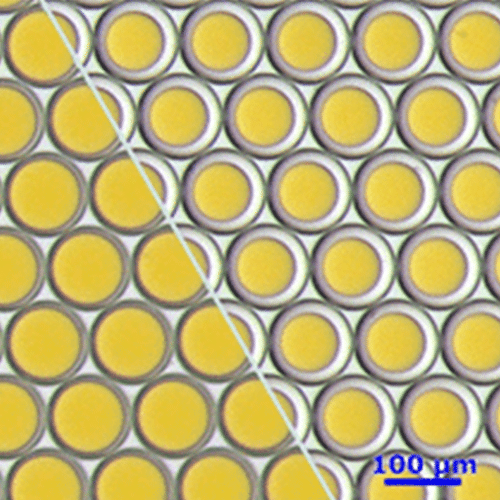

High monodispersity (CV < 2%)

Microfluidic Single Emulsion Device

[1DPRD01]RayDrop Single Emulsion

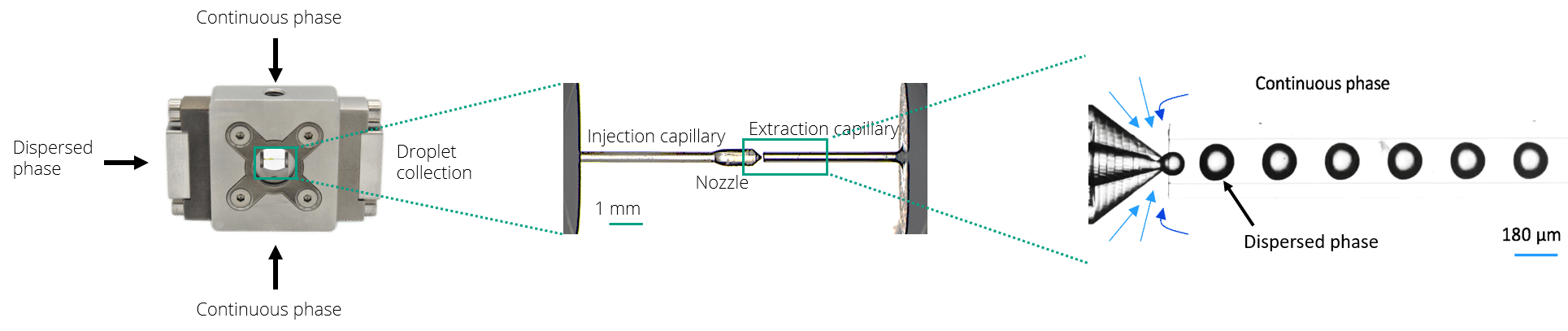

The RayDrop Single Emulsion Device is a microfluidic droplet generator composed of three main fully removable parts: two inserts on each side, a center section containing a nozzle, and an outlet capillary. There are four standard microfluidic connections, two on the box for the continuous phase, one on each insert for the dispersed phase entry, and one on the collecting emulsion outlet.

The RayDrop Single Emulsion Device’s specific design allows for multiple liquid type emulsification within the same device without any coating needed. This allows users to cover single and complex emulsions.

Applications from encapsulation of active pharmaceutical ingredient (in both polymer microparticle) to cell and fragrance encapsulation in hydrogel microbeads are covered, such as:

- Reproducible

- Flexible

Multiple applications

- Easy

Coating-free

“My team has started using the Fluigent microfluidic kit for making polymer based particles. We tried different microfluidic systems in the past but unfortunately they were not suitable for our application. The main issue was chip blockage which rendered the process quite laborious.

The RayDrop microfluidic chip from Fluigent gave us the best results with a better control over the process.

I have to mention the excellent technical support from Fluigent, their team visited my lab 3 times to deliver training and help to optimize the process”

Dr Omar QUTACHI – Senior Lecturer in Pharmaceutics – Health and Life Sciences – Montfort University , The Gateway, Leicester

Features of the Microfluidic Droplet Generator

A flexible device

Droplet size from 20 µm to 450 µm diameter. Frequency of up to 10 000 Hz. Water-in-oil (w/o) and oil-in-water (o/w) droplets.

A unique device

One device for multiple applications

Surface coating-free

As opposed to standard droplet makers, the Raydrop does not require any surface coating steps.

Easy to use

- Standard connection (Upchurch).

- No surfactant for droplet generation.

- Easy-to-clean, exchangeable nozzle.

- Full disassembly for cleaning.

- Easy microscope visualization.

Related applications

Description of the RayDrop droplet maker

Single emulsions are mixed systems consisting of two immiscible liquids in which the inner phase is homogeneously dispersed in the continuous phase in a droplet-wise manner. The single emulsion microfluidic method produces different microsized W/O or O/W emulsion droplets with the desired homogeneous size, shape and tailored structure by simply tuning the experimental parameters, such as pressure, flow rate and regimen, dimensionless parameters (e.g., Reynolds and capillary numbers), as well as taking advantage of the properties of the two fluid phases (interfacial tension and viscosity (1).

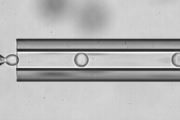

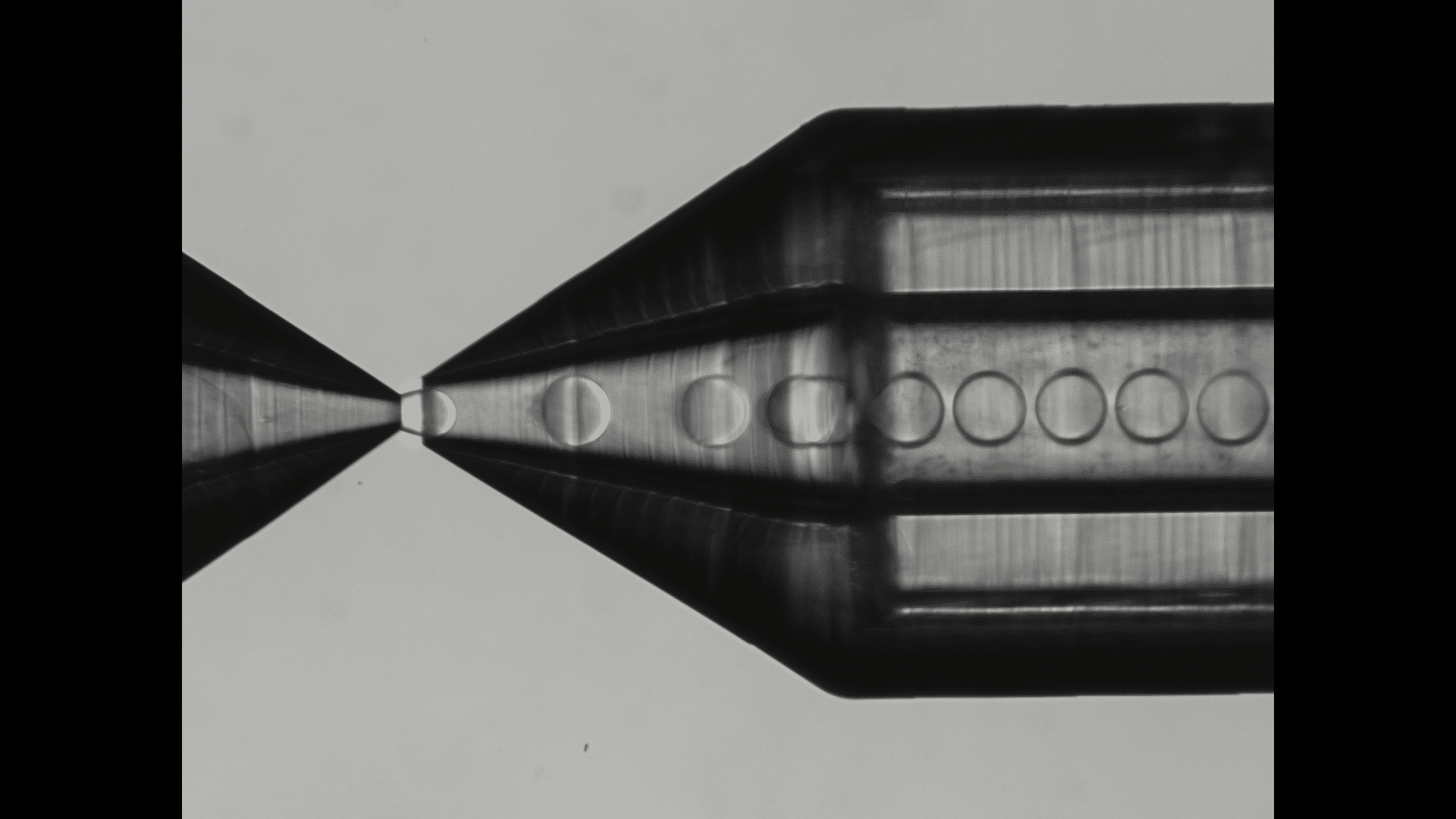

The RayDrop Single Emulsion Device, developed and manufactured by Secoya technologies, relies on the alignment of two glass capillaries inside a pressurised chamber. A 3D-printed micro-nozzle is additionally connected at the tip of the injection capillary, enforcing the dripping (fluids flow at low rates) of small droplets. This non-embedded design presents both the characteristics of a co-flow (axisymetric geometry) and a flow focusing (dramatic local accelerations of the continuous phase), and is thereby called non-embedded co-flow focusing (2). The nozzle and outlet capillary are aligned in the continuous phase chamber, the dispersed phase comes through the nozzle to create the microparticles into the continuous phase and exit by the outlet insert.

The technological breakthroughs of RayDrop Single Emulsion Device’s design is two-fold:

- Firstly, the droplet maker enables the high-throughput generation of monodisperse droplets intrinsic to the dripping regime for a wide variety of fluids, due to the continuous phase not being confined before entering the extraction capillary, allowing for the flushing of viscous continuous phases.

- Secondly, the microfluidic droplet generator benefits from specific fabrication techniques and materials compatible with a large-scale production of the device, while ensuring a precise and reproducible alignment of the two capillaries in the chamber (2).

Secoya, Raydrop Microfluidic Droplet Generator

The Single Emulsion Device is characterised by:

– Nozzle on the extraction capillary:

- High throughput of small droplets/bubbles without high pressure drop

- Increased squeezing for fluids with low interfacial tension

– Co-flow of two miscible phases for nanoparticle production:

- Very homogeneous conditions at the fluids interface due to the axisymmetry.

- Production of nanoparticles and liposomes with a small size distribution

The Single Emulsion Device is available in three standard configurations (Nozzle size-Extraction capillary size), in order to target a broader droplet size range:

- 30µm-150µm

- 60µm-300µm

- 90µm-450µm

As all capillaries from the RayDrop Single Emulsion Device are easily exchangeable, it’s easy to change either the nozzle capillary or the collecting capillary with another nozzle or capillary size.

The droplet maker can also be tuned to target different droplet sizes by changing capillary size and nozzle configuration.

Small droplet configuration: 30µm-60µm

Small droplet configuration: 30µm-70µm-90µm

This two nozzle configuration allows users to decrease single emulsion size down to 15µm droplet size.

WEBINAR REPLAY – Raydrop, a universal droplet generator based on a non embedded co flow focusing

Most commercial microfluidic droplet generators rely on the planar flow-focusing configuration implemented in polymer or glass chips. The planar geometry, however, suffers from many limitations and drawbacks, such as the need of specific coatings or the use of dedicated surfactants, depending on the fluids in play. On the contrary, and thanks to their axisymmetric geometry, glass capillary-based droplet generators are a priori not fluid-dependent. Nevertheless, they have never reached the market because their assembly requires art-dependent and not scalable fabrication techniques.

In the context of a growing demand of controlled droplets in many areas, discover the Raydrop that emerges as a very robust and versatile solution easily implementable in laboratories with little experience and facilities in microfluidics.

Watch our webinar ‘Raydrop, a universal droplet generator based on a non embedded co flow focusing’ to learn more about the features and performance of the RayDrop Single Emulsion Device. In this webinar, we present the advantages of the Raydrop as compared to conventional microfluidic droplet generators, which are usually made in PolyDiMethilSiloxane (PDMS) using laborious and not scalable fabrication steps and require special coatings depending on the type of emulsion the user wants to make.

This webinar was done in collaboration with our partner Secoya Technologies.

What you will learn:

- Introduction to droplet-based microfluidics

- Current method & technologies present on the market droplet & emulsion production

- Understand the advantages & challenges of droplet-based microfluidics

- Discover a new method for droplet and emulsion production

Speakers:

Adrien Dewandre, Technology Lead, Secoya Technologies

Adam Meziane, Product manager, Fluigent

Benoit Scheid, Professor, Université libre de Bruxelles

Specifications

| Device characteristics | Co-Flow focusing design |

| Droplet type | water in oil and oil in water |

| Droplet size | 15 to 450 µm |

| Generation rate | 10 000 Hz (measured for the smallest double emulsion size) – can go higher under specific conditions |

| Nozzle type | Methalcrylate resin Glass |

| Nozzle size | 30 µm ID 60 µm ID 90 µm ID |

| Outlet capillary | 150 µm ID 300 µm ID 450 µm ID |

| External dimensions | L*l*h = 60 mm * 40 mm * 13 mm |

| Weight | 205 |

| Operating pressure | 0 – 5 bar |

| Burst pressure | 10 bar |

| Wetted material: continuous phase | PEEK, FEP, glass, stainless steel, polyimide, Kalrez (seal), methalcrylate resin or glass (nozzle) |

| Wetted laterial: dispersed phase | PEEK, FEP, glass, methalcrylate resin or glass (nozzle) |

| Internal volume | 600µL |

| PN | Product Name | Capillary sizes | Nozzle type |

| 1DPRD01 | Complete Raydrop | 30µm-150µm | Methacrylate Resin |

| ORDRPSE-60-300 | Complete Raydrop | 60µm-300µm | Methacrylate Resin |

| ORDRPSE-90-450 | Complete Raydrop | 90µm-450µm | Methacrylate Resin |

| O-SE-RDRPC04-EUP | Complete Raydrop | 30µm-60µm | Methacrylate Resin |

| O-SE-RDRPC05-EUP | Complete Raydrop | 30µm-90µm | Methacrylate Resin |

| O-SE-RDRPC06-EUP | Complete Raydrop | 60µm-90µm | Methacrylate Resin |

| ORDRPSNO-30 | Simple nozzle insert | 30µm | Methacrylate Resin |

| ORDRPSNO-60 | Simple nozzle insert | 60µm | Methacrylate Resin |

| ORDRPSNO-90 | Simple nozzle insert | 90µm | Methacrylate Resin |

| ORDRPCOL-150 | Collecting capillary insert | 150µm | Glass |

| O-SP-CCI300-CO | Collecting capillary insert | 300µm | Glass |

| O-SP-CCI450-CO | Collecting capillary insert | 450µm | Glass |

| O-SE-RDRPC01G-EUP | Complete Raydrop | 30µm-150µm | Glass |

| O-SE-RDRPC02G-EUP | Complete Raydrop | 60µm-300µm | Glass |

| O-SE-RDRPC03G-EUP | Complete Raydrop | 90µm-450µm | Glass |

| O-SE-GSNO30-EUP | Simple nozzle insert | 30µm | Glass |

| O-SE-GSNO60-EUP | Simple nozzle insert | 60µm | Glass |

| O-SE-GSNO90-EUP | Simple nozzle insert | 90µm | Glass |

Expertise & resources

-

Microfluidics Case Studies Using dSurf for High Throughput Laser-Induced Fluorescence Droplet Micro-Thermometry (LuMIn) Read more

-

Tutorial videos Microfluidics for Alginate Microbeads Production – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 2: How To Clean the Nozzle (1/3) ? – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 1: How To Fill the Raydrop ? – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 3: How To Clean the Nozzle (2/3) – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 4: How To Clean the Nozzle (3/3) – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 6: How To Change Nozzle ? – Fluigent Read more

-

Tutorial videos RayDrop Tutorial episode 5: How To Clean the Chamber – Fluigent Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Interviews & Testimonials Interview with Benoit Scheid from Secoya Read more

-

Fluigent Products Datasheets Raydrop single emulsion datasheet Download

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes Liposome Nanoparticle Synthesis Read more

-

Microfluidic Application Notes PLGA Microparticles Synthesis Read more

-

Microfluidic Application Notes UV-Crosslinking of Microparticles Read more

-

Microfluidic Application Notes Water in Fluorocarbon Oil Emulsions Read more

-

Microfluidic Application Notes Water in Oil Emulsions Read more

-

Microfluidic Application Notes Oil in Water Emulsions Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Application of microfluidic chip technology Read more

Related products

REFERENCES

- Fontana, F., Ferreira, M., Correia, A., Hirvonen, J., & Santos, H. (2016). Microfluidics as a cutting-edge technique for drug delivery applications. Journal Of Drug Delivery Science And Technology, 34, 76-87. doi: 10.1016/j.jddst.2016.01.010

- Dewandre, Adrien & Rivero-Rodriguez, Javier & Vitry, Youen & Sobac, Benjamin & Scheid, Benoit. (2020). Raydrop : a universal droplet generator based on a non-embedded co-flow-focusing.