Highly precise pressure control

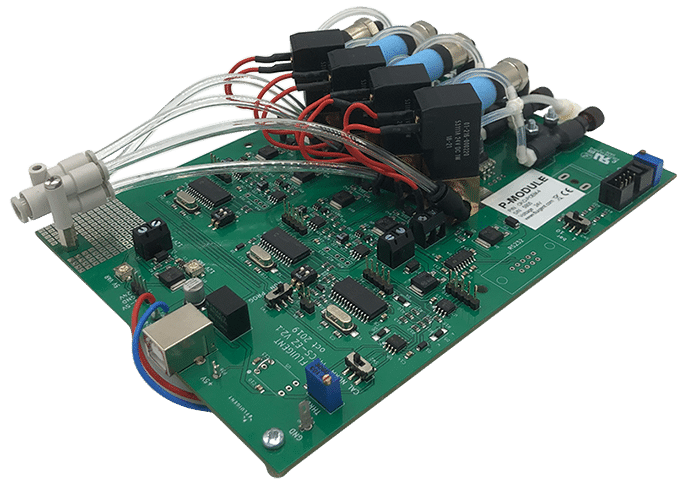

P-OEM

[XXX-POEM]- Best Seller

- Customize your own

Microfluidic Flow Management Unit

- Accurate

- Compact

Adapted to industrial uses

- Cost-effective

Reduced reagents consumption

- Versatile

Highly customizable through numerous options

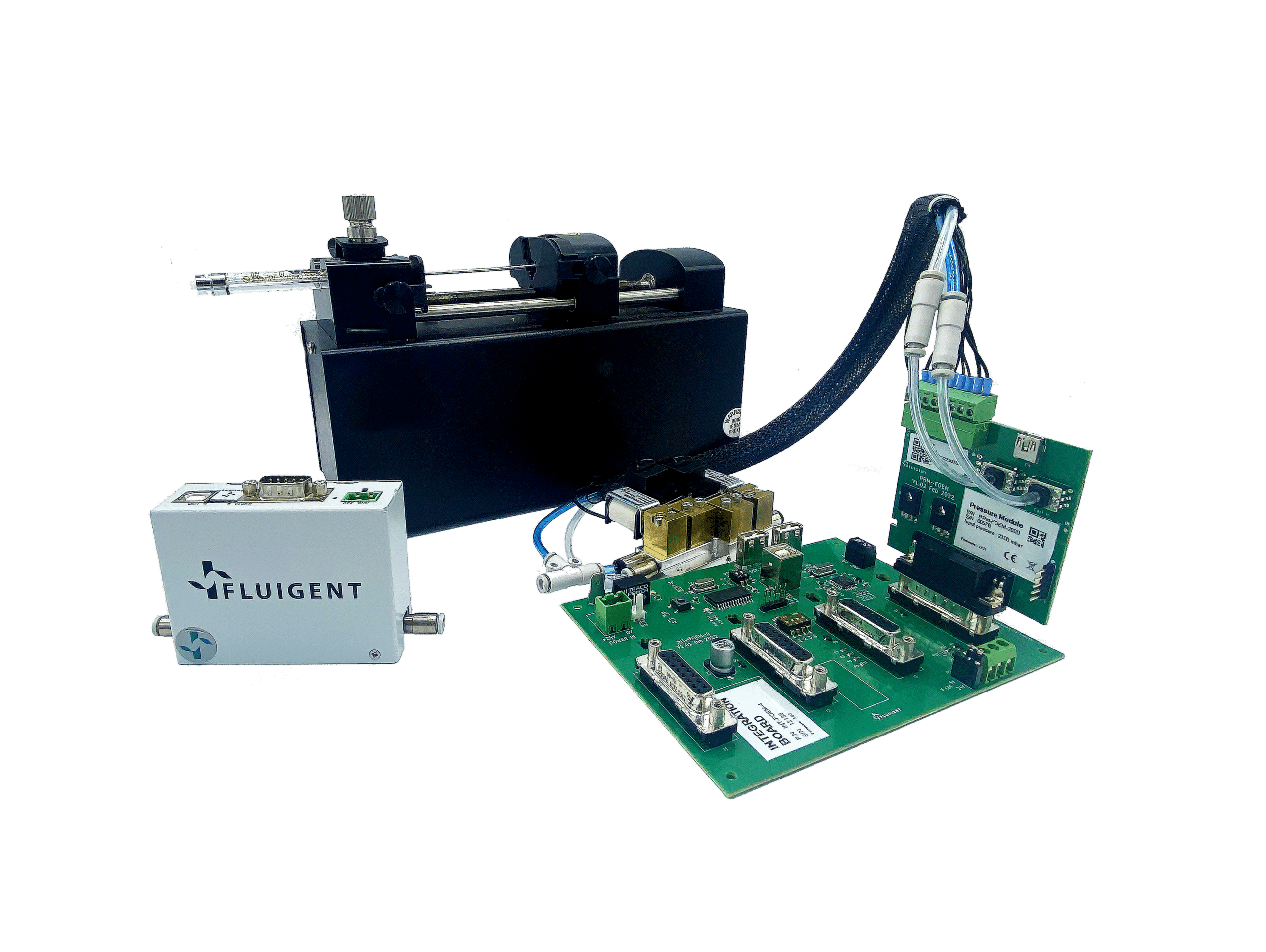

The Microfluidic Flow Manager Unit P-OEM series, using Fluigent pressure-based flow control technology, offers excellent response time and highly stable flow conditions for industrial precision microfluidic applications compared to conventional syringe pumps or peristaltic pumps.

Specifications

| Pressure range | -800 to 7000 | mbar |

| Pressure stability CV (on measured values) | < 0.1% | full scale |

| Accuracy | 0.25% | full scale |

| Repeatability Standard deviation of mean values for same pressure order | < 0.001% | full scale |

| Sensor resolution | 0.03% | full scale |

| Mechanical response time | < 10 | ms |

| Minimum settling time | 40 | ms |

| Typical settling time (from 15 mL reservoir from 0 to 2 bar) | 6 | sec |

| Typical depressurization time (from 15 mL reservoir from 2 to 0 bar) | 12 | sec |

| Operating temperature range | 10 to 80 | °C |

| Operating humidity | 0-100 | %HR |

| Digital Communication interface | RS232, USB | |

| Weight | from 300 to 450 | g |

| Dimensions : Slim board up to 3 channels | 19 x 9.5 x 6.5 | cm |

| Dimensions : Standard board up to 4 channels | 19 x 14 x 6.5 | cm |

| Dimensions : Large board up to 8 channels | 19 x 24 x 6.5 | cm |

P-OEM Available Pressure Ranges

| Pressure range | Required pressure supply | Maximum pressure supply |

|---|---|---|

| 0 to 25 mbar (0.4psi) | 500 mbar (7.25 psi) | 600 mbar (8.7 psi) |

| 0 to 69 mbar (1 psi) | 500 mbar (7.25 psi) | 600 mbar (8.7 psi) |

| 0 to 345 mbar (5 psi) | 800 mbar (11.6 psi) | 900 mbar (13.05 psi) |

| 0 to 1000 mbar (15 psi) | 1300 mbar (18.85 psi) | 1400 mbar (20.3 psi) |

| 0 to 2000 mbar (30 psi) | 2400 mbar (34.8 psi) | 2600 mbar (37.7 psi) |

| 0 to 7000 mbar (100 psi) | 7400 mbar (107.32 psi) | 7600 mbar (110.22 psi) |

| 0 to –25 mbar (-0.4 psi) | -800 mbar (-12 psi) | |

| 0 to –69 mbar (-1 psi) | -800 mbar (-12 psi) | |

| 0 to –345 mbar (-5 psi) | -800 mbar (-12 psi) | |

| 0 to –800 mbar (-12 psi) | -800 mbar (-12 psi) |

Technical downloads

Microfluidic Flow Manager Features

Designed for industrial integration

The OEM Flow Management Unit’s multi-channel design is highly compact, ranging from 1 to 4 or 5 to 8 channels. Since fluids are not in contact with the instrument, there is no routine cleaning, and cross-contamination is drastically reduced. The P-OEM Module design is cost-effective and relies on patented technologies.

A large range of pressure and flow rates

Positive/negative pressure ranges can be applied to different channels of the same microfluidic flow management unit. The optional advanced multi-channel Flow-Rate Control Module Software combined with the FS Series device makes it possible to have full control on flow rates in any coupled multi-channel configuration while keeping the benefits of a pressure actuation.

Benefits of pressure control

In addition to a more stable flow rate, the flow settling time is drastically reduced (< 1 s) in both single or multi-channel configurations, enabling significant reagent cost-savings and saving time.

Related applications

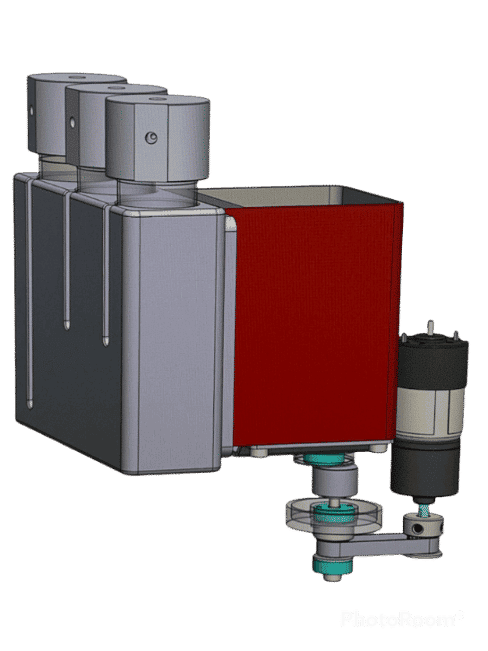

A tailor-made P-OEM Flow Manager

As each Microfluidic Flow Management Unit is made on-demand, it can fit your custom requirements in the most compact fashion, all integrated and ready-to-use. We work closely with our customer to build a definition file that summarizes the features chosen among:

- Number of channels

- Pressure range of each channel (that can be defined from the flow rates needed and the physical properties of the set up)

- Dimensions of pneumatic tubing at the inlet and the outlet

- Choice of communication interface

- Flowboard integration for flow rate control with our OEM flow sensors

- Switchboard integration for coupling with our OEM valves

- Purge valve

- Pressure source

- Power supply

And other options (please contact us for more information).

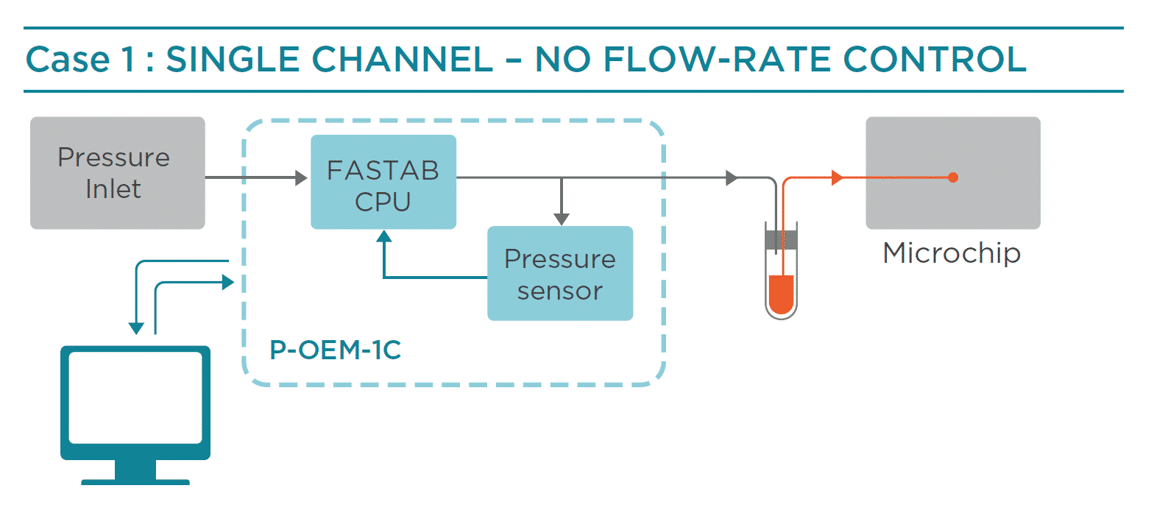

How can the Microfluidic Flow Management Unit be used?

Example 1: Custom P-OEM module consisting of a single channel. Only pressure control is available here.

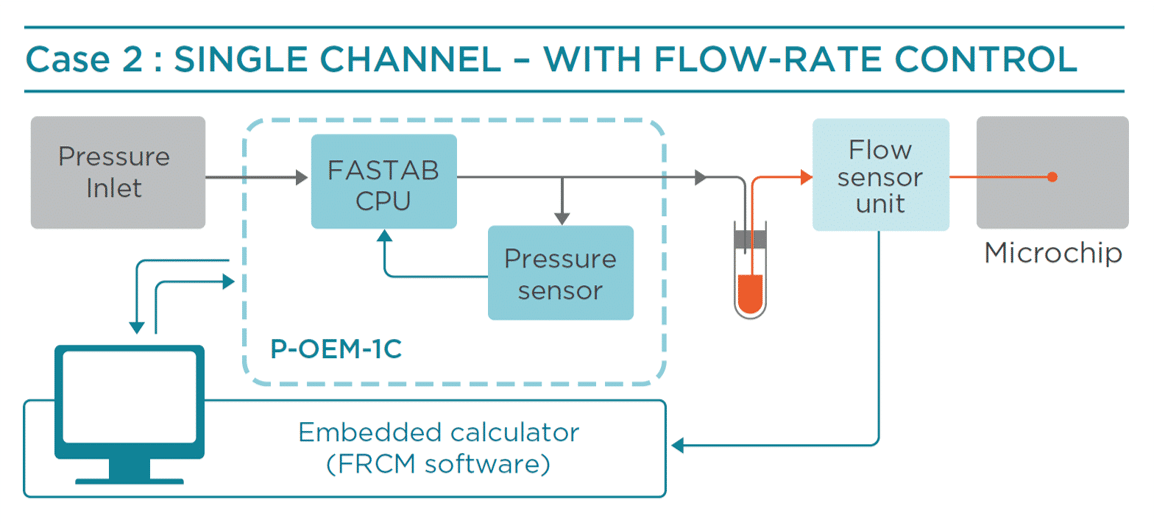

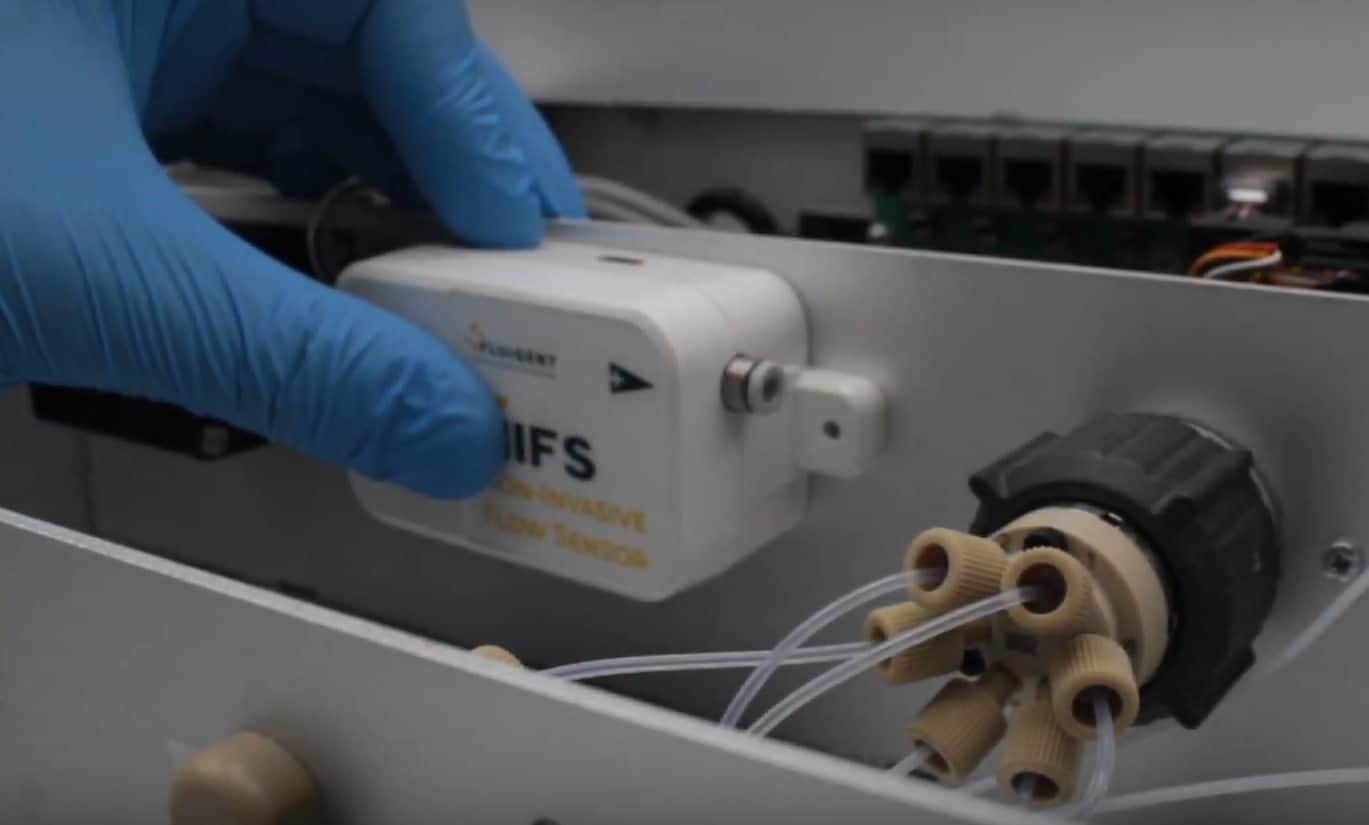

Example 2: Custom P-OEM module consisting of a single channel. A flow sensor from our FS series is added into the fluidic system, allowing for flow rate control.

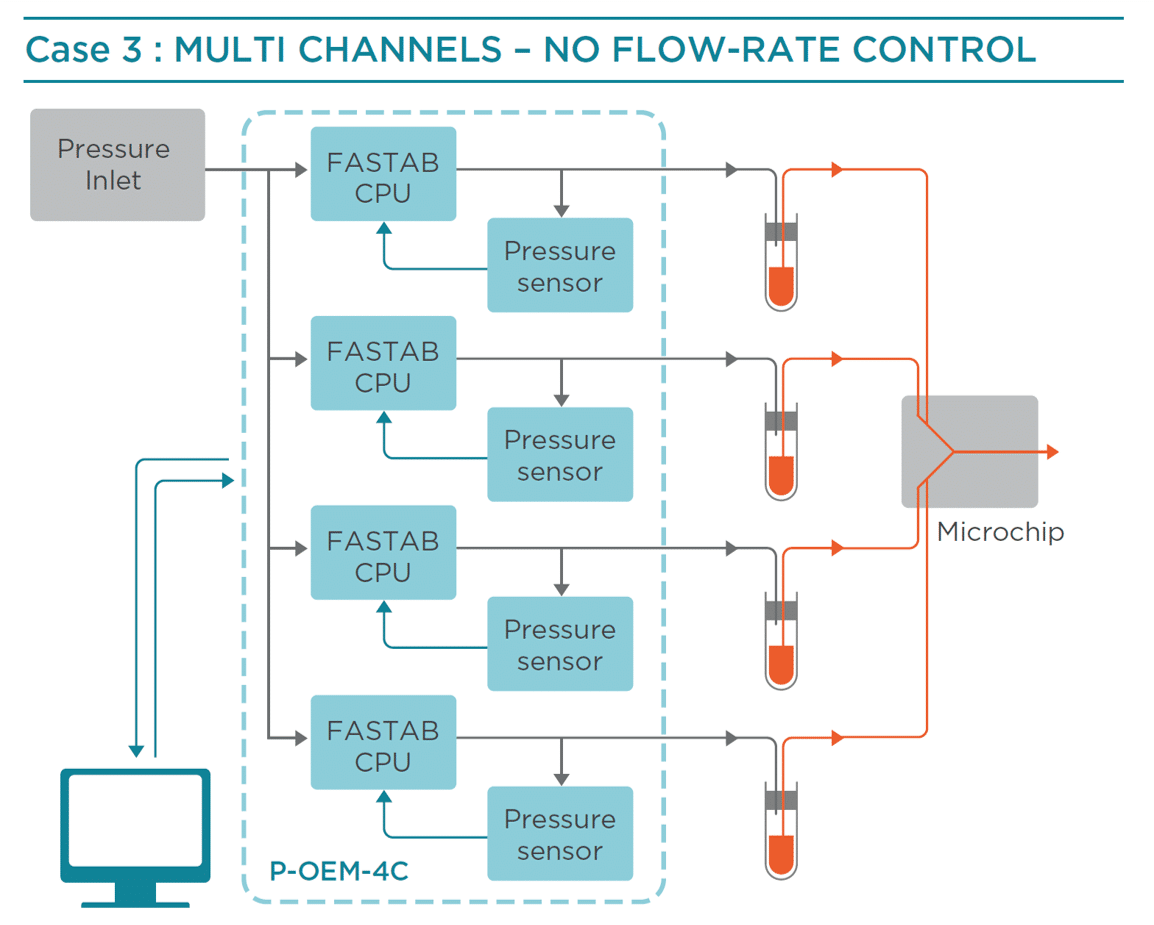

Example 3: Custom P-OEM module consisting of four channels. Only pressure control is available here.

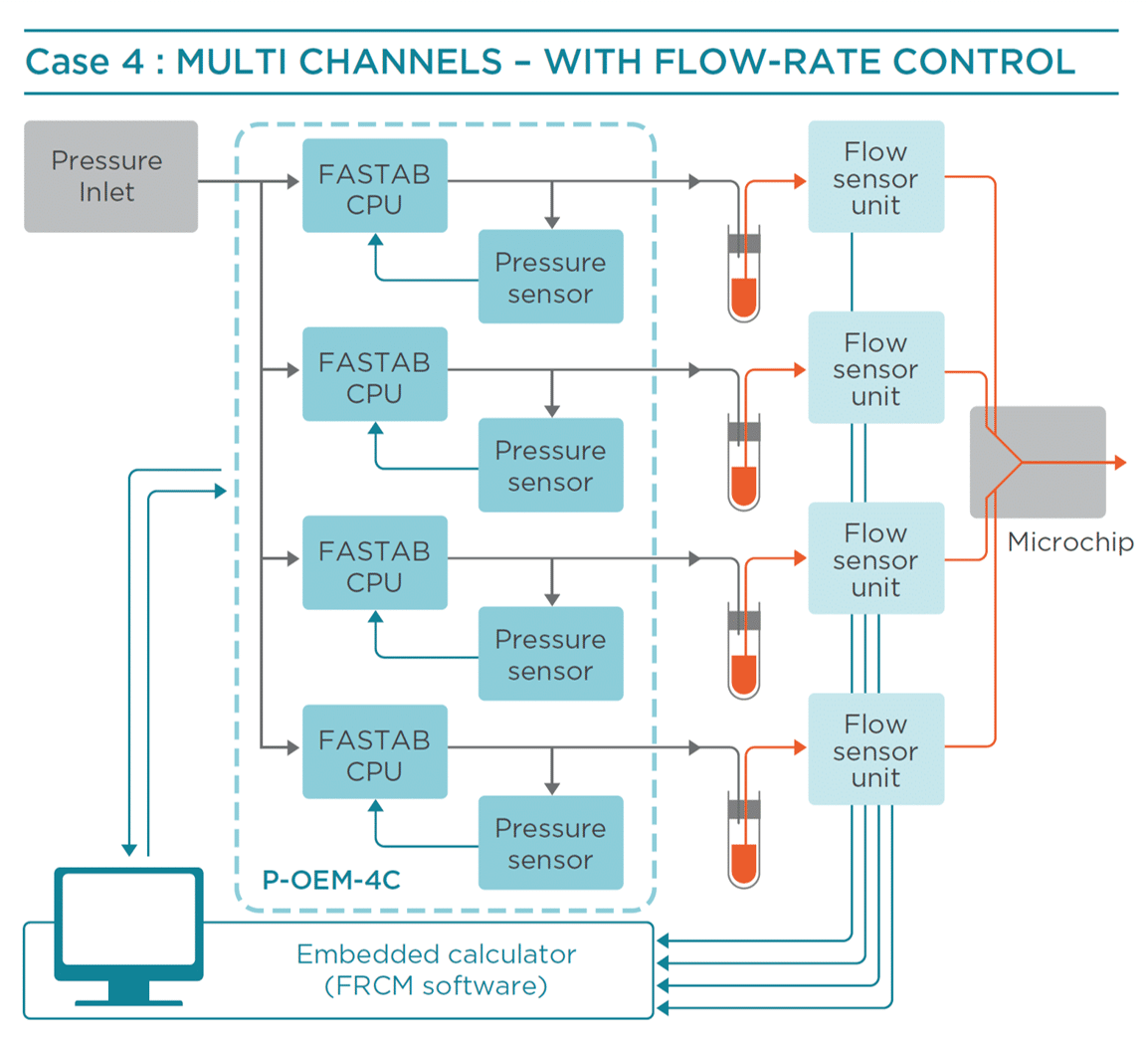

Example 4: Custom P-OEM module consisting of four channels. For flow rate control, a flow sensor from our FS series is added on each line of the fluidic system, (four flow sensors in total).

Can industrial pressure controllers be used to monitor multiple fluids at different flow rates?

Context

An industrial device manufacturer partnered with Fluigent to transform their benchtop water testing device into a mobile device.

Solution

The compact and highly customized dual channel P-OEM module is a completely mobile laboratory that limits human involvement.

Result

The compact size and stable performance of the resulting suitcase-sized microfluidic flow manager unit allows for testing at various points of need.

Context

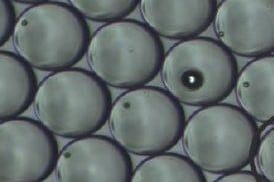

A digital PCR device manufacturer needs to achieve improved monodispersity and control for their next-generation device.

Solution

The P-OEM microfluidic flow management unit, through its accuracy, allowed them to reach the specification needed to achieve optimum fluid delivery and treatment.

Result

The new generation of devices has improved performance with a more consistent size and frequency of droplet generation. The demand for the new generation devices has scaled up since.

Context

An international Organ-on-a-Chip platform developer required a flow control solution for their new drug testing platform.

Solution

Based on the development of a recirculation protocol with the client, the P-OEM module was optimized for fast response time and smooth sine wave generation.

Result

The protocol implemented in the microfluidic flow management unit reproduces lung functionality (up to 90 cycles/min).

OxyGEN

Control in real-time, protocol automation, data record and export |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 21.0.0.0 or more recent |

Expertise & resources

- Expert Reviews: Basics of Microfluidics

Key considerations for fluidic system integration

Read more - Fluigent Products Datasheets

P-OEM Datasheet

Download - Expert Reviews: Basics of Microfluidics

Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications

Read more - Microfluidic Application Notes

Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications

Read more - Fluigent Products Datasheets

P-OEM Technical Specifications

Download

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more

DFC, “Self-Learning” Microfluidic Flow Control Algorithm

Read more

Liquid Stirring Solutions

Read more

Microfluidic Temperature Control module

Read more

Non-Intrusive Flow Sensing Technology

Read more