Integrate a pressure/vacuum source

Microfluidic Flow Control System

- Customize your own

MFCS™ series

The MFCS™, or Microfluidic Flow Control System, is a pressure based microfluidic flow controller. Either 4 or 8 channels are available with different pressure ranges for microfluidic experiments. By using the patented FASTAB™ microfluidic technology, the MFCS™ generates a constant pressure-driven flow rate that allows for reliable and repeatable experiments.

- Customizable

- Adaptable

Up to 8 channels with various ranges

- Reliable

Patented & Field-proven technology

- Compact

Flat & Light design for benchtop use

Features of the MFCS

Easy to set up & use

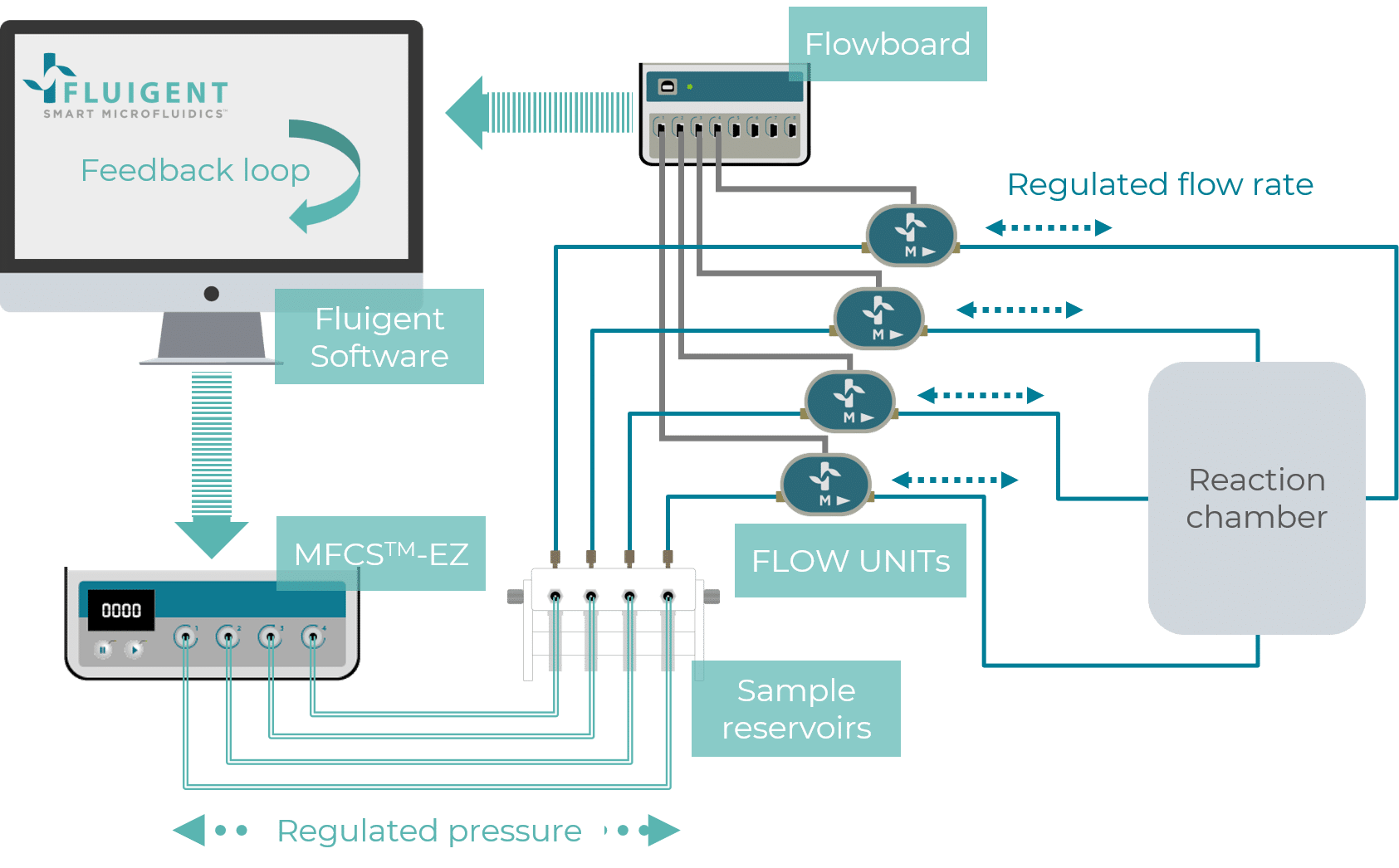

The Microfluidic Flow Control System can be controlled by Fluigent software to automate your protocols. It can easily be connected to other microfluidic devices such as FLOW UNIT sensors to allow for flow-rate control.

Independent channels

Each channel can be controlled independently and deliver a specific amount of pressure or vacuum to handle fluids. Available pressure ranges from -800 mbar for vacuum aspiration up to 7 bar for pressure.

Get superior results fast

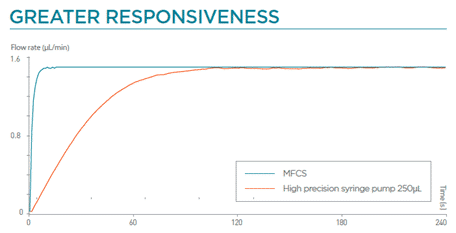

Reach your pressure targets rapidly and get your experiment started instantaneously. The field-proven technology lets you quickly obtain reliable and superior results for your experiments.

Reliable & Reproducible results

The FASTAB™ microfluidic patented technology used by the MFCS™ Microfluidic Flow Control System series avoids cross-contamination as there is no direct contact between the instrument and the reagents. The pulseless and precise control enabled by our pressure-driven technology is critical for repeatable results in many applications.

Adaptability & Integration

The MFCS™ system can provide negative or positive pressures as needed by using up to four or eight independently controllable channels. In addition, a microfluidic pressure pump can easily be integrated into a setup with the Software Development Kit (SDK).

Fully customizable

The design of our Microfluidic Flow Control System depends on your needs. You can choose the number of channels in the device (4 or 8), with each channel ranging from -800 mbar to 7 bar, and you even have the option to integrate a pressure or vacuum source inside the instrument. Customize your controller to meet your control needs.

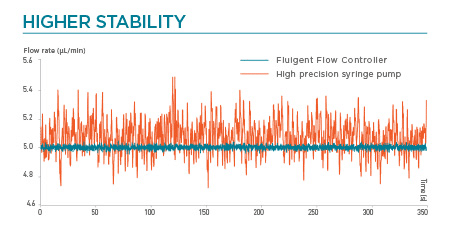

Pressure-based microfluidic controller: Better stability & responsiveness

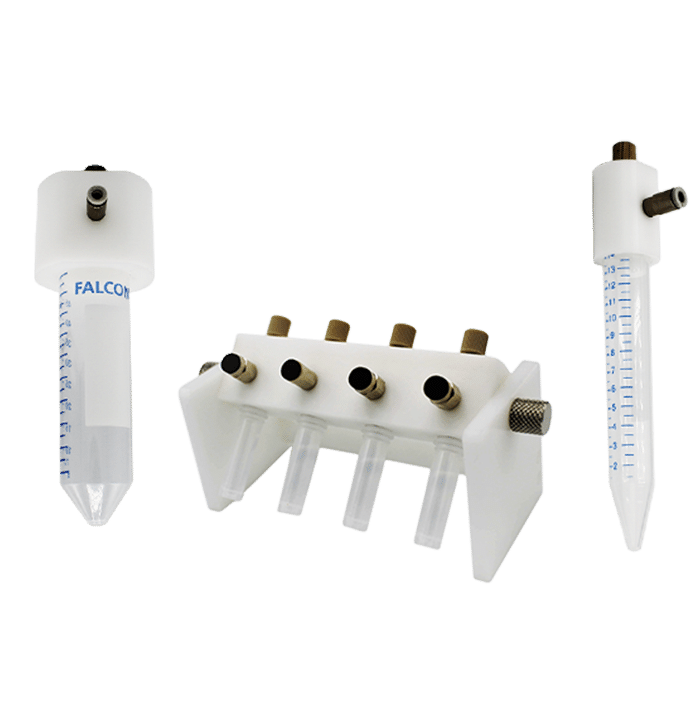

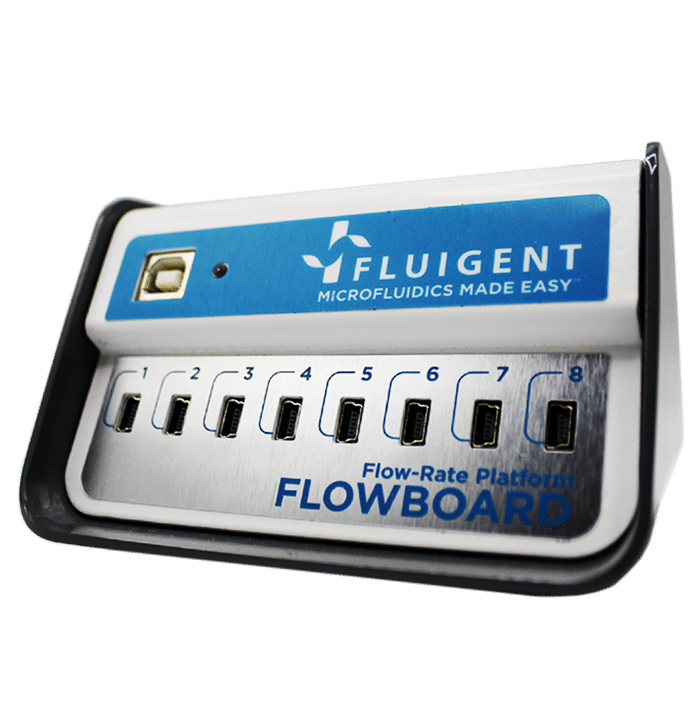

The MFCS™ series product range is the first generation of microfluidic systems. Along with the MCFS™-EZ or MCFS™-EX, a manifold can be added to redirect pressure to multiple fluid reservoirs.

The flow generated can be measured or controlled with FLOW UNITs and the Flowboard. The MFCS™-EX provides up to 8 negative or positive pressure channels to pressurize multiple fluid reservoirs. It can have an integrated pressure/vacuum source or be coupled with the FLPG+, an external pressure source, for those who don’t have access to a laboratory bench-mounted gas source. The Microfluidic Flow Control System can be integrated, automated or controlled in real time using Fluigent Software Solutions.

The technology used in this pressure pump avoids cross-contamination because liquids only contact air. The pulseless flow provides improved reliability and reproducibility of results. The use of pressure to handle fluids also provides a quick response time allowing for precise operations such as stop flow and accurate pressure/flow rate steps. The MFCS™ series products are well suited to manipulating fluid volumes in the low to sub microliter per minute range.

“We use the combination of the pump (FLPG), pressure controller (MFCS), and flow meter for organs-on-chip applications in diabetology, utilizing multielectrode array electrophysiology. As we measure signals with very low frequencies (from 0.1 Hz), our recording conditions are highly sensitive to the noise that could be induced by flow rate variations. We have published several papers using the complete Fluigent system (Perrier et al., Biosens Bioelectron 2018; Jaffredo et al., Diabetes 2021; Lalloulet et al., Lab Chip 2025) and have never encountered issues with insufficient pump pressure or the pressure controller failing to deliver equal pressure on both sides. The responsiveness of the pressure controller to flow rate changes is also excellent. Additionally, the Switchboard, which allows multiple M-switches to be connected in one place easily, and the software, which is very user-friendly, further enhance the system’s efficiency. I recommend this system.”

Matthieu Raoux, Professor, Group Leader, Cell Biology & Biosensors, CBMN UMR CNRS 5248, University of Bordeaux

“We have bought Fluigent flow control solution (MFCS™ + FLOWELL, old Flow-Rate Platform, with Flow Rate Control Module) to replace our usual high precision syringe pumps to generate monodisperse microfluidic droplets. Fluigent solution provides a very efficient and reliable flow rate control as well as a significantly higher stability at low flow rates in comparison with syringe pump-based systems. The whole set-up including both hardware and software is very intuitive and easy to work with.”

Michael Ryckelynck Associate Professor / Institut de Biologie Moléculaire et Cellulaire (I.B.M.C.) / UPR-9002 du CNRS, FRANCE

Specifications

PERFORMANCE

| Stability | <0.1% on the measured value |

| Resolution | 0.03% full range |

| Accuracy | 0.25% full range |

| Repeatability | <0.001% full scale |

| Response time | Down to 10 ms |

PRESSURE/VACUUM RANGE

| Channel part number (MFCS™-EZ) | Channel part number (MFCS™-EX) | Pressure/Vacuum range | Maximum pressure supply | Required supply |

| EZ-00345001 | EX-00345001 | 0 to 345 mbar (0 to 5,00 psi) | 1100 mbar (15,95 psi) | 900 mbar (13,05 psi) |

| EZ-01000001 | EX-01000001 | 0 to 1000 mbar (0 to 14,50 psi) | 1100 mbar (15,95 psi) | 1400 mbar (20,3 psi) |

| EZ-01000002 | EX-01000002 | 0 to 2000 mbar (0 to 29,01 psi) | 2100 mbar (30,46 psi) | 2600 mbar (37,7 psi) |

| EZ-07000001 | EX-07000001 | 0 to 7000 mbar (0 to 101,5 psi) | 7100 mbar (103,0 psi) | 7600 mbar (110,22 psi) |

| EZ-80025001 | EX-80025001 | 0 to -25 mbar (0 to -0,36 psi) | -800 mbar (-11,6 psi) | N/A |

| EZ-80069001 | EX-80069001 | 0 to -69 mbar (0 to -1,0 psi) | -800 mbar (-11,6 psi) | N/A |

| EZ-80345001 | EX-80345001 | 0 to -345 mbar (0 to -5,00 psi) | -800 mbar (-11,6 psi) | N/A |

| EZ-80800001 | EX-80800001 | 0 to -800 mbar (0 to -11,6 psi) | -800 mbar (-11,6 psi) | N/A |

STANDARD OPERATING CONDITIONS

| Operating temperature | 20°C (68°F) |

| Operating humidity | 40% HR |

WEIGHT AND DIMENSIONS

| MFCS™-EZ | MFCS™-EX | |

| Dimensions | 160 x 230 x 63 mm | 265 x 262 x 73 mm |

| Weight | 2.0 kg (4.4 lbs) | 3.5 kg (7.7 lbs) |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 1.5 W |

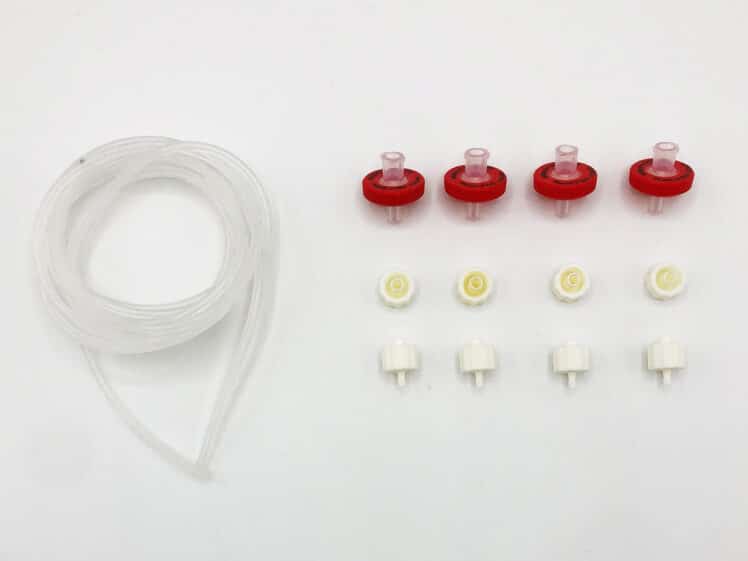

| Output connectors | Female luer lock (-800 to 2000 mbar) 4mm OD tube (7 bar) |

| Pneumatic connections | Speedfit |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

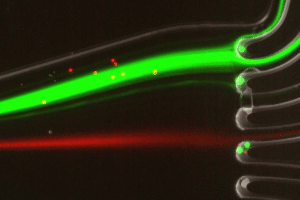

Migrating cells in gradient

Migrating cells in dynamic chemical gradients generated by a microfluidic chamber (cells, gray; chemoattractant with fluorescein,green). Video courtesy of Pr Satoshi Sawai ( University of Tokyo, Japan).

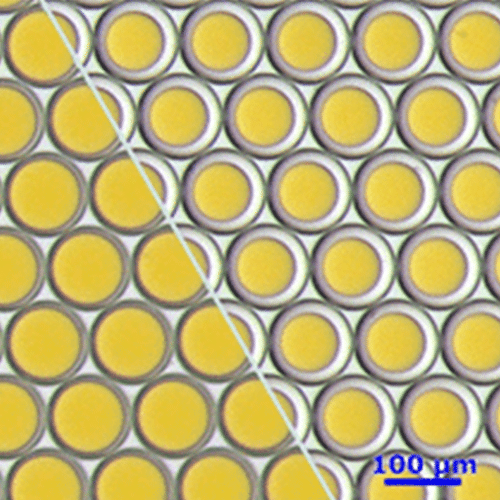

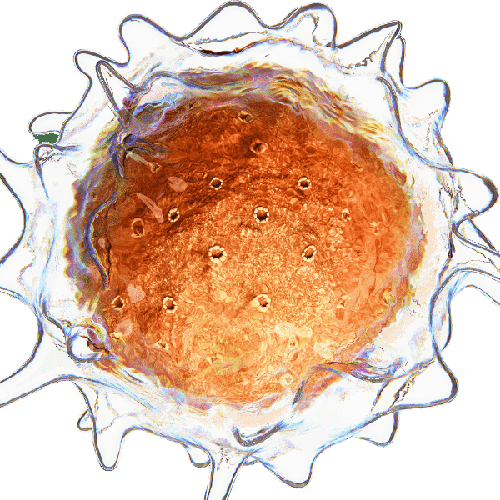

Microfluidic cell sorting

With the Fluigent Microfluidic Flow Control System (MFCS-4C) one can sort cells by size, shape and deformability as shown in this publication in the journal Lab-on-a-Chip and explained in the next video.

Separation of parasites from human blood

See an example of applications using the MFCS series: « Separation of parasites from human blood using deterministic lateral displacement, S. H. Holm, J. P. Beech, M. P. Barrett and J. O. Tegenfeldt, Lab Chip, vol.11, 2011

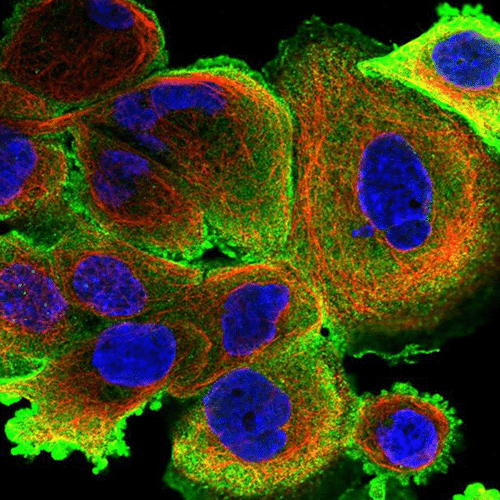

Microfluidic cell perfusion

The MFCSTM series and Flow EZTM with Fluigent valves can be used for automated cell perfusion as in the next video.

Expertise & resources

-

Microfluidics Case Studies CNRS/UTC: study of a liver-on-a-chip model Read more

-

Expert Reviews: Basics of Microfluidics Choosing the Right Microfluidic Pressure Range Read more

-

Fluigent Media Kit product icons & images Fluigent product icons & images Read more

-

Microfluidics Case Studies Success story of SEED Biosciences: Single cell impedance analysis Read more

-

Microfluidics Case Studies University of Cambridge: Microfluidic GUV production and testing Read more

-

Microfluidics Case Studies The Micro/Nano Bioelectronics and Biosensors (MBIOS) from Tianjin University Read more

-

Microfluidic Application Notes Microbiome culture in droplet using dsurf surfactant Read more

-

Microfluidic Application Notes Droplet and particle manipulation using electrophoretic flow control Read more

-

Expert Reviews: Basics of Microfluidics High Throughput Single Cell Analysis Read more

-

Microfluidic Application Notes Cartilage-on-a-chip, an example of complex mechanical stimulation using Fluigent’s technology Read more

-

Fluigent Products Datasheets MFCS™-EX Datasheet Download

-

Fluigent Products Datasheets MFCS™-EZ Datasheet Download

-

Fluigent products manual MFCS™ series User Manual Download

-

Expert Reviews: Basics of Microfluidics The Importance of Flow Control Stability in Microfluidics Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more

-

Expert Reviews: Basics of Microfluidics Pump Responsiveness in microfluidics Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Resistance Read more

Related products

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Microfluidic Flow Sensor Hub

Microfluidic Flow sensor hub

See the offer

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Compact Vacuum Pump

VACUUM SOURCE

See the offer