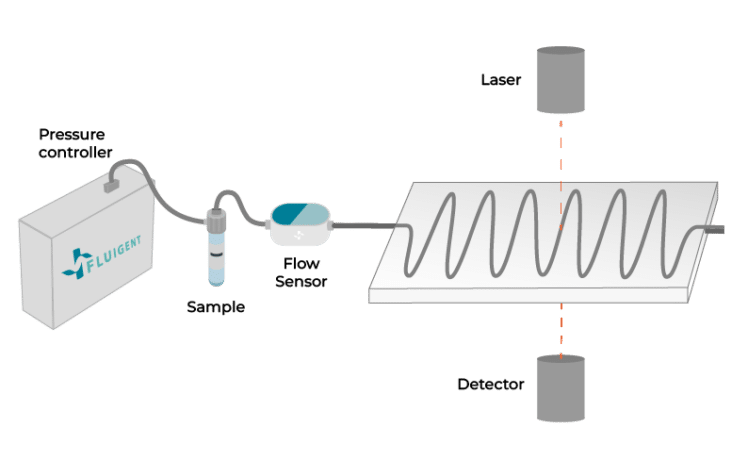

Pressure-based direct flow rate control

FS Series

[IFSXX]- New release

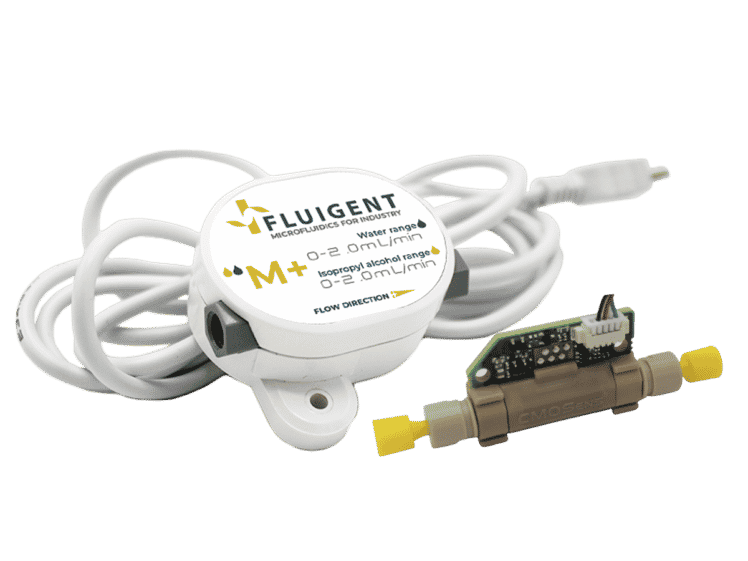

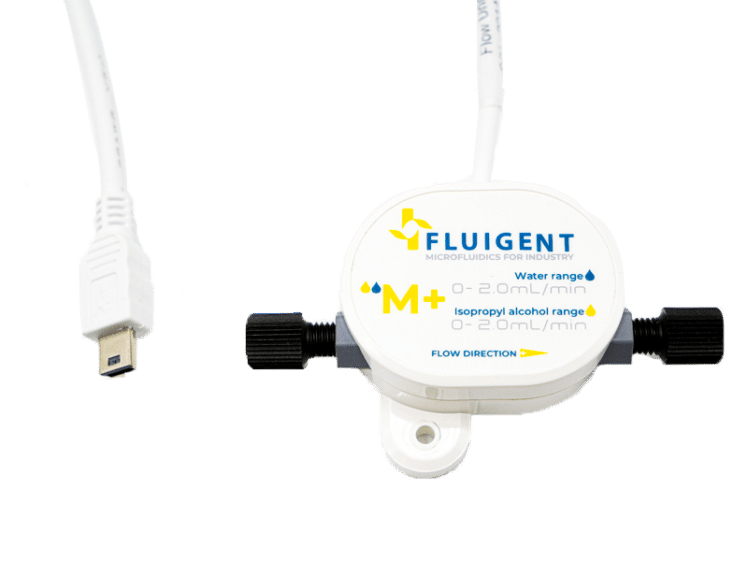

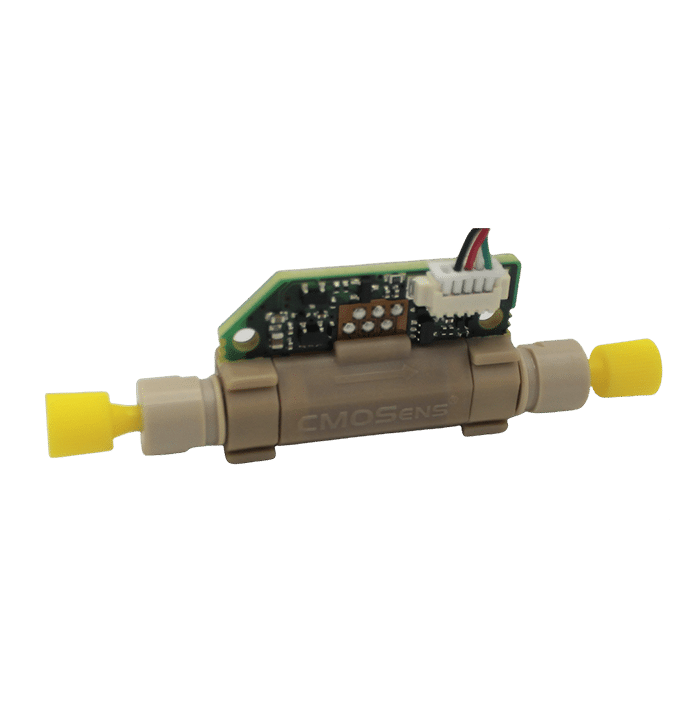

Microfluidic OEM Flow Sensor

- Short response time

- High stability

High reliability & long-term stability

- Reliable

Industry-proven technology

- Intuitive

Easy-to-use systems

Our microfluidic OEM flow sensor FS series is dedicated to flow rate control and monitoring. When combined with Fluigent pressure controllers, it permits pressure-based flow control. It enables precise and accurate measurements of dynamic liquid flow rates from 0 – 1.5 µL/min and up to 40 mL/min bi-directionally.

Performance

| Flow rate range | 0 – 40 | mL |

| Accuracy | 5 – 20 % | m.v. |

| Calibrated media | Water, IPA, HFE | |

| Maximum pressure | 12 – 200 | bar |

| Sensor technology | Thermal sensor | |

| Port communication | Micro USB | |

| Software control | OxyGEN, Fluigent SDK |

FS Series

| Series | FS series | FS series | FS+ series | FS+ series |

|---|---|---|---|---|

| Sensor model | XS | S | M+ | L+ |

| Part number | IFSXS1 | IFSS1 | FLU-M+-OEM | FLU-L+-OEM |

| Range | 0±1.5µL/min | Water 0±7µL/min IPA 0±70µL/min | 0±2mL/min | 0±40mL/min |

| Accuracy (m.v.= measured value) also applies to negative values | Water 10% m.v. above 75 nL/min 7.5 nL/min below 75 nL/min | Water 5% m.v. above 0.42 µL/min 21 nL/min below 0.42 µL/min IPA 20% m.v. above 4.2 µL/min 210 nL/min below 4.2 µL/min | Water 5% m.v. above 2.4 µL/min 0.12 µL/min below 2.4 µL/min IPA 20% m.v. above 25 µL/min 5 µL/min below 25 µL/min | Water 5% m.v. above 0.04 mL/min 1.5 µL/min below 0.04 mL/min IPA 20% m.v. above 0.5 mL/min 100 µL/min below 0.5 mL/min |

| Calibrated media | Water | Water IPA | Water IPA | Water IPA |

| Lowest detectable flow increment | 3.7 nL/min | 10 nL/min | N/A | N/A |

| Sensor diameter | 25 µm | 150 µm | 400 µm | 400 µm |

| Maximum pressure | 200 bar | 200 bar | 12 bar | 12 bar |

| Wetted materials | PEEK & Quartz Glass | PEEK & Quartz Glass | PPS, stainless steel 316L Fittings: PEEK/ ETFE | PPS, stainless steel 316L Fittings: PEEK/ ETFE |

| Dimensions | 53x22x9mm | 53x22x9mm | 65x36x25mm | 65x36x25mm |

| Inner volume | 1µL | 1.5µL | ~ 28µL | ~ 58 µL |

Technical downloads

Features of our industrial flow sensor

High accuracy for various flow rate ranges

Highly precise flow measurement with an accuracy of less than 5% error on the measured value. The different Flow Sensor models offer an extensive choice of flow-rate ranges to best match your needs over the range of 7nL/min to 40 mL/min.

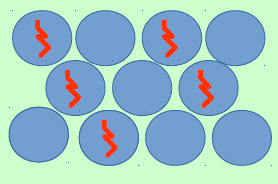

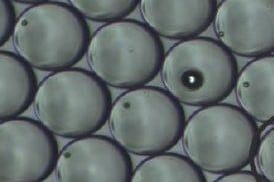

Air bubble detection*

In addition to liquid monitoring, it is possible to detect bubbles using the microfluidic OEM flow sensor during an experiment.

*Bubble detection is only available for the FS+ series

Plug & Play

Using Fluigent electronics and algorithms, the sensors are directly recognized by Fluigent systems and SDK/software for starting experiments right away.

Compact and fast integration

The microfluidic OEM flow sensors were developed to be cost-effective and easily integrated into any system.

Related applications

Why can flow rate be vital for your application?

Flow rate may need to be tightly controlled for a number of applications. In droplet microfluidics, it is useful to correlate the droplet size with the droplet frequency (generation rate). For dynamic organ-on-chip applications, the flow rate is needed to evaluate the shear stress imposed on cells. It is also an important feature for applications that require dispensing a specific volume of liquid, such as for cell imaging applications in which various reagents are delivered. Fluigent microfluidic OEM flow sensor is suitable for all types of aqueous liquids, such as distilled water, media, PBS, etc.

It is useful for many biological applications, including:

- Next-generation sequencing (NGS) applications using microfluidic Digital PCR to quantify ctDNA in liquid biopsies for oncology, to detect low-level genetic variants in infectious diseases

- Microscopy for cell biology research, DNA-PAINT imaging, genomics research, live cell imaging

- Drug discovery using microphysiological systems such as 3D-(co)-cultures, organoids, organ-on-chip models

- Molecular analysis including microfluidic modulation spectroscopy or mass photometry

Benefits of the FS Series and FS Series + industrial flow sensor

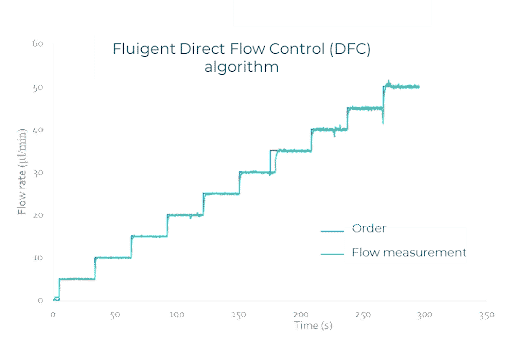

Fluigent provides highly stable and responsive real-time flow control

By directly connecting a microfluidic OEM flow sensor to Fluigent pressure controllers, it is possible to monitor or control the flow rate in real time. The algorithm includes a continuous optimization of the parameters, allowing it to adapt to the interactions between fluidic channels in complex situations.

Fluigent’s powerful pressure regulation algorithm is based on physical equations and self-learning routines that offer several benefits:

- No overshoot/undershoot, allowing for a responsive, accurate, and stable flow rate

- Adapts to any reservoir size

- Compatible with a wide pressure or vacuum range (up to 7,000 mbar, -800 mbar vacuum, standalone pressure/vacuum regulation capability)

Select the best flow sensor for your application

Mid- and high-flow applications (7uL/min – 40 mL/min): FS + series

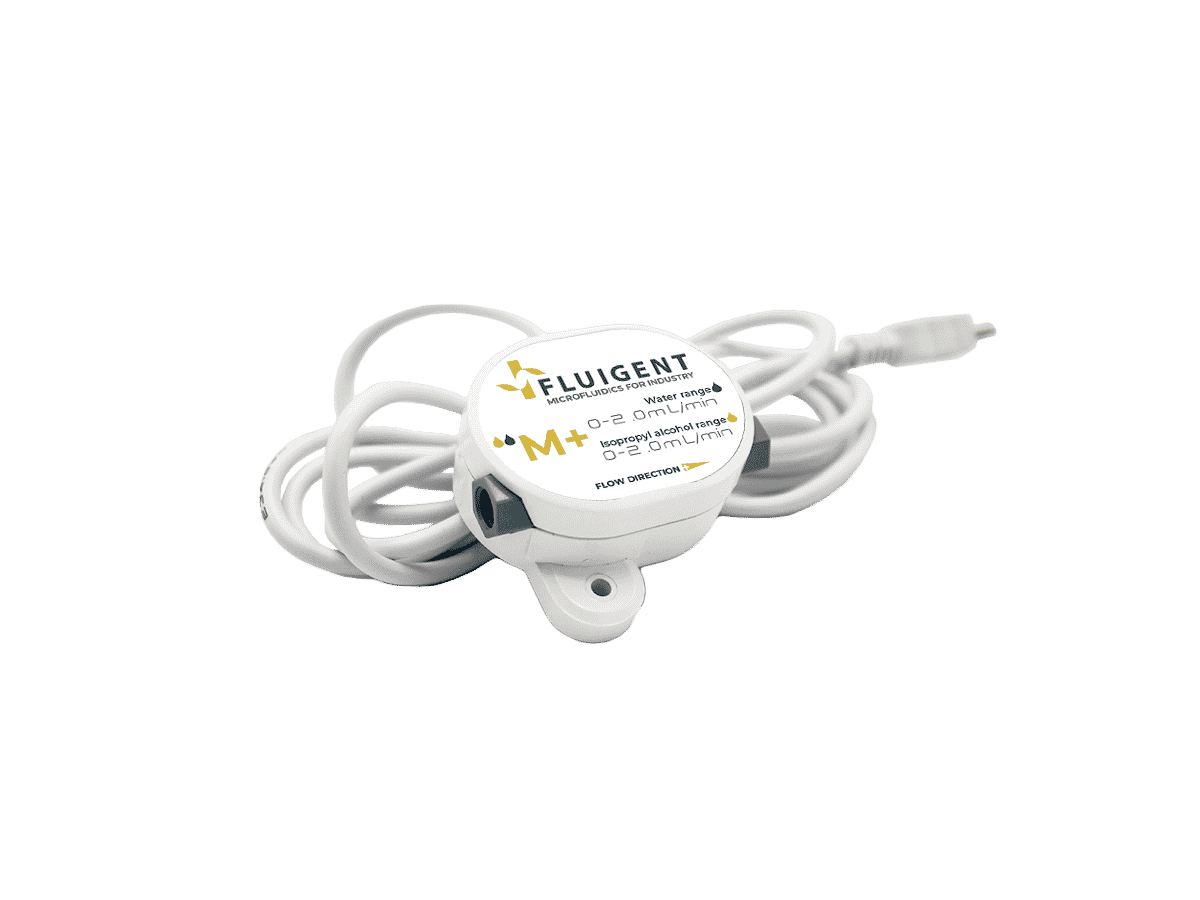

For applications that require flow rates ranging from 7 µL/min to 40 mL/min, we recommend our latest microfluidic OEM flow sensor series. It consists of a high-precision sensor and electronics integrated into a compact casing. Standard M3 sized screws can be used for fixing the device. Using these flow sensors, one can also monitor liquid temperature and detect air bubbles that pass through the sensor.

Two references are available: L+ and M+

FS series L+

H2O full-scale flow rate: 0 – ± 40 mL/min*

Accuracy: ±5 % of measured value if flow rate > 1 mL/min,

50 µL/min if flow rate < 1 mL/min

*Additional specifications available on the specification table and on the datasheet

FS series M+

H2O full-scale flow rate: 0 – ± 2 mL/min*

Accuracy: ±5 % of measured value if flow rate > 10 µL/min,

0.5 µL/min if flow rate < 10 µL/min

*Additional specifications available on the specification table and on the datasheet

Low flow applications (< 7 uL/min): FS series

For applications that require flow rates lower than 10 µL/min, we recommend our original flow sensor series. Two references are available: XS and S

For which fluids can these flow meters be used?

The choice of the flow sensor depends on the fluids used in a specific application. Indeed, the characteristics of a given fluid can influence the results displayed by the flow sensor.

For example, assessing the flow rate of a highly viscous fluid will not yield the same results as measuring the flow rate of water. Our OEM microfluidic flow sensors are pre-calibrated for water and IPA, which cover the most commonly used fluids. However, you can also use liquids with different properties; you just need to calibrate the sensor first.

Similarly, depending on the composition of the flow sensor, some corrosive fluids may not be safe to use, even though our flow sensors are chemically resistant. For our original flow sensor series, the wetted materials are PEEK and quartz glass, and for our FS series+, the wetted materials are Polyphenylene sulfide (PPS) and stainless steel 316L. Please ensure that your fluid is compatible with these materials before using the sensor.

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |