Pump Responsiveness in microfluidics

According to the Computer Science and Communication Dictionary, responsiveness refers to the specific ability of a system or device to quickly and accurately respond to changes in input or external conditions.

Achieving high responsiveness in microfluidics is a key goal for improving the efficiency and reliability of applications in fields such as lab-on-a-chip devices, point-of-care diagnostics, and drug delivery systems. Researchers and engineers continue to explore new materials, fabrication techniques, and control strategies to enhance the responsiveness of microfluidic systems.

Introduction to responsiveness in microfluidics

Microfluidics is a field that deals with the manipulation and control of small amounts of fluids, typically at the microliter or nanoliter scale, within microscale channels and structures.

In this context, we define responsiveness as the time it takes for the pressure or the flow-rate in the fluidic reservoir to reach a given set point.

Three different times can be defined to describe the responsiveness of a microfluidic system:

- The response time of a microfluidic system

- The rising time of a microfluidic system

- The settling time of a microfluidic system

Global responsiveness is the sum of these three times.

Pump responsiveness in microfluidic is crucial because these systems are often used for precise and rapid handling of fluids for various applications, such as chemical analysis, medical diagnostics, and biological research.

The ability to control and manipulate fluids with high responsiveness enables the execution of specific tasks, such as mixing, separation, and detection, with precision and efficiency.

Microfluidic Flow Controllers display major benefits in terms of responsiveness compared to other types of fluid handling solutions such as syringe or peristaltic pumps.

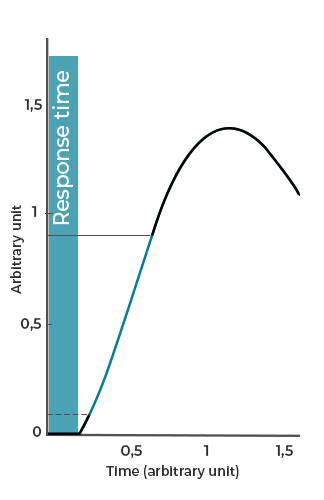

The response time of a microfluidic system

The response time is the elapsed time between the sending of a command from the computer system and the beginning of a response.

In microfluidics, response time is the duration between a command and the the start of flow (the first reaction of the microfluidic pump). When using a pressure controller, flow will start once a sufficient pressure rise occurs in the fluidic reservoir. The electrical and mechanical response times of the hardware components such as valves need to be as low as possible in order to decrease the response time.

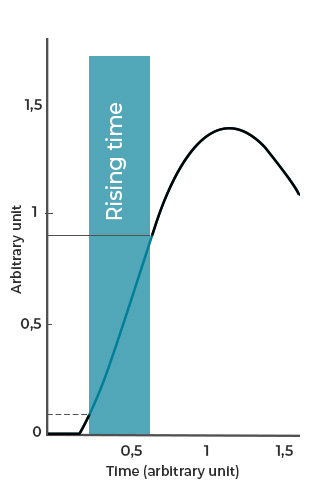

The rising time of a microfluidic system

The rising time is the time a system takes to move from a starting value to a set value.

It gives an idea of how quickly the system is able to change its value. However, it does not give any information about the fact that the setpoint is reached.

Some microfluidic devices may have an excellent response time but also provide long transient states until flow is stable. This is typical of syringe pumps with particularly highly resistant systems as well as other pressure pumps with poorly developed algorithms.

In microfluidics, the rising time is the time elapsed to go from 10% to 90% (or sometimes 95%) of the requested pressure or flow-rate.

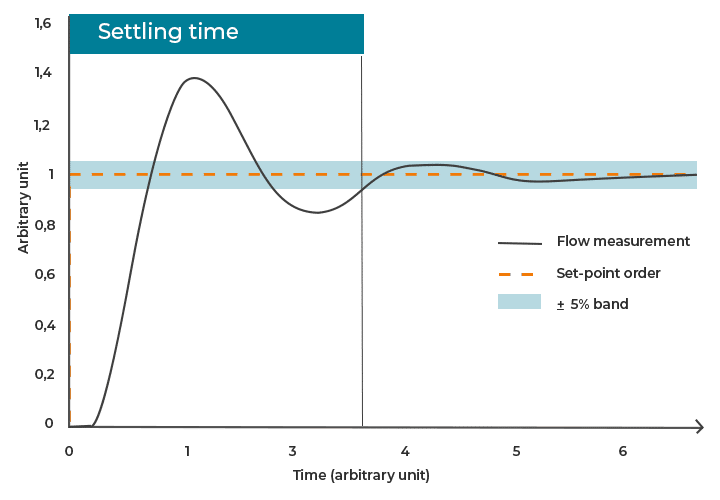

1. The settling time of a microfluidic system

The settling time is the elapsed time between the command and the moment the pressure or flow-rate gets and stays within a given range around the target value.

It gives information about how fast the system reaches the set-point in a stable way. The settling time includes the response time, plus the rising time and finally, the time needed to be within the specified error margin.

In microfluidics, the settling time is generally defined as the time needed for the response of flow to reach and remain within an error band of ±5% of the final value of the flow. This is a function of the delivery system as well as the fluidic system resistance.

2. How to improve responsiveness of microfluidic setups

Each microfluidic setup and experiment needs specific requirements, as responsiveness can be influenced by factors such as fluid properties, system architecture, and experimental conditions.

Improving the responsiveness of microfluidic pumps is crucial for achieving precise and dynamic control in fluidic systems. Here are several strategies to enhance the responsiveness of microfluidic pumps:

- Optimizing tubing and connections: when tubing used in the microfluidic system is of appropriate diameter and material, it will minimize friction and maintain a smooth flow. Extra attention should be given to leaks, kinks, or air bubbles in the tubing and connections which might hinder fluid flow.

- Minimizing dead volume: Dead volume refers to the volume of fluid that remains in the system and doesn’t contribute to the desired flow. Minimizing dead volume by using minimal tubing lengths and reducing the size of reservoirs is recommended.

- Calibration and parameters control: Regularly calibrating the microfluidic pump ensures accurate and consistent performance.

- Using high-performance valves: They can open and close quickly to achieve rapid changes in flow rates.

- Implementing feedback control systems: Integrating feedback control mechanisms to monitor and adjust pump performance in real-time can compensate for changes in environmental conditions or variations in fluid properties.

- Temperature control: Fluctuations in temperature can impact the viscosity of fluids and, consequently, the pump’s responsiveness in microfluidics. Implementing temperature control systems helps maintain a consistent environment.

- Choosing the Right Pump Type: Select a microfluidic pump that suits the requirements of your application. Different pump types (syringe pumps, peristaltic pumps, pressure-driven pumps) have varying response times and capabilities.

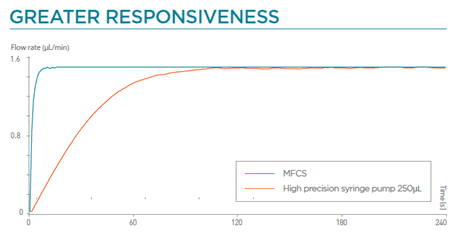

3. Advantages of pressure based fluid delivery solutions

When choosing a microfluidic instrument, it is important to not only look at the response time but also at the settling time to conduct the experiment at steady state as fast as desired.

Pressure based flow controllers present several benefits compared to other technologies. The valves used in our instruments usually have response times below 10 ms, which is lower than most motors used in syringe pumps.

Very reactive systems such as the Flow-EZTM and its FASTAB technology have very low rising and settling times. The graph below shows the response times of a MFCS flow controller with one of the best syringe pumps on the market.

The impact of the pump responsiveness in microfluidic systems

One limitation to all systems comes from the fluidic system itself. The microfluidic resistance and hydraulic capacitance (coming from the elasticity that is present in the channel walls, especially when using PDMS) induce a delay in the response in terms of flow-rate.

One can think of it this way: at the beginning, before reaching steady state, one must pump enough energy into the compliant parts of the system so that all the energy coming from the source can be dedicated to moving the fluid.

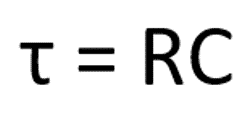

If the resistance of the system is very high, it can take some time to do that first step. It is possible to define a typical response time like its electrical analog:

Typical response times for microfluidic systems range from less than a microsecond to several seconds. To get very fast response times, the best strategy is to use very short and rigid connecting tubes.

Expertises & Resources

-

Expertise Addressing Air Bubble Issues in Microfluidic Systems Read more

-

Expert Reviews: Basics of Microfluidics Choosing the Right Microfluidic Pressure Range Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

-

Expert Reviews: Basics of Microfluidics The Importance of Flow Control Stability in Microfluidics Read more

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more

-

Expert Reviews: Basics of Microfluidics Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications Read more