Wide negative and positive pressure & vacuum range

Microfluidic Push Pull controller

[ELUPPU1000]- Best Seller

Push Pull

The LineUp™ Push-Pull is a 2 in 1 pressure-based controller with the ability to deliver finely regulated negative and positive pressure through a single outlet over the range of -800 to +1000 mbar. It can be used without a PC or controlled with Fluigent Software Solutions to benefit from control in real-time, protocol automation, graphic displays, and custom integration. Combined with a FLOW UNIT, the microfluidic Push Pull controller allows for direct control of the flow rate.

- Versatile

- Compact

Uses minimum bench space

- Modular

Easily expand as needed

- Adaptable

Use with or without a PC

What is a Push Pull Controller?

The Push Pull is a pressure and vacuum controller that can alternate between positive pressure (Push) and negative pressure (Pull) through the same port to precisely control fluid flow in microfluidic systems. By applying positive pressure, fluids can be pushed through channels and microdevices, while negative pressure enables pulling fluids back.

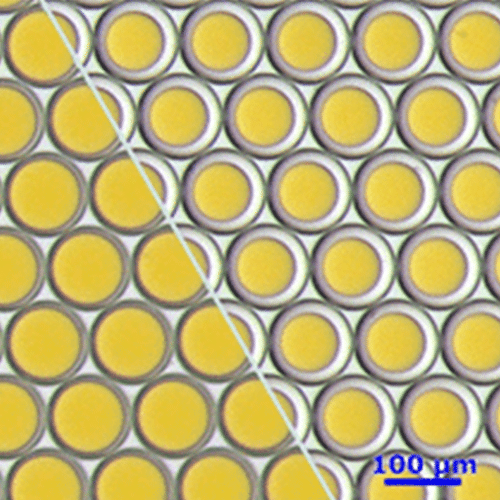

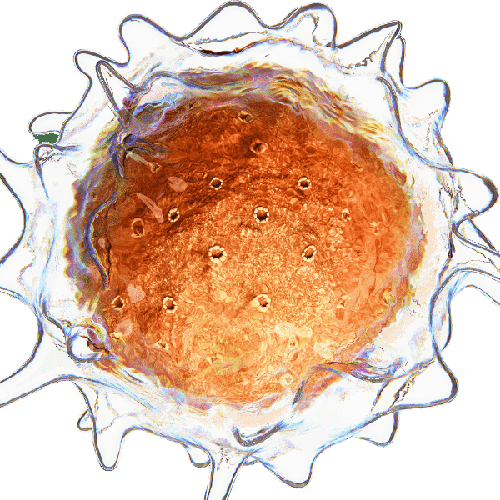

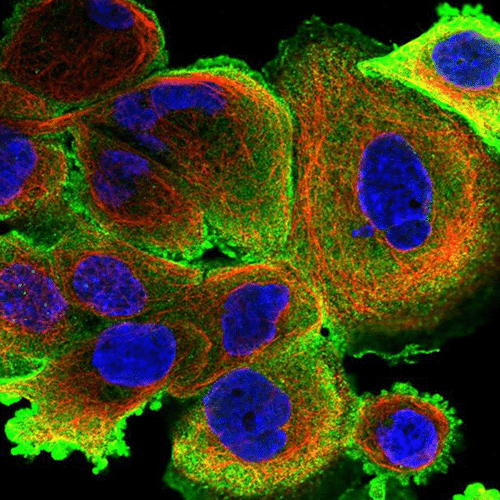

The microfluidic Push Pull controller allows for the dynamic and reversible control of pressure, enabling various applications such as fluidic mixing, particle trapping, cell manipulation, and droplet generation. By rapidly switching between positive and negative pressures, the Push Pull mode offers enhanced flexibility and control over fluid flow and manipulation processes.

Fluigent’s 2 in 1 negative and positive pressure controller empowers researchers and scientists to perform complex and dynamic fluidic operations in microfluidic systems, creating possibilities for advanced experimentation and innovation in a wide range of scientific disciplines.

Push-Pull Features

Expand as needed

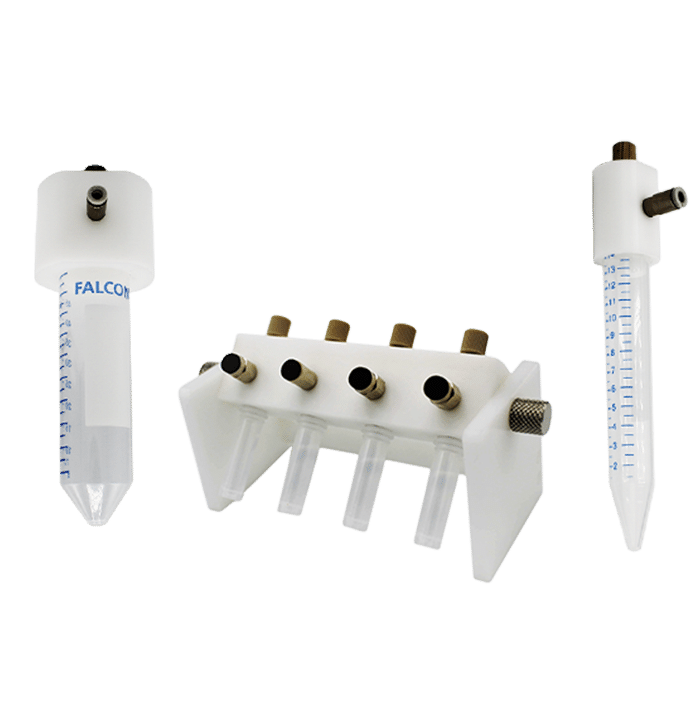

Combine up to 8 modules as your workflow grows. Each module is a separate and independent pressure channel.

Wide range

Our microfluidic Push Pull Controller allows for the regulation of positive pressure up to 1 bar and vacuum pressure down to -800 mbar from one single channel.

Local control

Control without a PC using the Push Pull hardware interface with one hand. Focus on the experiment instead of looking at the PC.

Precise volume delivery

When our pressure/vacuum controller is combined with a flow sensor FLOW UNIT one can control the flow rate directly or deliver dispensed volumes as needed.

Various reservoir sizes

Support reservoir sizes from 2 mL to one-liter laboratory bottles. The microfluidic Push Pull Controller can maintain continuous, pulseless flow for days without refilling.

How does our Push Pull controller work?

Based on our industry leading experience, Fluigent has developed the patented pneumatic system, the most advanced microfluidic pumping technology available. It is the heart of the Fluigent’s next-generation performance, providing the fastest, most stable and compact system for microfluidics available.

In the base configuration, the Push Pull controls pressure or vacuum rate, and the liquid flows as a function of system resistance, fluid viscosity, etc. The addition of a FLOW UNIT enables one to control or monitor flow rate as well as measure a dispensed volume. The pressure automatically adjusts in the background to maintain the set flow rate.

When combined with the LINK module, the Push Pull capabilities are extended by using Fluigent software to control the system, or to generate time based protocols and record data (OxyGEN software).

The 2 in 1 negative and positive pressure-based controllers are available in different pressure and vacuum ranges to provide the optimum level of pressure control and resolution. These can easily be combined to match all application requirements or reconfigure the system for a new experimental design.

Enhanced flexibility and control over fluid manipulation

With a compact and modular design, the microfluidic Push Pull controller allows users to set and benefit quickly from the pressure-based flow control advantages for experiments.

Part of our LineUp Series

Pressure and vacuum control, flow rate control, microfluidic valve automation, and software control. Select and combine the modules you need from our range of LineUp™ products. Our devices have become the gold standard for microfluidic flow control over the years.

“The device is well designed and allows for easy control of my microfluidic chips. What I like most is that you are independent of a computer and can directly control both positive and negative pressure.”

Christoph Trenzinger – Stratec

Flow rate control with the benefits of responsive, pulse-free flow

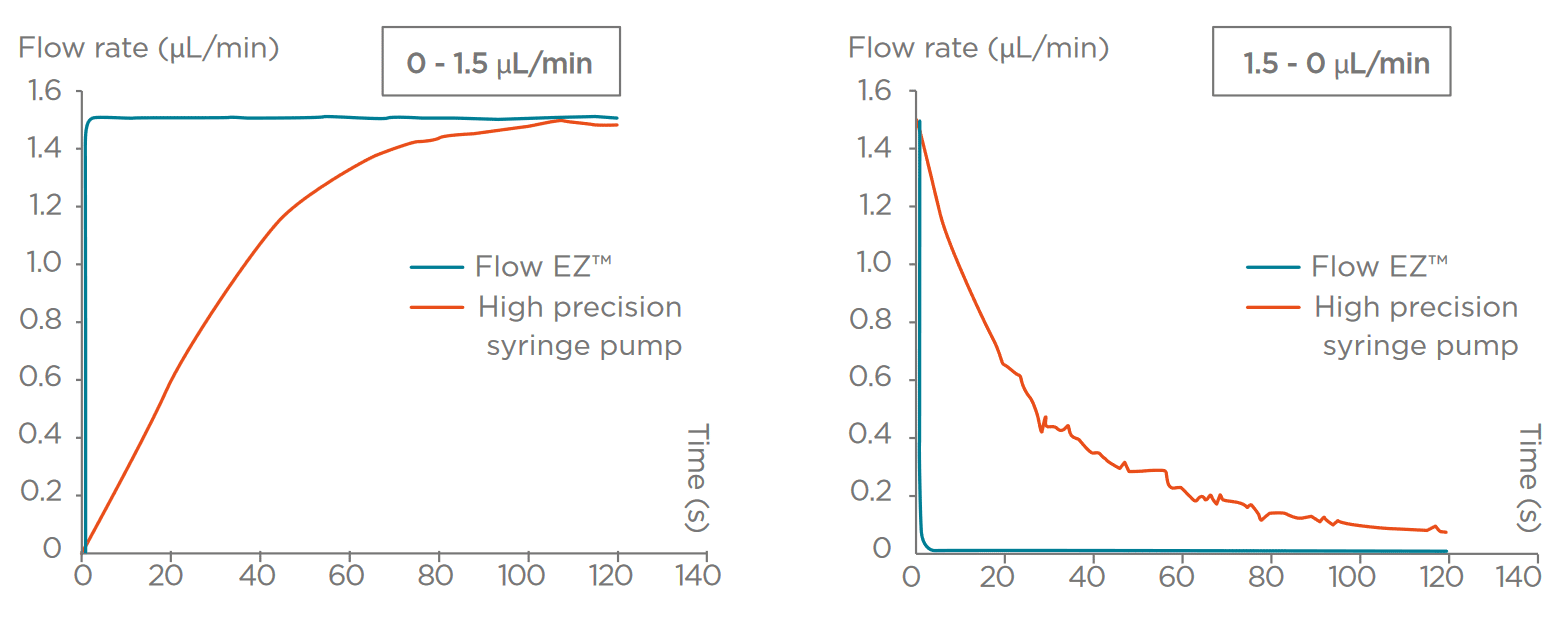

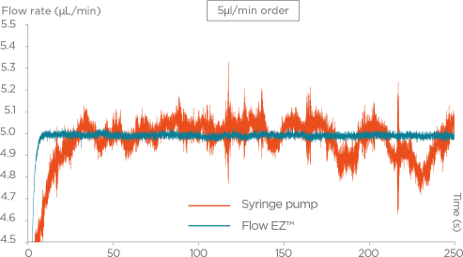

With the use of pressure instead of mechanical action, the Flow EZTM microfluidic flow controller reports a responsiveness ten times faster than syringe pumps. A low response time allows users to quickly execute operations such as stopping flow and implementing pressure/flow rate steps.

“The Fluigent LineUp series, including the new push-pull pump, enables precise and highly controlled aspiration and respiration of liquids. The set-up allows us to further advance our research in both continuous flow and droplet microfluidics.”

Prof. Jeroen Lammertyn, KU Leuven Belgium – Biosensors group.

Pulse-free flow is critical for generating high quality and repeatable results. Fluigent’s vacuum and positive pressure-based controller integrates the all-new DFC (Direct Flow Control)algorithm. This allows the user to set a flow rate directly on the instrument display. The applied pressure will automatically adjust to maintain the flow rate.

Focus on the microscope. No PC is required

Instead of looking at the PC, users can keep their eyes on the microscope by adjusting the control dial with one hand. In this stand-alone configuration, the vacuum/pressure controller allows for pressure or flow rate control and volume dispense, making it ideal for benchtop use.

Specifications

PRESSURE AND VACUUM RANGE

| Maximum pressure | Up to 1000 mbar (14,50 psi) |

| Maximum vacuum | Down to -800 mbar (-11,6 psi) |

| Required pressure supply | 1100 mbar (16 psi) |

| Required vacuum supply | -800 mbar (-11,6 psi) |

| Maximum pressure supply | 1400 mbar (20,3 psi) |

PERFORMANCE

| Resolution | 600 µbar |

| Stability | 0,1% on the measured value (effective beyond 10% of the maximum pressure) |

| Response time | Down to 30 ms |

| Accuracy | 4,5 mbar |

| Repeatability | 180 µbar |

STANDARD OPERATING CONDITIONS

| Operating temperature | 20°C (68°F) |

| Operating humidity | 40% HR |

WEIGHT & DIMENSIONS

| Dimensions | 91,9 x 71,8 x 131 mm (3.6 x 2.8 x 5.15 in) |

| Weight | 636 g (1.4 lbs) |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 6 W |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Expertise & resources

-

Tutorial videos Flow EZ Tutorials Episode 8: Switch it off – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 7: Use the P=0 button – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 6: Add my FLOW UNIT – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 5: Disconnect a Flow EZ – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 4 : Apply a pressure order – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 3 : Add a Flow EZ – Fluigent Read more

-

Tutorial videos Flow EZ Tutorial Episode 2 : Insert in my setup – Fluigent Read more

-

Tutorial videos Flow EZ Tutorial Episode 1 : Getting started – Fluigent Read more

-

Expert Reviews: Basics of Microfluidics Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications Read more

-

Fluigent Products Datasheets Push-Pull Datasheet Download

-

Fluigent products manual LineUp™ series User Manual Download