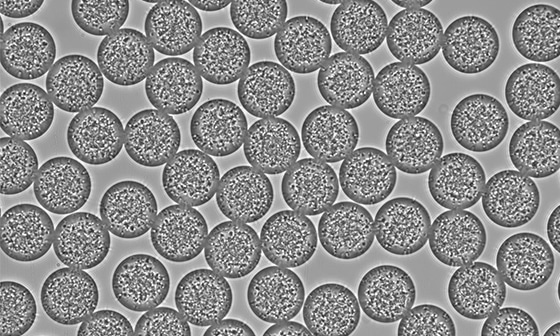

Case study: Single crystal formation in core-shell microcapsules.

Overview:

This webinar introduces the latest advances in core-shell microcapsule technology. Discover how microcapsules are used as a versatile tool in drug delivery, encapsulation, crystallization, compound characterization, and more.

To begin with, we’ll explore the challenges of traditional micro-encapsulation methods, followed by an overview of how microfluidic technology is transforming the field by enabling the production of precise, uniform microcapsules. Gain insights into the advantages of UV light crosslinking for rapid and solvent-free capsule production (Methacrylate-based resins, PEGDA, PEGDMA).

Next, the program includes a case study focusing on the use of microcapsules for the screening of crystallization conditions.

Finally, you will learn how to generate hundreds of identical UV-crosslinked microcapsules per second, produced by Secoya Technologies’ RayDrop and its all-in-one platform.

Agenda:

✅ Introduction to microfluidic-based core-shell microcapsules: Technology, advantages, and drawbacks compared to traditional methods.

✅ Presentation of the double emulsion device (RayDrop) and platform: How to simplify microcapsule complexity production with high precision, low investigated volumes, and an all-in-one platform (microfluidics, droplets, optics, UV-crosslinking).

✅ Case Study in crystallization: Single crystal formation in core-shell microcapsule applications.

✅ Interactive Q&A Session

Speakers:

Joseph Farah : Microfluidic Application Engineer·

Marie Mettler : R&D Engineer – Secoya Technologies

Adrien Dewandre : Technology Lead – Emulsification & Droplet generation – Secoya Technologies

The Potential of Microfluidics in Double Emulsion

Double emulsion microfluidics—defined as a process of encapsulating droplets within other droplets—allows for a higher level containment, encapsulation, compartmentalization, and controlled delivery of biological samples or templates. This technique proves useful in drug delivery, single cell studies, material development, or even formulating food and cosmetics. With precise control over release dynamics, core size, and shell thickness, double emulsions serve as an adaptive basis for creating complex engineered systems designed to specific requirements.

Interested in learning more? Discover key reviews covering into the potential and techniques behind double emulsion microfluidics

- Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Explore more - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Explore more - Microfluidic Application Notes

A quick and efficient double encapsulation method for FACS-based droplet sorting

Explore more

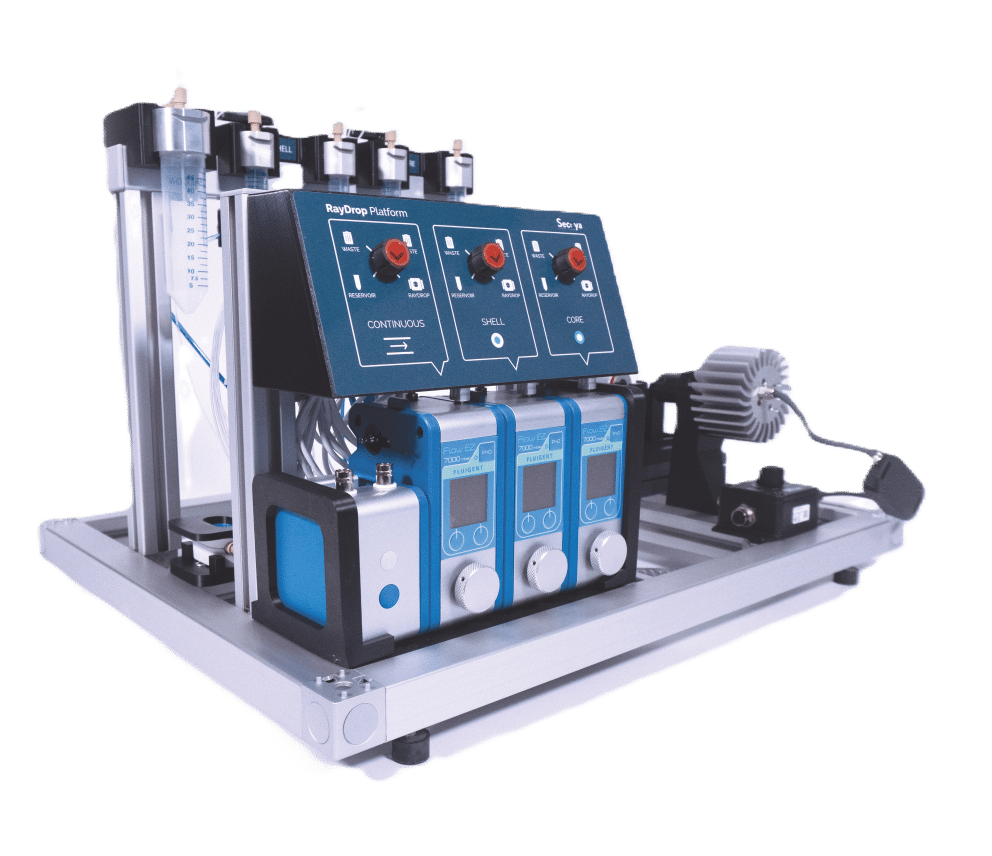

UV-crosslinked microcapsule production platform

The UV-crosslinked microcapsule production platform, developed and manufactured by Secoya Technologies, is a complete system for the continuous creation of core-shell microcapsules with control over size and structure.

Based on a droplet microfluidic approach, Secoya Technologies’ RayDrop device produces monodisperse double emulsions which lead to monodispersed microcapsules, while Fluigent’s Flow controllers and Flow Units guarantee high flow stability and responsiveness. Microfluidic, mechanical, optical, and UV modules are all included in the platform for easy, fast, and practical usage.