High-quality pressure control

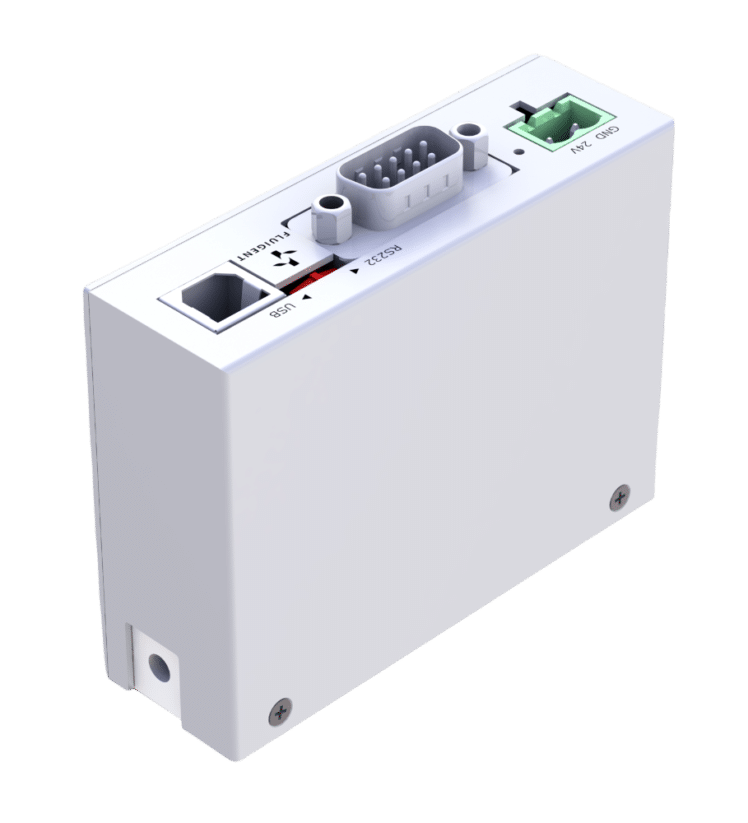

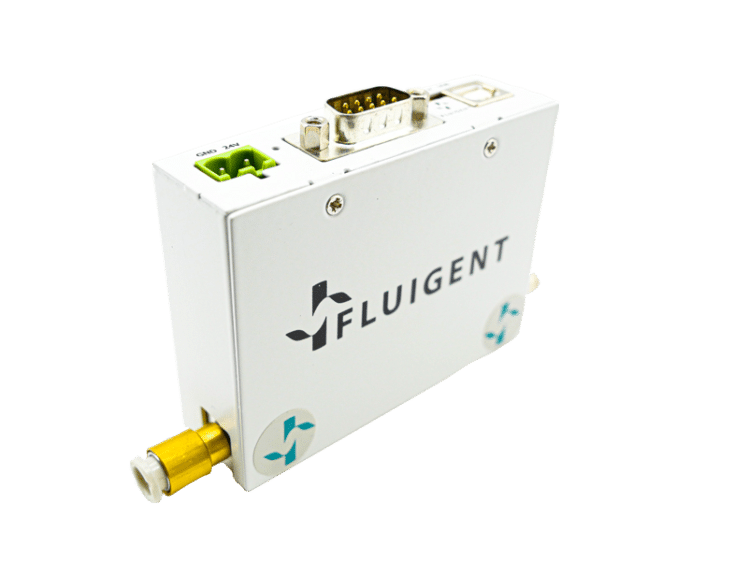

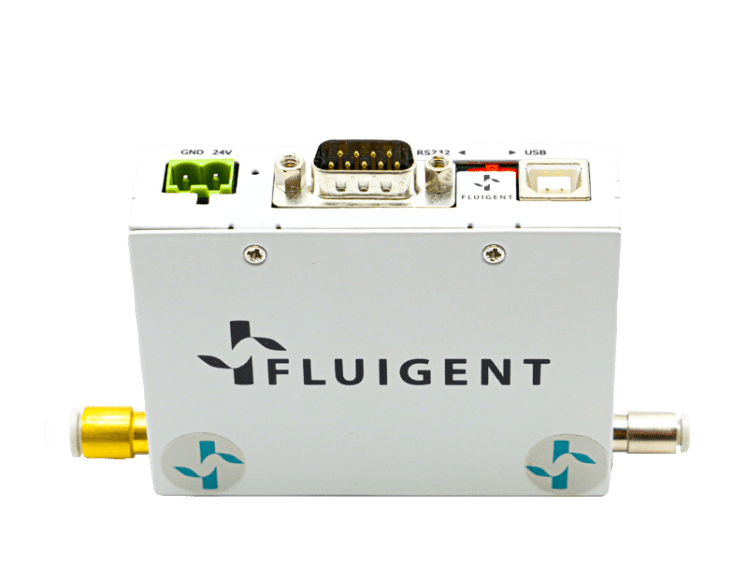

Fluigent PX

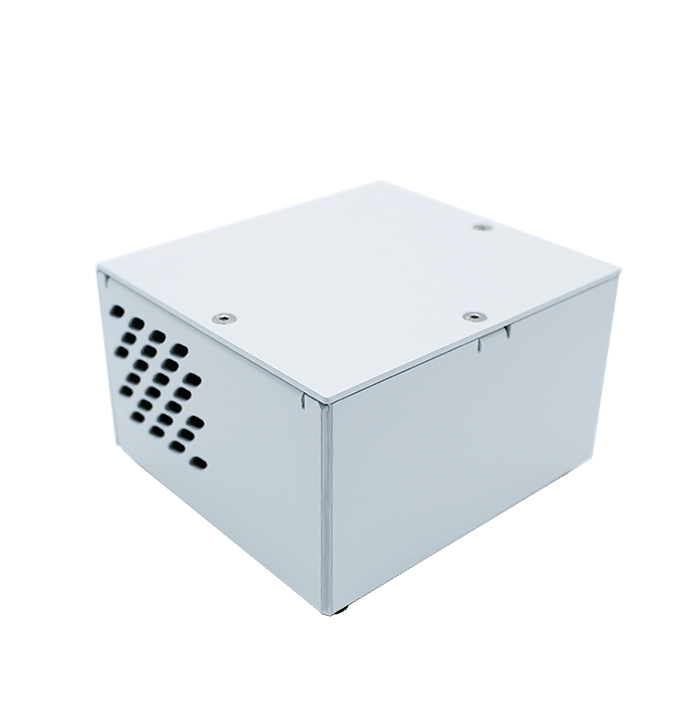

[ICPXXX]Microfluidic OEM Pressure Controller

- High precision

- Compact design

Designed for industrial integration

- Cost-effective

Unmatched price-performance ratio

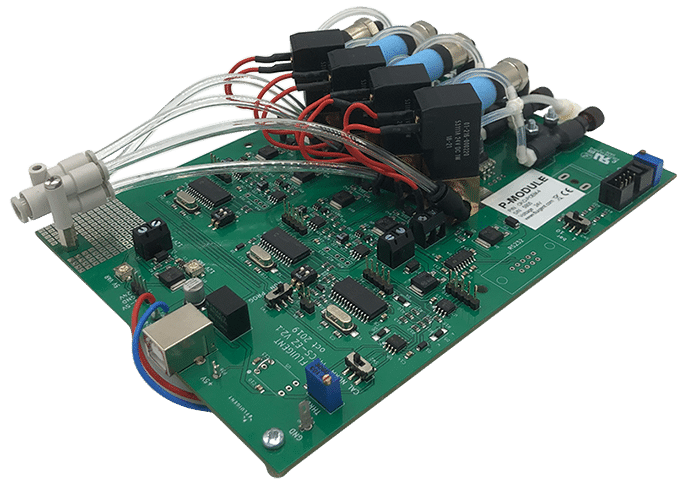

The FLUIGENT PX patented, field-proven Fastab™ technology allows for fast settling times and outstanding stability.

Our microfluidic OEM pressure controller provides a dual interface USB and RS232 for high versatility in the integration. The delivered software package is suitable for Windows and Linux platforms.

Specifications

| Pressure range | -750 to 2000 | mbar |

| Pressure stability | < 0.5 | % FS |

| Accuracy | 0.25 | % FS |

| Repeatability (1σ) | < 0.01 | % FS |

| Sensor resolution | 0.03 | % FS |

| Mechanical response time | < 10 | ms |

| Minimum settling time – system dependent | < 150 | ms |

| Typical settling time (from 15 mL reservoir from 0 to 2 bar) | 6 | sec |

| Typical depressurization time (from 15 mL reservoir from 2 to 0 bar) | 12 | sec |

| Operating temperature range | -10 to 80 | °C |

| Operating humidity | 0-100 | %HR |

| Digital Communication interface | USB, RS232 | |

| Weight | 192 | g |

| Dimensions | 82.4 x 25.7 x 67.9 | mm |

PX Series

| PX-1 | ICPX11 | 0 to 1000 mbar (0 to 14.5 psi) | 1300mbar +/- 50 mbar (18.8 psi +/- 0.72 psi) | 2000 mbar (29 psi) | N/A |

| PX-2 | ICPX21 | 0 to 2000 mbar (0 to 29 psi) | 2400mbar +/- 50 mbar (34.8 psi +/- 0.72 psi) | 3000 mbar (43,5 psi) | N/A |

| PX-345 | ICPX345 | 0 to 345 mbar (0 to 5 psi) | 800mbar +/- 50 mbar (11.6 psi +/- 0.72 psi) | 2000 mbar (29 psi) | N/A |

| PX-V1 | ICPV1 | 0 to -600 mbar (0 to -8.7 psi) | Vacuum below -300 mbar (-4.35 psi) | N/A | -900 mbar +/- 50 mbar |

| PX-V2 | ICPXV2 | 0 to -750 mbar (0 to -10.8 psi) | Vacuum below -300 mbar (-4.35 psi) | N/A | -900 mbar +/- 50 mbar |

Technical downloads

Detailed features and description

Different models to fit your needs

The PX OEM Microfluidic Pressure Controller is a CE and RoHS compliant single-controller available in 5 pressure ranges. It is suitable for vacuuming and pressure of up to 2 bars. It’s designed to maximize versatility with its dual interface USB and RS232 ports and is delivered with a full software package (SDK) to ease integration into Windows or Linux-based software platforms.

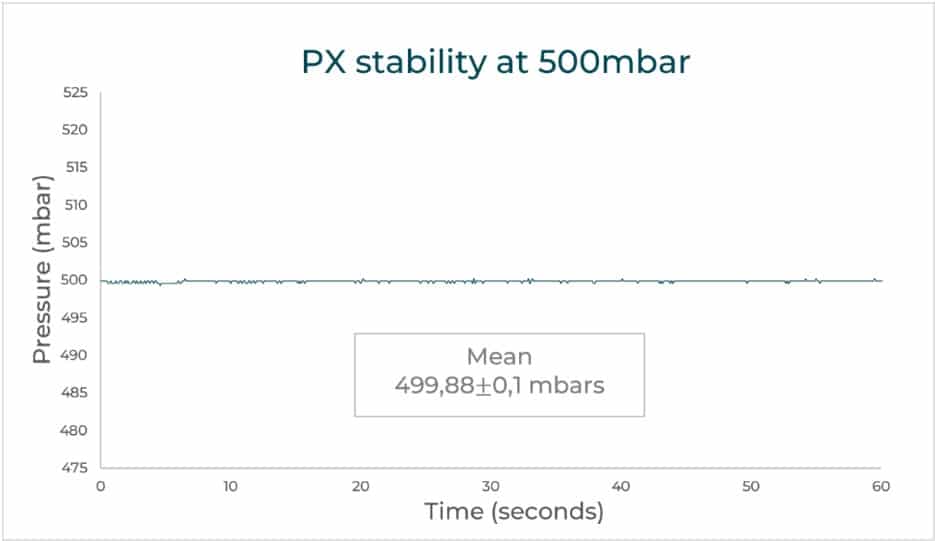

Best-in-class stability

Due to our field proven, patented FASTAB™ technology, the PX allows for optimal flow control with the robustness required in demanding industrial environments.

Precise fluid injection

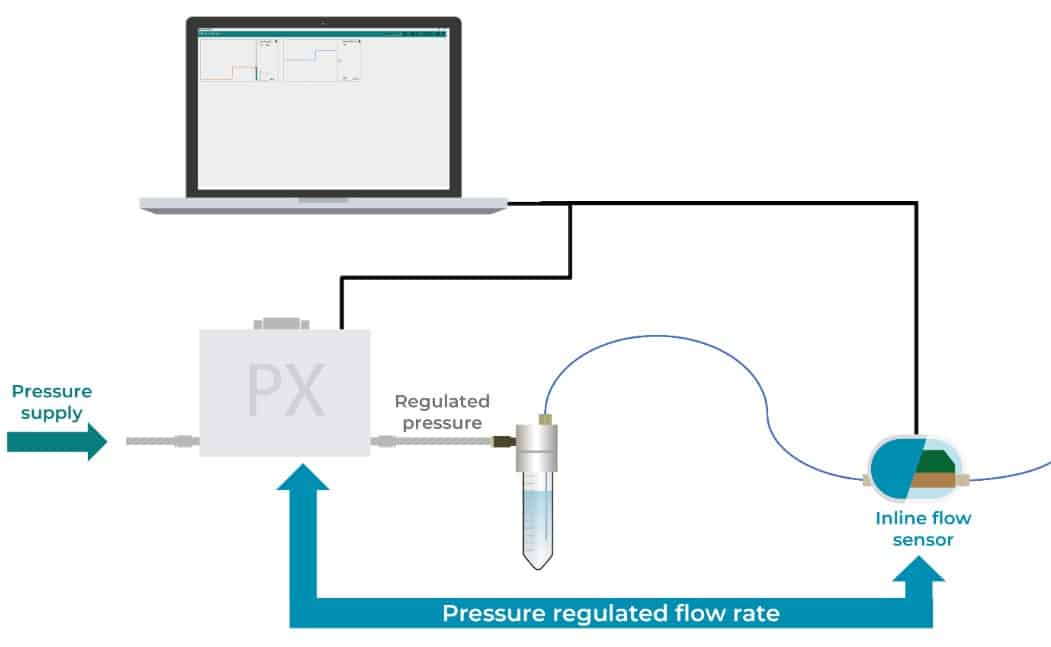

Combine the PX with a flow sensor to regulate directly in flow rate and inject precise amounts of volume in the system.

Expand as needed

Combine as many modules as needed to fit your application needs. Each module consists of a separate pressure channel and can be controlled independently.

In the base configuration, the system controls pressure, and the liquid flow is a function of system resistance, fluid viscosity, etc. The addition of a flow sensor enables one to control or monitor flow rate as well as dispense volume. The pressure automatically adjusts in the background to maintain the flow rate. When connected to a computer, one can use our Fluigent software to benefit from automation or live monitoring while also recording of data.

The PX microfluidic OEM pressure controller is available in different pressure and vacuum ranges, to provide the optimum level of pressure control and resolution. These can easily be joined together to match all application requirements or reconfigure the system for a new experimental design.

Fluigent provides unique pressure controllers with high precision and stability

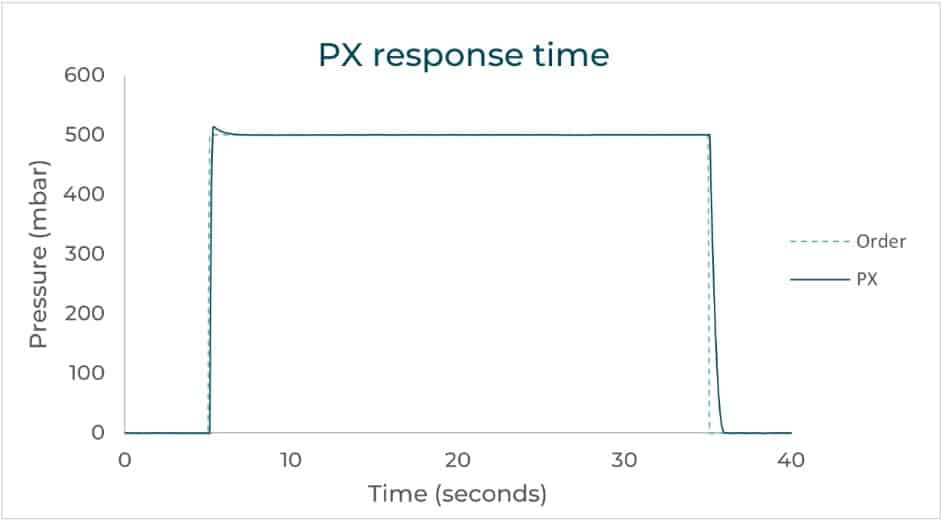

The PX is suited for performing microfluidic protocols while providing stable flow rates. With stability better than 0,5% full scale, users are ensured a continuous pressure input without any risk of drifts on a long-term basis (see experimental graph on the right).

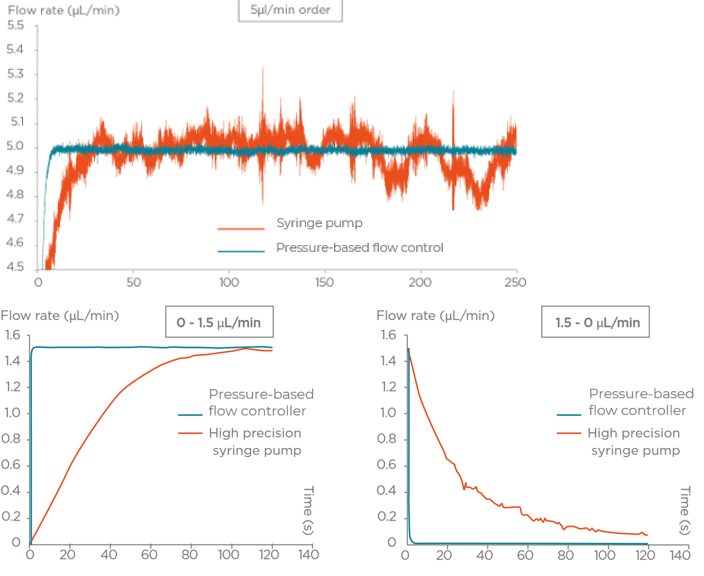

Benefit from fast and accurate response to input

With a response time of less than 10ms, the PX is one of the most reactive microfluidic OEM pressure controllers in the market. Less than 150ms is necessary for it to settle to the ordered value, and high stability is ensured afterward. Choose the PX for rapid, precise, and repeatable pressure changes for your liquid handling system.

Related applications

Why choose pressure controller?

- Better suited to resistive fluidic paths

- Responsiveness

- Ability to deliver larger volumes of liquid without refill (>1 liter)

- Use one pressure controller and simple valving to deliver multiple solutions

FASTAB Microfluidic patented technology

Fluigent’s patented FASTAB™ technology is a pressure-driven technology with an advanced feedback control algorithm to maintain precise pressure control.

The technology used in this pressure pump avoids cross-contamination because liquids only contact air. Improved reliability and reproducibility of results are possible due to its pulseless flow.

The use of pressure to handle fluids also provides a quick response time allowing for precise operations such as stop flow and accurate pressure/flow rate steps.

Fluigent enables flow rate control with high precision and responsiveness

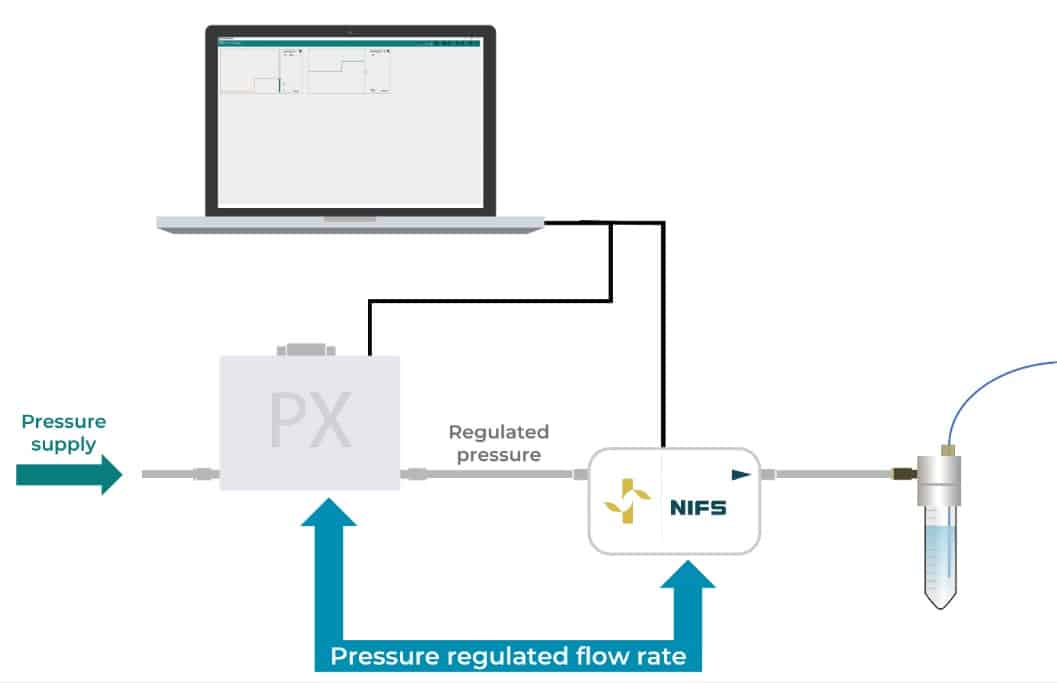

Combine the PX with a flow sensor and benefit from our expertise in flow rate management. Our patented technology, FASTAB™, uses a feedback loop system to adjust the pressure provided by the PX pressure controller to reach and maintain the targeted flow rate. It can also be coupled with our non-invasive flow sensor, the NIFS, to perform precise flow measurement and regulation for experiments and protocols in demanding environments where contamination should be avoided, and sterility is maintained.

An OEM pressure controller and a flow sensor or NIFS can be combined in a very simple way. See schematics above.

Can industrial pressure controllers be used to monitor multiple fluids at different flow rates?

Context

A photonic technology institute tests a variety of lab-on-a-chip systems, the number of flow channels and the required pressures vary from one test to another.

Solution

Due to its individually stacked channels adapted for different pressures, the PX series allows for control of the different pressure variations required.

Result

The PX microfluidic OEM pressure controller simplifies fluid management in multiple fluids, and reduces the time needed to add or remove channels. It provides flexibility without compromising performance (accuracy and response time).

Softwares

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 21.0.0.0 or more recent |

Expertise & resources

-

Fluigent Products Datasheets PX Technical Specifications Download

-

Expert Reviews: Basics of Microfluidics Key considerations for fluidic system integration Read more

-

Fluigent Products Datasheets Fluigent PX Datasheet Download

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more

-

Expert Reviews: Basics of Microfluidics Microfluidics overview: History and Definition Read more

-

Microfluidic Application Notes Pressure predictions for lab-on-a-chip operations using a microfluidic network solver and Fluigent PX Download

Related products

Microfluidic Flow Management Unit

P-OEM

See the offer

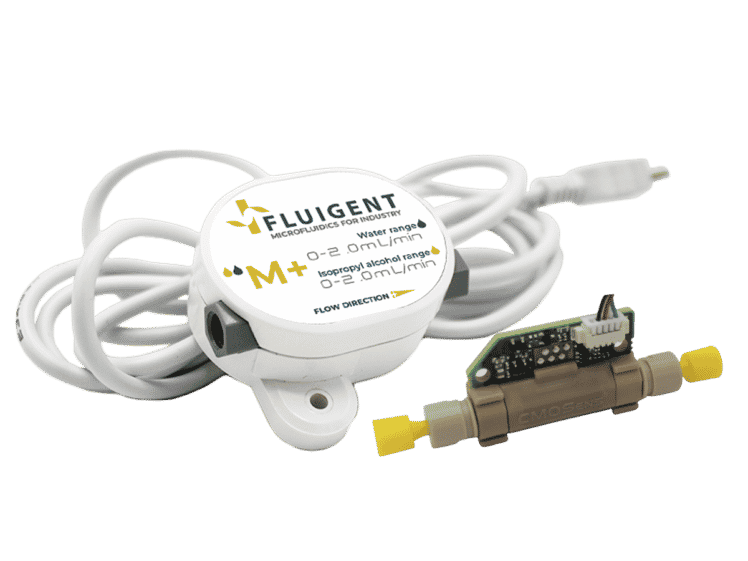

Microfluidic OEM Flow Sensor

FS Series

See the offer

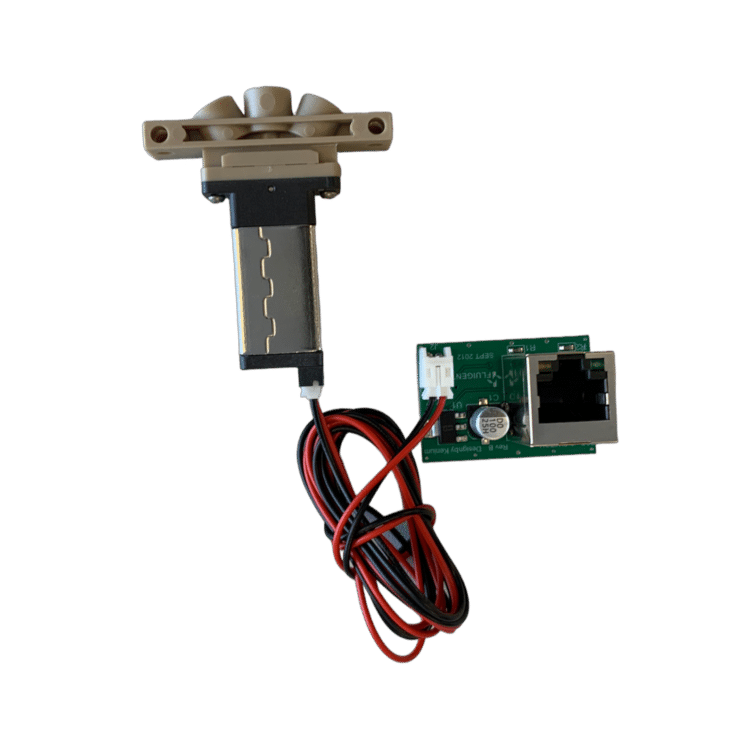

3-port/2-way bidirectional valve for industry

Fluigent 2-X

See the offer

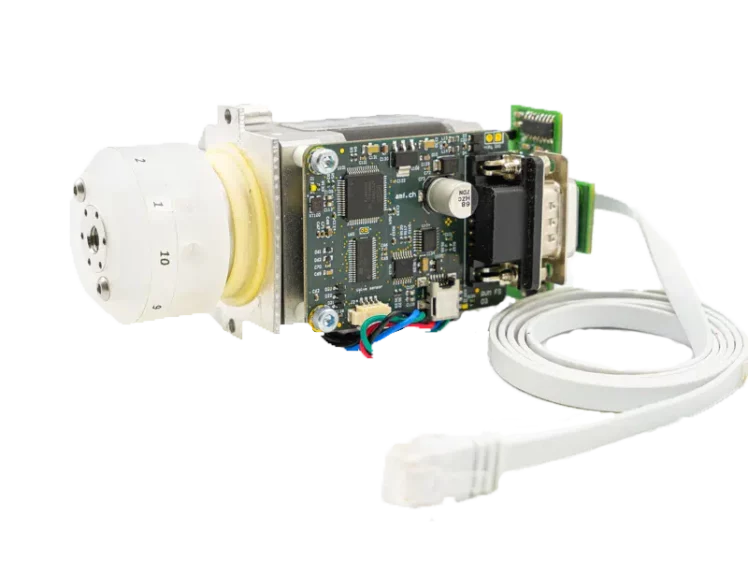

Rotary multi-port microfluidic valve for industry

OEM microfluidic electric rotary valve with multi-port (Fluigent M-X)

See the offer