Valve actuation time

Microfluidic Injection Valve

[LSW001]L-SWITCH™ 6-port/2-position

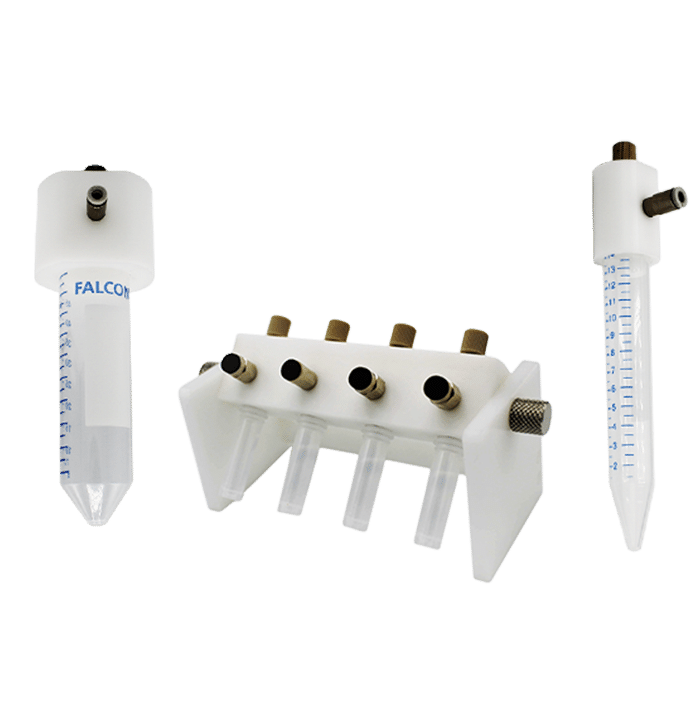

The L-SWITCH™ is a 6-port/2-position bidirectional microfluidic injection valve used to handle liquids through different valve ports. It is ideal for precise volume injection or for switching between different fluids, as it allows automation of sample injection in your fluid line.

- Quick

- Compact

Uses minimum bench space

- Biocompatibility

Biologically compatible

- Accurate

Low internal volume

Features of the bidirectional switch

6-port/2-position

Peripheral ports (numbered from 1 to 6) can alternatively be connected to the right or the left channels. The L-SWITCH™ is actuated by a motor that drives a rotor – where the fluidic path is engraved – against a stator – containing the fluidic paths.

Sample injection

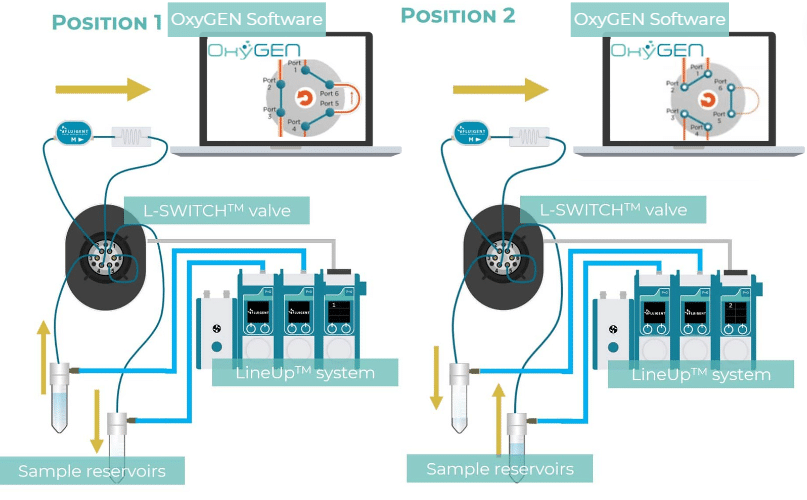

The L-SWITCH™ microfluidic injection valve enables one to load and inject a precise volume of fluid. By selecting the position of the L-SWITCH™ you will choose when you want to load the fluid and then inject it (using a sample loop). Several sample loops are available from 20 µL to 200 µL.

Workflow automation

The valve can be controlled by OxyGEN software for long-term experiments. Create a time-based protocol to set the actuation timing of the valve(s).

Smart control and automation of your fluidic path

Discover Fluigent microfluidic valves, a set of compact instruments allowing to complexify and easily handle the fluidic path of your system. Once integrated in the set-up, the valves can be controlled in real-time and even without the requirement of a PC.

How to perform sample injection with the L-SWITCH bidirectional switch

The L-SWITCH is a 6-port / 2-position microfluidic injection valve that, combined with Fluigent’s pressure controllers, allows us to inject a small volume of sample into a liquid stream, reducing cost, as well as to run and automate long-term experiments with high reproducibility and reliability.

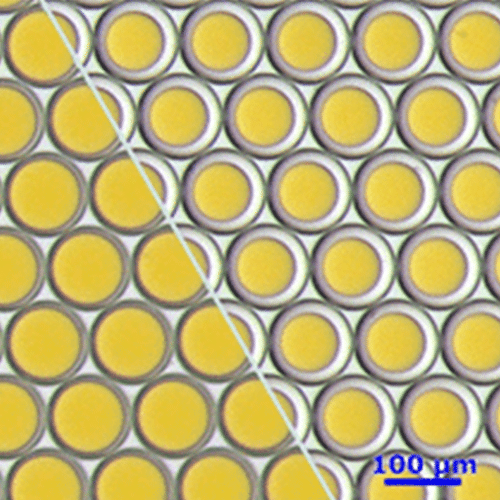

The microfluidic injection valve has 6 inputs and two interchangeable configurations shown on the images below. Each input is connected to a neighbor output, either on the right or the left depending on the configuration.

Example of use

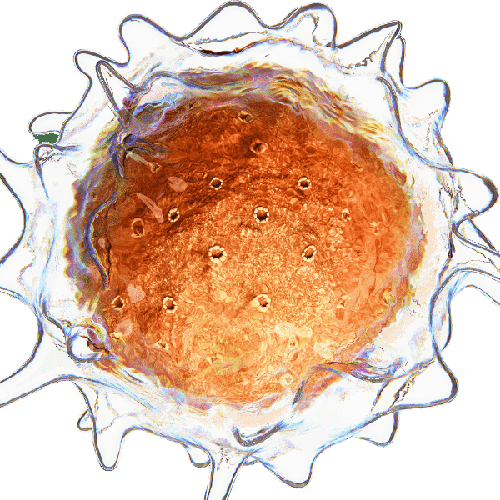

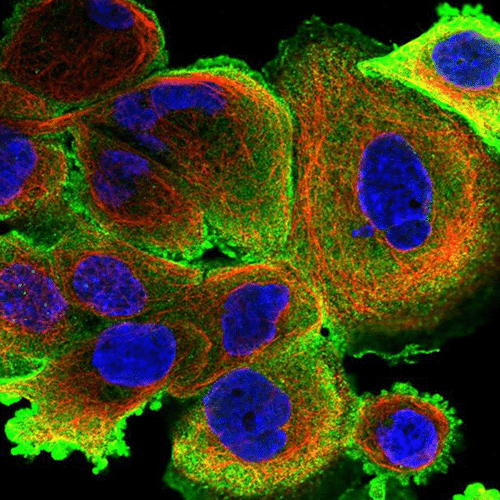

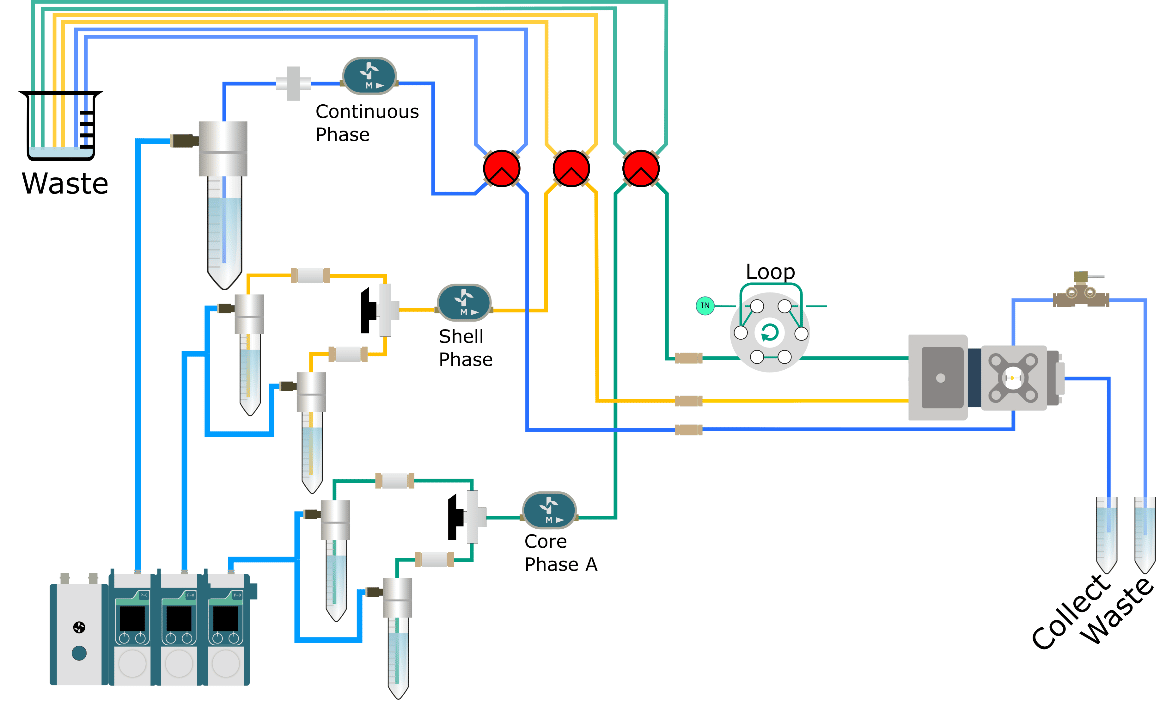

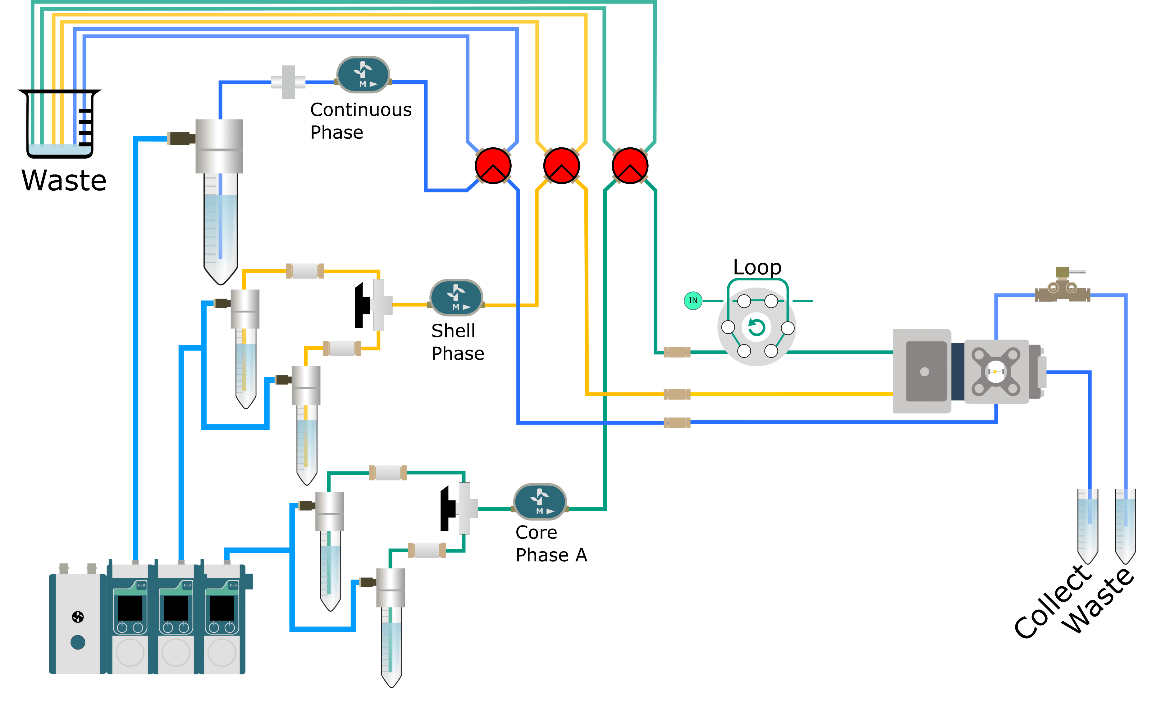

By combining the bidirectional switch with our cell encapsulation platform, it is possible to work with samples with a reduced volume (e.g. working with cells of limited availability, such as stem cells, primary cells from patients…). It is also ideal for the use of rare cells or expensive reagents with a total volume lower than 500µl/.

Benefits of the L-SWITCH injection valve

- No overpressure: Switch between 2 flow configurations in less than 100ms

- No waste: No dead volume and low carryover volume.

- Biocompatible: High chemical and biological compatibility

- Reproducibility and Reliability: Perform identical injections

Specifications

PERFORMANCE

| Switching time | 100 ms |

| Maximum pressure | Up to 7 bar (100 psi) |

HARDWARE SPECIFICATIONS

| Internal volume | 660 nL |

| Internal diameter | 0.3 mm |

| Dead volume | None |

| Wetted materials | PEEK |

| Fittings | Flangeless (1/16’’ OD) |

WEIGHT & DIMENSIONS

| Dimensions | 70 x 90 x 150 mm |

| Weight | 475 g |

ELECTRICAL SPECIFICATIONS

| Power Supply Voltage | 24 VDC |

| Port communication | RJ45 |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Expertise & resources

-

Product presentation videos MICROFLUIDIC VALVE AUTOMATION: How to make it easy [SWITCH EZ] – Fluigent Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

-

Fluigent Products Datasheets L-SWITCH™ Datasheet Download

-

Fluigent products manual Easy Switch Solutions User Manual Download

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

Related products

Microfluidic valve controller for flow redirection

SWITCH EZ

See the offer

Microfluidic Sampling Valve

2-SWITCH™ 3-port/2-way

See the offer

M-SWITCH™ Microfluidic bidirectional valve

M-SWITCH™ Microfluidic bidirectional valve

See the offer

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Recirculation Valve

L-SWITCH™ 6-port/2-position

See the offer