Down to 2% monodispersity

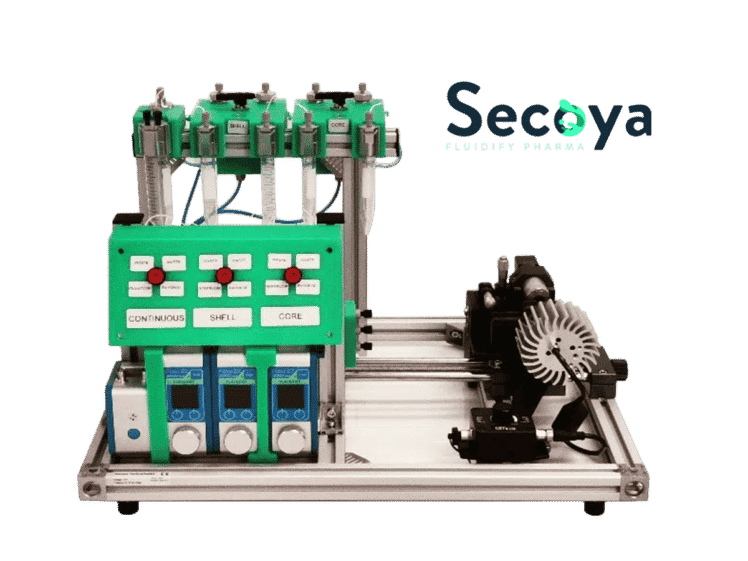

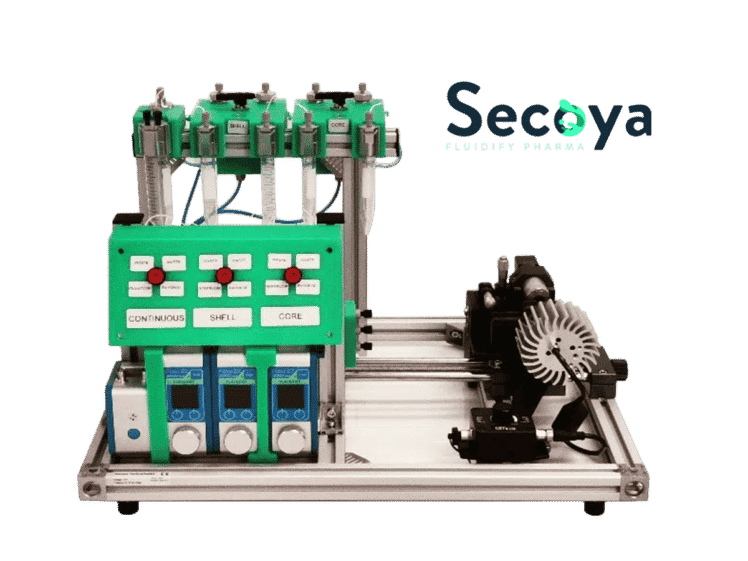

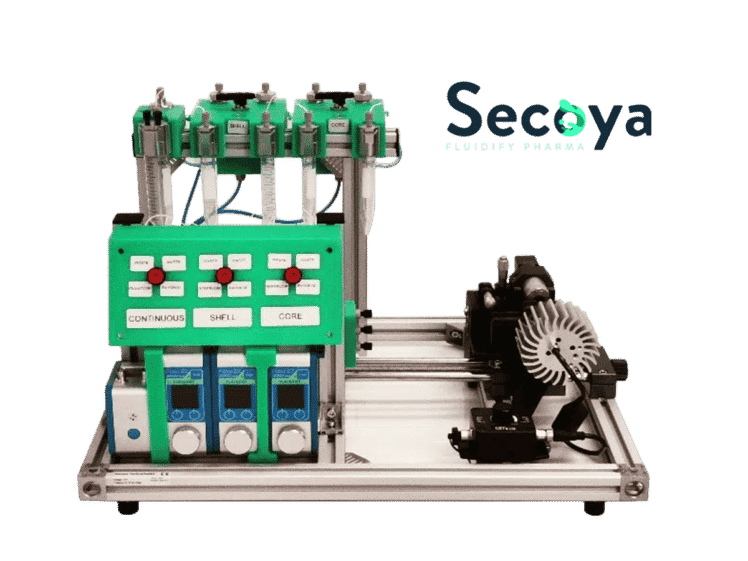

Double Emulsion Generation Pack

[O-DE-STD-PCK]A complete system for producing monodisperse double emulsions

Double emulsions have an extremely diverse application potential across various industries. However, many traditional methods for their production, such as the batch method, have limitations. Droplet-based microfluidics with the use of Raydrop, a droplet generator developed and manufactured by Secoya Technologies, offers a way to minimize these limitations, particularly in terms of better size distribution and mixture (1).

The Fluigent double emulsion generation pack is a robust and complete system for producing outstanding monodisperse double emulsions in a single device.

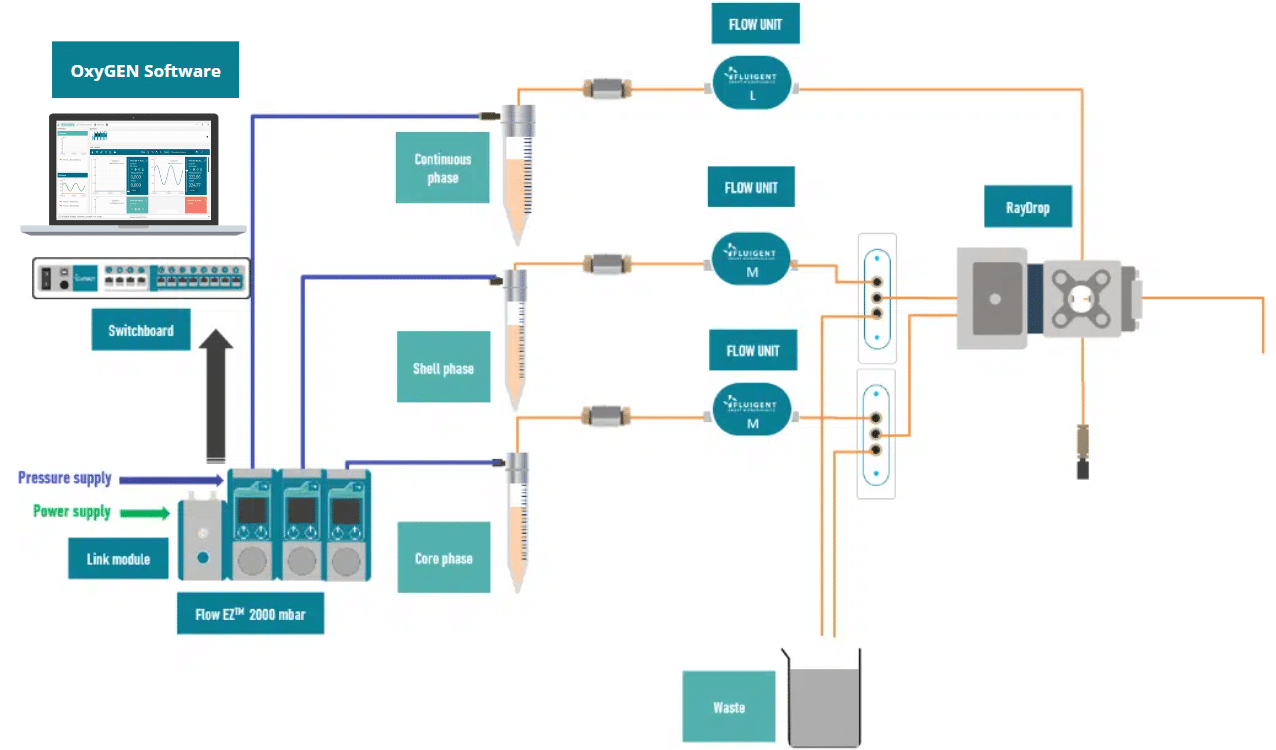

Its performance relies on the combination of Fluigent’s LineUP microfluidic pumps and the RayDrop device, a breakthrough technology for highly monodisperse and stable double emulsions.

With our Double Emulsion Production Pack, you will be able to generate double emulsion with high monodispersity, precision and stability. Moreover, with our packages, it is possible to use both common fluids (mineral oils, fluorocarbon oils, etc.) and specific fluids (PLGA, PLA, alginate, agarose, etc.), as described in the application note.

- High precision

- Flexible

All types of emulsions, adjustable shell thickness

- Robust

Continuous production

Features of the double emulsion pack

Complete system

With this double emulsion generation pack, you have all the components needed to start generating double emulsions.

Dedicated protocol

A protocol is available to assist you in setting up and starting your experiments.

Engineered solution

We built the package with the right pressure controllers, microfluidic chips, and valves to give you the greatest possible flexibility in terms of droplet size and generation rate.

Customization

We can adapt the package to meet your needs (droplet size, generation rate).

Double Emulsion Generation Resources

In this application note we have demonstrated how we can produce a robust different type of double emulsion with a single device.

- Microfluidic Application Notes

Double Emulsion Generation

Read more - Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Read more - Fluigent Products Datasheets

Double emulsions station datasheet

Download - Fluigent products manual

Double emulsions protocol

Download - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Read more

Main products of the Double Emulsion Generation Pack

Double Emulsion Generation Pack

Double Emulsion Generation Pack

Microfluidic flow controller

Flow EZ™

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

Microfluidic Sampling Valve

2-SWITCH™ 3-port/2-way

Real-Time Control & Lab Automation Software

OxyGEN – The new way to get full control of your microfluidic system and automate your lab setup.

Microfluidic valve controller for flow redirection

SWITCH EZ

Microfluidic Software Control

Microfluidic Software control

Airtight metal tube caps for microfluidics

P-CAP series

Applications of the double emulsion production pack

Many traditional methods for double emulsion production, such as the batch method, have their limitations. However, these limitations can be overcome by employing droplet-based microfluidics with Fluigent’s LineUP microfluidic pumps and the RayDrop device, a droplet generator, both included in the double emulsion generation pack. This advanced technology offers significant advantages in terms of improved size distribution and mixture quality. This breakthrough technology for highly monodisperse and stable double emulsions has a wide range of potential applications in diverse industries, including:

- Cell encapsulation

- Microencapsulation of bacteria and yeast

- Microcapsule/microparticle synthesis

- Bacteria culture in droplets

Double emulsion pack webinars and tutorial

Because this flagship Fluigent product gives users access to so many applications, our teams and Secoya’s teams have taken the time to organize webinars and prepare tutorials to help you better understand this pack and its different methods of use. You can find all the information by watching or rewatching these different videos.

How to produce double emulsions with the RayDrop – Tutorial

This tutorial, presented by the Fluigent team, shows you how to generate a double emulsion with the double emulsion generation pack. The technology is presented theoretically and a live demonstration of the experiment is performed. This format is ideal for a quick introduction to the pack and its use.

Mastering double emulsion production – Webinar

Presented by the Fluigent and Secoya teams, these workshops/webinars provide comprehensive guidance on generating a double emulsion using the double emulsion production pack. By watching this video, you can delve into the technical intricacies and envision how this pack can enhance your projects. First the Raydrop is introduced, followed by a live demonstration of the experiment. To address common queries, the videos conclude with a FAQ segment. This format is perfect for gaining a thorough understanding of the pack’s technology and envisioning its potential applications for your specific needs.

Double emulsion production made easy – Webinar

This method shows advantages and potential in many applications such as in food for flavor release or cosmetics for fragrance and flavor release (toothpaste, perfume…), in pharmaceutics for drug delivery ( Protection of API in microcapsules for control drug release) and other. Whereas double emulsion is a promising method for many applications, technologies to make double emulsion such as batch methods are all suffering from various limitations (low reproducibility, big size distribution…)

During this webinar, we are going to present the only device available on the market which allows to easily produce double emulsion with any kind of solution without chemical surface treatments needed.

Specifications

Package contents

| LineUp Flow EZ pressure controller (2000 mbar) x3 |

| LineUp LINK Module (software control) x1 |

| FLOW UNIT M (x2) and L (x1) |

| P-CAP series 50 mL (x2) and 15 mL (x1) |

| LineUp Switch EZ (x1) |

| 2-SWITCH x2 |

| Raydrop Double Emulsions 30µm-70µm-150µm x1 |

| dSurf x1 |

Microfluidic device specifications

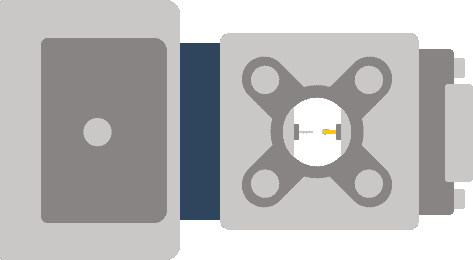

| Design | Co-flow focusing design |

| Inputs & Outputs | 3 inputs, 1 output |

| Types of emulsion | Water-in oil-in-water and oil-in-water-in-oil double emulsion |

| Double emulsion size* | Shell: from 70 to 130 µm, Core: from 20 to 120 µm |

| Monodispersity | CV <2% |

| Generation rate | 5 000 Hz (measured for the smallest double emulsion size) can go higher under specific conditions |

| Capillaries dimension | Nozzle: Core: 30 µm & ID Shell: 70 µm ID Output: 150 µm ID |

| Wetted material continuous phase | PEEK, FEP, glass, stainless steel 316L, poluimide, Viton (seal), resin (nozzle) |

| Wetted material dispersed phase | PEEK, FEP, Glass, resin (nozzle) |

| Fluids compatibility | Water, mineral oil, fluorinated oil, ethanol, ethyl acetate, IPA, Acetone, Chloroform |

Flow Control

| Pumps | Fluigent Flow EZ (2000mbar) |

| Flow Sensors | Fluigent FLOW UNIT (M & L) |

| Automated valves | Fluigent 2-SWITCH |

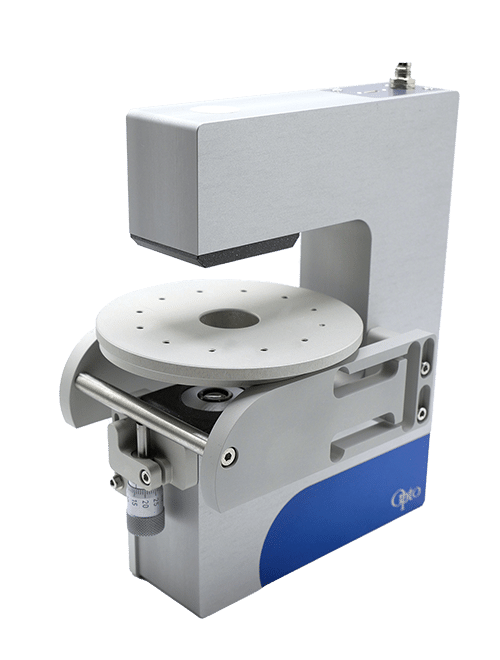

Imaging (optional)

| Microscope | Fluigent Digital high-speed microscope |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Imaging

| OptoViewer Software |

Performance

| Batch method | Fluigent microfluidic method | |

| Process | multiple step process | direct double emulsion production |

| Homogeneity | random distribution of single and double emulsion | high homogeneity |

| Particle size distribution | more than 50% | ~ 2% |

| Reproducibility | low | high |

| Live particle size control | no | precise |

| Continuous (in line) production | no | yes |

Expertise & resources

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidics White Papers Droplet-based Microfluidics – A Complete Guide Read more

-

Fluigent products manual Raydrop double emulsions protocol Download

-

Fluigent Products Datasheets Raydrop double emulsions datasheet Download

-

Expert Reviews: Basics of Microfluidics The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing Read more

-

Microfluidic Application Notes Double Emulsion Generation Read more

-

Fluigent Products Datasheets FLOW UNIT Datasheet Download

-

Fluigent products manual Double emulsions protocol Download

-

Fluigent Products Datasheets Double emulsions station datasheet Download

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Fluigent products manual LineUp™ series User Manual Download

-

Fluigent Products Datasheets Flow EZ™ Datasheet Download

Related products

Microfluidic Double Emulsion Device

RayDrop Double Emulsion

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

Microfluidic Complex Emulsion Production Platform

Platform for emulsions & droplets

See the offer

Encapsulation Platform for FACS

Platform for cell encapsulation in DE droplets

See the offer

UV-crosslinked microcapsule production platform

An all-in-one platform for continuous generation of UV-cured core-shell microcapsules

See the offer

Microfluidic flow controller

Flow EZ™

See the offer