Microfluidics in Cosmetics

Microfluidics in cosmetics offers new insights for the development of innovative products through the ability to control and monitor emulsion production with droplet microfluidics.

Offering totally new visual and sensorial experiences.

Advantages of Microfluidics in cosmetics

With Microfluidic Droplet Generation, cosmetics companies can offer high-quality product customization. More specifically, emulsions can use surfactants to mix and homogenize multiple immiscible oils with high accuracy and reproducibility, opening new and unprecedented product development possibilities. In addition, microfluidics technology is used in cosmetics research laboratories to study how formulations interact with the skin and skin capillaries at the micrometer level, while also enabling researchers to reduce or eliminate animal experiments in cosmetics through the use of microfluidic chips. Formulation development time is shortened through the use of microfluidic systems to rapidly develop new formulations and test them in high-throughput screening, significantly reducing the time required to bring new products to market. Microfluidics also make it possible to operate with very small volumes of materials, reducing waste and minimizing the costs associated with raw materials.

Advantages of droplet-based microfluidics for the cosmetics industry

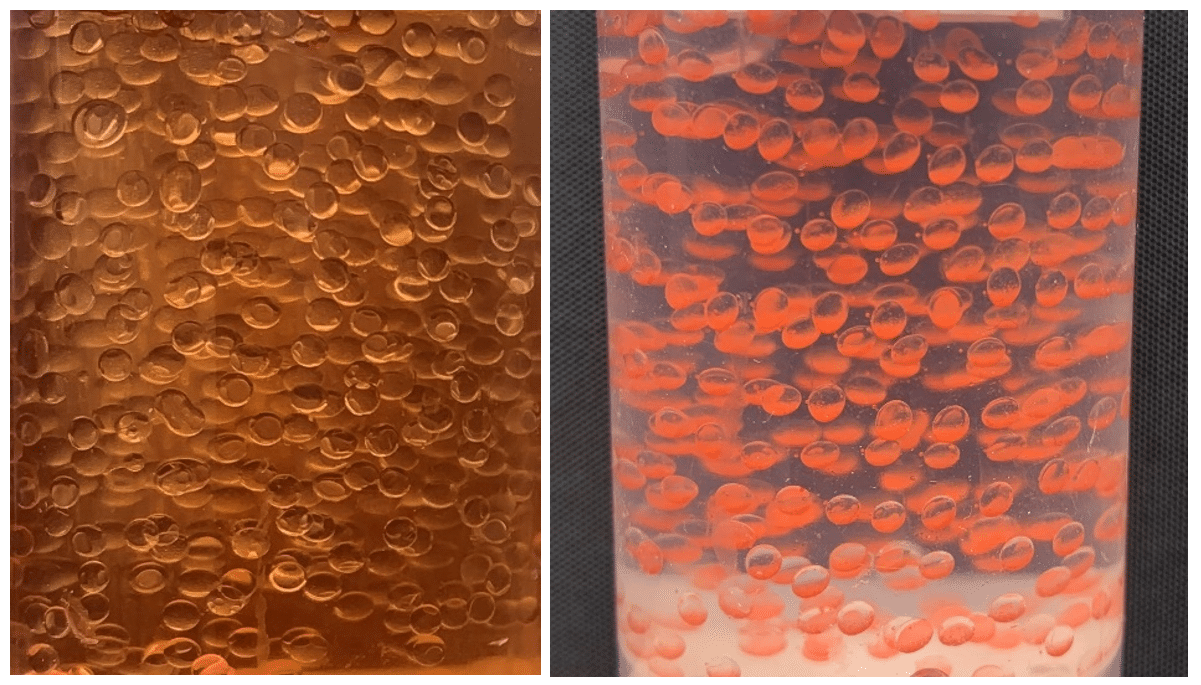

Droplet-based microfluidics offer significant benefits to the cosmetics industry. With reagents encapsulated in highly monodispersed droplets at the millimeter scale, active ingredients can be preserved and protected from the environment up until the moment of application. Different types of emulsions can be generated for the needs of the individual product, each with different purposes. Droplets do not burst until they are applied directly to the skin, providing a visual and sensory experience along with improved product efficacy and better moisturization or drug absorption.

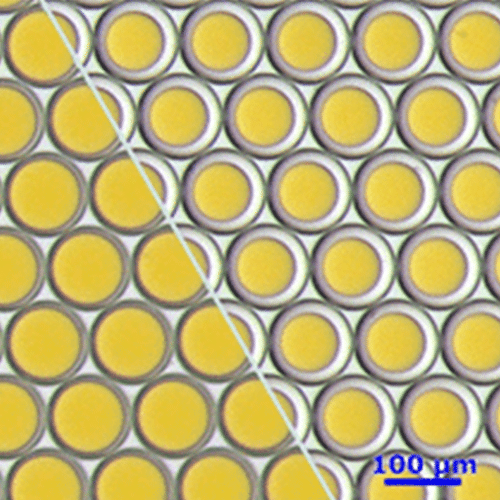

Unmatched droplet homogeneity

In cosmetics, microfluidics offer high control over an immense range of parameters, including droplet size, formulation, and aesthetics (colors, pigments), while also providing unmatched consistency compared to traditional batch methods. Manufacturers can develop custom products with visual and sensory feels specific to their brand – a must in the cosmetics industry. The ability to precisely monitor droplet size allows for direct control of drug loading capacity and product functionality. Microfluidic systems can be scaled up or down and automated with a high degree of reproducibility to meet specific production needs, making them adaptable to both small-scale laboratory research and large-scale manufacturing.

Related applications

Advantages of emulsions for the cosmetics industry

- Fine control over parameters like droplet size & shape

- High homogeneity

- Lower droplet size dispersion (CV: less than 2%)

- Scale-up capabilities

Related products

Research field

Encapsulation Platform for FACS

Platform for cell encapsulation in DE droplets

See the offer

Microfluidic Double Emulsion Device

RayDrop Double Emulsion

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Double Emulsion Generation Pack

Double Emulsion Generation Pack

See the offer

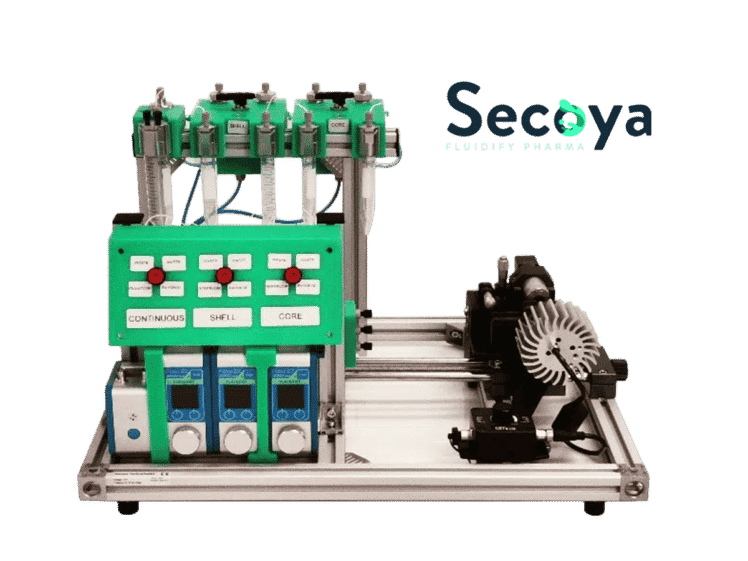

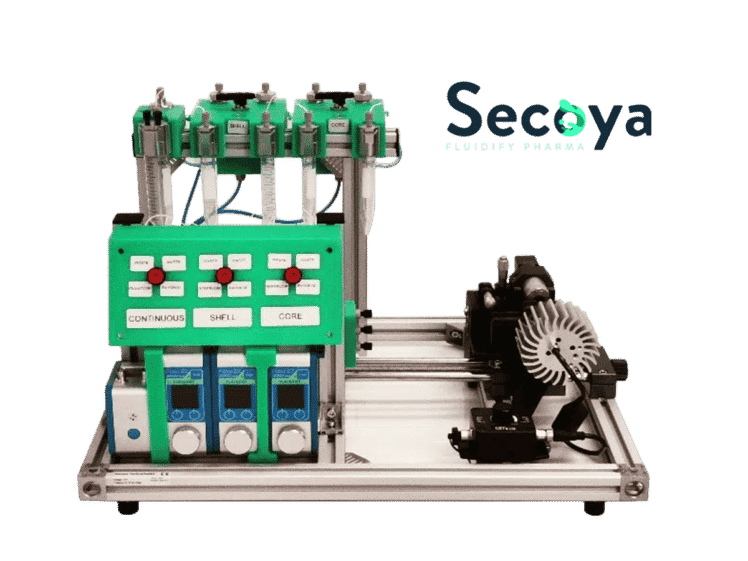

Microfluidic Complex Emulsion Production Platform

Platform for emulsions & droplets

See the offer

Industrial field

Expertise & resources

- Expert Reviews: Basics of Microfluidics

Flow control for droplet generation using syringe pumps and pressure-based flow controllers

Read more - Support & Tools

Droplet Size Calculator

Read more - Product presentation videos

DROPLET STARTER package – Make DROPLETS within minutes!

Read more - Expert Reviews: Basics of Microfluidics

Microfluidic Droplet Production Method

Read more - Microfluidic Application Notes

Encapsulation of multiple emulsions in a single droplet

Read more - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Read more - Array

Raydrop, a universal droplet generator based on a non-embedded co-flow-focusing

Read more - Microfluidic Application Notes

Generating a water emulsion in an oil solution using a droplet generator chip

Read more - Array

Robust technology for double emulsion production and focus on microcapsule/microparticle synthesis

Read more

Looking for a new market?

From life sciences to the food industry, many applications require the use of fluids driven at flow rates ranging from nanoliters to milliliters per minute. At low flow rates like these, the success of such applications strongly depends on the level of control and automation of fluidic operations.

These applications require flow control systems designed to ensure their success.