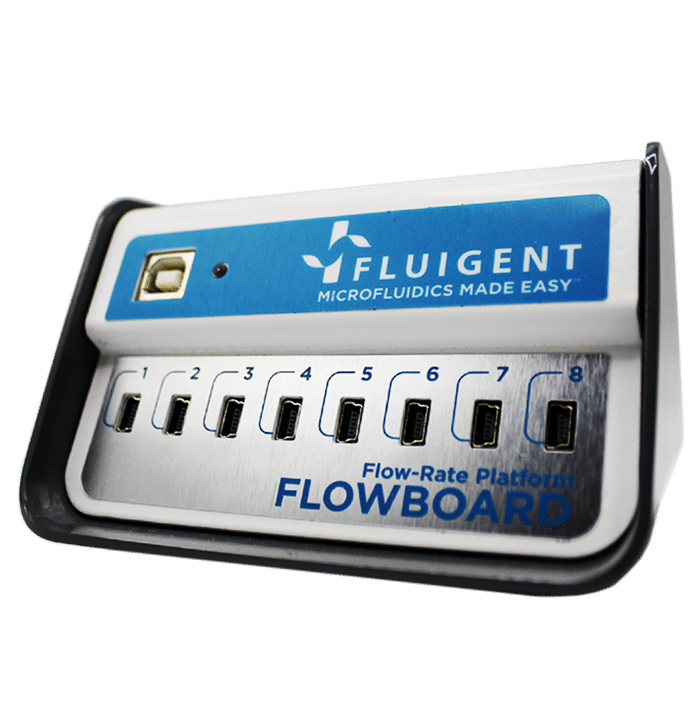

Up to 8 individual sensors

Microfluidic Flow Sensor Hub

[FLB]Flowboard

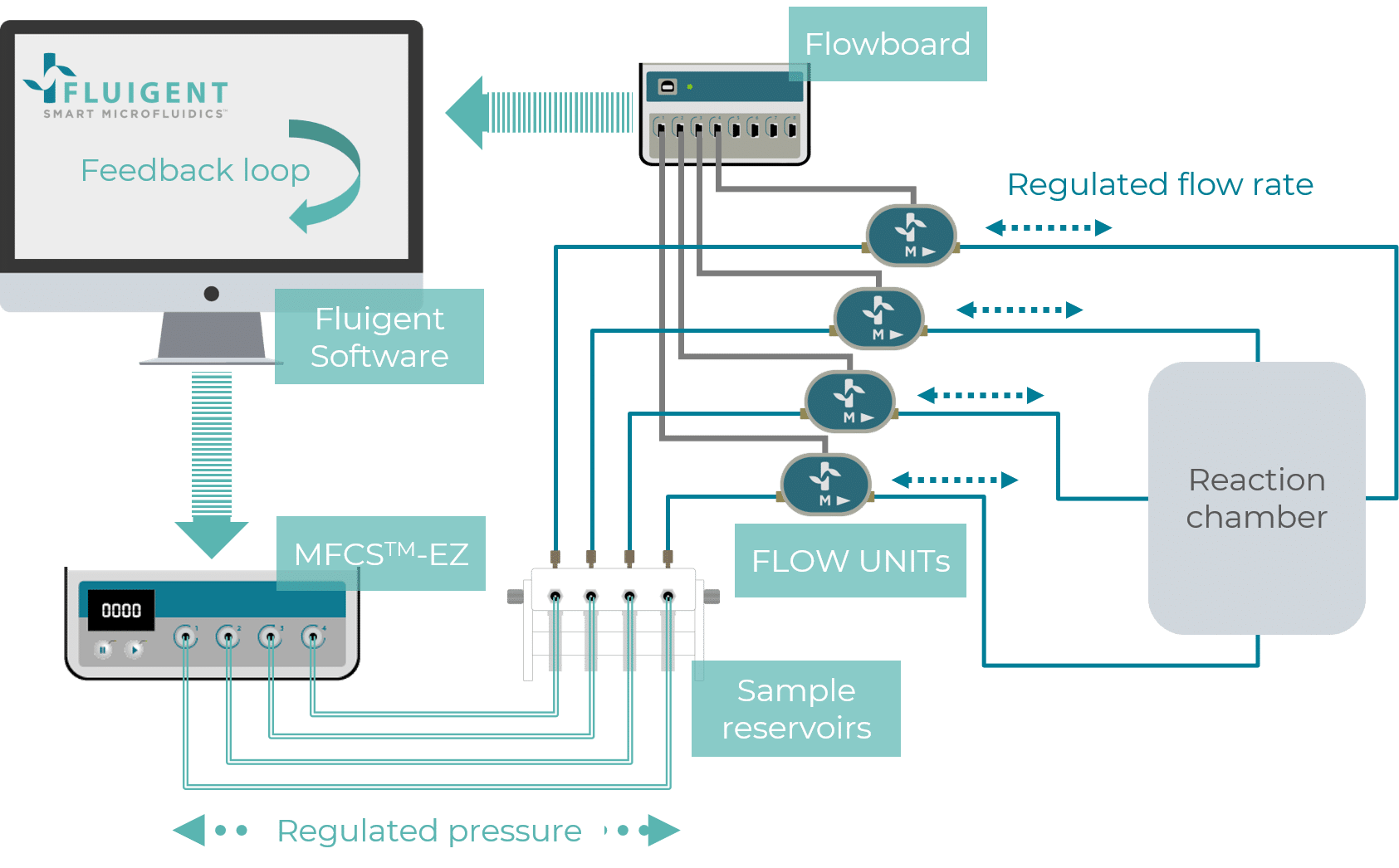

The Flowboard is a flow sensor hub that powers and communicates between Fluigent Software and up to eight FLOW UNITs . Together, they act as a Flow-Rate Platform to measure and display flow rates in real-time. The Flowboard is required for flow rate control when using an MFCS™ series flow controller. The flow unit station can be used to measure and display flow rate during a microfluidic experiment with any flow control system.

- Multiple

- Compact

Uses minimum bench space

- Adaptable

Compatible with any system

- Smart

Regulation in real-time

Features

Versatility

The Flowboard is compatible with all of our flow sensors (XS, S, M+, L+).

Parallelization

Up to 8 flow sensors of various types can be connected at the same time. The flow sensor hub lets you monitor the flow-rate of several different kinds of liquids at the same time, allowing complex experiments to be carried out.

Specifications

HARDWARE SPECIFICATIONS

| Dimensions | 114 x 102 x 70 mm |

| Weight | 478 g |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 15 V =-= (100 mA) |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Related products

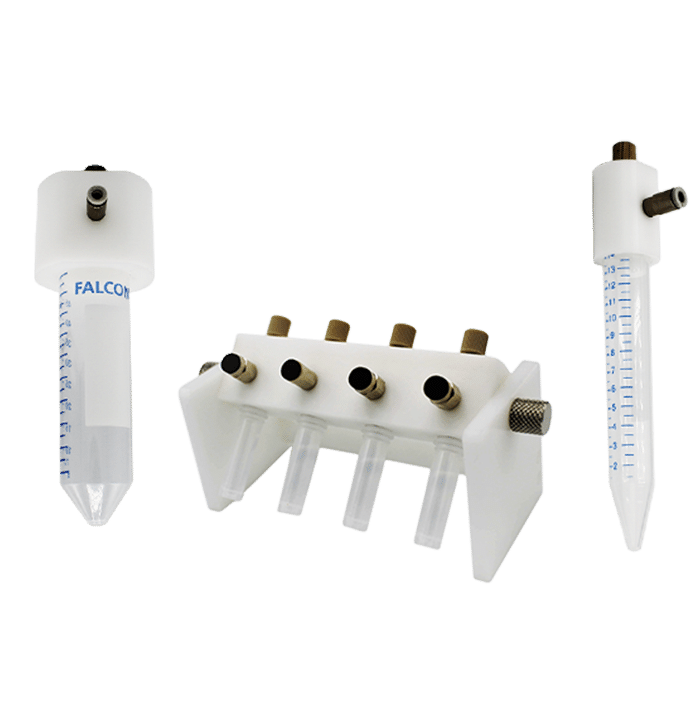

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Microfluidic Flow Control System

MFCS™ series

See the offer

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Microfluidic In-Line Pressure Sensor

Microfluidic In-Line Pressure Sensor

See the offer