Water in Oil Emulsions

Water in oil emulsions (W/O) comes from the mixing of oil as a continuous phase and water as a dispersed phase to form colloidal systems. They form the basis manufacturing techniques widely used in the industrial and R&D environments to manufacture droplets (e.g., for compartmentalization applications), hydrogel beads (e.g., alginate, agarose, or polyacrylamide), and polymer beads (e.g., acrylic, vinyl, and ethyl-based). Of particular importance is the ability to produce high-quality, monodisperse droplets and the ability to do so reproducibly and at a viable production rate.

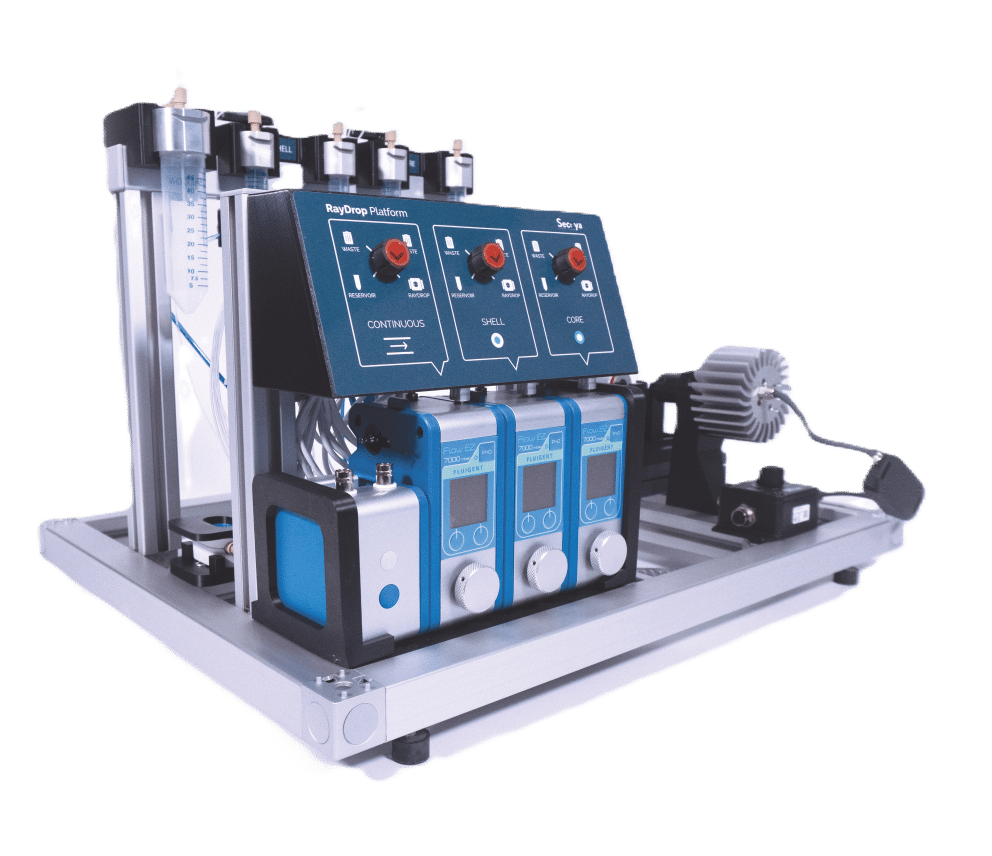

The combination of Fluigent pressure pump units and Raydrop microfluidic devices, developed and manufactured by Secoya, enable smooth fluid delivery, precision flowrate control, automation, and the reproducibility necessary to generate high-quality W/O emulsions.

We kindly thank of SMALL Biotechnologies for this collaboration.

Introduction

What are W/O emulsions?

Emulsions are colloidal systems composed of two liquid phases—oil and water—where one is dispersed into the other. Water-in-oil (W/O) emulsions involve the dispersion of an aqueous phase, formed into small droplets, within a continuous oil phase. Despite the natural immiscibility of oil and water, proper mixing and the use of stabilizing agents facilitate the creation of oil-in-water emulsions.

The specific structure of W/O emulsions makes them suitable for delivering hydrophilic compounds, offering various functions such as antimicrobial and antioxidant activities. The effectiveness of this system is heightened by the presence of small dispersed oil droplets, enhancing the bioavailability of pharmaceutical products and extending the shelf life of food and beverages. With applications in cosmetic, biological, pharmaceutical, agricultural, and food industries, water-in-oil emulsions hold significant potential.

What are the advantages of this type of emulsions?

In cell biology, compartmentalization of biological agents in discrete aqueous droplets dispersed in an oil phase is a popular alternative to the microwell strategy. Water-in-oil emulsion (W/O) has an aqueous volume from femtoliter to nanoliter, each representing an isolated micro-reactor or micro-incubator. The maximized surface-to-volume ratio of the micro-droplets enables highly efficient mass and heat transfers between the internal and external phases, resulting in precise and rapid perturbation of the microenvironment in the droplet.

Development of water in oil emulsions as delivery vehicles

W/O emulsions produced with bulk emulsion techniques are not uniform in size. Another limitation of bulk emulsion droplets is that multistep processing of droplets is difficult, although some strategies for reagent delivery such as nanodroplet fusion, uncaging of substrates, and adding of hydrophobic substrates through the oil phase are possible. This is why microfluidic devices were created, where up to 10,000 highly monodisperse aqueous droplets per second generate in a continuous oil phase. Biocompatible surfactant oil formulations have been developed to prevent droplet coalescence, allow oxygen diffusion, and prevent molecules leaking out into the oil phase. Water in oil emulsions can be divided, fused, incubated, analysed, sorted and broken up. Integration of these steps with control over timing can potentially create a system for biological experimentation with a level of control akin to experiments on the macroscopic scale.

The choice of microfluidics for droplet ‘management’ also allows access to typical advantageous engineering features of this format, e.g. the potential for automatisation, the low cost of microfluidic devices and improved heat.

What’s the Difference between Oil in Water and Water in Oil Emulsions?

In microfluidics, the distinction between water-in-oil (W/O) and oil-in-water (O/W) emulsions pertains to the arrangement of fluid phases within a microscale system. O/W emulsions involve the dispersion of oil droplets within a continuous water phase, making them suitable for encapsulating and transporting hydrophobic substances in an aqueous environment. They are commonly utilized for controlled drug release, chemical reactions in water, or the creation of microreactors. On the other hand, W/O emulsions comprise water droplets dispersed within a continuous oil phase, enabling the encapsulation and transport of hydrophilic substances in an oil medium. W/O emulsions find applications in microfluidic systems for bioassays, cellular studies, and chemical reactions that necessitate a non-aqueous environment. The choice between O/W and W/O emulsions in microfluidics depends on the specific experimental requirements, including the nature of the substances involved and the desired reaction conditions.

Material et method to generate water in oil emulsions

Reagents

Droplet Phase: Water (Mili Q)

Continuous phase: Decane + 2% (wt) SPAN 80

| Reagent | Supplier | Catalogue number | CAS Number |

| Water | Ultrapure 18.2 MΩ – cm | – | 7732-18-5 |

| Decane | Sigma Aldrich | D901 | 124-18-5 |

| SPAN 80 | Sigma Aldrich | 8.40123 | 1338-43-8 |

Microfluidic Setup for W/O emulsions

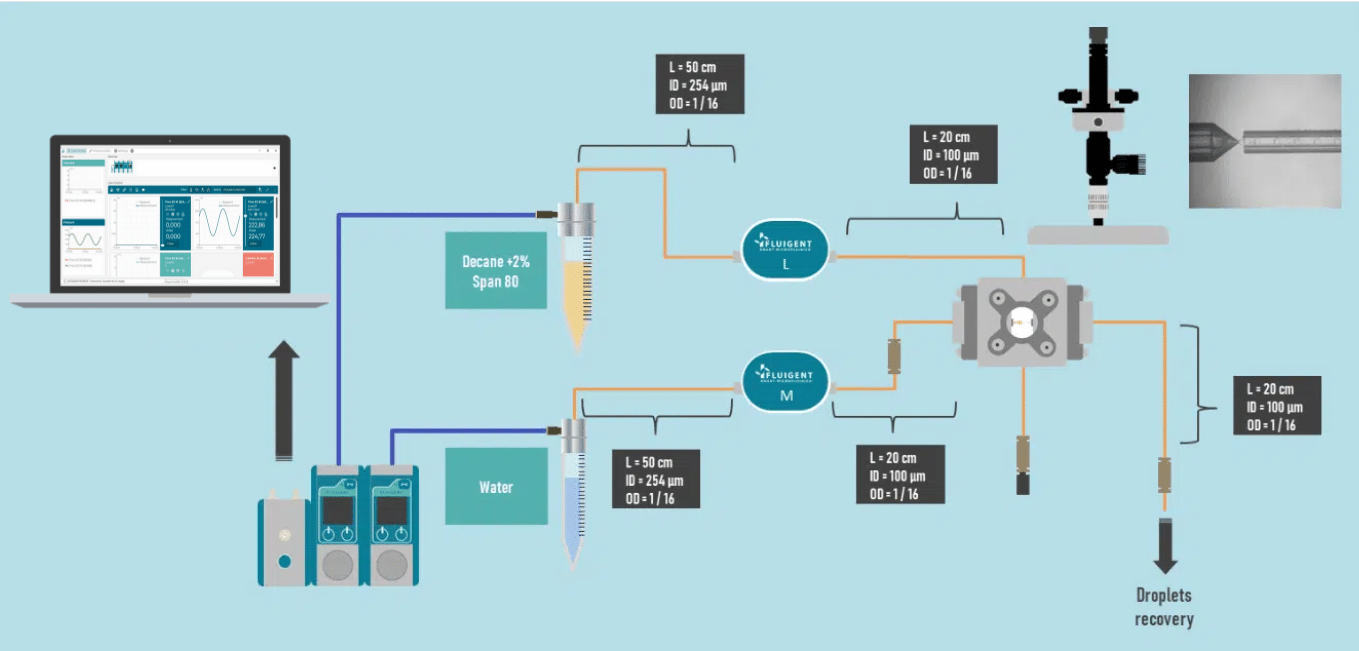

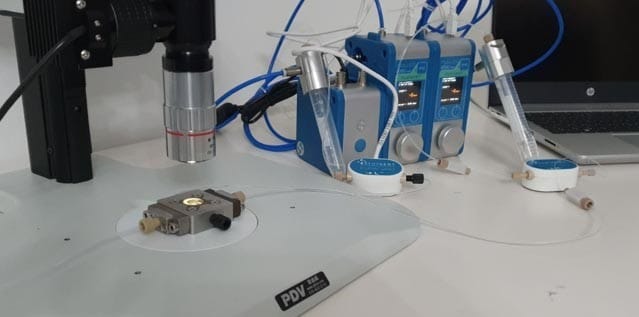

The microfluidic setup was composed of:

How to make water-in-oil emulsions

Protocols steps

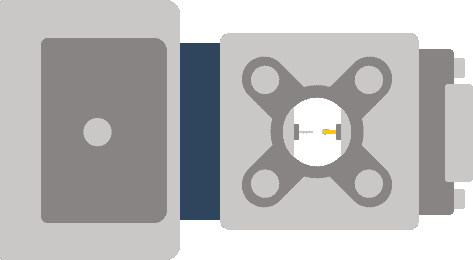

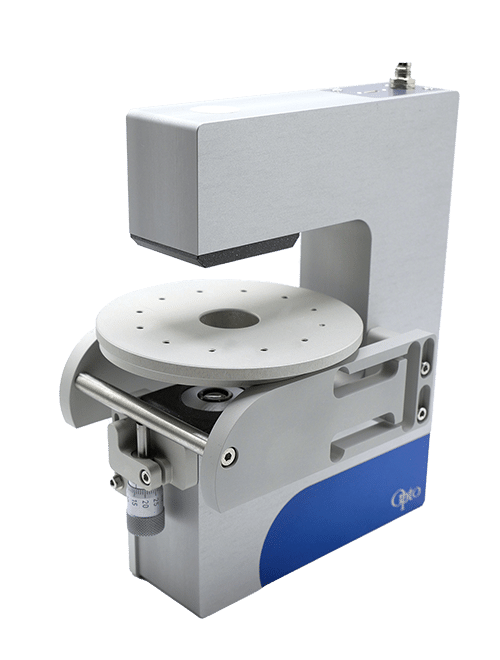

With the use of Fluigent pressure-based flow controller units and the Raydrop microfluidic device (figure 1), we have generated water in oil emulsions with control of particle size by adjusting the flow of the continuous phase and the dispersed phase.

Results

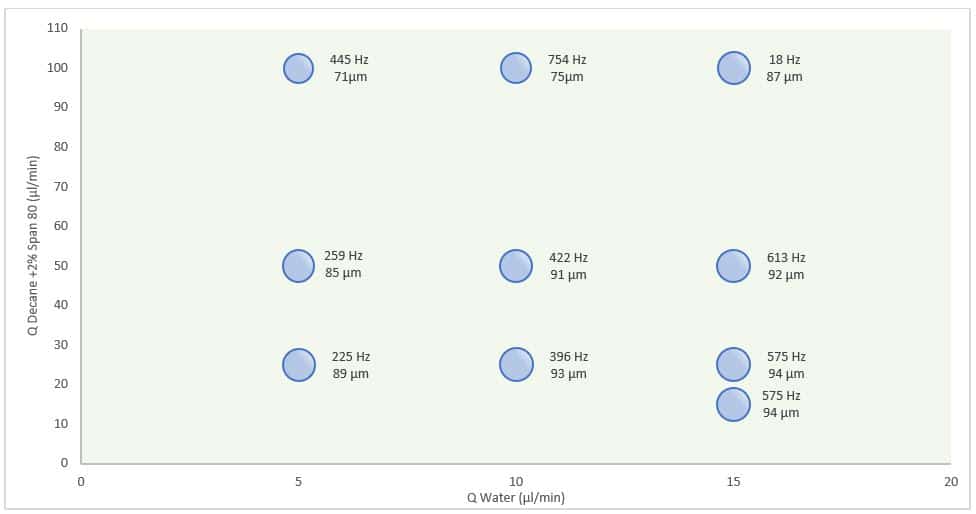

From these results, we can conclude that it is possible to influence droplet diameter as well as production rate. Indeed, by modulating the flowrate of the continuous phase and/or the droplet phase, droplet production characteristics vary. Figure 3, for example, shows the water in oil emulsions characteristics obtained for different flow rates of continuous phase (Q Decane + 2% Span 80) and droplet phase (water).

| Continuous phase flowrate (μl/min) | Droplet phase flowrate (μl/min) | Droplet diameter (μm) | Production rate (Hz) |

| 100 | 5 | 71 | 445 |

| 100 | 10 | 75 | 754 |

| 100 | 15 | 87 | 725 |

| 50 | 5 | 85 | 259 |

| 50 | 10 | 91 | 422 |

| 50 | 15 | 92 | 613 |

| 25 | 5 | 89 | 225 |

| 25 | 10 | 93 | 396 |

| 25 | 15 | 94 | 575 |

| 15 | 15 | 94 | 575 |

Conclusion

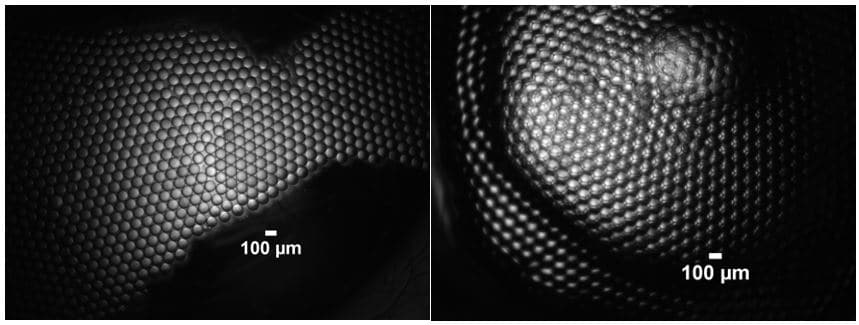

Fluigent pressure based flow controller units and Raydrop microfluidic devices were successfully used to generate high-quality, monodisperse droplets of water in hydrocarbon oil. The droplet size was controlled in the range of 75 – 94 μm by adjusting the continuous and dispersed phase flowrates. The peak stable droplet production rate was recorded for 75 μm droplets at 754 Hz. The water in oil emulsions production techniques developed here can be extended to the generation of hydrogel, protein, or polymer beads by adding appropriate post-processing steps.

Related Resources

- Microfluidic Application Notes

Generating a water emulsion in an oil solution using a droplet generator chip

Discover - Microfluidics White Papers

A review of Organ on Chip Technology – A White Paper

Discover - Support & Tools

Droplet Size Calculator

Discover - Microfluidic Application Notes

Oil in Water Emulsions

Discover - Microfluidic Application Notes

Water in Fluorocarbon Oil Emulsions

Discover