Ready-to-use system

Microfluidic Complex Emulsion Production Platform

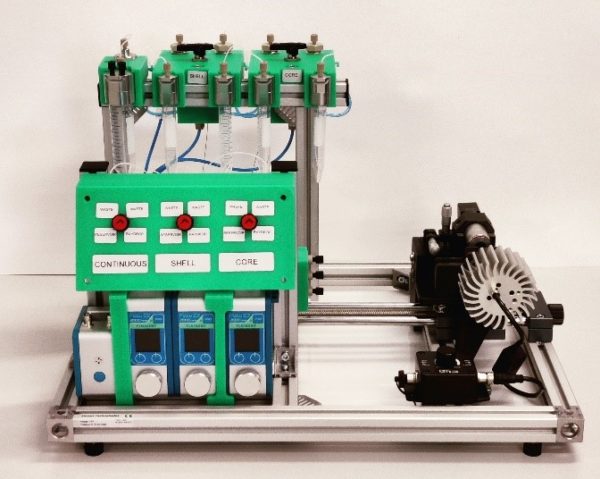

[O-DE-STD-PTF]A ready-to-use platform for all types of emulsions and droplets

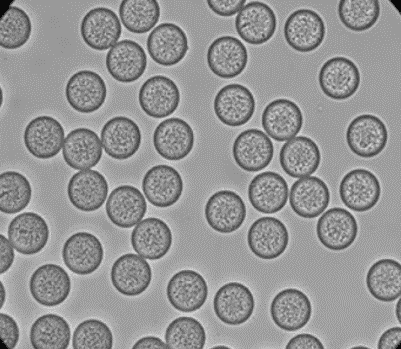

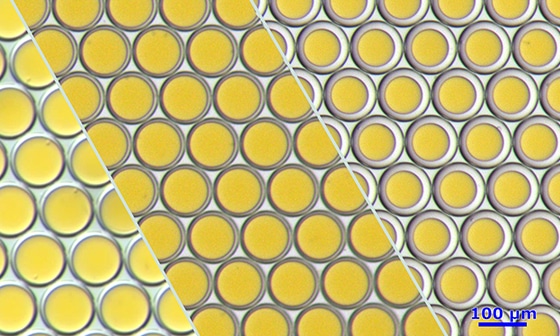

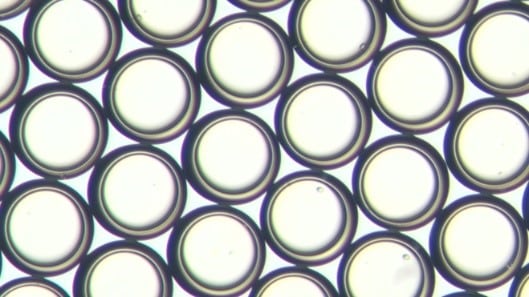

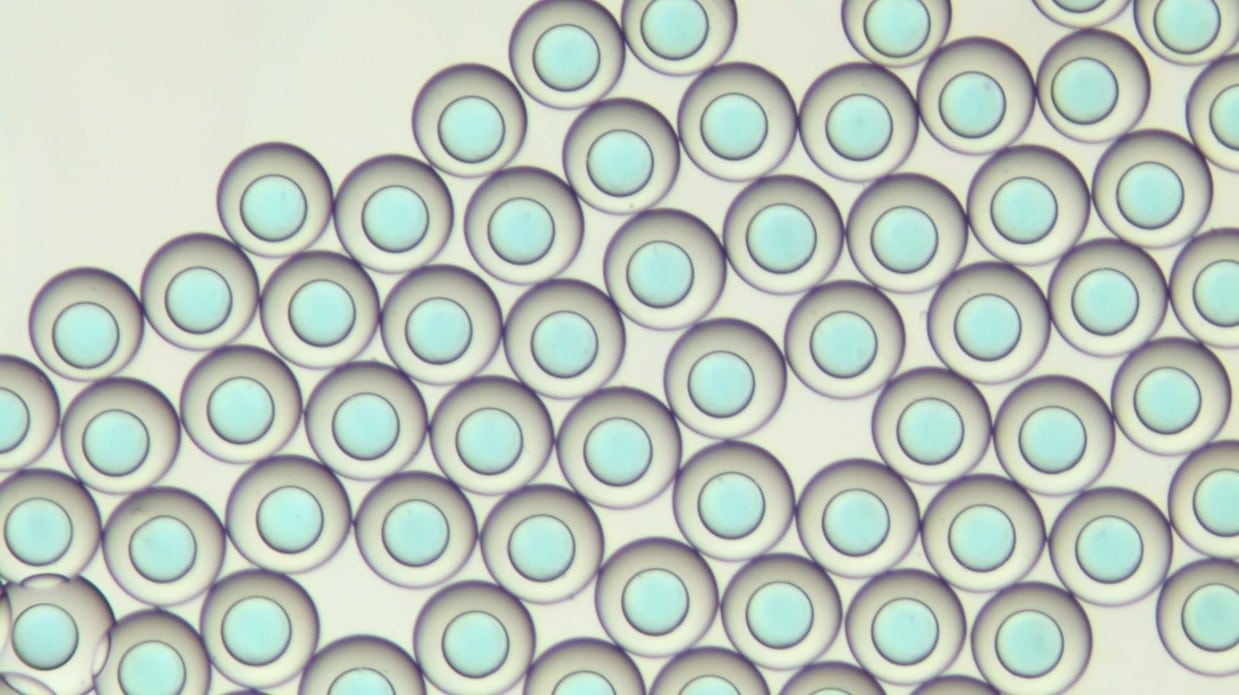

This complex emulsion production platform, developed by Secoya, and using our flow control equipment, is a fast and easy screening system to perform emulsification processes such as single emulsions and double emulsions. Save time with an integrated, organized, ready-to-use platform and get monodispersed complex emulsions rapidly.

- Easy

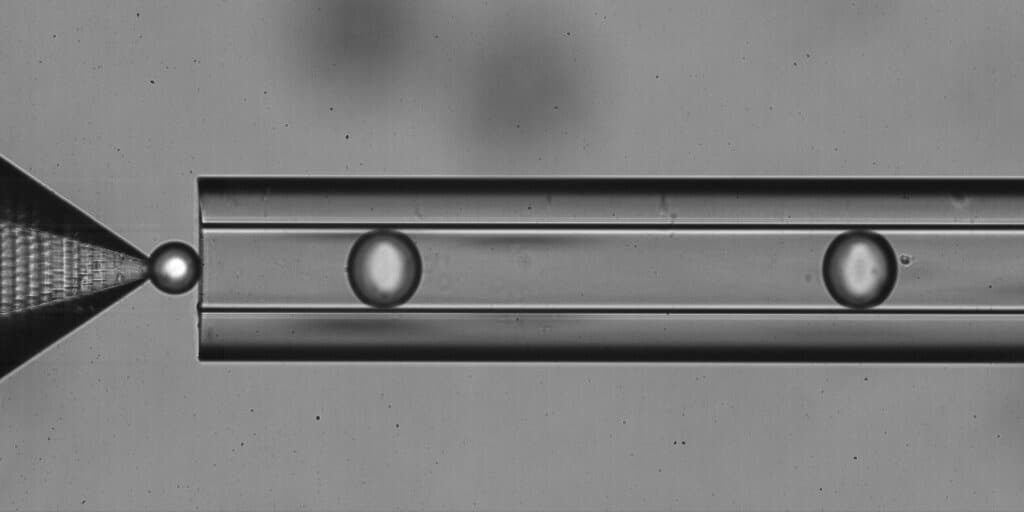

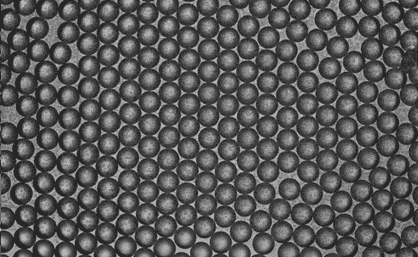

- High precisionDown to 2% monodispersity

- Flexible

All types of emulsions, adjustable shell thickness

- RobustContinuous production

Features of the complex emulsion platform

Start emulsion production right away

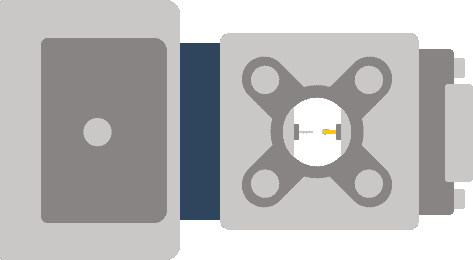

The system is a fully equipped, mounted and controlled tool to set up complex emulsion, microparticle and microcapsule production processes.

An engineered system

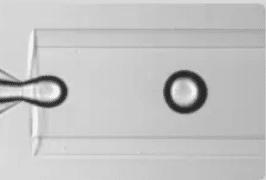

Simplified handling with an organized system. Easy priming and cleaning processes for better robustness. Dedicated optics for optimized droplet visualization at high frequency, and holder for air bubble troubleshooting.

Fluigent precision

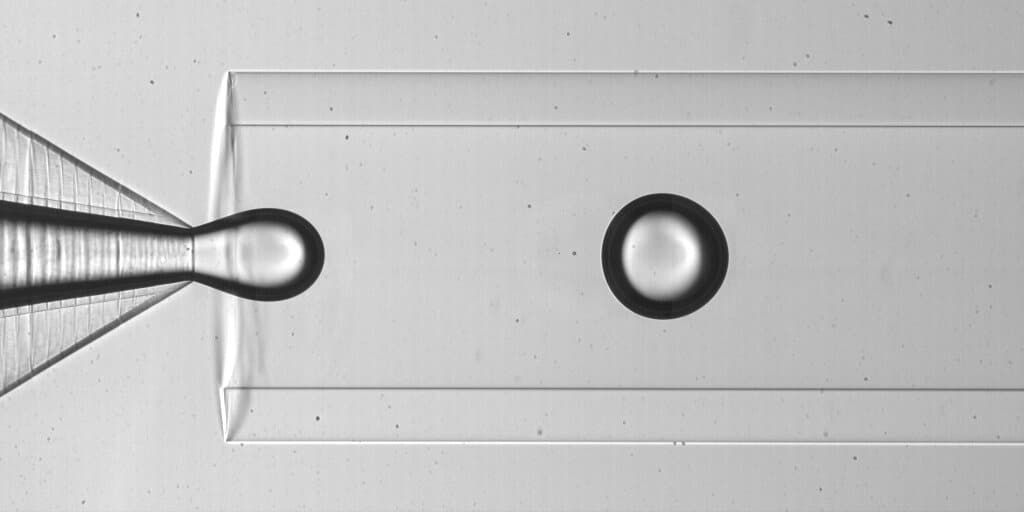

Produce robust, highly monodisperse emulsions using Fluigent pressure-based flow controllers and the Raydrop.

Related applications

Cutting-edge technology for complex emulsion production

The complex emulsion production platform includes an organized flow path with pressure controllers, filters, flowmeters, and valves to facilitate start-up, shut-down, and cleaning of the system between runs. Dedicated optics are included to optimize visualization of complex emulsion production at high generation frequency.

Workshop Replay – New platform for complex emulsion generation

Are you looking for improved performance in generating the right type of droplet-based emulsions for your needs? This online workshop may be of benefit to you.

- Learn how to generate droplet-based emulsions from simple single droplet to complex

- Discover the complex emulsion production platform that combines fluid handling, a microfluidic emulsion generator and an optical monitoring system

- Have live discussions with our experts about your specific application

- Gain familiarity with the newest materials and methods for generating highly monodispersed emulsions

Workshop Replay – Mastering production of Double Emulsions

This upcoming online workshop offers solutions and methods for improving complex emulsion production to enhance performance and meet your specific needs. Existing technologies for producing double emulsions have faced several limitations, such as low reproducibility, the requirement for multiple surface coatings, and large size distribution, among others, making generation of double emulsions a challenging task – until now. This replay features highlights and key takeaways from the 4 sessions.

It covers:

- Presentation of double emulsion generation using Raydrop

- Live demonstration of how to make double emulsions

- The most frequently asked questions & answers from 4 sessions

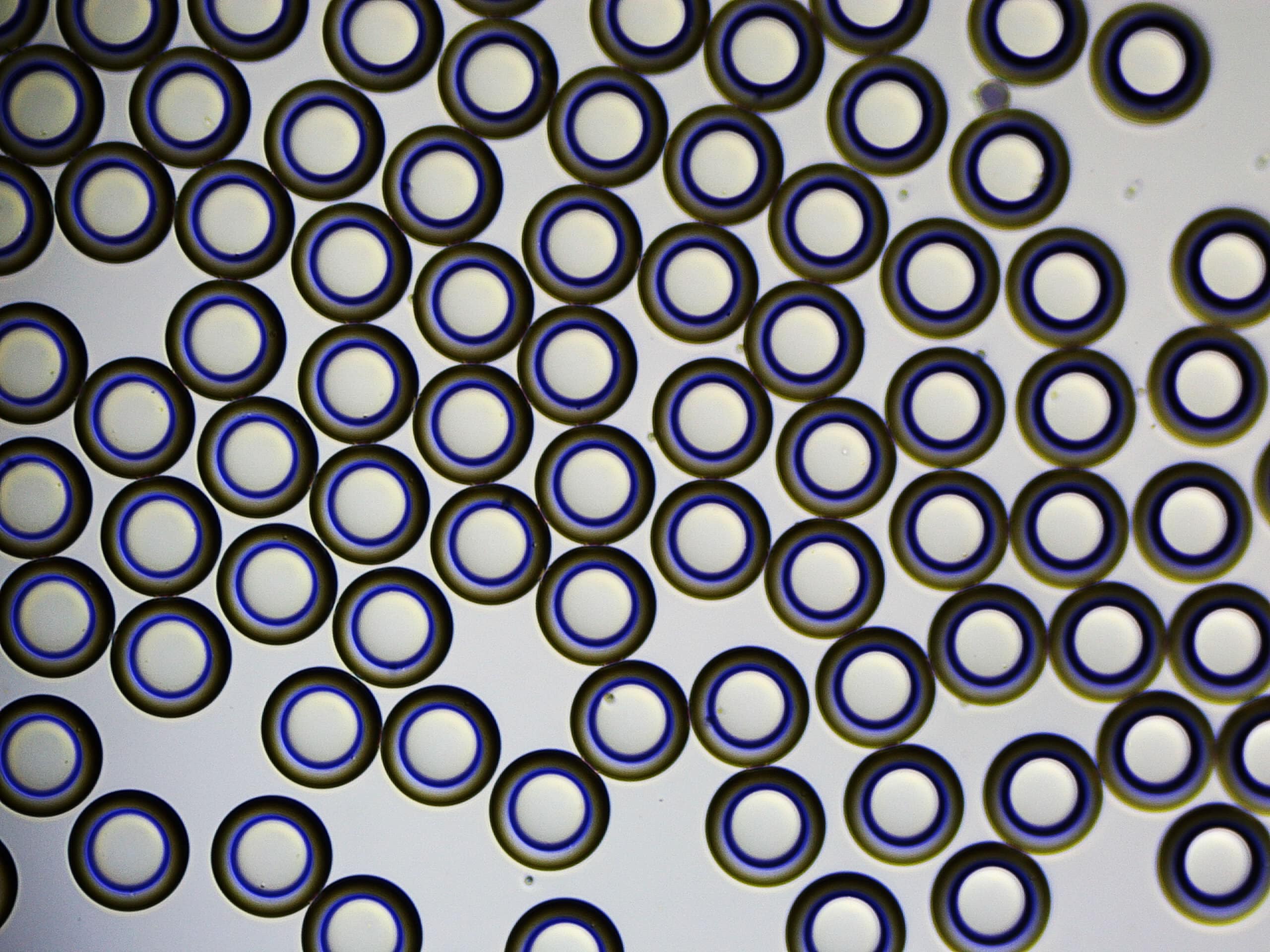

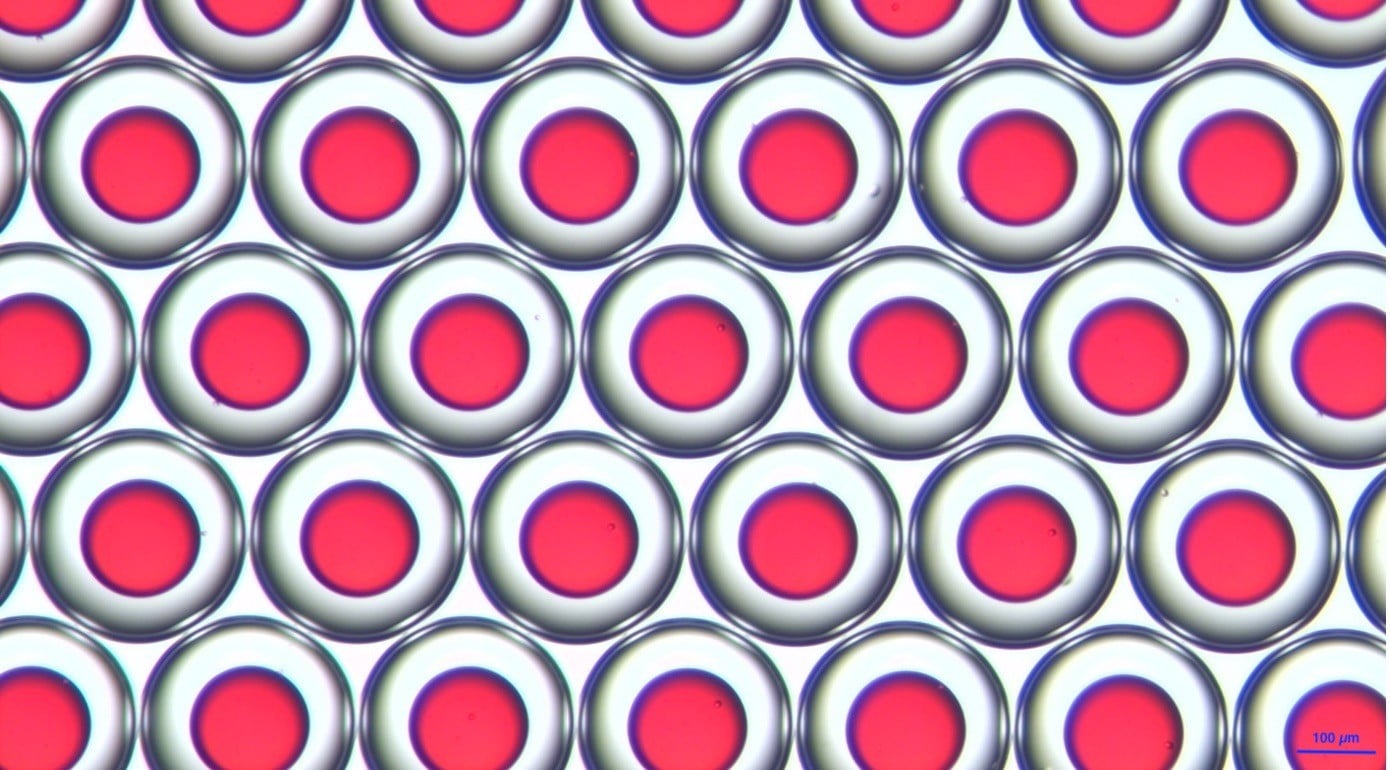

Webinar – Polymerization of microfluidics-produced liquid crystal double emulsions

𝗣𝗼𝗹𝘆𝗺𝗲𝗿𝗶𝘇𝗮𝘁𝗶𝗼𝗻 𝗼𝗳 𝗺𝗶𝗰𝗿𝗼𝗳𝗹𝘂𝗶𝗱𝗶𝗰𝘀-𝗽𝗿𝗼𝗱𝘂𝗰𝗲𝗱 𝗹𝗶𝗾𝘂𝗶𝗱 𝗰𝗿𝘆𝘀𝘁𝗮𝗹 𝗱𝗼𝘂𝗯𝗹𝗲 𝗲𝗺𝘂𝗹𝘀𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗺𝗮𝗸𝗶𝗻𝗴 𝘄𝗮𝘃𝗲𝗹𝗲𝗻𝗴𝘁𝗵 𝗮𝗻𝗱 𝗽𝗼𝗹𝗮𝗿𝗶𝘇𝗮𝘁𝗶𝗼𝗻-𝘀𝗲𝗹𝗲𝗰𝘁𝗶𝘃𝗲 𝗿𝗲𝘁𝗿𝗼𝗿𝗲𝗳𝗹𝗲𝗰𝘁𝗼𝗿𝘀.

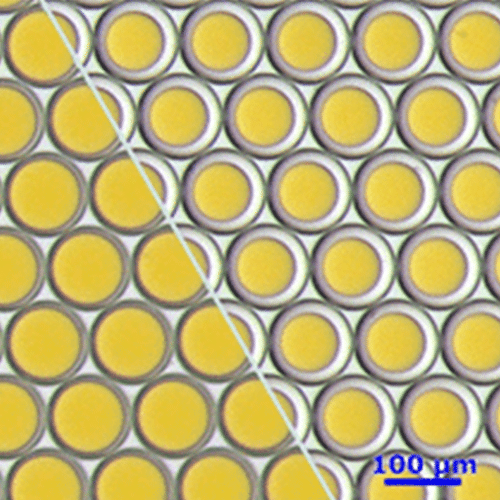

By combining the exquisite control of microfluidic double emulsion production with the self-assembly of liquid crystals, spherical shells with peculiar optical properties can be produced at high throughput and excellent reproducibility.

In this webinar by the Experimental Soft Matter Physics (ESMP) group at the University of Luxembourg in collaboration with Fluigent, we will demonstrate, first, that the liquid crystal shells form a rich and intriguing platform for innovative photonics research.

Benefits of the platform

The Complex Emulsion production platform is designed for droplet (single and double emulsion), microparticle and microcapsule production for encapsulation of Active Pharmaceutical Ingredients or other reagents inside different materials such as polymers (PLGA, UV polymerized materials), hydrogels and more.

An engineered system

Simplified handling with an organized system. Easy priming and cleaning processes for better robustness. Dedicated optics for optimized droplet visualization at high frequency, and holder for air bubble troubleshooting.

Fluigent precision

Produce robust and highly monodisperse emulsions using Fluigent pressure-based flow controllers and the Raydrop.

Perform high monodisperse and reproducible droplet generation

Controlling the droplet generation process is one of the important and central topics of microfluidics. As microfluidics is still a very new topic, it can be difficult to work with and get used to in comparison to other well-known technologies (batch method). There is a clear need for an easy-to-use complex emulsion production platform that is capable of producing droplets in a controlled manner, with high reproducibility and accuracy.

Specifications

| Description | Product | Part Number |

|---|---|---|

| Double Emulsion Production Device | Raydrop Double Emulsion (30-70-150) | ORDRPDE-30-70-150 |

| Fluid Handling System | 1*Link Module 3*Flow EZ 7 bar for all 3 phases | LU-LNK-0002 LU-FEZ-7000 |

| Reservoirs | Continuous phase: 1*50mL Pcap with 50mL Falcon tube Shell Phase: 2*15mL Pcap with 15mL Falcon tube Core Phase: 2*15mL Pcap with 15mL Falcon tube | P-CAP50-HP P-CAP15-HP |

| Flow meters | Continuous phase: 1* Flow Unit L Shell Phase: 1*Flow Unit M Core Phase: 1*Flow Unit M | FLU-M-D FLU-L-D |

| Optical System | Light Source Microscope objective Specific colour camera (up to 400 fps, 1µs integration time) XYZ translation stages | NA* |

| Tubing and Fittings | Tubing : – OD: 1/16 and 1/32 OD – ID: 250µm & 500µm – Materials: PFA Manual Valves: – 3*4 way valves – 2*2 way valves Filters: – 10µm filters for continuous phase – 2µm filters for dispersed phase | NA* |

| Wetted materials | Platform: PEEK, PFA, PCTFE, PTFE, SS316L, GLASS Sealing: FKM or EDPM | X |

| Unit dimensions | 61*41*43 cm3 (L*W*H) | X |

| Weight | 4kg without the protective hood 20kg with the protective hood | X |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

What is the difference between the Double Emulsion Production Station and the Complex Emulsion Production Platform?

Double Emulsion Production Station

- Production of either W/O/W or O/W/O double emulsion s

- For microcapsule production, an additional component needs to be added

- Suitable for a microfluidic user or scientist who wants to build their own setup

Complex Emulsion Production Platform

- An integrated system for non-microfluidic users and scientists who don’t want to spend time on system design

- Everything is ready to use for various types of liquid double emulsions and microparticle generation

Expertise & resources

-

Microfluidics case studies Using dSurf for High Throughput Laser-Induced Fluorescence Droplet Micro-Thermometry (LuMIn) Read more

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidics White Papers Droplet-based Microfluidics Read more

-

Fluigent products manual Raydrop double emulsions protocol Download

-

Fluigent Products Datasheets Complex emulsion production platform datasheet Download

-

Fluigent Products Datasheets Raydrop double emulsions datasheet Download

-

Expert Reviews: Basics of Microfluidics The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing Read more

-

Microfluidic Application Notes Double Emulsion Generation Read more

-

Microfluidic Application Notes Microfluidic Chitosan Microcapsules Production Read more

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes PLGA Microparticles Synthesis Read more

-

Microfluidic Application Notes UV-Crosslinking of Microcapsules Read more

-

Microfluidic Application Notes UV-Crosslinking of Microparticles Read more

-

Fluigent Products Datasheets FLOW UNIT Datasheet Download

-

Microfluidic Application Notes Water in Oil Emulsions Read more

-

Microfluidic Application Notes Oil in Water Emulsions Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Fluigent Products Datasheets Flow EZ™ Datasheet Download