Excellent response time, pulseless and highly stable

F-OEM

Modular OEM Microfluidic Flow Controller

- Best performance

- Flexible

Configurable with pressure and switch control modules

- Compact

Standalone platform adapted to industrial uses

- Contamination-free

Not in contact with liquid

- Cost-effective

Reduced reagent consumption

Our F-OEM microfluidic flow controller offers our highest performance, efficiency, and widest pressure and flow rate ranges to support the most demanding industrial applications, including microfluidic and nanofluidic applications (microchannels, nanochannels, capillaries, lab on a chip…). It is a standalone, modular platform that will perform complex fluidic operations. Discover our latest industrial flow controller.

Specifications

| Pressure range Push Pull available | -800 to +7000 | mbar |

| Pressure stability CV (on measured values) | <0.1 | % full scale |

| Accuracy | 0.25 | % full scale |

| Repeatability (1σ) | < 0.01 | % full scale |

| Sensor resolution | 0.03 | % of max pressure |

| Mechanical response time | Down to 30 | ms |

| Minimum settling time | <70 | ms |

| Typical settling time (for 15 mL reservoir from 0 to 2 bar) | 2.5 | sec |

| Typical depressurization time (for 15 mL reservoir from 2 to 0 bar) | 0.4 | sec |

| Operating temperature range | -10 to 80 | °C |

| Operating humidity | 0-95 | %HR |

| Flow rate control | Compatible with Fluigent flow rate sensors for direct flow rate monitoring and control | |

| Microfluidic valve control | Compatible with Fluigent OEM 2 position switches and rotary valves (2-Switch, M-switch, L-switch) | |

| Electrovalve control | Electrovalve control module for actuating up to 8x 3/2 electrovalves or other ON/OFF state devices | |

| Communication | USB and RS232 |

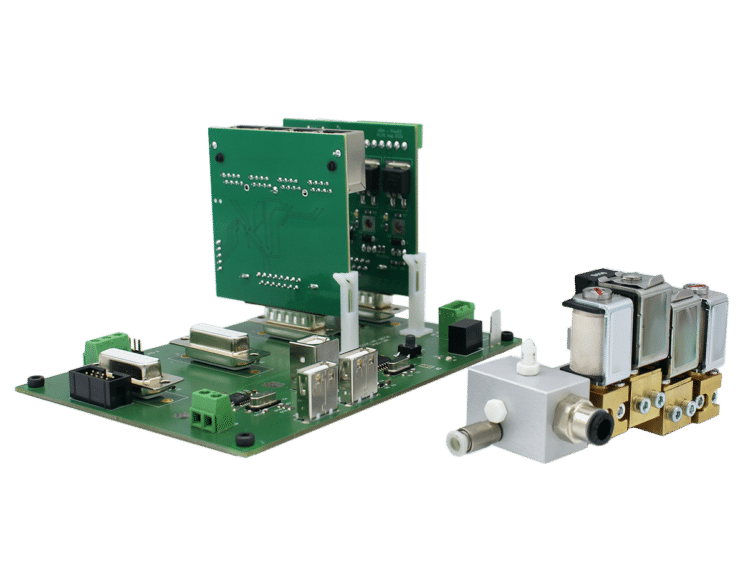

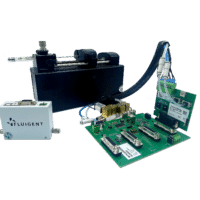

F-OEM Components

| Function | Component | Part number | Details |

|---|---|---|---|

| Base board | Integration board | INT-FOEM | Main board to accomodate valve and pressure modules. Extension slots available |

| Base board | Integration board RS232 | INT-FOEM-RS232 | Main board to accomodate valve and pressure modules RS232 version |

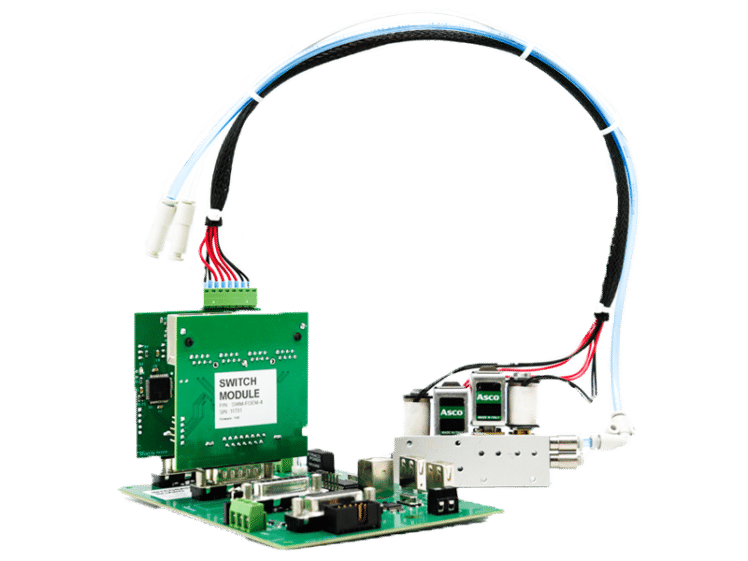

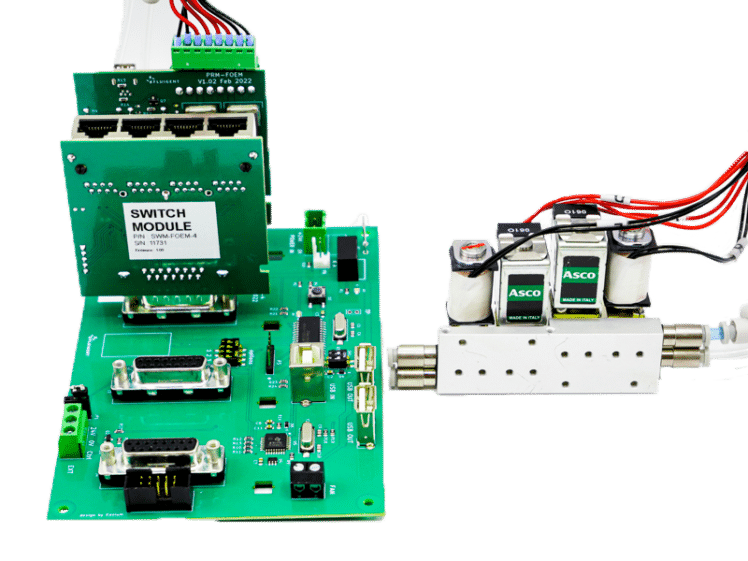

| Valve connections | Switch module | SWM-FOEM-4 | Accomodate Fluigent OEM microfluidic valves for direct control |

| Electrovalve connections | Electrovalve module | MEV-FOEM-4 | Actuate up to 8x 3/2 electrovalves or other ON/OFF state devices |

| Pressure control | Pressure module | PRM-FOEM-PP | “Push and Pull” Pressure and vacuum control module from –800 to 1 bar |

| Pressure control | Pressure module | PRM-FOEM-0025 | Control pressure for 25 mbar |

| Pressure control | Pressure module | PRM-FOEM-0069 | Control pressure from 0 to 69 mbar |

| Pressure control | Pressure module | PRM-FOEM-0345 | Control pressure from 0 to 345 mbar |

| Pressure control | Pressure module | PRM-FOEM-1000 | Control pressure for 1000 mbar |

| Pressure control | Pressure module | PRM-FOEM-2000 | Control pressure for 2000 mbar |

| Pressure control | Pressure module | PRM-FOEM-7000 | Control pressure for 7000 mbar |

| Pressure control | Pressure module | PRM-FOEM-N025 | Vacuum control from –25 to 0 mbar |

| Pressure control | Pressure module | PRM-FOEM-N069 | Vacuum control for –69 mbar |

| Pressure control | Pressure module | PRM-FOEM-N345 | Vacuum control for –345 mbar |

| Pressure control | Pressure module | PRM-FOEM-N800 | Vacuum control for –800 mbar |

| Pressure regulator | Pressure regulator | PRG-FOEM | If modules with different pressure supply are needed |

| Connectors & tubing kit | Connectors & tubing kit | FOEM-CTQ-KIT01 | Kit content: USB Cable 1.8m (x1) 4mm pneumatic tubing (4m), 6mm pneumatic tubing (3m), double Y manifold 1x 6 mm to 4x 4 mm (x1), 4 mm red plug (x4)ing (4m) |

Technical downloads

Features of the F-OEM

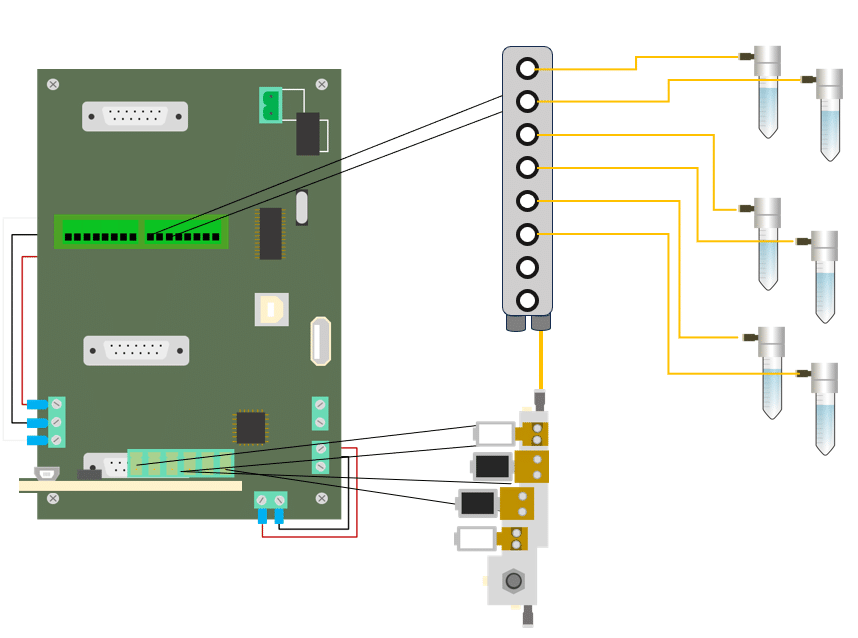

All-in-one OEM microfluidic flow controller

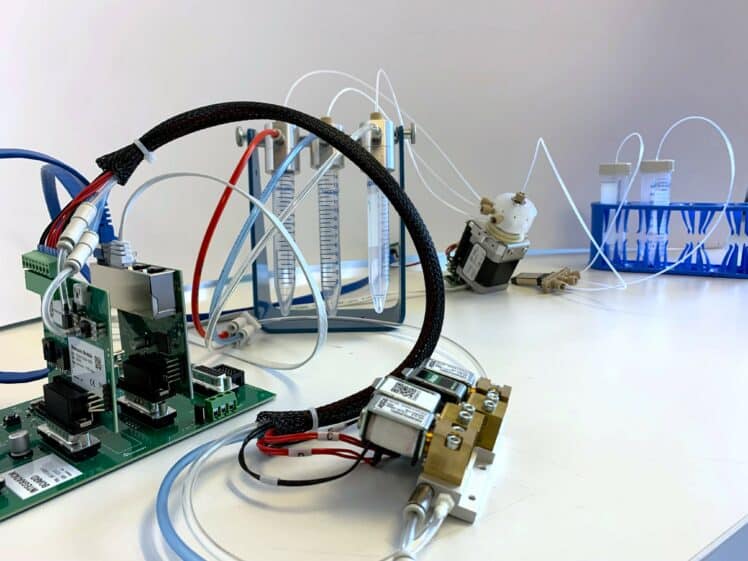

Pressure modules (positive pressure, negative pressure, or push-pull modules), microfluidic valve modules, and flow sensors are directly connected to the main platform.

Modular

The platform allows one to choose the number of pressure modules (with different ranges, if required), valve modules, and flow sensors. Combine up to 8 pressure modules on a single F-OEM platform.

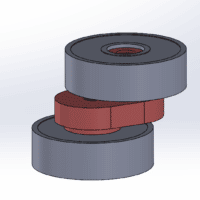

Fluigent latest pressure/flow control technology

The F-OEM makes use of Fluigent’s patented Fastab 2 technology. It provides the best response time, pulseless, and highly stable flow conditions for high precision industrial microfluidic applications. This OEM flow control system allows optimal flow control with the reliability required for demanding industrial environments.

Largest range of pressure and flow rates

Supports both pressure control and direct volume flow rate control depending on user needs. The F-OEM range of modules allows for regulation of vacuum/pressure down to –

800 mbar and up to 7 bar, with the possibility to use a push-pull module (-800 / +1 000 mbar). Liquid flow rate ranges from a few nL/min to 5 mL/min.

All-in-one modular flow control platform

Configure your own system:

The F-OEM consists of a main board to which one can add pressure and switch control modules depending on the configuration required. Mixed pressure ranges can be connected to the same board (positive and negative pressures, and Push-Pull).

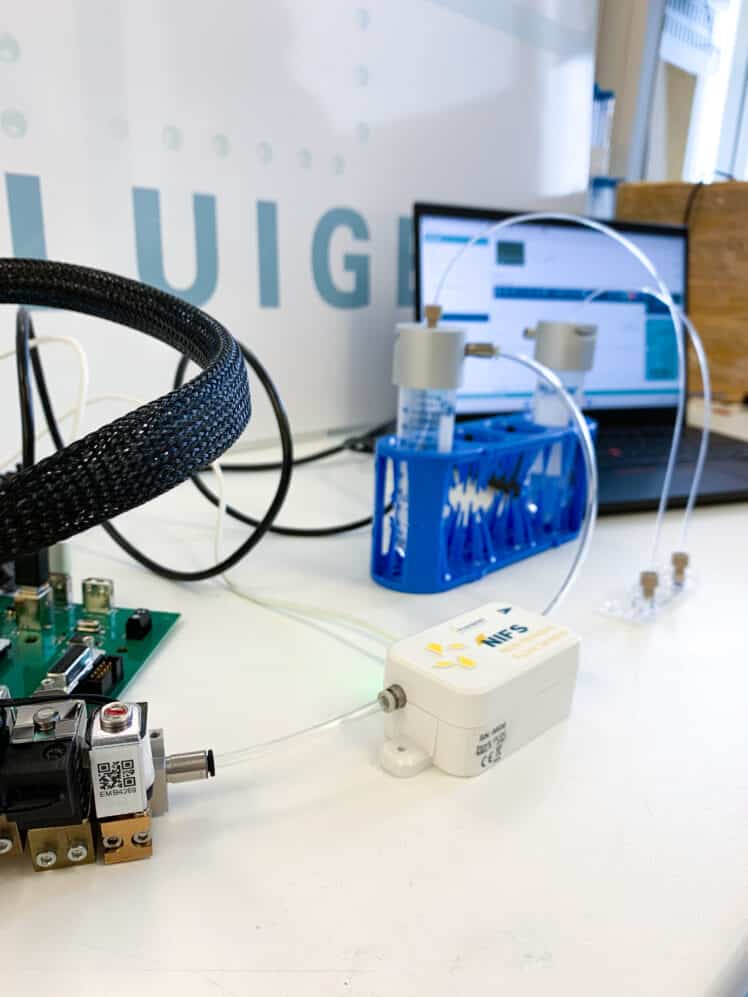

Integrated flow control:

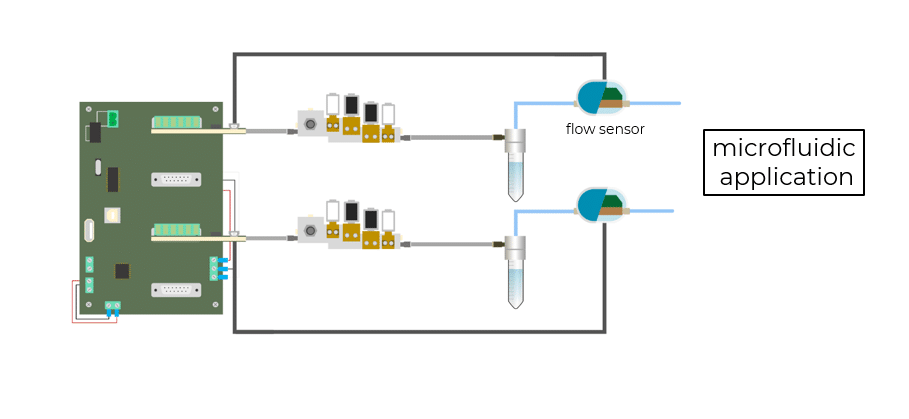

To switch from pressure control to flow rate control, one can directly add a flow sensor from our industrial FS series to the OEM microfluidic flow controller without the need of an additional board. Flow-rates can be monitored or controlled using Fluigent DFC “self-learning” flow rate control algorithm.

Single gateway for industrial-grade microfluidic control:

This industrial microfluidic flow controller can be used to control a pressure source and power other third-party devices required in the microfluidic system.

Related applications

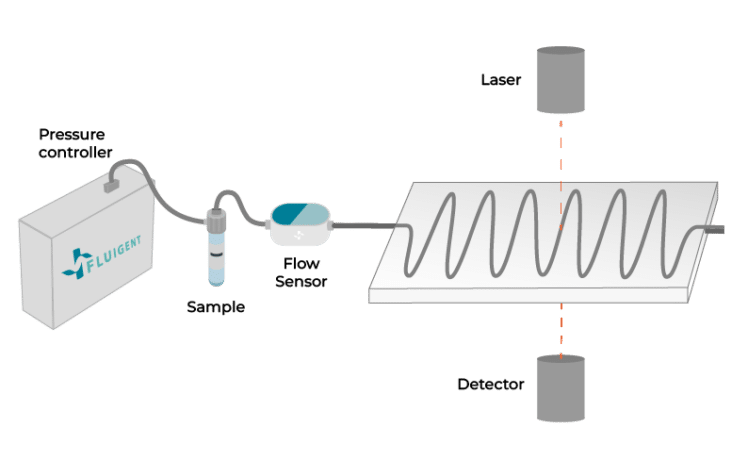

Combining Microfluidics and Spectroscopy

DiscoverValve Automation with the F-OEM for Microfluidic Applications

DiscoverContamination-free Liquid Handling System

DiscoverMicrofluidic Drug Discovery

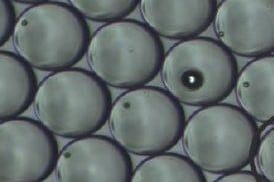

DiscoverFlow Expertise for Cell Encapsulation and Single-Cell Analysis

DiscoverDroplet Digital PCR (ddPCR)

Discover

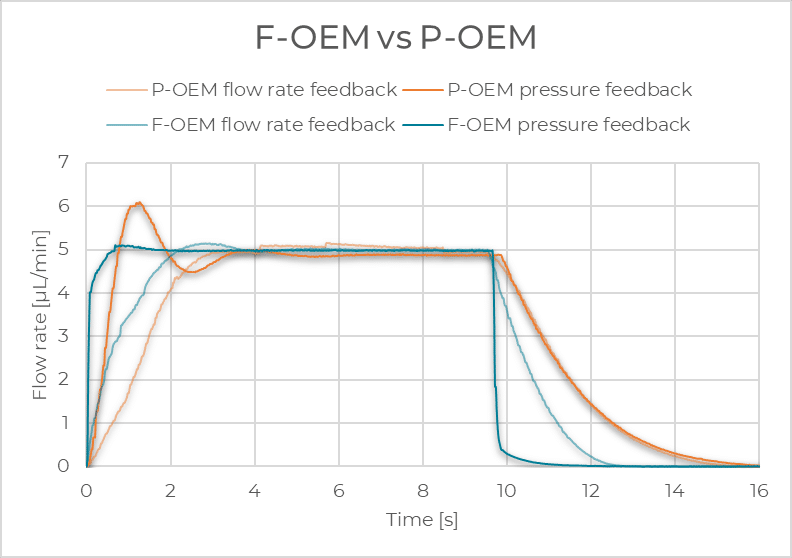

Our OEM flow controller offers our best performance for industrial applications

The F-OEM Microfluidic Flow Controller makes use of the best combination of pneumatic, mechanical, and electrical elements associated with our new generation algorithm: Fluigent Direct Flow-rate Control (DFC) – a self-learning algorithm that performs continuous adjustment over the algorithm parameters based on the actual response time. Its improved reactivity allows countering, in real-time, the interactions between microfluidic channels in complex situations. It allows to overcome syringe pumps limitations in terms of performance, stability, cost-efficiency, contamination hazards and maintenance.

There are many advantages to direct control:

- Adapted to cell culture or other experiments involving resistance variations: the algorithm adjusts its model to the setup resistance in real-time

- Save precious sample or reagent: reduced time to reach desired flow rates uses less liquid during a calibration step

- Save time with reduced settling time and no calibration

General functions

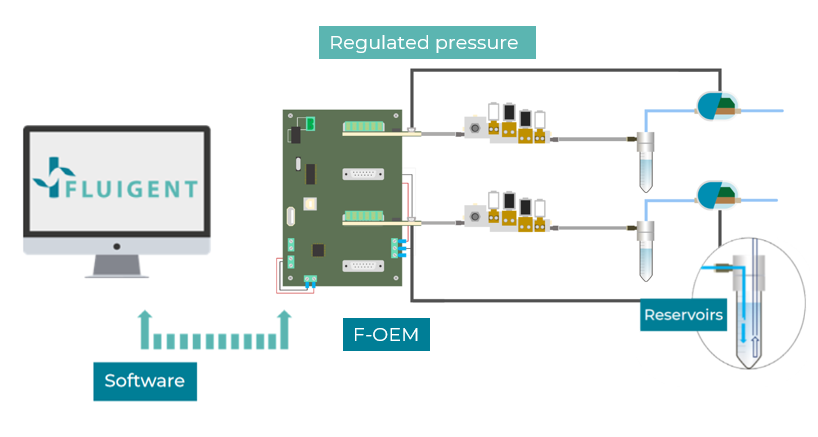

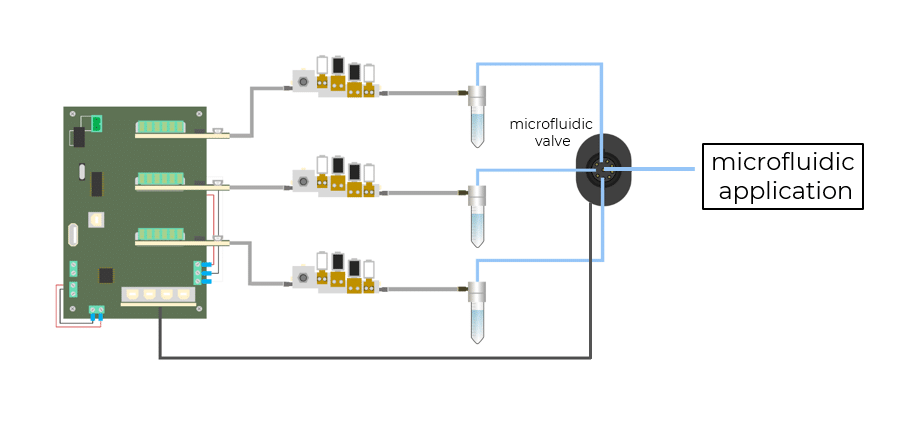

A pneumatic path combined with Fluigent’s regulation algorithm has been developed to deliver regulated pressure from a pressure source. The principle of pressure actuation in microfluidic systems is shown in the figure. The benefits of this technology are listed below.

- Output pressures, flow rate, and valves can be controlled by using OxyGEN Fluigent software, or our Software Development Kit (SDK) for custom software applications.

- The OEM microfluidic pressure controllers immediately provide the requested pressures with very high stability thanks to the feedback loop.

- Connecting the pressure outputs to airtight reservoirs provides precise and smooth control of the sample flow into the microfluidic device.

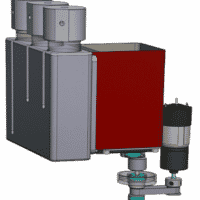

Configuration examples

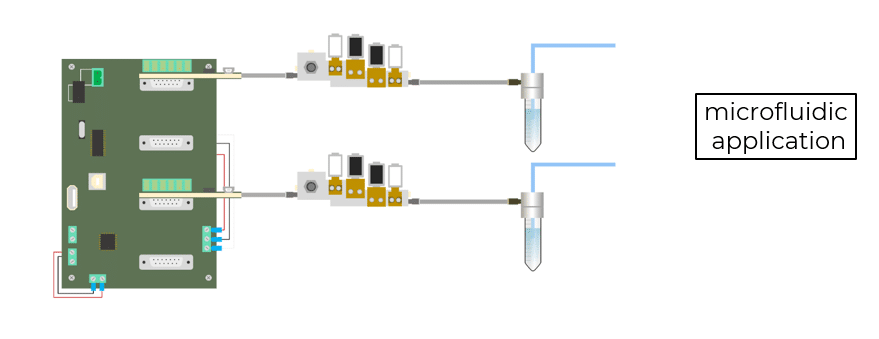

Configuration 1: 2 pressure modules. Two pressure modules consisting of a 0 – 2000 mbar and -800 – + 1000 mbar are connected to the main F-OEM board for pressurizing two fluidic reservoirs, allowing for pressure-based fluid handling. No flow sensors. No switch modules. No microfluidic valves.

Configuration 2: 2 pressure modules – 2 flow sensors. Two pressure modules consisting of a 0 – 2000 mbar and -800 – + 1000 mbar are connected to the main F-OEM board for pressurizing two fluidic reservoirs, allowing for pressure-based fluid handling. Flow sensors are connected for flow rate monitoring and control.

Configuration 3: 3 pressure modules – 1 switch module. 3 pressure modules consisting of two 0 – 2000 mbar and a -800 – + 1000 mbar are connected to the main F-OEM board for pressurizing two fluidic reservoirs, allowing for pressure-based fluid handling. A switch module is also directly connected to the F-OEM main board, allowing for connecting a bidirectional 11-port / 10-way microfluidic valve for injection or selection of up to 10 different fluids (Fluigent M-X).

Configuration 4: 1 pressure module and a electrovalve module. The electrovalve module is connected to a 3/2 valve manifold consisting of 8 valves allowing to pressurize on demand up to 8 reservoirs. The manifold is fed with one pressure controllers.

Components that can be connected to the F-OEM

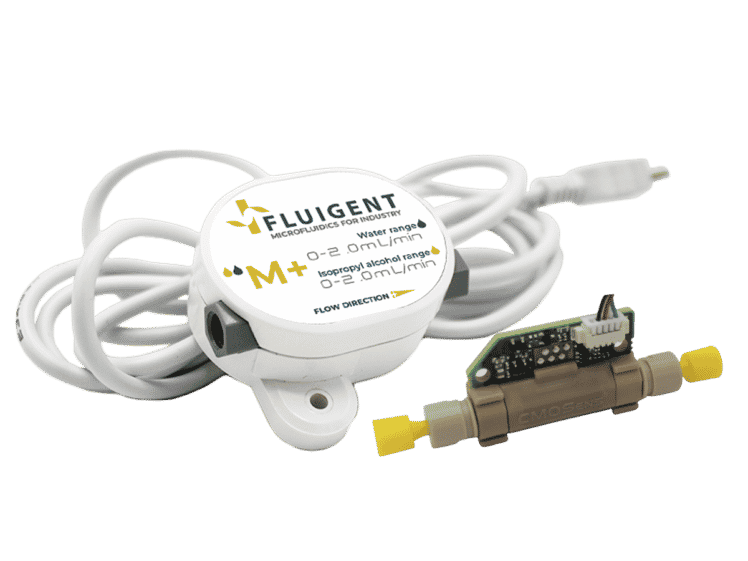

| FS series – bidirectional flow sensors (Flow sensor input integrated into the pressure control modules) | For flow-rate monitoring and control. We have a large range of flow sensors ranging from 0-1.5 µL/min to 0-5 mL/min. |

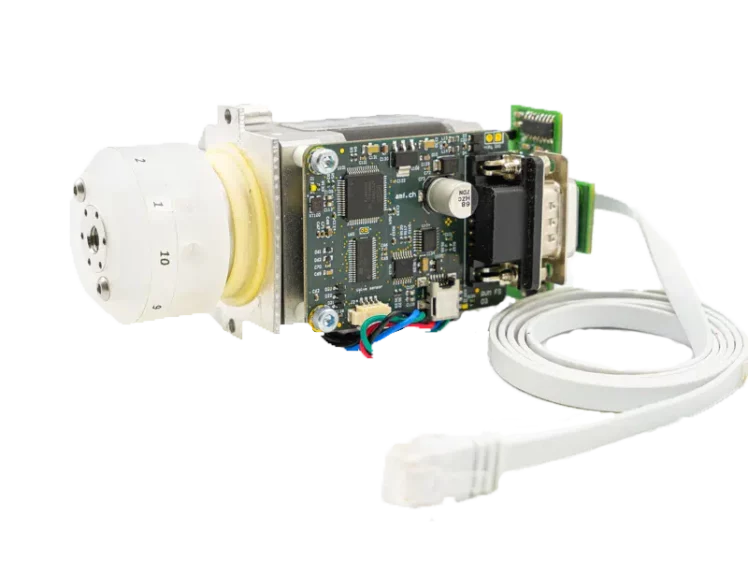

| Microfluidic valves (Directly connected to the switch control modules) | Inject and switch different flow paths. Valve and switch platform for directing the fluid flow, including bidirectional and rotary multi-port port valves – Fluigent 2-X: 3-port/2-way microfluidic valve – Fluigent MX: 11-port / 10-way microfluidic valve for injection or selection of up to 10 different fluids – Fluigent L-X: 6-port/2 position microfluidic valve. It is designed for precise sample injection or fluid recirculation in cell culture applications. |

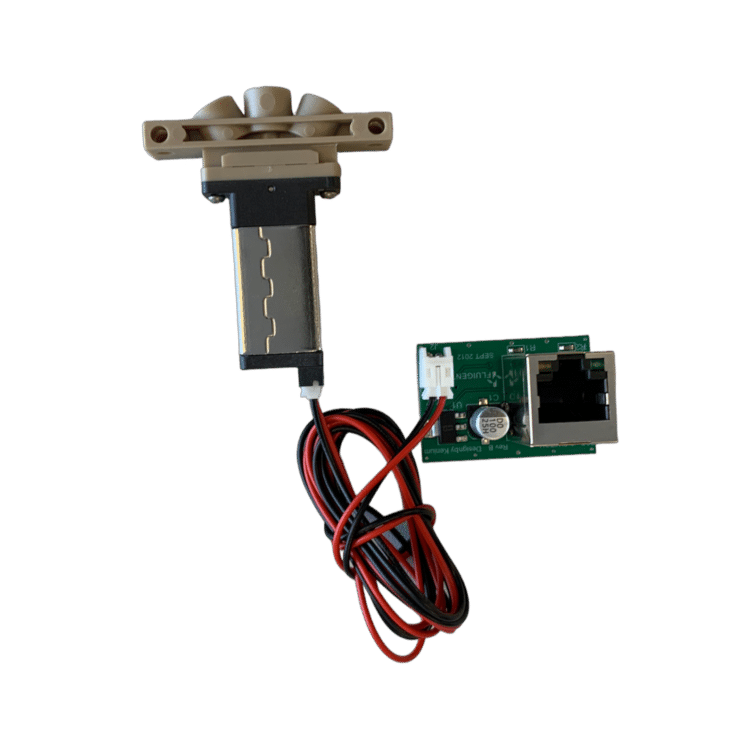

| Electrovalves Module | The F-OEM electrovalve control module was developed for connecting and actuating up to 8 x 3/2 electrovalves. This valve system efficiently manages multiple pressure valves using one or two pressure controllers. It can be used to control the state of the devices, with ON/OFF states with 0-24V with 3W power consumption. |

OxyGEN

| Get full control of the setup in a single interface with plug and play capabilities available for all desktop OS, that allows control, monitoring, and automation features. |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application: Public SDK libraries are available on GitHub for all integration into the users’ proprietary software |

| ver. 21.0.0.0 or more recent |

Expertise & resources

-

Fluigent Products Datasheets F-OEM Technical Specifications Download

-

Microfluidics Case Studies OEM Case Study: Microfluidic Drug Screening Read more

-

Fluigent products manual F-OEM User Manual Download

-

Expert Reviews: Basics of Microfluidics Key reliability indicators for OEM components to ensure long-term performance of your flow control system Read more

-

Expert Reviews: Basics of Microfluidics Key considerations for fluidic system integration Read more

-

Fluigent Products Datasheets F-OEM Datasheet Download

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

-

Expert Reviews: Basics of Microfluidics The Importance of Flow Control Stability in Microfluidics Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Pump Responsiveness in microfluidics Read more

Technologies

A Microfluidic Pressure Controller Comparison for Your Ultimate Fluid Control System

Read the technology5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read the technologyNon-Intrusive Flow Sensing Technology

Read the technologyLiquid Stirring Solutions

Read the technologyDFC, “Self-Learning” Microfluidic Flow Control Algorithm

Read the technologyCompact All-In-One Microfluidic Micropump

Read the technologyMicrofluidic Temperature Control module

Read the technologyMicrofluidics in Water analysis

Read the technology

Related products

Microfluidic OEM Flow Sensor

FS Series

See the offerRotary multi-port microfluidic valve for industry

OEM microfluidic electric rotary valve with multi-port (Fluigent M-X)

See the offerSample injection and recirculation microfluidic valve for industry

OEM 6 port 2 position valve (Fluigent L-X)

See the offer3-port/2-way bidirectional valve for industry

Fluigent 2-X

See the offer