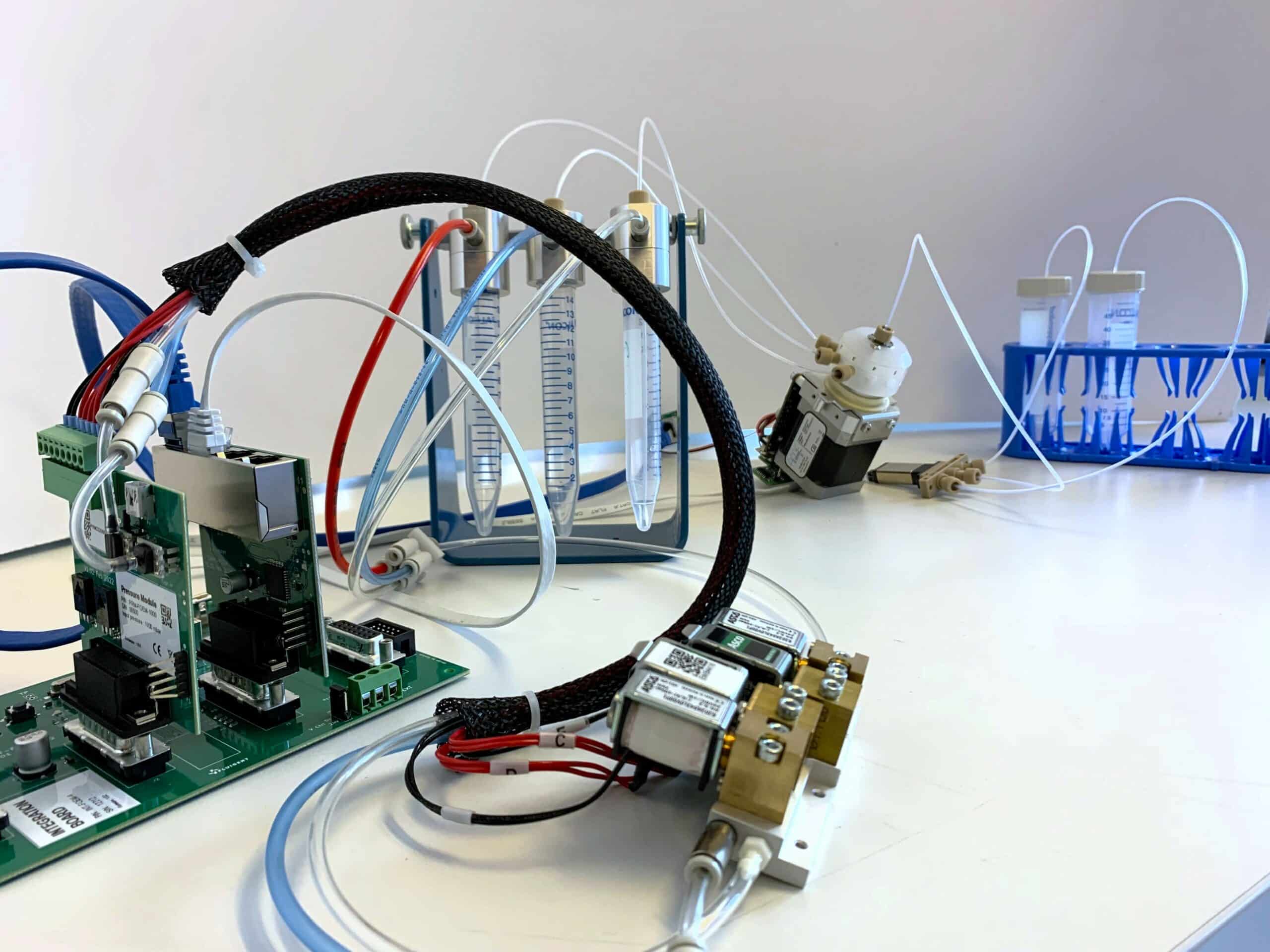

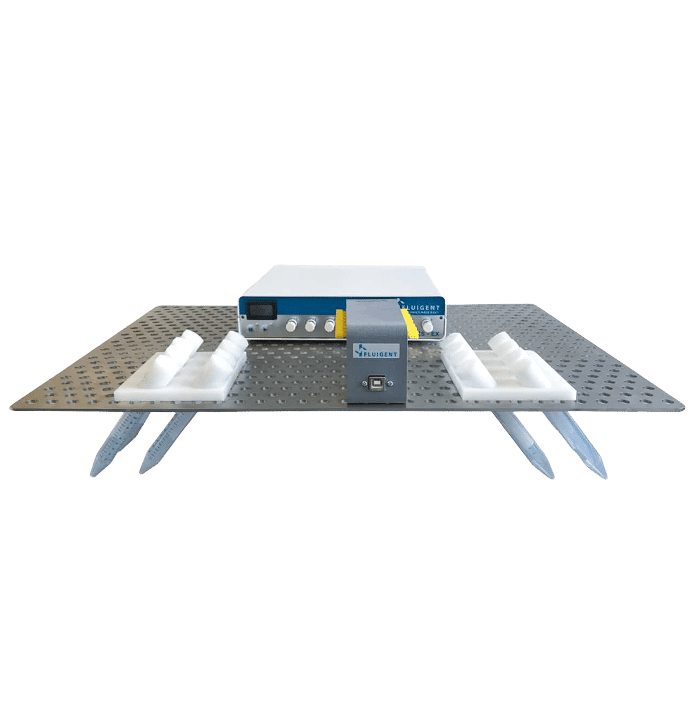

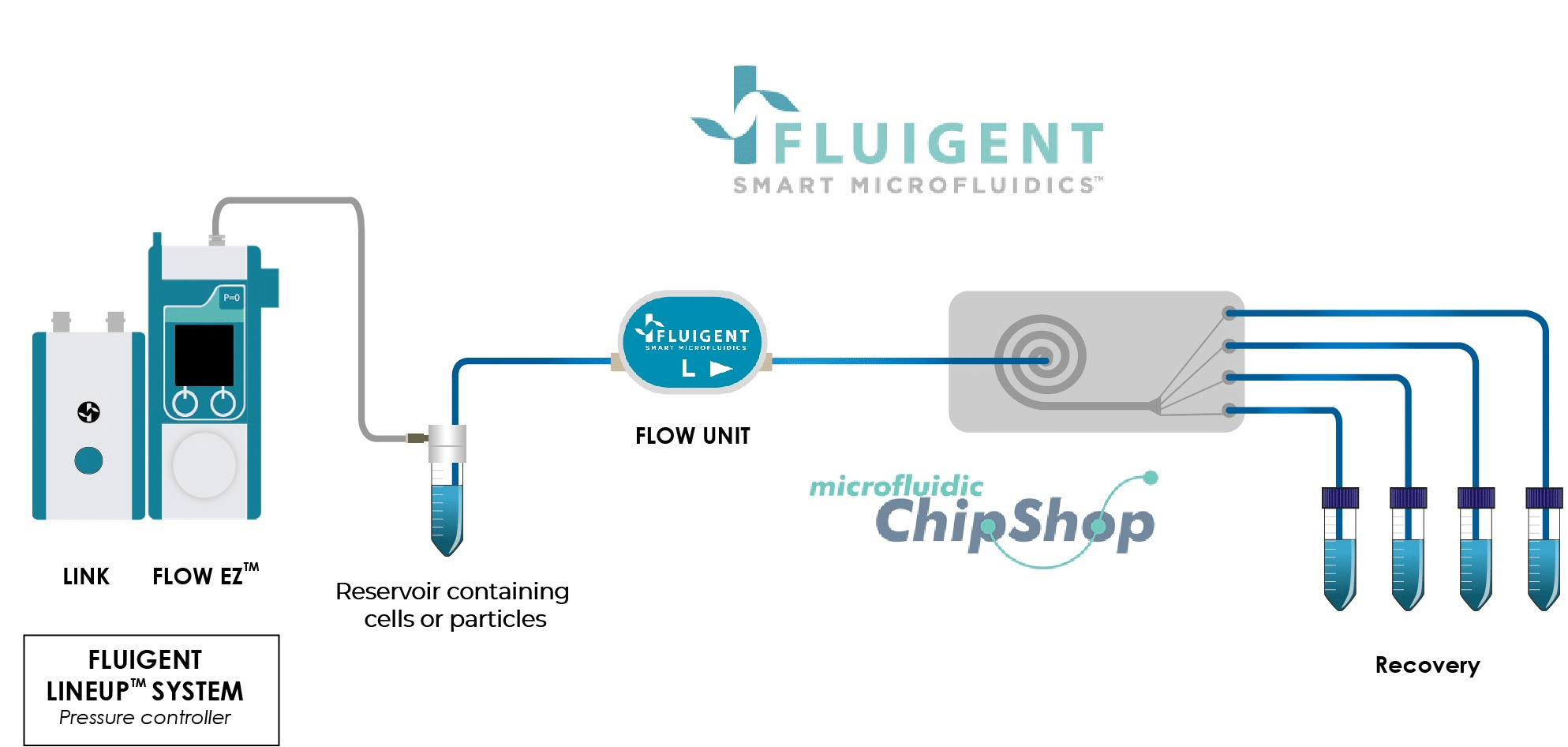

Flow control systems for industrial digital PCR

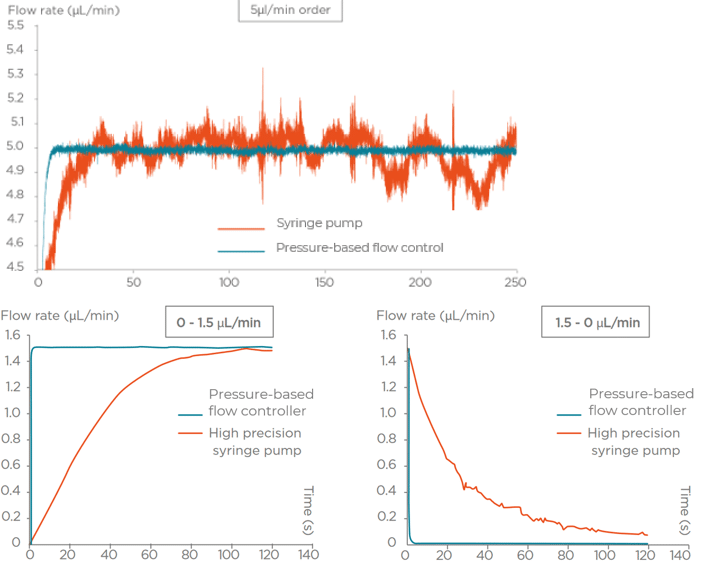

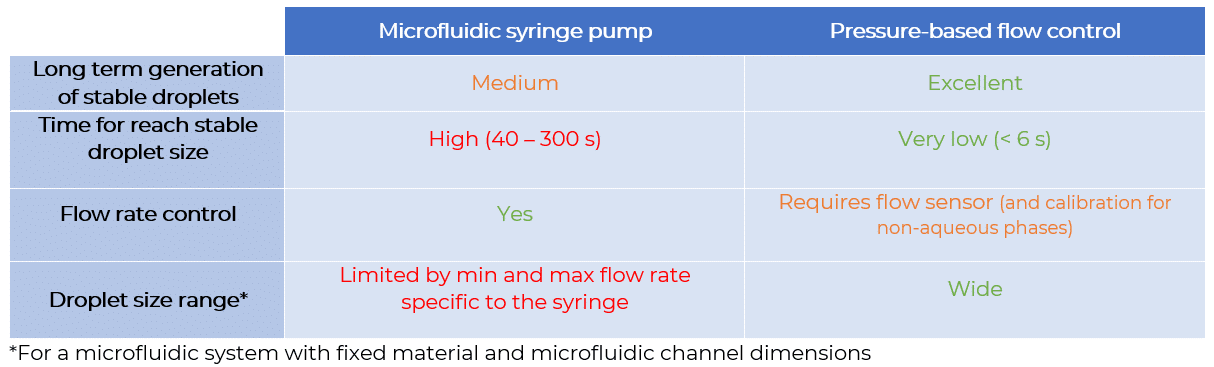

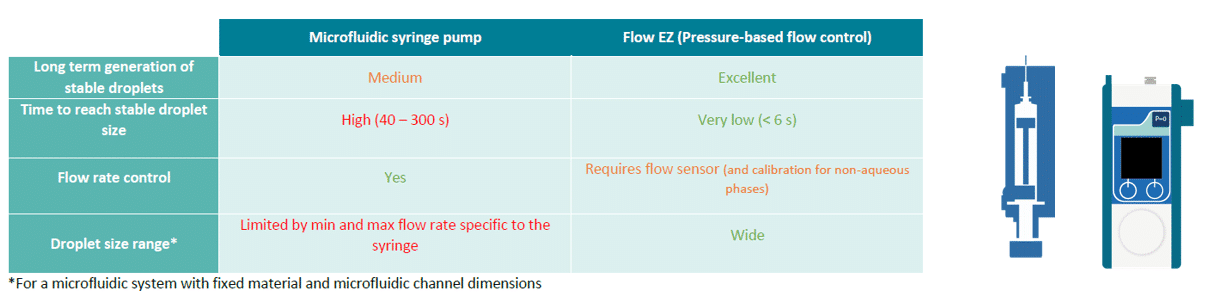

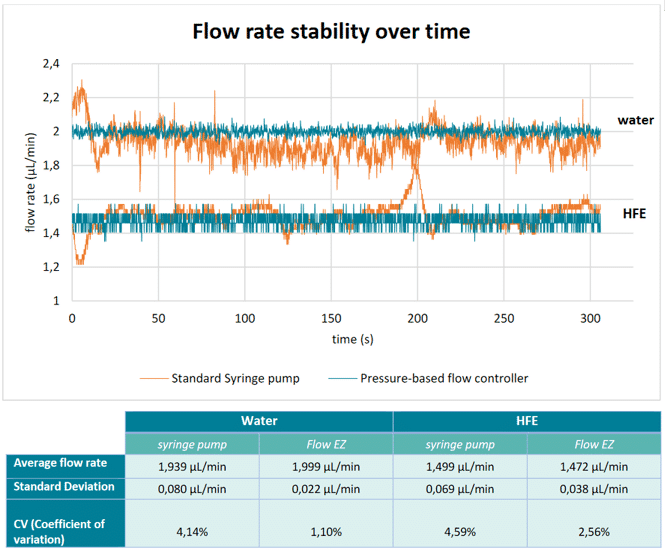

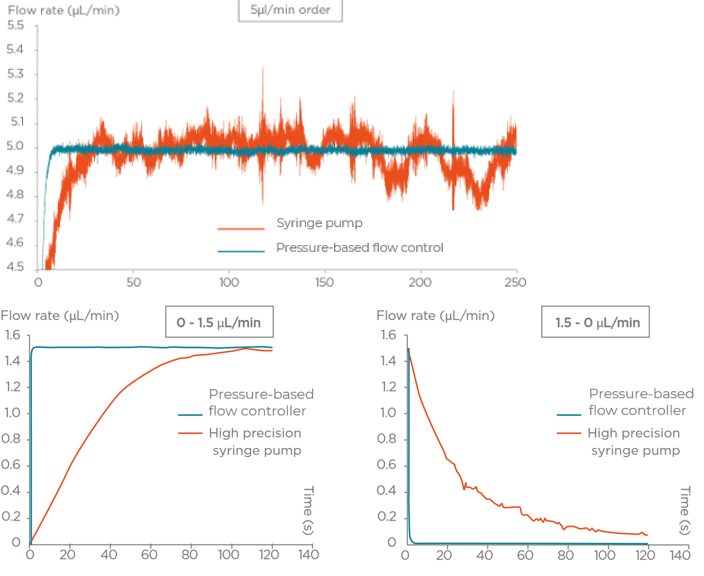

Flow rate stability is thus critical for having repeatable reactor volumes and reproducible results in droplet digital PCR experiments. Syringe pumps are commonly used for generating droplets. Depending on the model in use, syringe pumps show limited flow control. As a consequence, the droplet size, proportional to the flow rate, is affected. In addition, the actual flow rate cannot be monitored with such devices. The flow rate value is displayed on the device, but no information on the time required for reaching a set flow rate is given (the time for flow equilibrium may vary depending on the microfluidic setup, and flow can oscillate depending on the instrument). An alternative to syringe pumps is pressure-based flow controllers. These show that high-precision flow control, fast reaction time, and flow monitoring are possible.

We compared the production of water-in-oil emulsions using microfluidic syringe pumps and pressure-based flow controllers. Using pressure control, the desired droplet size is quickly obtained (< 6 s), and monodisperse droplet generation is ensured over time. Thus pressure controllers are the instruments of choice for droplet digital PCR.

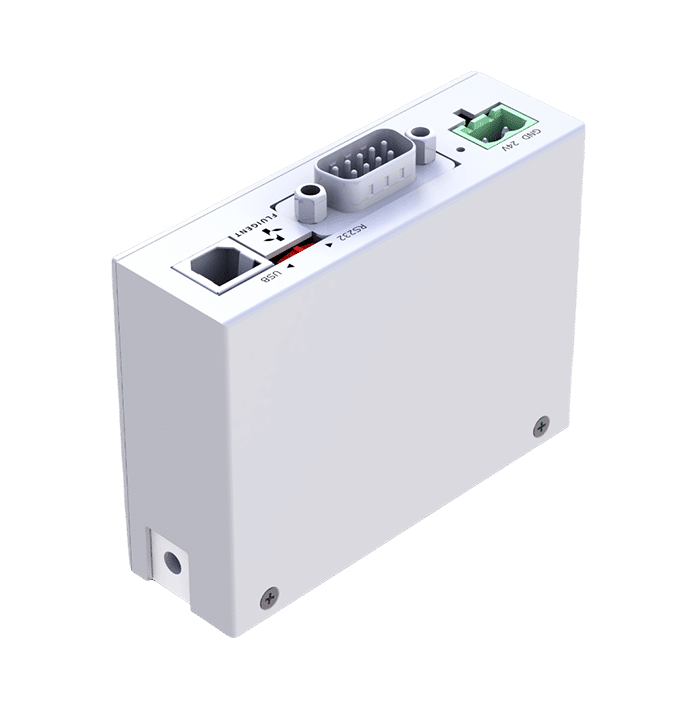

The benefits of choosing Fluigent for your ddPCR system

- Best in class stability: < 0.5% due to our field-proven, patented FASTAB™ technology allowing optimal flow control with the robustness required in demanding industrial environments.

- Straightforward workflow automation included in Fluigent’s software

- An expert engineering time specializing in microfluidic design and mechanical and software integration

References

1. Whale, A. S. et al. Comparison of microfluidic digital PCR and conventional quantitative PCR for measuring copy number variation. Nucleic Acids Research40, (2012).

2. Emslie, K. R. et al. Droplet volume variability and impact on digital pcr copy number concentration measurements. Analytical Chemistry91, 4124–4131 (2019).

3. Emslie, K. R. et al. Supporting information Droplet volume variability and impact on digital PCR copy number concentration measurements Author names and affiliations.

Introduction to DNA Screening Using Digital PCR

Polymerase Chain Reaction, or PCR, has an almost ubiquitous presence in biomedical sciences. Due to the ease of execution and the exquisite sensitivity offered by PCR, which covers amplification from a single template molecule up to about nine orders of magnitude, the applications of PCR are widespread. This includes targeted mutagenesis, DNA screening using digital PCR, virus diagnosis and analysis, and more. (1).

Droplet microfluidics offers significant advantages for performing high-throughput screens and sensitive assays. Droplets make it possible to considerably reduce sample volumes, which lowers costs. Compartmentalization in droplets increases assay sensitivity by increasing the effective concentration of rare species and decreasing the time required to reach detection thresholds. Droplet microfluidics combines these powerful features to enable previously inaccessible high-throughput screening applications, including single-cell and single-molecule assays (2).

Droplet digital PCR (ddPCR) is based on the amplification of single target DNA molecules in many separate droplets, which provides a new method for accurate quantification of DNA copy numbers. In a ddPCR assay, the distribution of target DNA molecules among the reactions follow Poisson statistics, which means that the majority of reactions contain either one or zero target DNA molecules. DdPCR has several advantages over more traditional qPCR methods.

- It enables the absolute quantification of target nucleic acid without the reliance on rate-based measurements and the need to use calibration curves.

- It demonstrates high sensitivity and precision for low-copy-number target nucleic acids. (2,3).

In this application note, the objective is to use Fluigent products to perform DNA screenings using digital PCR by isolating individual DNA molecules and analyzing the enzymes resulting from their expression.

How to perform high-throughput digital DNA screening

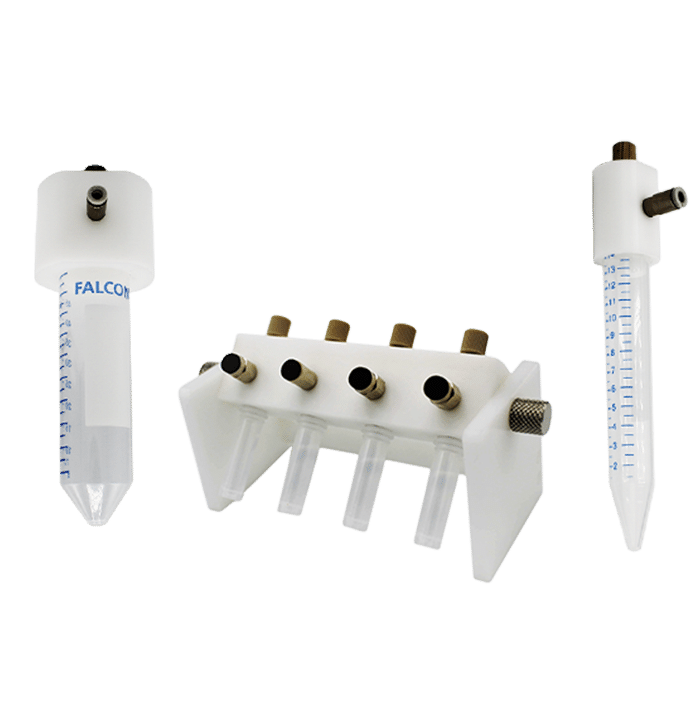

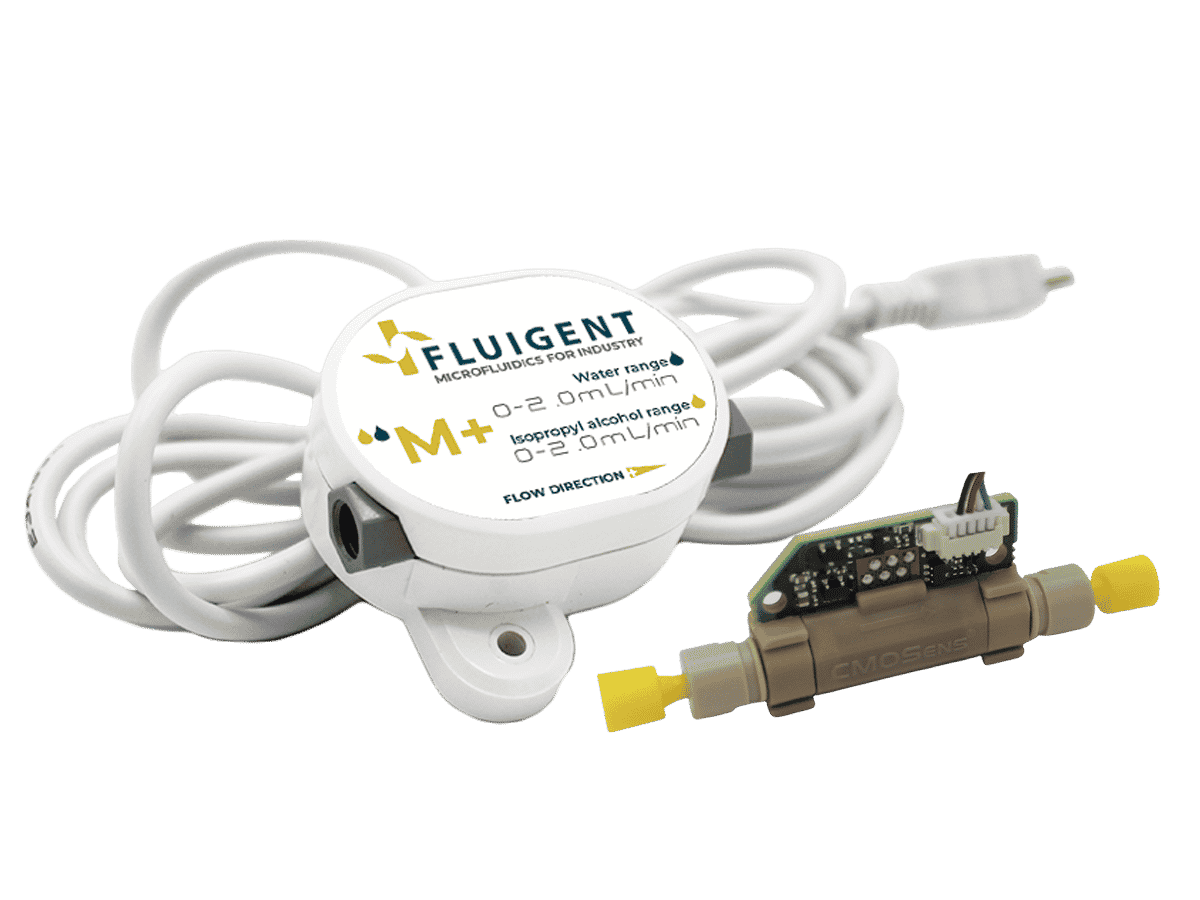

Materials: Products

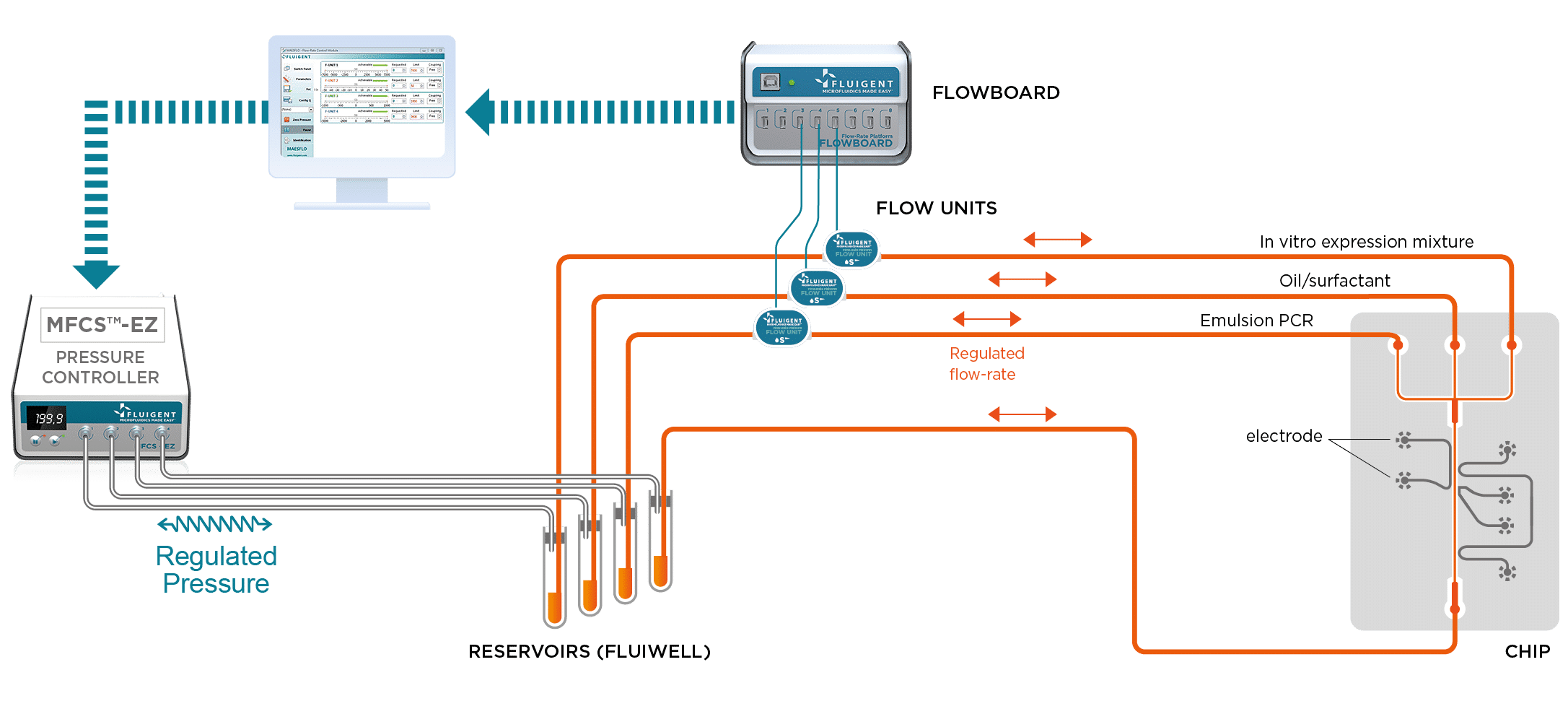

Fluigent pressure-driven flow control solutions are ideal for high-throughput droplet generation for DNA screening, as the excellent flow stability offered by this technology ensures high droplet monodispersity, a controlled encapsulation rate, and experimental reproducibility.

Methods

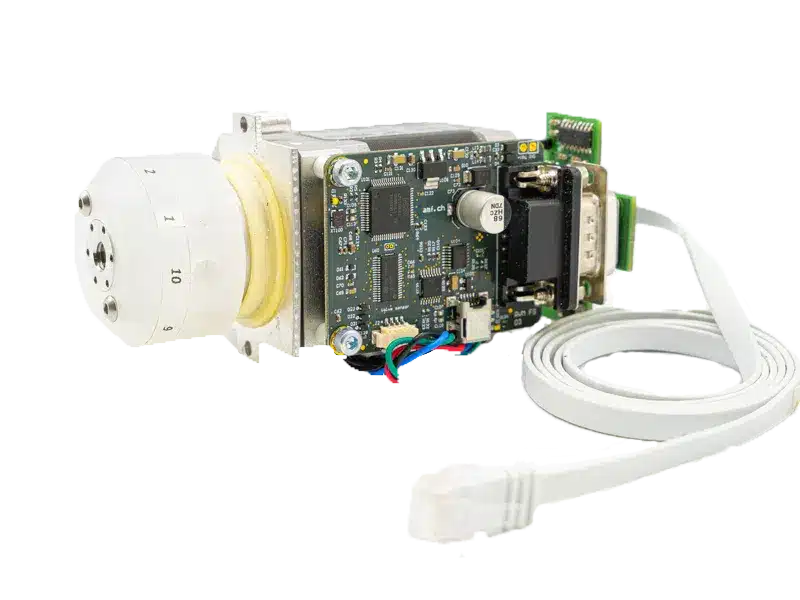

For these studies, it is important that the droplets be generated at the correct frequency and at a uniform size. Using the MFCS™-EZ in this experiment is critical, as the device generates stable flows and precise control of the different phases.

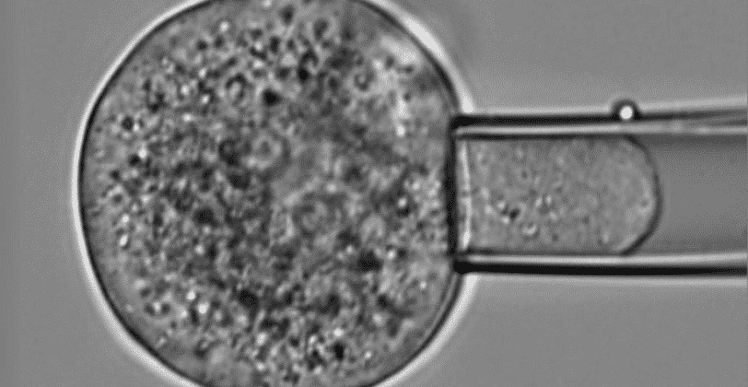

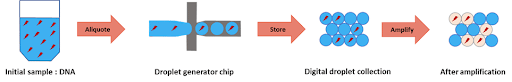

Part one: generation of the pcr/dna droplets

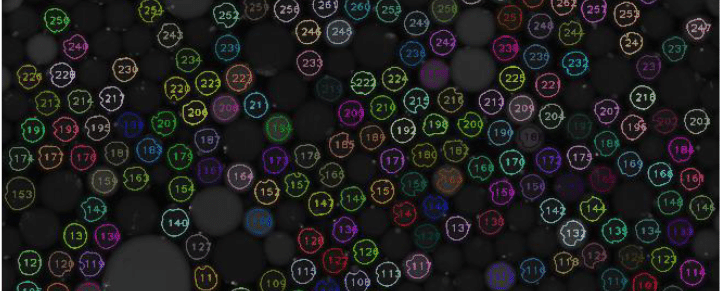

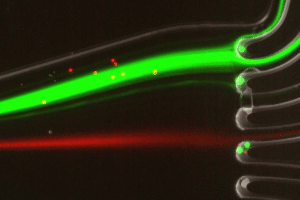

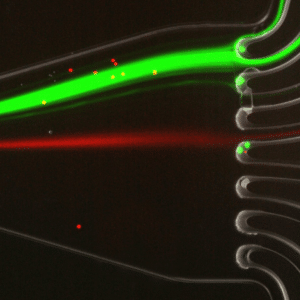

To perform DNA high-throughput digital screening using digital PCR, two separate emulsions were first generated. The first one encapsulated an aqueous phase of a PCR and DNA mixture in an organic continuous phase on a dedicated chip. To do this, the initial sample is injected into the microfluidic droplet generator, where it is cut into highly-monodisperse droplets by a perpendicular stream of perfluorinated oil (figure 2). Each droplet contains either one or zero molecules of DNA. The amplification step triggers the activation or production of a fluorescent dye in the droplets containing the targeted DNA. Counting the number of fluorescent droplets is equivalent to counting the number of DNA molecules.

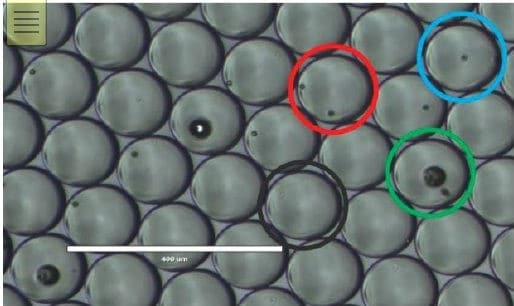

Part two: fusion of one pcr droplet with one ivt droplet generated on a chip

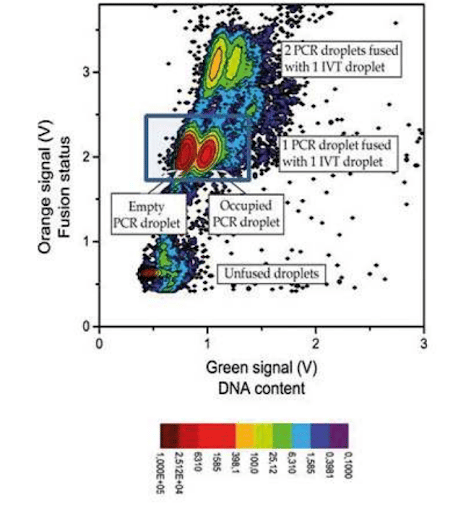

A green fluorescent marker is added to the PCR primers to make them visible at the end of the process. These droplets either contain DNA to be enhanced or are empty. An orange dye is also added to measure the size of the droplet, where the intensity of the light captured by a CCD camera is proportional to the size of the droplet.

For DNA screenings using digital PCR, after amplification, the PCR droplets must be injected into a second chip. This chip generates IVT droplets, while also synchronizing them to create one PCR droplet that is inserted between two IVT droplets. The IVT droplets contain an orange dye to differentiate the contents. Fusion is processed by the application of an electric field.

Results

Our set-up features fast start-up and an automated configuration that allows the experiment to be performed without constant adjustments, thus saving time and enabling systemic screening. By continuously measuring the lows and pressures, the performance of the fluidic system can be evaluated at a glance, providing full control of the process.

In our experimental DNA screening using digital PCR, we obtained a 1/1 fusion at an 85% to 88% success rate (no fusion: 10%, double fusion: 5%) with stable and synchronized decays.

This graph represents a count of droplets with given orange and green signals. The darker red dot signifies a large number of droplets with these characteristics, while light blue represents a low number of droplets. The green signal shows the presence of DNA in the PCR droplet, and the orange one is relevant for detecting the occurrence of fusion.

Conclusion

To perform DNA screening using digital PCR, it is essential to have high stability in order to obtain reproducible and optimal results. Flow-rate control solutions based on pressure actuation provide:

- High droplet monodispersity (even at low low-rates over long time periods.)

- Straightforward, easily automated setup

- Precise volume and low control – even with complex, multi-channel chips to minimize cross-talk between low channels.

- Ability to detect and compensate for small disruptions such as air bubbles.

Related resources

References

- Hoshino, T. and Inagaki, F. (2012) “Molecular quantification of environmental DNA using microfluidics and digital PCR,” Systematic and Applied Microbiology, 35(6), pp. 390–395. Available at: https://doi.org/10.1016/j.syapm.2012.06.006.

- Payne, E.M. et al. (2020) “High-throughput screening by droplet microfluidics: Perspective into key challenges and future prospects,” Lab on a Chip, 20(13), pp. 2247–2262. Available at: https://doi.org/10.1039/d0lc00347f.

- Markey, A.L., Mohr, S. and Day, P.J.R. (2010) “High-throughput droplet PCR,” Methods, 50(4), pp. 277–281. Available at: https://doi.org/10.1016/j.ymeth.2010.01.030.

Download the white paper

* Required field.

TABLE OF CONTENTS

I. WHAT ARE EMULSIONS AND DROPLETS?

1) Definition.

2) Applications

II. WHY USING DROPLET MICROFLUIDICS?

1) The limitations of traditional methods for droplet generation.

2) Microfluidic devices for controlled emulsions.

III. DYNAMICS OF DROPLET MICROFLUIDICS

2) Droplet formation (single emulsions)

3) Droplet generation regimes.

4) Double emulsions.

5) Complex droplet formation.

IV. IMPORTANCE OF FLOW RATE CONTROL FOR DROPLET STABILITY

V. SURFACTANTS FOR STABILIZING DROPLETS

VI. DROPLET AND PARTICLE GENERATION USING MICROFLUIDICS

1) Microparticles.

2) Nanoparticles.

3) Microcapsules.

VII. APPLICATIONS OF DROPLET-BASED MICROFLUIDICS

1) Drug delivery.

2) Diagnostics using droplet digital PCR (ddPCR)

3) Cosmetics.

References.

Why Use Droplet-based Microfluidics?

Droplet-based microfluidics is a rapidly growing interdisciplinary field of research combining soft matter physics, biochemistry and microsystems engineering. Its applications range from fast analytical systems or the synthesis of advanced materials to protein crystallization and biological assays for living cells. Precise control of droplet volumes and reliable manipulation of individual droplets such as coalescence, mixing of their contents, and sorting in combination with fast analysis tools allow to perform chemical reactions inside the droplets under defined conditions.

Learn More About Droplet Microfluidics With This Review

In this expertise white paper, we provide a complete overview on droplet-based microfluidics, including definitions, the reasons for using droplets (limitations of traditional methods and the emergence of new microfluidic devices), the physics behind microfluidic droplet generation, the methods of generation of different types of droplets (single emulsion, multiple emulsion…), the importance of different parameters (flow rate, surfactants…), the type of materials that can be produced, and related applications.

Next Webinar Incoming

Complex Microfluidic Emulsions: How to Optimize Production, Flow Control & Monodispersity

May 22, 2025 – Get the best of Flow Control Technologies to perform highly monodispersed droplets. Learn everything you need in our exclusive webinar.

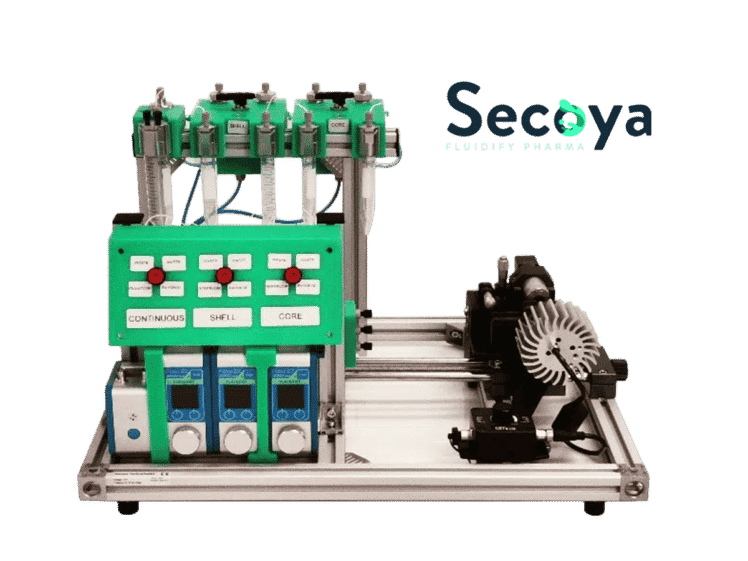

✅ Precision in Emulsion Creation using the RayDrop from Secoya

✅ Mastering Flow Control through FlowEZ Pressure pump from Fluigent

✅Case Study: Fluorescent Complex Emulsions

May 22, 2025

All White Papers

- Microfluidics White Papers

A review of Organ on Chip Technology – A White Paper

Download - Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Download - Microfluidics White Papers

An exploration of Microfluidic technology and fluid handling

Download

Related Ressources

A quick and efficient double encapsulation method for FACS-based droplet sorting

PLGA nanoparticle synthesis using 3D microfluidic hydrodynamic focusing

Alginate Microbeads Production

10 Tips for Reliable Droplet Generation

Microfluidics in Drug Delivery: A New Era of Precision Medicine

Agarose microcapsules synthesis

What can droplet microfluidics be used for?

Drug delivery

In recent years, biodegradable microcapsules/microparticles have gained widespread importance in the delivery of bioactive agents. Polymer-based microcapsules/microparticles are one of the most successful new drug delivery systems.

They can be used in various areas such as long-term release systems, vaccine adjuvant, and tissue engineering.

Droplet-based microfluidics produce highly monodispersed droplet and microcapsule/microparticle production opposed to batch emulsion methods and provide an “In-line” continuous droplet production process.

Formulation

The encapsulation of active ingredients to create flavors or fragrances for cosmetics and food products is a key part of their formulation. A challenge of droplet generation applied to encapsulation is to prevent the leakage of the encapsulated species.

The possibility to encapsulate these compounds allows users to control the release of the compound and improve pharmacokinetics. Modern drug encapsulation methods allow efficient loading of drug molecules inside nanoparticles, thereby reducing systemic toxicity associated with drugs.

Targeting nanoparticles can enhance the accumulation of nanoencapsulated drugs at the diseased site.

Next generation sequencing (NGS)

Encapsulation of a single cell inside a droplet increases NGS efficiency. The ability to study cells at single cell level using droplet based systems combined with NGS techniques allow for the sequencing of mRNA from a large number of cells.

The power of this technology, combined with droplet generation, resides in the fact that during sequencing, one can distinguish where the original information came on a cell-to-cell basis. This allows one to make a gene expression map of the cell, or even to distinguish cell populations within a tissue.

Drug discovery

In-vitro cell culture is a fundamental component of biological production systems and biotechnological research. The ability to grow cells outside of their natural environment offers many industry solutions from the high quantity production of enzymes to cell toxicity studies and drug discovery.

Droplet generationallows one to encapsulate single or multiple cells into tiny droplets of pL volume which are generated at a rate of approximately one thousand per second.

Diagnostics

A key measurement challenge in diagnostic research involves identifying small changes in nucleic acid sequences that are commonly associated with genetic diseases such as Down’s syndrome and many cancers.

Digital PCR (dPCR) carries out a single reaction within a sample as standard PCR, however the sample is separated into a large number of partitions where reactions take place in each partition individually. This is an excellent solution to partition a sample, and dPCR technology that makes use of droplet microfluidics is often called droplet digital PCR (ddPCR).

How to control droplet size and volume using fluid handling technology ?

When it comes to particle or droplet generation, having control of the fluid delivery system is important. During particle or droplet production, the flow rate of each phase must remain constant and stable to allow the production of monodisperse droplets.

The ability to control the flow rate of each phase allows for more control over the process, precisely and easily regulating the size of the droplet or particle generated.

Which flow control system to generate monodisperced droplet ?

Flow rate stability is critical for having repeatable reactor volumes and reproducible results. Syringe pumps are commonly used for generating droplets in microfluidic experiments. Depending on the model in use, syringe pumps show limited flow control.

As a consequence, the droplet size (proportional to the flow rate), is affected. The actual flow rate cannot be controlled with syringes or peristaltic devices. The flow rate value is displayed on the device, but no information on the time required for reaching a set flow rate is given.

The time for flow equilibrium may vary depending on the microfluidic setup, and flow rate can oscillate depending on the instrument. An alternative to syringe pumps for the generation of droplets are pressure-based flow controllers. These show high-precision flow control and fast response times. Read more on the expertise page.

How are liquid droplets created with microfluidics pressure controllers?

To underline the importance of pressure control, our application note compares the production of water-in-oil emulsions using microfluidic syringe pumps to pressure-based flow controllers. Droplet size, stability, and the time required to reach several droplet diameters are dependent on each instrument.

Resources

-

Microfluidic Application Notes Encapsulation of Cells In Small Double Emulsions Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidics Case Studies The Hebrew University: Encapsulation and culture in 3D hydrogels for Single cell sequencing Read more

-

Microfluidics Case Studies University of Cambridge: Microfluidic GUV production and testing Read more

-

Expert Reviews: Basics of Microfluidics The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing Read more

-

Microfluidic Application Notes Double Emulsion Generation Read more

-

Microfluidic Application Notes Microfluidic Chitosan Microcapsules Production Read more

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes PLGA Microparticles Synthesis Read more

-

Microfluidic Application Notes UV-Crosslinking of Microcapsules Read more

-

Microfluidic Application Notes UV-Crosslinking of Microparticles Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

This technology can be integrated in any custom project. Users will receive the following benefits:

- Contact-free: suitable for use when sterility is required

- No calibration needed: liquid-independent

- Suitable for Industrial use: can be integrated into many devices and systems

- High precision and accuracy: Fluigent regulation control

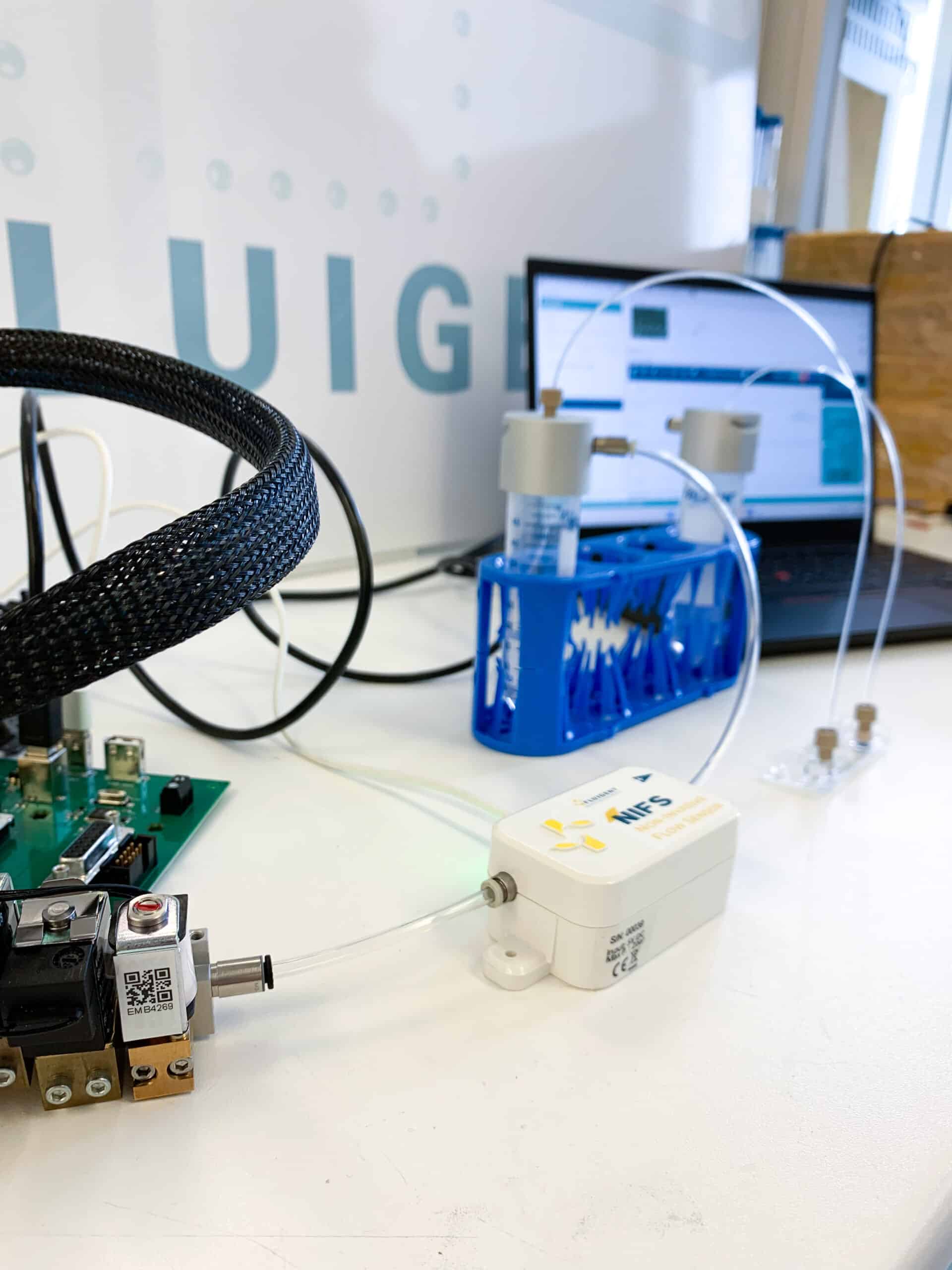

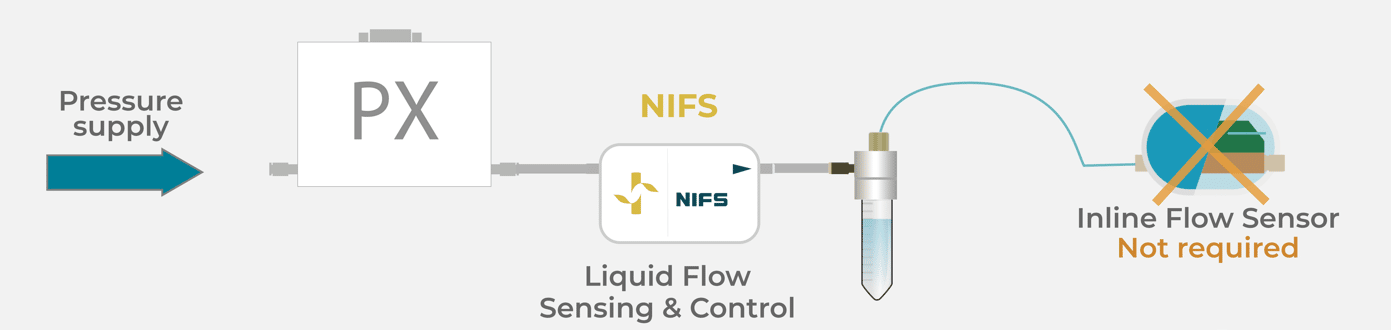

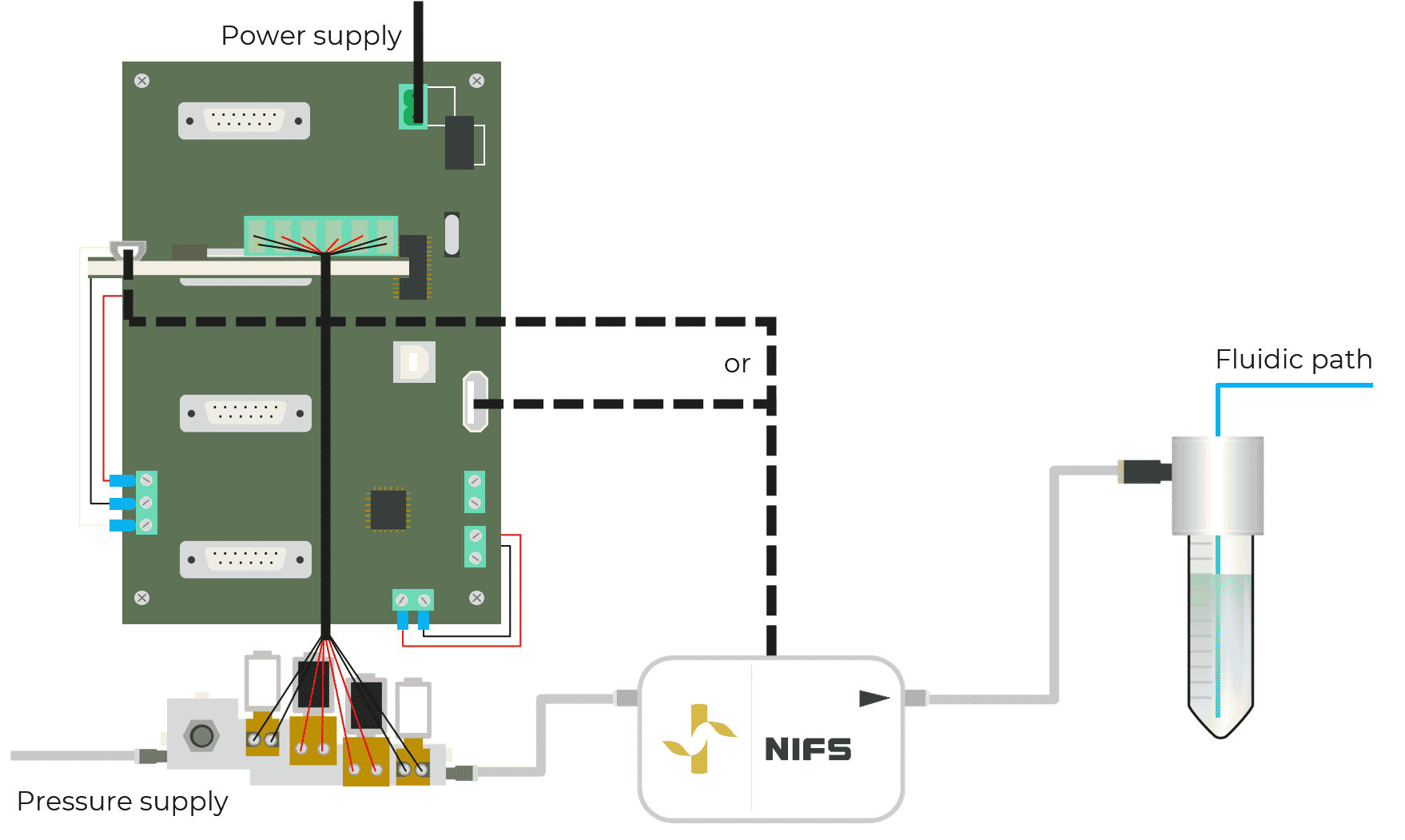

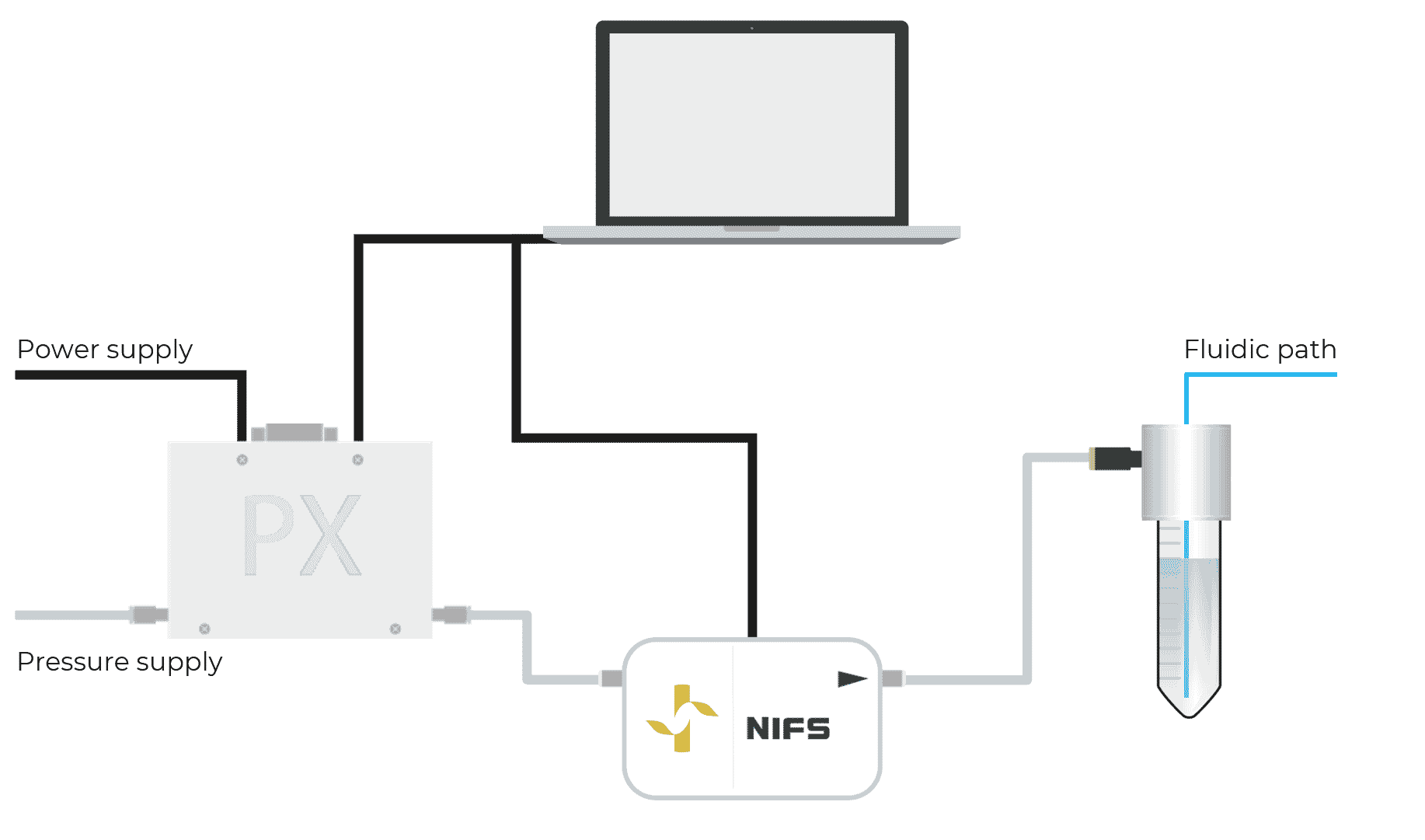

How does our non-intrusive liquid handling system work?

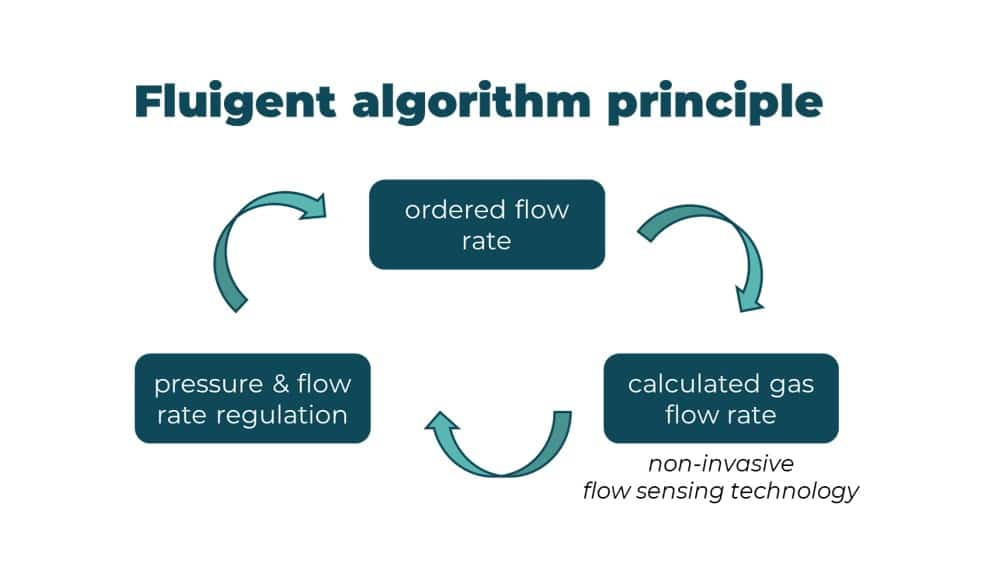

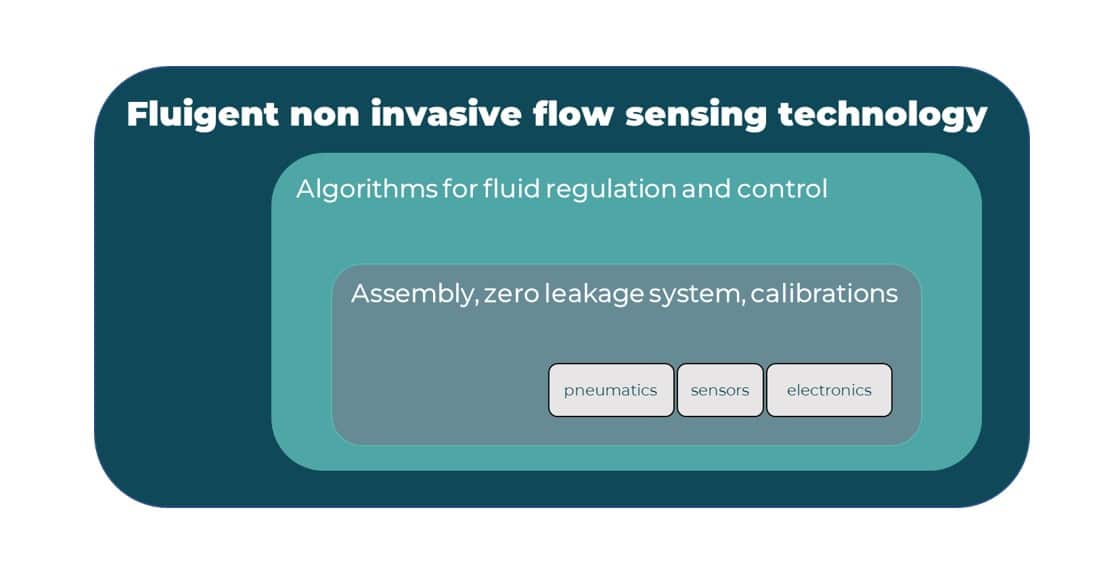

Fluigent expertise for fluid flow rate adapted to gas flow rate

Thanks to Fluigent’s expertise, including “self-learning” algorithms and calibrations, our non-intrusive flow sensing technology determines the fluid flow rate from gas flow rate measurements. Using internally developed software, the input pressure is automatically adjusted by our pressure controller to monitor or control the liquid fluid flow rate in real-time.

The technology consists of a uniquely engineered assembly of sensing, pneumatic and electronic elements that allow for precise volumetric flow rate measurement. Thanks to the conception of a zero leakage (completely sealed) system, the gas flow rate is proportional to the fluid flow rate.

No contact with the fluidic path

As described in figure 3, the technology is located at the pneumatic part of the system, between the regulated pressure controller and the fluidic reservoir (for more information about pressure-based flow control, see our expertise page). The flow sensing technology is never in contact with fluids.

No fluid-calibration needed

Traditional microfluidic flow sensing technologies are based on a calorimetric measurement principle and depend on fluid properties. They are generally calibrated for aqueous fluids, and additional calibrations need to be performed by the user. As explained above, with the new device, the fluid flow rate is determined by measuring the gas flow rate and is independent of the fluid properties (density, viscosity, surface tension, etc.). It makes this non-intrusive flow sensing technology universal and fluid calibration-free.

This is a technology of choice if one:

- Is working in a sterile/contamination-free environment

- Is working with several types of fluid: aqueous fluids (e.g. as water, media, PBS), blood, plasma, oils, surfactants, alcohols …

- Performs continuous operations with slow flow response time needs

A contamination-free flow sensing technology unlocking new features

PERFORMANCE

| Calibrated media | Air |

| Range | 100 μL/min to 10 mL/min |

| Accuracy | 5% reading |

| Lowest detectable flow increment | 5 μL/min |

| Response time | 10 s for reading 10 to 30 seconds for regulation (depends on the volume to control and the setup) |

HARDWARE SPECIFICATIONS

| Dimensions (L*W*H) | 99.85 x 45.00 x 33.50 mm |

| Weight | 117 g |

| Maximum pressure | 2 bar |

| Penumatic connector ports | 4 mm OD |

| Length of the electrical cable | 1 m |

COMPATIBILITY

| Products | FOEM: via micro-USB or via USB-A connected to computer POEM/PX: via USB-A connected to computer NOT COMPATIBLE WITH Flowboard OEM |

| Accessories | 2 mL reservoir + P-CAP screw 15 mL reservoir + P-CAP screw 50 mL reservoir + P-CAP screw |

| Product | NIFS | FS series |

| Invasiveness | Noninvasive: connected to the pneumatic path | Invasive: connected to the fluidic path |

| Calibration | Not required | Required for fluids with different viscosity than water |

| Flow rate range | 100 µL/min to 10 mL/min | 75 nL/min to 10 mL/min |

| Maximum pressure | 2 bar | 15 bar |

| Response time | 10 to 30 sec* | < 1 sec* |

| Flow stability | Excellent | Excellent |

| Recommended use | – Control of different liquid (no calibration/cleaning steps) – Long-term processes that risk contamination or clogging (non-intrusive) | – Manipulation of aqueous fluids only (no calibration step) – Processes with many flow rate changes (excellent response time and stability at low flow rates) |

*Depends on the volume to control and the setup

Applications of the non-invasive liquid handling system

Emerging applications make use of more complex fluidic operations and require compact systems. Our technology is fit for such applications as it is fully connected, compact, and provides excellent fluidic performance.

- Cell biology: biological applications such as cell culture under perfusion, immunostaining, organoid culture, organ-on-a-chip, drug discovery, single-cell analysis, cell cytometry and other applications that require a sterile environment. When using fluids such as culture media, PBS, buffers, blood, or plasma, every component in the fluidic path should be disposable, or able to be sterilized. Fluigent’s new non-intrusive flow sensing technology is ideal for such applications as it is not in contact with the fluids in play.

- Microfluidic droplet generation: When generating droplets, several types of fluids with different properties are used (aqueous solutions, oil, surfactants, alcohols). Using traditional flow sensing technology requires fluid calibration to be performed for every fluid. This step should be repeated periodically as fluid properties can differ from one batch to another. Inaccurate calibration affects the flow rate and the size of the droplets. The new sensing technology is ideal as no fluid calibration step is required, allowing one to precisely control flow rate for all types of liquids.

- (bio)chemical and molecular analysis: Chemical and molecular components can be screened using droplet microfluidic technology for drug, enzyme, or food analysis. The advantages of using this non-intrusive flow sensing technology are listed above.

- Quality monitoring and system failure prevention: flow sensors monitor fluidic protocol in real-time and warn the user of unexpected flow rate fluctuations.

Expertises & resources

Manufacturing capabilities for industrials

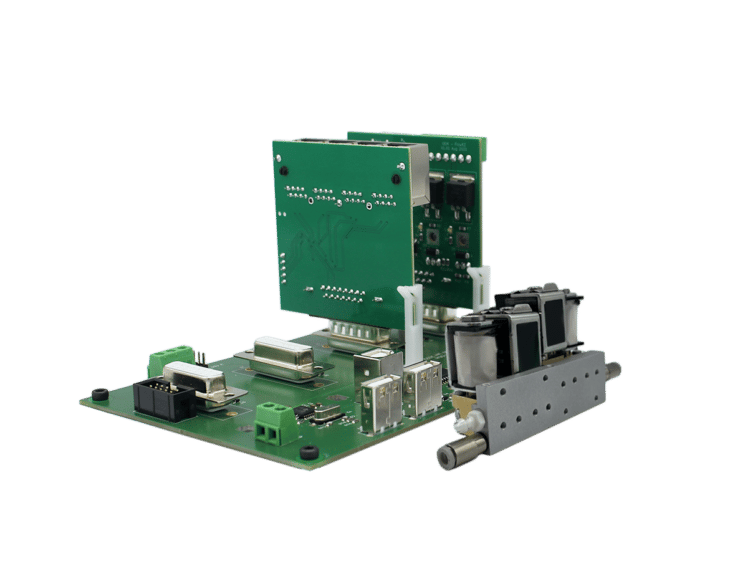

Fluigent’s OEM products build on our 15 years of pressure-based flow control expertise and proprietary technologies to bring versatile, cost-effective, and customizable microfluidic OEM fluid handling products and systems to life science and diagnostic equipment manufacturers.

Microfluidic Functionalities

Pressure controllers for liquids

State of the art, modular, and integrable microfluidic OEM modules to handle fluids in industrial systems. Discover our field-proven liquid handling modules.

Microfluidic components

State of the art, modular, and integrable microfluidic OEM modules to automate fluid management and to build your complete microfluidic system.

Fully integrated system development

Bring the vision of your device to life

Complete development of a fully operational device based on your requirements. Benefit from our microfluidic OEM expertise and unique portfolio of cutting-edge technologies to accelerate time to market.

We empower your microfluidic application

From droplet microfluidics to live-cell imaging, our experts will provide valuable insights for your application.

Explore areas of applications where microfluidics catalyzes the results, production and yield of industrial processes.

“I was impressed with the quality of the product. In particular, I would like to highlight the Fluigent team’s clear and open communication, their smooth management style, and of course, great R&D work.”

A trusted partner for your microfluidic OEM system

Over the past 10 years, we’ve provided more than 1, 500 microfluidic OEM modules and systems to businesses worldwide. Our R&D team represents more than 30% of the company, leading us to earning more than 20 patents.

65

OEM/Industrial customers around the world

20

Patents put us at the forefront of innovation

15

Different fully integrated OEM systems developped

1500+

OEM systems and components delivered

10

Years of experience in OEM lab automation

Highest quality standards and compliance – ISO 9001

We continuously improve the quality of our products and processes to ensure compliance with our OEM microfluidic solutions. We have a commitment to quality and remain ISO 9001 certified. In addition, we’ve successfully completed several external audits and effectively provide components and systems with additional certifications such as UL, or IP65

We are committed to customer satisfaction and provide long-term support to develop the best solutions for our customer’s needs

Why is water testing important?

As water is consumed by every living being every day, it is a critical resource that needs to be monitored closely. Whether for human consumption, livestock, or agriculture, water quality must be assessed and ensured at all times to prevent mass contamination and maintain the health of human and animal populations and soils. This testing can be done by different actors, from governmental organizations to individual consumers, making it essential to have fast, easy-to-use, and reliable solutions. To respond to these needs, microfluidics in water analysis is a cost-effective and efficient solution for water testing.

Industrial applications

Research applications

How does conventional water analysis work?

Multiple different steps are needed for conventional water testing. They typically include sample collection and preservation if the test needs to be done remotely (since some devices are only available in specific locations), followed by filtration to separate solid particles from the liquid before being analyzed. During analysis, various methods can be used to determine the concentration of contaminants or parameters of interest like turbidity, pH, heavy metals, or bacteria concentration. The results are then compared to established guidelines or regulations to determine whether the water meets regulatory requirements.

Microfluidics as a solution to current limitations on water quality monitoring

Conventional water monitoring is mainly based on laboratory instruments or sophisticated and expensive handheld probes for on-site analysis. This requires trained personnel and can be time-consuming. Microfluidics in water analysis is field-deployable, providing a way to perform scanning at remote or hard-to-reach locations directly at the point of sampling. Microfluidics also provides increased sensitivity, with the ability to detect lower contaminant concentrations than with traditional methods. The analysis time is drastically reduced, allowing for real-time monitoring and increased efficiency while preventing water waste through the use of very small samples. Reduced measurement times, improvements in sensitivity, enhancement of selectivity, and high repeatability are all advantages of using microfluidic devices when integrated into miniaturized chemical systems for water quality analysis.

Related products

Research field

Microfluidic flow controller

Flow EZ™

See the offer

Modular OEM Microfluidic Flow Controller

Modular OEM Microfluidic Flow Controller

See the offer

Airtight metal tube caps for microfluidics

P-CAP series

See the offer

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

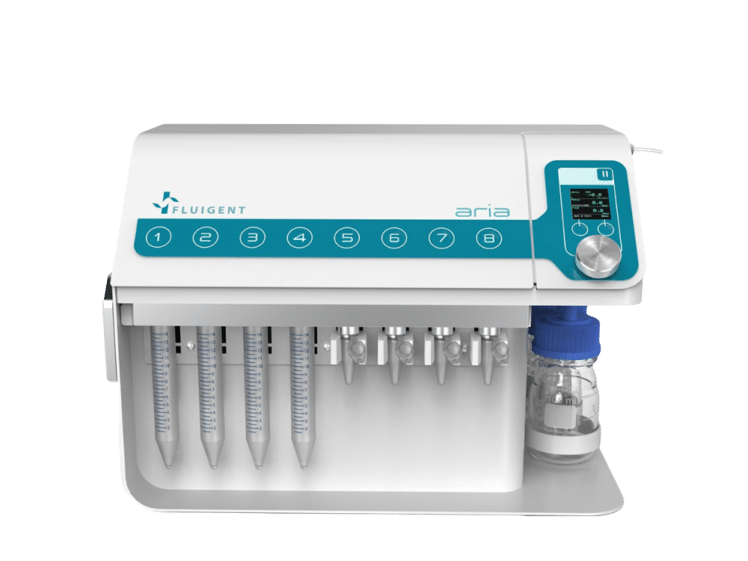

Aria, An Automated Perfusion System

Platform for Spatial Omics

See the offer

Industrial field

Expertise & resources

- Expert Reviews: Basics of Microfluidics

Microfluidics overview: History and Definition

Read more - Expert Reviews: Basics of Microfluidics

What is the history of microfluidics?

Read more - Microfluidics White Papers

An exploration of Microfluidic technology and fluid handling

Read more

Microfluidic OEM

Read more

Looking for a new market?

From the life sciences to the food industry, many applications require the use of fluids driven at flow rates ranging from nanoliters to milliliters per minute. At low flow rates like these, the success of such applications strongly depends on the level of control and automation of fluidic operations.

These applications require flow control systems designed to ensure their success.

Microfluidics in Pharmaceutics

Drug delivery

Microparticles and emulsions are used for a wide variety of pharmaceutical products including intravenous, intramuscular, ocular, or orally delivered compounds. Emulsions are also used as templates for polymer microparticles, lipid nanoparticles, or microcapsules. These are later used for drug delivery, with the emulsion being the active pharmaceutical ingredient (API) itself, or as an adjuvant for co-administration.

Droplet microfluidics technology produces multiunit drug delivery systems with precise dosage control, targeted release, and homogeneous distribution. Conventional methods struggle to achieve monodispersity (<5%) required for efficient drug delivery. Our technology revolutionizes drug delivery, offering improved treatment options and personalized therapies and advancing pharmaceutical development and patient care.

To learn more about droplet microfluidics for pharmaceutical applications, read our white paper about droplet microfluidics.

Disease modeling and characterization

Animal studies are the current standard for evaluating potential treatments, but they often struggle to correlate with human outcomes due to physiological differences and genetic variations. These studies are costly, time-consuming, and raise ethical concerns. Human clinical studies face challenges due to individual diversity and research complexity. Microfluidic models in an organ-on-chip format offer a promising alternative, providing an efficient, cost-effective, and ethical approach for drug discovery and personalized medicine. This technology advances the field of pharmaceutics by enabling the development of predictive methods to evaluate new compounds and therapeutics. It then helps in disease modeling and characterization, enhancing the drug discovery and development process.

To delve deeper into the topic of microfluidics for pharmaceutical applications using organ-on-chip systems, read our OOC white paper.

Related products

Research field

Encapsulation Platform for FACS

Platform for cell encapsulation in DE droplets

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Double Emulsion Device

RayDrop Double Emulsion

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

Double Emulsion Generation Pack

Double Emulsion Generation Pack

See the offer

Microfluidic Complex Emulsion Production Platform

Platform for emulsions & droplets

See the offer

PLGA Microparticle Production Pack (Automation Pack)

PLGA Microparticle Production Pack (Automation Pack)

See the offer

Industrial field

Related Ressources

Looking for another market?

From the life sciences to the food industry, many applications require the use of fluids driven at flow rates from nanoliters to milliliters per minute. At such low flows, the success of these applications strongly depends on the level of control and automation of the fluidic operations.

These applications require flow control systems that are adapted for ensuring their success.

A new level of technology

Microscopy and cell biology

Flow cells or microfluidic chips combined with a fluid perfusion system and microscopy are compatible with a variety of applications, including DNA and RNA hybridization, drug combination and long-term perfusion, and immunostaining.

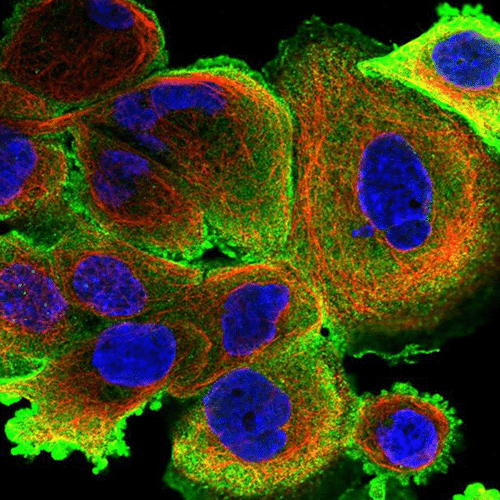

Cell culture and Organ-on-a-chip

This area is an ideal microenvironment to study molecular and cellular-scale activities that underlie human organ function as well as identify new therapeutic targets in vitro.

Digital PCR

Microfluidic dPCR offers a new level of insight compared to quantitative PCR (qPCR). Droplet-based microfluidics is an excellent solution for partitioning a sample.

Want to learn more about the capabilities of microfluidics in life science? See Fluigent’s CEO France Hamber discuss microfluidic disruptive discoveries

Research applications

Microfluidics in biology and medicine

Microfluidics has emerged as a transformative technology, revolutionizing various areas of research, diagnostics, and therapeutics. By enabling precise manipulation and control of small volumes of fluids at the microscale level, microfluidic devices, also known as lab-on-a-chip, have opened up new possibilities in the study of cells, diagnostics, DNA sequencing, and drug discovery. In biology, microfluidics allows researchers to analyze and manipulate individual cells, paving the way for advancements in cell biology and single-cell genomics. In medicine, microfluidic platforms offer portable, rapid, and cost-effective point-of-care diagnostics, bringing healthcare to resource-limited settings, e.g. by using organ-on-chip platforms.

As an example, microfluidics in life science has accelerated RNA sequencing technologies, enabling high-throughput sequencing at reduced costs. In the application note linked below, Fluigent presents the Drop-Seq method, a high-throughput method that enables sequencing of the mRNA from a large number of cells. The Drop-Seq method pairs barcoded beads and cells in droplets, capturing cell-specific RNA on beads. Tagged cDNA is generated, amplified, sequenced, and bioinformatically analyzed. Barcode sequences identify cells, and transcript sequences are mapped to a reference genome, forming cell-specific gene-expression profiles.

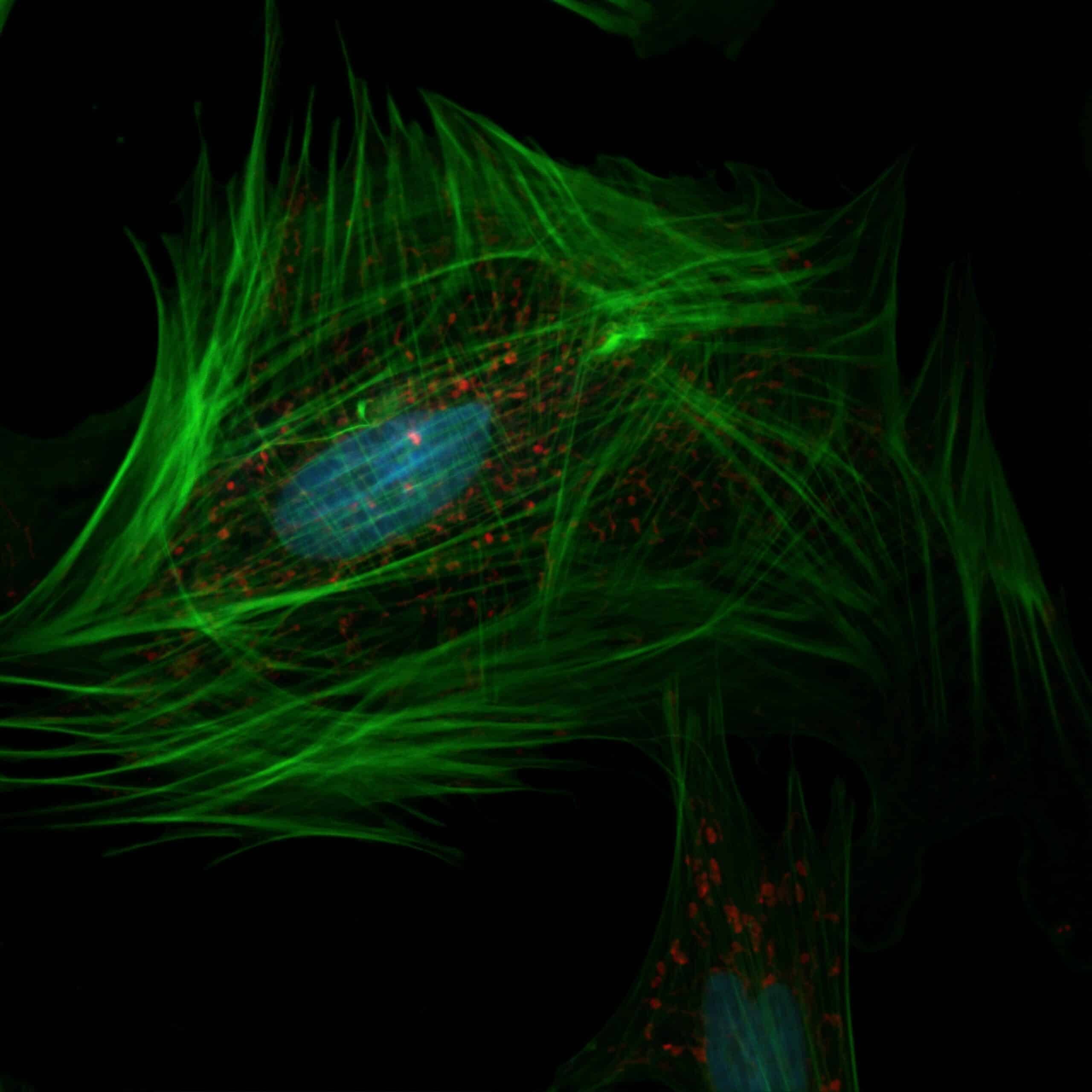

Microfluidic tools for cell biological research

Cellular biology plays a crucial role in the field of medical science and drives innovation. A comprehensive understanding of how cells react during infections and pathological conditions is instrumental in the discovery of novel disease treatments. Essential to the analysis and visualization of cellular behavior are microscopy and imaging technologies. In the realm of cell biology, the integration of precise fluid flow control within microfluidic systems has revolutionized the study of cells by providing an automated platform that mimics their natural environment.

Microfluidics facilitates the delivery of fluids at controlled flow rates, minimizing errors. It finds applications in diverse areas such as RNA and DNA hybridization, enabling real-time imaging of gene expression in living cells. Microfluidics also contributes to drug combination therapies, long-term perfusion studies, and improved immunostaining protocols. By replacing traditional methods, microfluidics in life science offers several advantages including enhanced control, sensitivity, throughput, cost-effectiveness, and reduced material consumption. Its potential impact extends to cancer diagnosis, enhancing our understanding of cancer biology, and driving advancements in medical research.

Advantages of pressure-based flow controllers for life science experiments

Pressure-based flow controllers offer several advantages over peristaltic pumps and syringe pumps in microfluidics for life science applications. Firstly, it provides precise and accurate control of flow rates, allowing for better reproducibility and control of experimental conditions. Secondly, the pressure-based system is less prone to pulsations and variations in flow, resulting in more stable and consistent flow profiles. Additionally, using pressure-based controllers in life sciences allows researchers to work with much smaller volumes, which is useful when the samples to be studied are expensive or rare.

Finally, using pumps like the Flow EZ allows for use of various accessories such as reservoir mixers or block heaters, which can reproduce the physiological conditions of cells, for example, and keep the sample homogeneous, which is much more complex, if not impossible, with other types of pumps.

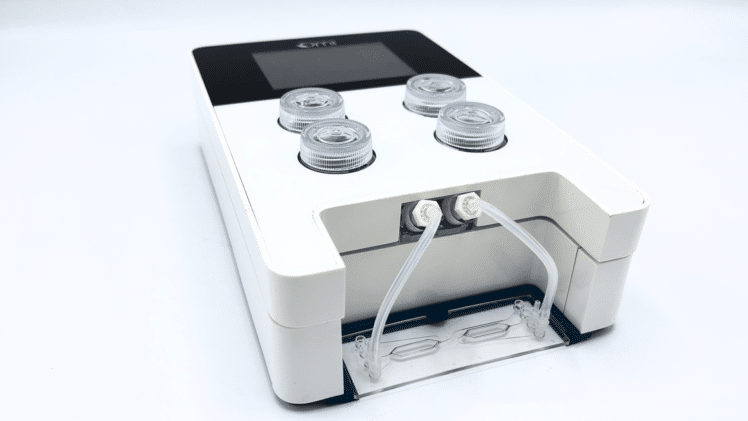

Organ-on-chip studies for life science

Organs-on-chips (OoC) are microdevices that mimic organ functions. They use microfluidics and 3D culture to replicate human physiology. OoC models show that dynamic culture conditions affect system maturation. They aim to recreate tissue barriers, parenchymal tissues, and inter-organ interactions. An OoC system includes a microfluidic chip with cell culture chambers, fluid channels, and optional components like membranes or gels. Biosensors and bio-actuators may be added. This technology is very useful for microfluidics in life science applications, as it offers more realistic lab modeling of organs and tissues. To that end, Fluigent has created Omi, a versatile and automated platform for organ-on-chip studies.

Omi allows for long-term cell culture with controlled shear stress conditions through continuous flow. It offers customizable and automated protocols for various functions, such as perfusion, recirculation, sampling and injection. This platform caters to the requirements of both novice cell culture researchers and experienced organ-on-chip researchers, addressing their needs for automation and reproducibility.

Microfluidic in Life Science Case Study

Hans-Knöll-Institut, New Antibiotics, Cultivation in Droplets

This project focuses on how Fluigent’s customers use microfluidics to achieve outstanding results in their technology experiments.

Our speakers are Prof. Dr. Miriam Agler-Rosenbaum (Head of Bio Pilot Plant Department), Dr. Sundar Hengoju, Dr. Dede Man from the Bio Pilot Plant Department of the Leibniz Institut for Natural Products Research and Infection Biology (Hans Knöll Institute).

- How are they trying to find new antibiotics?

- Why is this important for infection biology?

- How do they research natural products?

- What are these products exactly?

- How does microfluidics allow them to cultivate microbes in droplets?

- How does the technology increase their efficiency millions of times over?

- In which cases are pressure pumps better than syringe pumps?

- How can microfluidic droplets be stabilized?

Watch this episode to find out – and note that this is just one story told. There are many possible applications for microfluidics.

Related products

Research field

Fluid Degassing Device for Microfluidic System

Microfluidic Fluid Degassing Device

See the offer

Microfluidic Injection Valve

L-SWITCH™ 6-port/2-position

See the offer

Aria, An Automated Perfusion System

Platform for Spatial Omics

See the offer

High Throughput Cell Perfusion Pack

High Throughput Cell Perfusion Pack

See the offer

Organ on Chip Perfusion Pack

Perfect organ-on-chip cell perfusion set

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Recirculation Valve

L-SWITCH™ 6-port/2-position

See the offer

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Industrial field

Related Expertises

Looking for another market?

From the life sciences to the food industry, many applications require the use of fluids driven at flow rates from nanoliters to milliliters per minute. At such low flows, the success of these applications strongly depends on the level of control and automation of the fluidic operations.

These applications require flow control systems that are adapted for ensuring their success.

Features of the cell sorting package

Complete system

This package includes all the components necessary to start cell sorting experiments.

Engineered solution

We built the package with quality pressure controllers, microfluidic chips, tubing and fittings to provide the most optimized and versatile system.

Customization possible

We can adapt the package to fulfil your needs.

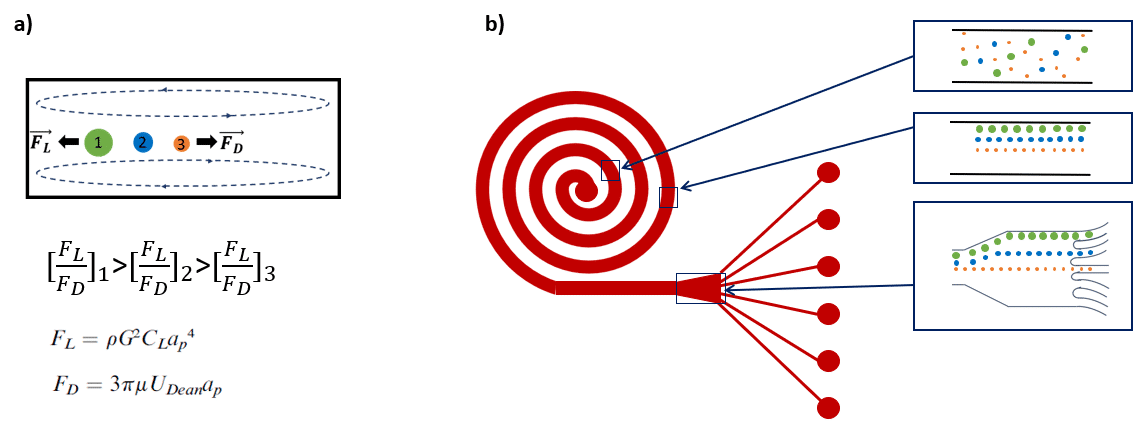

Cell Sorting Working Principle

The working principle of the cell size sorting pack is the combination of forces experienced by the particles. Particles that flow in a spiral microchannel with a rectangular cross-section experience a combination of Dean drag forces and an inertial lift. The position at which particles of different sizes equilibrate depends on the ratio of these two forces.

This results in several particle streams that are size dependent, which can be extracted by designing appropriate outlets (see figure on the right).

Why use microfluidic for size sorting?

Control flow rate with the benefits of responsive, pulse free flow

Pulse-free flow is critical for generating high quality and repeatable results in our cell sorting pack. The Flow EZ™ integrates the all-new DFC (Direct Flow Control) algorithm, which allows the user to set a flow rate directly on the instrument display. The applied pressure will automatically adjust to maintain the flow rate.

With the use of pressure instead of mechanical action, the Flow EZ™ gets a responsiveness ten times faster than syringe pumps. A low response time allows one to quickly execute operations such as stop flow and pressure/flow rate steps.

Main products of the package

Specifications

Fluigent package

| LineUp Flow EZ pressure controller 2 bar x1 |

| LineUp LINK Module (software control) x1 |

| FLOW UNIT L x1 |

| Spiral sorter chips Fluidic 382 from microfluidic ChipShop (x3) |

| P-CAP x1 |

| Fluigent connectors and tubing kit x1 |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Expertise & resources

-

Microfluidic Application Notes Single cell sorter microfluidic platform Read more

-

Fluigent Products Datasheets FLOW UNIT Datasheet Download

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more

-

Expert Reviews: Basics of Microfluidics Application of microfluidic chip technology Read more

-

Fluigent Products Datasheets Flow EZ™ Datasheet Download