Flow control for droplet generation using syringe pumps and pressure-based flow controllers

Micrometer droplets and particles are widely used in a broad range of industries. Droplet production using microfluidic systems was implemented for applications where monodispersity is of high importance. Within micrometer-sized channels, one droplet at a time is generated, allowing for the production of monodisperse droplets. With this level of control, applications that would not have been possible before, have also emerged, such as digital PCR and single cell encapsulation within droplets.

The importance of flow control for droplet production

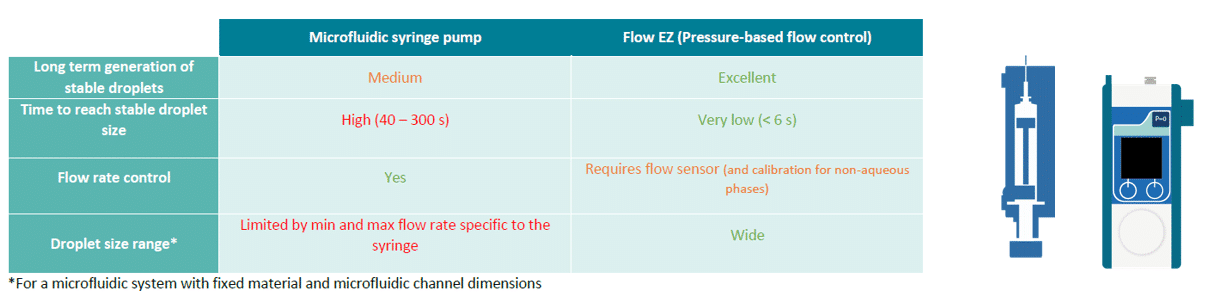

Syringe pumps are commonly used for generating droplets in microfluidic experiments, but can show limited flow control. As a result, the droplet size, which is proportional to the flow rate, is affected. Therefore, flow control for droplet generation is critical for having repeatable reactor volume and reproducible results. An alternative to syringe pumps is pressure-based flow controllers. These show that high-precision flow control, high reaction time, and flow monitoring is possible.

We compare the production of water-in-oil emulsions using microfluidic syringe pumps and Fluigent pressure-based flow controllers. Droplet size stability and the time required to reach several droplet diameters are determined for the two instruments.

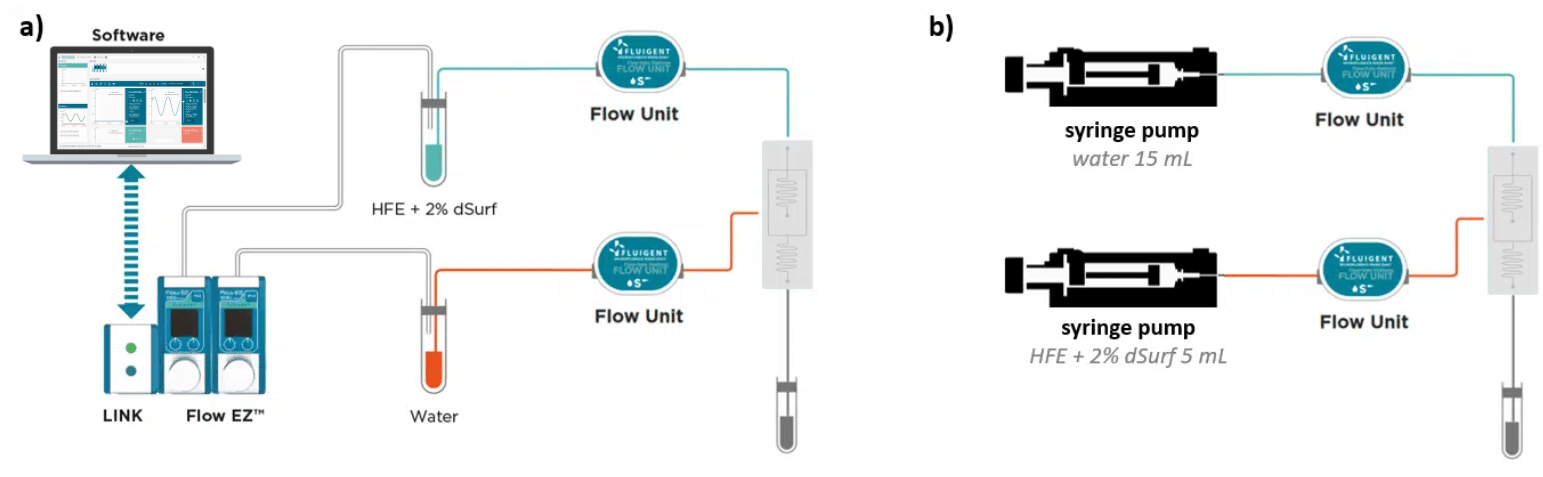

Droplet production under identical experimental conditions

Flow rate stability over time when generating droplets

To determine the droplet stability over time achieved with the different instruments, droplets are generated within a microfluidic chip, working with constant water and oil flow rates of 2.0 µL/min and 1.5 µL/min, respectively.

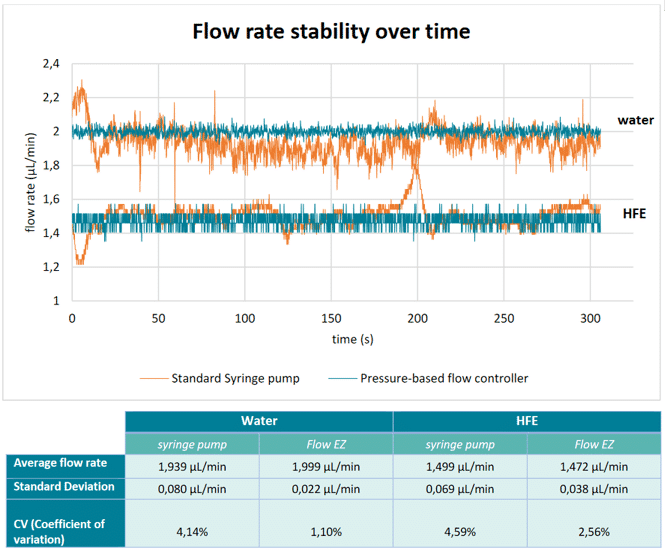

Figure 3 shows the flow rate of water and oil as a function of time for standard syringe pumps and for the Flow-EZ, the pressure-based flow controller. The average flow rates, standard deviations, and coefficients of variation were also calculated. The water and HFE flow rate variations using the Flow EZ are lower than when using standard syringe, confirming the enhanced flow stability over time of pressure-based flow controllers.

Figure 3: Flow rate stability of water and HFE over time with the Flow EZ and syringe pump

Table 1: Water and HFE average flow rate, STD and CV with the Flow EZ and syringe pump

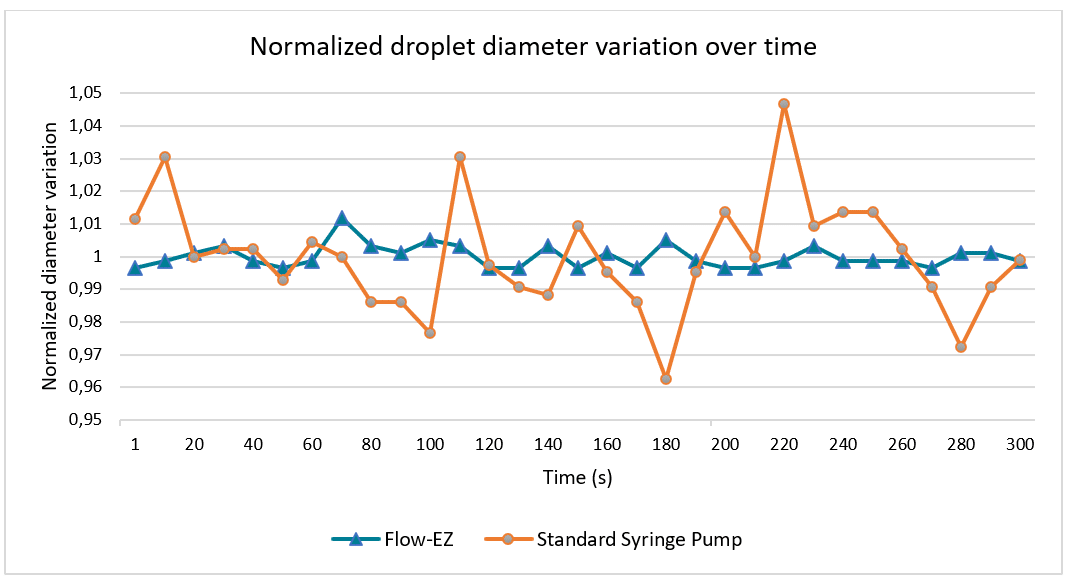

To determine the effect of flow control for droplet generation, and thus the effect of flow rate on droplet stability, a picture of the channels was taken every 10 seconds, and the average diameter over 5 minutes was calculated for each device. To better compare between the different instruments, we use normalized values.

The figure at left shows the normalized diameter variation over time. We can observe that droplets are more stable over time using the Flow EZ compared to the standard syringe pump. This aligns with the results obtained for flow rate stability and confirms that the more precise the flow rate, the more monodisperse the droplets will be.

Impact of precise flow control on droplet diameter over time

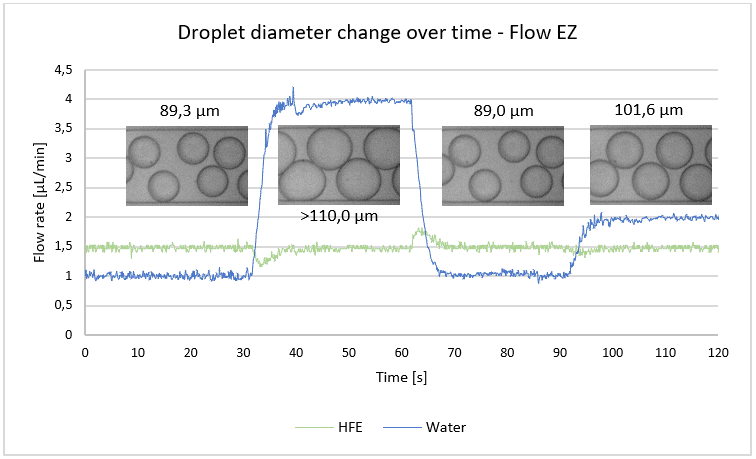

It can also be of interest to be able to quickly move from one droplet size to another. We can determine the response time for reaching a specific droplet diameter. The water flow rate is varied, while the oil flow rate is kept constant at 1.5 µL/min. The set flow rates were the following: 1 µL/min – 4 µL/min – 1 µL/min – 2 µL/min.

Figure 6 shows the results obtained using the Flow EZ. We observe that the set flow rates are reached in a few seconds. After reaching a set flow rate, we can observe the droplet size that results.

In the analysis of the effect of flow control on droplet generation, droplets of 89 µm, 101 µm and approximately 110 µm in diameter were obtained via flow rates of 1 µL/min, 2 µL/min and 4 µL/min, respectively, when using the Flow EZ.

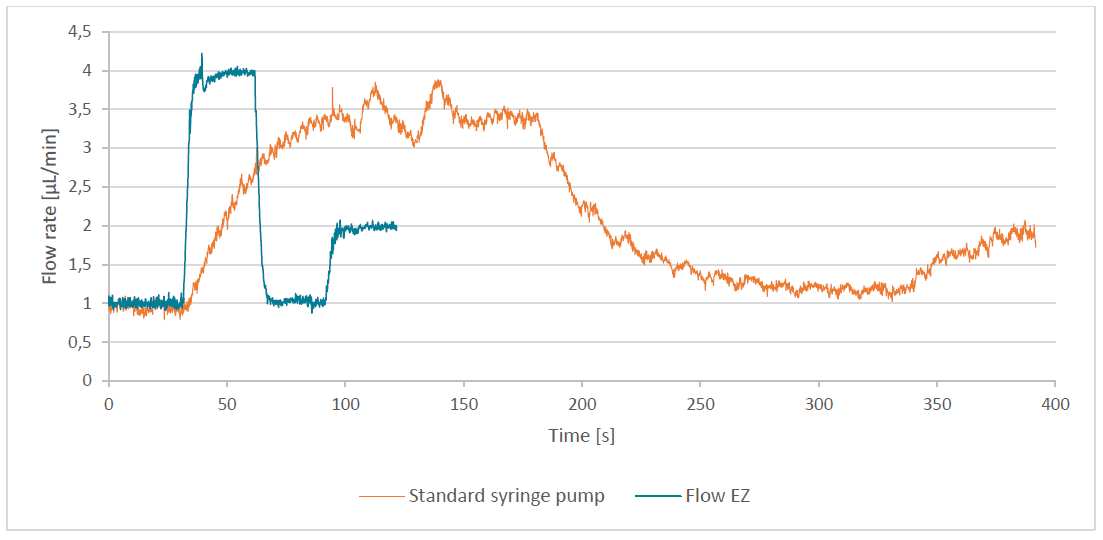

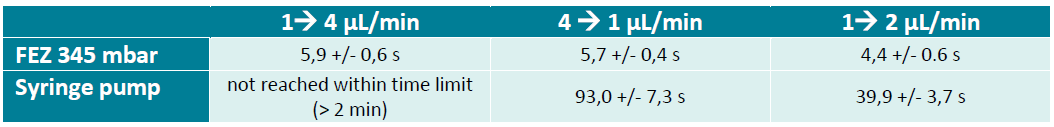

Figure 7: Time required to change from one water flow rate to another using the Flow EZ and syringe pumps.

Figure 7 shows the water flow rate as a function of time for the syringe pump and the Flow EZ, and the table below shows the time required to move from one flow rate to the other after starting the system. We observe that the maximum time required to switch to another flow rate using the Flow EZ and the syringe pump are 6 s and 93 s, respectively.

We can therefore see that the Flow EZ is the instrument with the shortest response time. This allows users to rapidly change from one droplet size to another.

Conclusion

In analyzing the effect of flow control on droplet generation, more stable flow rates were observed when generating droplets with the Flow EZ, resulting in more monodisperse droplets compared to syringe pumps. These results confirm the relationship between flow rate and droplet size.

The difference in response time between the different devices was also determined. Better response times were observed when using the Flow EZ, allowing for responsive control over droplet size during an experiment.

Micrometer-size droplets and particles are widely used in a broad range of industries. Fluigent provides complete, cost-effective solutions for the production of monodisperse droplets., allowing users to control droplet size and frequency by adjusting flow parameters.

Related content

- Expert Reviews: Basics of Microfluidics

Microfluidic Droplet Production Method

Read more - Microfluidic Application Notes

Encapsulation of multiple emulsions in a single droplet

Read more - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Read more - Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Read more - Support & Tools

Droplet Size Calculator

Read more

Related products

-

Bubble trap kit Read

Bubble trap kit Read -

Encapsulation Platform for FACS Read

Encapsulation Platform for FACS Read -

Modular OEM Microfluidic Flow Controller Read

Modular OEM Microfluidic Flow Controller Read -

Highly stable fluorosurfactant for microdroplet generation Read

Highly stable fluorosurfactant for microdroplet generation Read -

Fully Custom Microfluidic Device Read

Fully Custom Microfluidic Device Read -

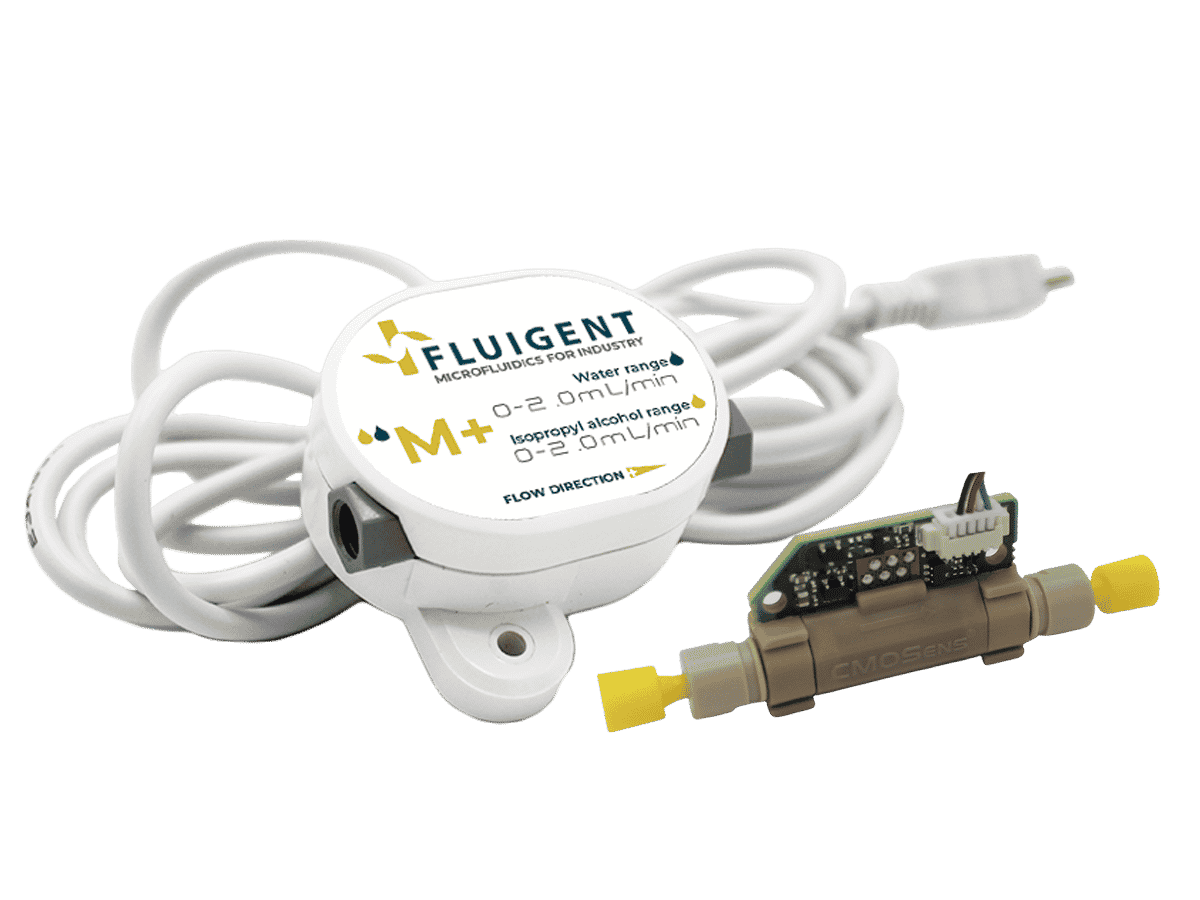

Microfluidic OEM Flow Sensor Read

Microfluidic OEM Flow Sensor Read -

Microfluidic OEM Pressure Controller Read

Microfluidic OEM Pressure Controller Read -

Microfluidic Complex Emulsion Production Platform Read

Microfluidic Complex Emulsion Production Platform Read -

Microfluidic Double Emulsion Device Read

Microfluidic Double Emulsion Device Read -

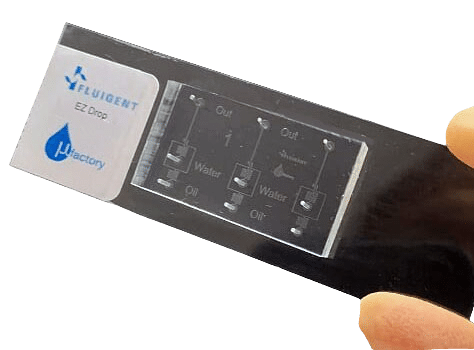

Microfluidic Single Emulsion Device Read

Microfluidic Single Emulsion Device Read -

PDMS Drop-seq chip for Drop-seq experiments Read

PDMS Drop-seq chip for Drop-seq experiments Read -

Microfluidic Flow Control System Read

Microfluidic Flow Control System Read -

Drop-Seq Pack Read

Drop-Seq Pack Read -

Microfluidic Droplet Pack Read

Microfluidic Droplet Pack Read -

Microfluidic flow controller Read

Microfluidic flow controller Read -

Bidirectional Microfluidic Flow Sensor Read

Bidirectional Microfluidic Flow Sensor Read -

Easy droplet generation chip Read

Easy droplet generation chip Read