Alginate Microbeads Production

Microencapsulation is one of the most interesting fields in pharmaceutical technology since its inception many years ago. Microencapsulation products (microparticles, microbeads) are small entities that contain an active agent or core material surrounded by a shell or embedded into a matrix structure. [1] Among all these materials, alginate remains a suitable candidate for many applications.

Alginate Microbeads are one of the most widely investigated cell encapsulation materials as they are biocompatible, non-toxic, biodegradable, and cost effective. [2] Following is a method for encapsulation of reagent into alginate spheres with total control of bead formation.

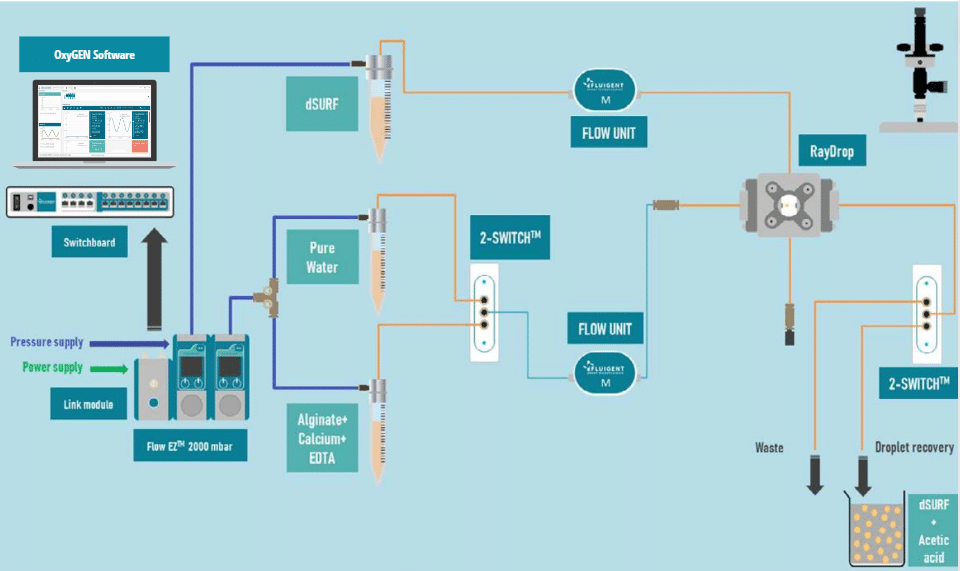

The generation is performed with the RayDrop developed and manufactured by Secoya, this droplet-based microfluidic method is used to precisely control the production of microbeads without the drawbacks of large size distribution found in other methods.

Secoya Technologies developed and manufactured the RayDrop used to perform this application note.

Features of Fluigent’s Alginate Microbeads Production Station

Complete system

The alginate beads generation package contains all the necessary components to begin generating alginate droplets.

Engineered solution

The package contains accurate pressure controllers, microfluidic chips, and valves for the highest flexibility in terms of droplet size and generation rate.

Dedicated protocol

A protocol is available to assist you in setting up your experiments.

Customization possible

We can adapt the package to fulfil your needs (alginate beads size, generation rate).

How to Produce Mono-dispersed Alginate Beads?

Microencapsulation Technique

Microencapsulation is a versatile technique employed across various industries, including chemicals, pharmaceuticals, cosmetics, and printing. This innovative process involves packaging solid, liquid, or gaseous active ingredients within a protective secondary material, safeguarding them from external environmental factors.

The applications of microencapsulation are widespread, contributing to advancements in controlled drug release, enhanced product stability, and improved efficiency in diverse manufacturing processes.

Explore the benefits and applications of microencapsulation to stay at the forefront of technological advancements in your respective industry.

Why Choose Alginate for Microencapsulation?

When considering microencapsulation techniques, the choice of material plays a pivotal role in determining the success of the encapsulation process. Alginate, a naturally derived polymer extracted from seaweed, emerges as a standout option for various reasons.

1. Natural and Sustainable:

Alginate’s origin from seaweed underscores its natural and sustainable characteristics, aligning with the growing emphasis on eco-friendly practices in various industries.

2. Gel Formation Expertise:

A unique attribute of alginate is its ability to form a gel when dissolved in water and exposed to specific salts. This gelation reaction offers a high degree of versatility, allowing for the creation of wet or dry spherical beads with customizable properties.

3. Visual Appeal and Functionality:

The manipulability of the gelation process enables the formation of visually appealing alginate microbeads. These beads serve various purposes, including encapsulation of diverse materials and agglomeration of powders, adding both aesthetic and functional value to the microencapsulation process.

4. Biodegradable and Biocompatible:

Alginate microbeads exhibit biodegradability, ensuring environmentally friendly disposal. Additionally, their biocompatibility and non-toxic nature make them ideal candidates for applications such as drug delivery systems.

5. Versatile Drug Delivery:

One of Alginate’s remarkable features is its suitability for the controlled release of both hydrophobic and hydrophilic drugs. This versatility positions alginate microencapsulation as a preferred choice in pharmaceutical and medical applications.

Usual Alginate Beads Generation Methods

Several methods and techniques are potentially useful for the preparation of polymeric microparticles in the broad field of microencapsulation, including extrusion, the batch method or spray drying.

The preparation method will determine the type and size of alginate microbeads and influence the ability of the interaction among the components used in microbead formulations.

Although there are multiple methods for production, each presents numerous technical challenges, most commonly the high viscosity of the polymer fluids.

The critical design considerations of alginate microbeads are highly dependent on the applications. Among the considerations are size, size distribution, shape, mass transport properties, biocompatibility, swelling properties, solubility, and mechanical and chemical stability. The carrier qualities can be influenced by the alginate composition and concentration, the presence of impurities, the type and concentration of gelling ions and non-gelling ions, as well as the production process conditions.

The most popular way to produce monodispersed alginate beads is by using the dripping technique. In this method, the alginate solution is extruded through a capillary at a low volumetric rate and allowed to drip under gravity. Although this method has been used for many years, the formation of beads with desired size and spherical shape often requires some trial-and-error work on the liquid formulation and experimental setup (e.g., solution viscosity or surface tension, tip size, collecting distance etc.). If the conditions are not optimum, deformed alginate beads or beads with a tail could be produced, and this is a significant limitation because in microbead production, particle size is a key parameter.

As the reproducibility of such methods is low, there is a demand for better techniques and control of the process to produce alginate microbeads.

Droplet-based Microfluidic for Alginate Encapsulation

Droplet-based microfluidics offers an efficient method for improvement of this process. It is a powerful tool which allows the production of micrometric monodispersed droplets, without the disadvantage of the irregular particle sizes of the other methods.

Therefore, with microfluidics, it’s possible to have more optimal control over the production and encapsulation process, reaching a higher monodispersity of microbeads than the other methods (extrusion methods, batch…). In addition, a higher reproducibility is obtained as it is a continuous (in-line) production.

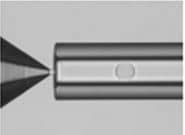

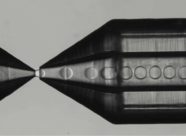

Following is a method for encapsulation of reagent into alginate microbeads with total control of bead formation. The generation is performed with the RayDrop, a device developed and manufactured by Secoya. This droplet-based microfluidic method is used to precisely control the production of microbeads without the drawbacks of large size distribution common in other methods.

The RayDrop is an emulsion generator based on the alignment of two capillaries immersed in pressure containing the continuous phase that controls the generation of alginate droplets. The dispersed phase exits one of the capillaries through a 3D printed nozzle placed in front of the extraction capillary for collecting the droplets. This particular geometry solves all wettability issues that sometimes appear in other microfluidic chips.

With the combination of Secoya’s RayDrop device and Fluigent’s LineUP microfluidics pumps, Fluigent has developed an innovative system for the production of monodisperse alginate beads.

Conclusion

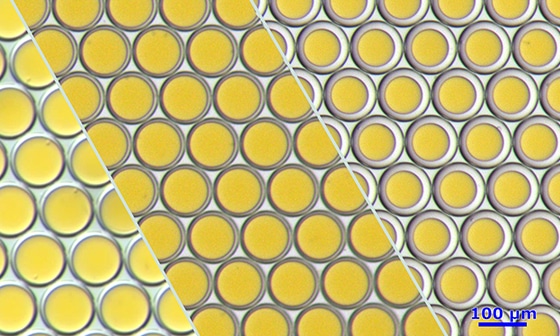

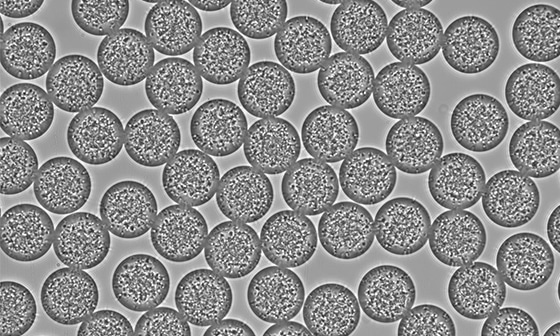

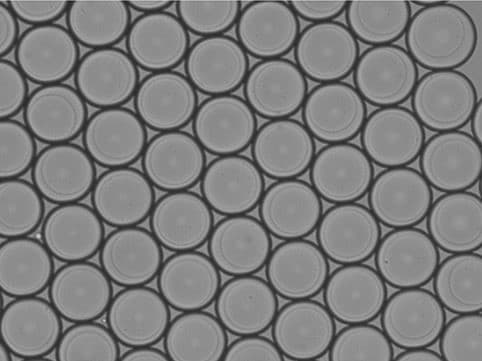

In this application note, we have demonstrated that using our setup, we were was able to produce alginate beads with a dispersion in bead size lower than 2%. Microbeads of 95-160µm diameter are generated with standard RayDrop configuration (Nozzle of 30µm and outlet capillary 150µm) using alginate solution at 1% in water. By using the same procedure, other alginate concentrations, including 2%, which is frequently used in biological applications, have also been tested successfully. In this last case, a more viscous solution necessitates the use of tubing with a larger internal diameter. This set up and protocol can therefore be used to encapsulate bacteria, mammalian cells, and other reagents into alginate microbeads. We have successfully shown that using Fluigent products enables precise control over the production of high monodispersity alginate beads. As demonstrated, using the RayDrop with various nozzle sizes enables greater versatility. To target various droplet sizes, the user can easily change the capillary size.

In this application note, we showcase our capability to produce highly uniform alginate beads with a size dispersion below 2% using our specialized setup.

Employing the standard RayDrop configuration (30µm nozzle and 150µm outlet capillary) and a 1% alginate solution in water, we consistently generate microbeads with diameters ranging from 95-160µm.

Extending the versatility of our approach, we have successfully tested varying alginate concentrations, including the commonly used 2% in biological applications. For the latter, the use of a more viscous solution requires tubing with a larger internal diameter.

This setup and protocol prove effective for encapsulating diverse materials such as bacteria, mammalian cells, and other reagents into alginate microbeads.

Our utilization of Fluigent and Secoya Technologies products ensures precise control over the production process, resulting in high monodispersity alginate beads. The demonstrated flexibility of the RayDrop, with its compatibility with various nozzle sizes, enhances versatility. Users can effortlessly tailor the capillary size to target different droplet sizes, offering a customizable and efficient microencapsulation solution.

References

[1] Obeidat, W. M. (2009). Recent Patents Review in Microencapsulation of Pharmaceuticals Using the Emulsion Solvent Removal Methods, 178–192.

[2] Andersen, Therese & Strand, Berit & Formo, K. & Alsberg, Eben & Christensen, B.E.. (2011). Alginates as biomaterials in tissue engineering. Carbohydrate Chemistry. 37. 227-258. 10.1039/9781849732765-00227.

Resources & Expertises

-

Expert Reviews: Basics of Microfluidics Microfluidics in Drug Delivery: A New Era of Precision Medicine Read more

-

Expert Reviews: Basics of Microfluidics 10 Tips for Reliable Droplet Generation Read more

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidic Application Notes Alginate Microcapsule Synthesis Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidics White Papers Droplet-based Microfluidics – A Complete Guide Read more

-

Expert Reviews: Basics of Microfluidics Prostate Organoid Culture in Microbeads Read more