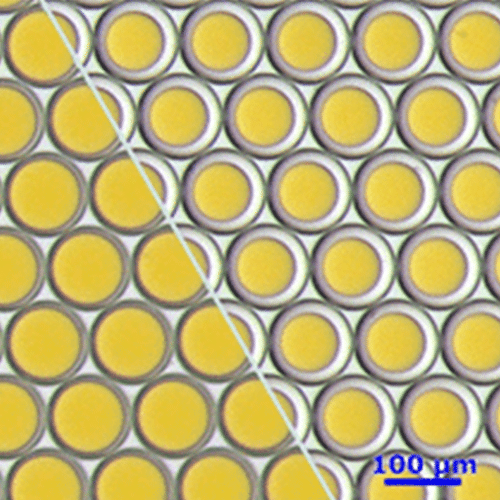

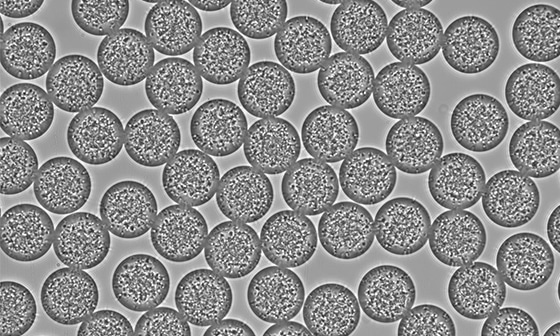

High monodispersity (2%)

PLGA Microparticle Production Standard Pack

[1DPPL01]Produce monodispersed PLGA microparticles

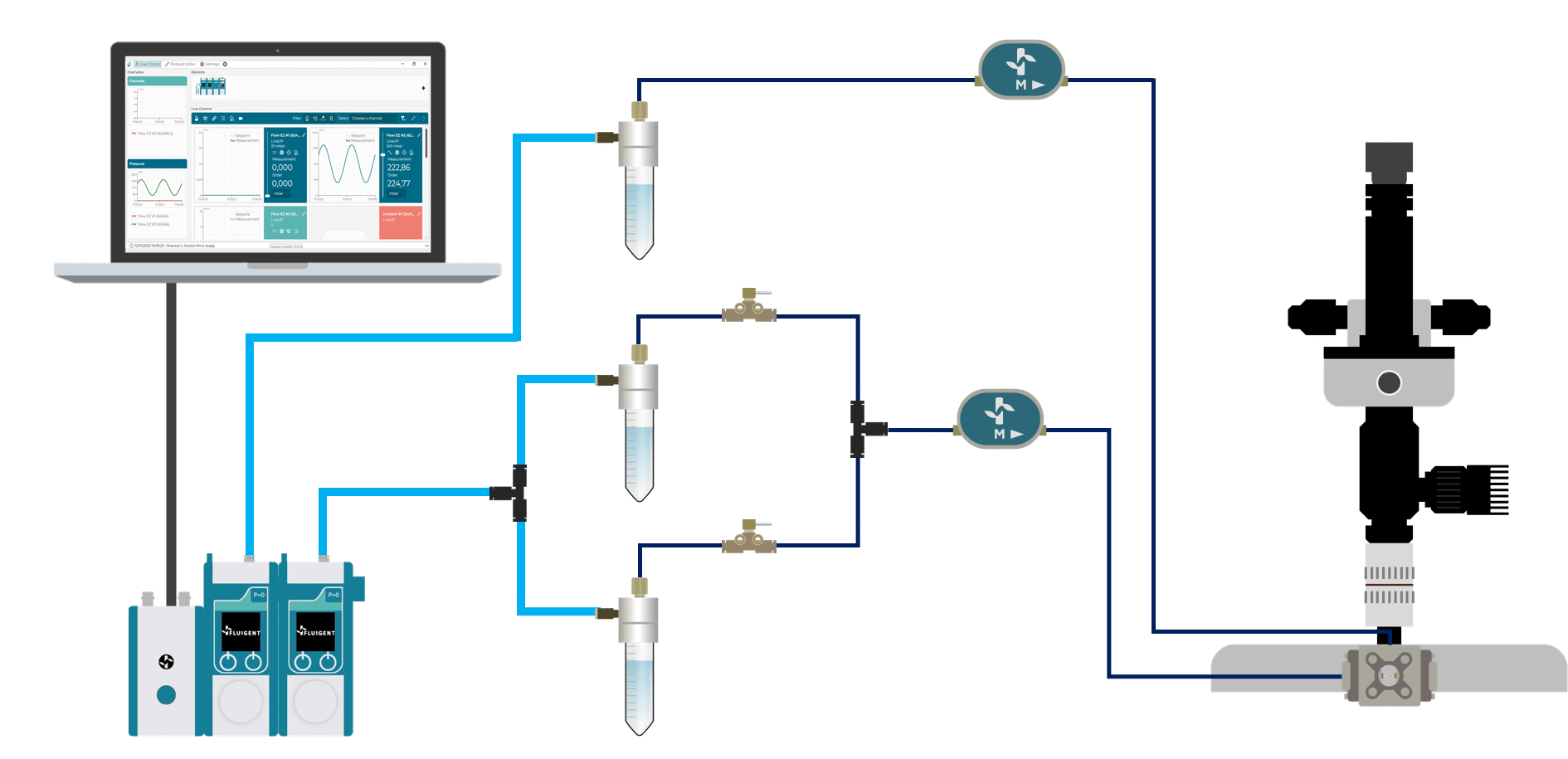

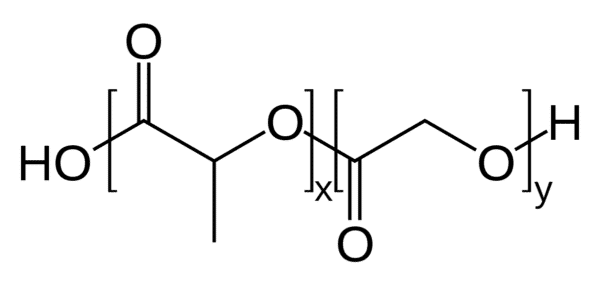

The PLGA microparticle production station is a robust, high-performance solution for generating polymer microparticles in a homogenous and fully controlled manner. The performance provided by the RayDrop droplet generator, together with the combination of poly(lactic-co-glycolic acid) as an encapsulation polymer and ethyl acetate as a solvent, offers a biocompatible solution lowering both hazard risk and precipitation time. Suitable for biological applications, the RayDrop and its station offer a semi-automated solution for one of the most successful drug delivery systems used in laboratories and clinics. Droplet based microfluidics shows potential as a powerful tool in solving the current problems of PLGA microparticle synthesis. Droplet control and generation allows for highly monodisperse, stable and continuous production as compared to batch emulsion methods.

The PLGA Microparticle Production Standard Pack offers the option to generate PLGA microparticles manually by using the potential of the RayDrop device and the fluid control precision and stability of Fluigent instruments.

- Repeatability

- Flexibility

Control over particle size

Ease of use

Ease of useStraight forward set up

Features

A complete system

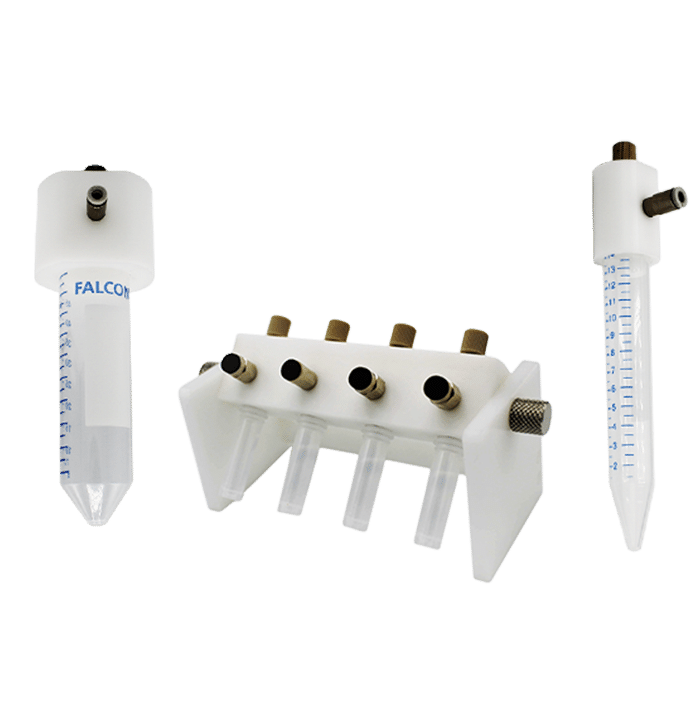

With the PLGA pack, you have all the components needed to start generating PLGA microparticles

An engineered solution

We built the package with the right pressure controllers, microfluidic chips, and valves to give you maximum flexibility in terms of droplet size and generation rate

A dedicated protocol

A protocol is available to assist you in setting up and starting your experiments

Customization possible

We can adapt the PLGA Microparticle production standard pack to meet your needs (droplet size, generation rate, double emulsion)

Main products of the package

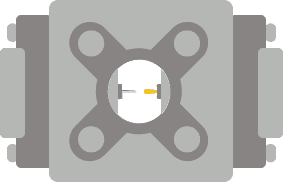

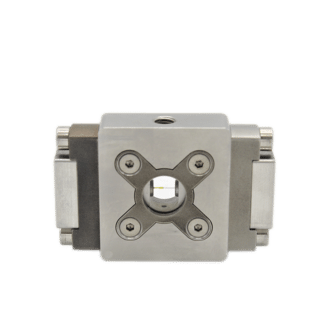

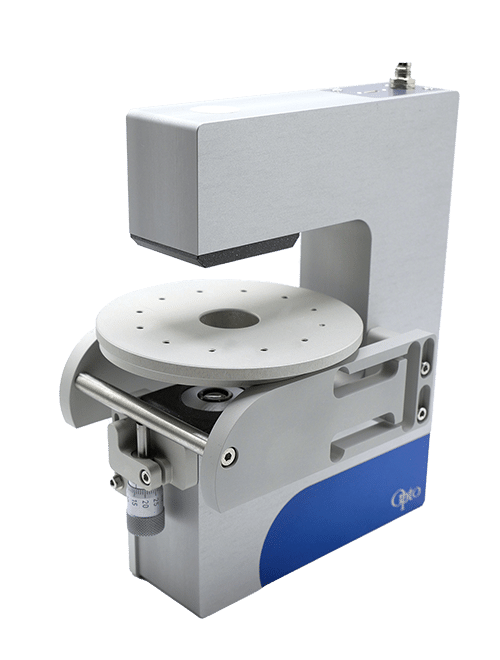

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

Microfluidic flow controller

Flow EZ™

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

Airtight metal tube caps for microfluidics

P-CAP series

Microfluidic Software Control

Microfluidic Software control

Real-Time Control & Lab Automation Software

OxyGEN – The new way to get full control of your microfluidic system and automate your lab setup.

Webinar – Drug encapsulation in biocompatible microparticles for drug delivery

In pharmaceutical area, Active Pharmaceutical Ingredient (API) encapsulation into biodegradable and biocompatible polymers is widely used for producing new smart Drug Delivery Systems. The goal of these drug delivery systems is to supply doses of drugs for a sustained period of time at targeting specific sites in the body.

This can be achieved by efficiently loading drugs into microparticles which will protect the API during physiological transport and release it when the microparticles have reached their specified target location(s). To regulate the release of the drug, it is critical to controllably produce microparticles with known sizes and a homogeneous size distribution as the rate of drug release is proportional to microparticle size.

Among all techniques available for microparticle production, microfluidic and droplet-based microfluidic ones appear as the best solutions to precisely control microparticle production in terms of size, API loading and encapsulation efficiency.

In this webinar, we discuss how microfluidics can allow API encapsulation into biocompatible and biodegradable microparticles for drug delivery.

Summary

- How microfluidics can be used for API encapsulation in microparticles?

- What is droplet microfluidics?

- Learn a new method for microparticle production

April 30th 2020

Specifications

PLGA PARTICLE PRODUCTION

| Dispersed phase | PLGA lactide: glycolide (75:25), mol wt 66,000-107,000 |

| PLGA concentration used | 2%, 5% ans 10% |

| Continuous phase | Ethyl acetate |

| Doplet size range | 60µm to 120 µm |

| Particle size range | 20µm to 50 µm |

| Production rate | Up to 60mg/h |

| Production frequency | U to 1000Hz |

| Monodisperity | 2% |

FLOW CONTROL

| Pumps | Fluigent Flow EZ™ (2000mbar) |

| Flow sensors | Fluigent FLOW UNIT (M and L) |

| Automated valves | Fluigent 2-SWITCH™ |

IMAGING

| Microscope | Fluigent Digital high-speed microscope |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Imaging

| OptoViewer Software |

| Traditional methods (Batch methods) | Fluigent PLGA microparticle production station | |

| Particle size distribution | ~20% | ~2% |

| Reproducibility | Low | High |

| API mixing | Uneven | Uniform |

| Live particle size control | No | Precise |

| Continuous / In line production | No | Yes |

| Microfluidic methods available on the market | Fluigent PLGA microparticle production station | |

| Particle size distribution | ~5% | ~2% |

| Semi automated production | No | Yes |

| Ethyl acetate dedicated protocol | No | Yes |

| Device regeneration | No (glass chip changed when clogged) | Yes (the RayDrop can be maintained) |

| Connectors | Non standard, user dependant quality (leakage, blockage) | Standard fittings for better sealing |

Can I use a polymer other than PLGA?

The method has been designed for PLGA. Changing polymers may change the physical fluid properties and lead to different results.

How can I prevent the clogging from PLGA?

Follow the procedure detailed in the application note. Please note the priming and cleaning procedures.

The nozzle (or capillary) sems clogged with PLGA. How can I fix it?

If the usual cleaning procedures from the good practice guide cannot unclog the nozzle, contact customer support for help.

Some of the ethyl acetate has flowed into the continuous phase chamber. What should I do?

If some ethylacetate without PLGA has flowed into the chamber it can be flushed out easily.

Follow the instructions in the good practice guide.

I can see a drop of ethlacetate fixed on the outside of the nozzle. How can I get ride of it?

If some ethylacetate without PLGA is fixed around the nozzle, it can be easily flushed out.

Follow the instructions in the good practice guide.

Some of the PLGA solution has flowed into the chamber. What shoulg I do?

If some PLGA gets into the chamber, it has to be eliminated quickly.

Refer to the good practice guide for the exact procedure.

Air bubbles regularly appear during the experiment. What should I do?

If air bubbles appear during experiment we advise one to switch to the ethyl acetate solution (if you are in the PLGA configuration) and let it flow for a minute to remove all PLGA from the system.

Then make sure that all connectors are tightened properly.

Refer to the application note procedure to avoid air bubble infiltration.

Expertise & resources

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Fluigent products manual Good practice guide PLGA station Download

-

Microfluidics White Papers Droplet-based Microfluidics Read more

-

Fluigent Products Datasheets PLGA Microparticle production station Datasheet Download

-

Fluigent Products Datasheets Raydrop single emulsion datasheet Download

-

Expert Reviews: Basics of Microfluidics The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing Read more

-

Microfluidic Application Notes PLGA Microparticles Synthesis Read more

-

Fluigent Products Datasheets FLOW UNIT Datasheet Download

-

Expert Reviews: Basics of Microfluidics Application of microfluidic chip technology Read more

-

Fluigent Products Datasheets Flow EZ™ Datasheet Download

Related products

PLGA Microparticle Production Pack (Automation Pack)

PLGA Microparticle Production Pack (Automation Pack)

See the offerMicrofluidic Single Emulsion Device

RayDrop Single Emulsion

See the offerMicrofluidic flow controller

Flow EZ™

See the offerMicrofluidic Software Control

Microfluidic Software control

See the offerReal-Time Control & Lab Automation Software

OxyGEN – The new way to get full control of your microfluidic system and automate your lab setup.

See the offerBidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer