Water in Fluorocarbon Oil Emulsions

Water in fluorocarbon oil emulsions (W/FO) are widely used in R&D environments such as Drop-Seq and RNA-Seq, primarily to achieve compartmentalization of biological samples within droplets and prevent egress of the material to the surrounding media. Of particular importance is the ability to produce high-quality, monodisperse droplets and the ability to do so reproducibly and at a high production rate.

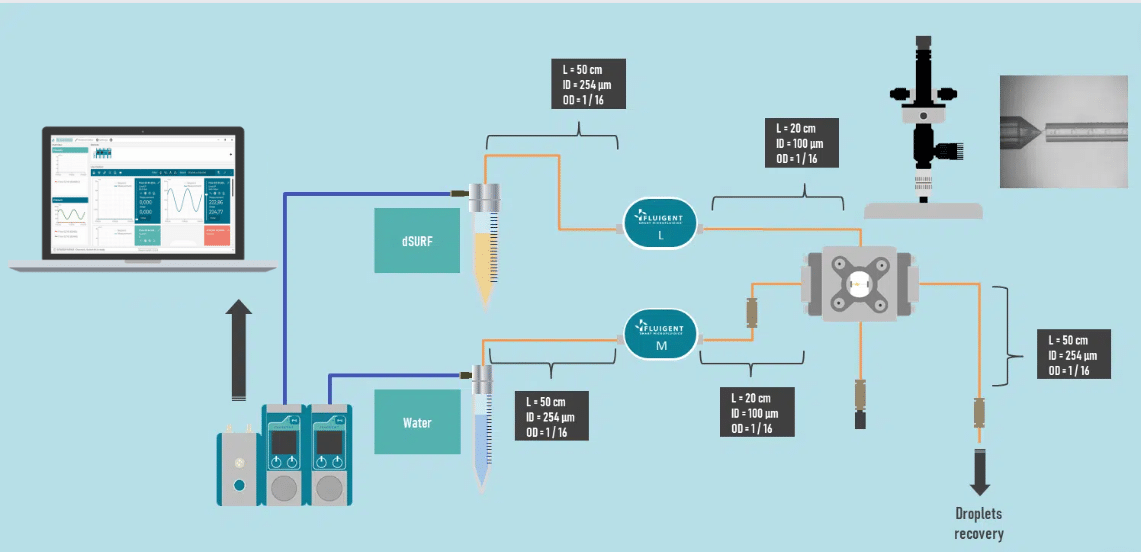

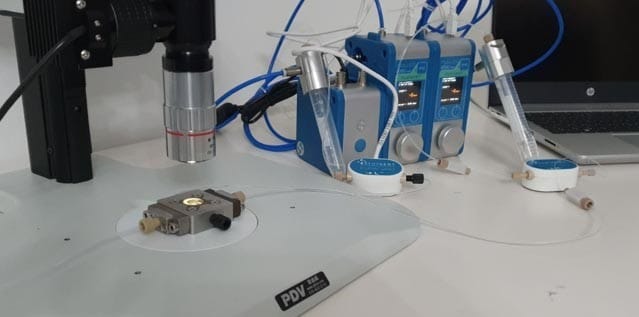

The combination of Fluigent pressure pump units and Raydrop microfluidic devices developed and manufactured by Secoya enables the smooth fluid delivery, precision flowrate control, automation, and reproducibility necessary to generate high-quality reverse fluorocarbon oil emulsions.

We kindly thank of SMALL Biotechnologies for this collaboration.

Why is encapsulation in droplets a good alternative for compartmentalizing reagents?

Microfluidic devices have the potential to revolutionize high-throughput screening because they enable assays to be performed within liquid volumes as small as the picoliter scale. In order to conduct millions of individual small-volume reactions, it is necessary to compartmentalize reagents.

This can be achieved by fabricating microfluidic devices with nanoliter-scale chambers. However, such devices are rather complex, they are limited in the number of compartments that can be used simultaneously, and they cannot be reused without an intermediate cleaning step (1).

A much easier and more robust alternative is to encapsulate reagents in droplets of water surrounded by fluorocarbon oil. Droplets are especially useful for biological assays, as the individual picoliter-scale microvessels can contain small numbers of molecules or cells which can nevertheless be at biologically relevant concentrations (2).

Avoiding cross-contamination between drops when using reverse fluorocarbon oil emulsions

As compared to hydrocarbon oils, water in fluorocarbon oil emulsions also result in less swelling of polydimethylsiloxane (PDMS), a commonly used material for fabricating microfluidic channels.

Finally, fluorocarbon oils have good solubility for gases, (2) which is necessary for the viability of encapsulated cells. However, drops are prone to coalesce, so for any drop-based application, surfactants are critical for ensuring that drops remain stable. Moreover, surfactants must ensure that biomolecules do not adsorb to the interface.

What are the possible applications?

Potential applications can be found in organ administration of drugs and other agents. The agents to be delivered (which include surfactants, antibodies, antioxidants, steroids, nucleic acids, vasoactive agents, and cytotoxic drugs) are usually not soluble in fluorocarbons in significant amounts. Water in fluorocarbon oil emulsions allow for uniform, reproducible distribution of the agents, including to the deeper parts of the organs.

How to generate reverse fluorocarbon oil emulsions

Reagents

Droplet Phase: Water (Mili Q)

Continuous phase: dSurf

| Reagent | Supplier | Catalogue number | CAS Number |

| Water | Ultrapure 18.2 MΩ – cm | – | 7732-18-5 |

| dSURF | Fluigent | DR-RE-SU-12 | – |

Microfluidic Setup

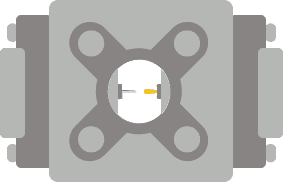

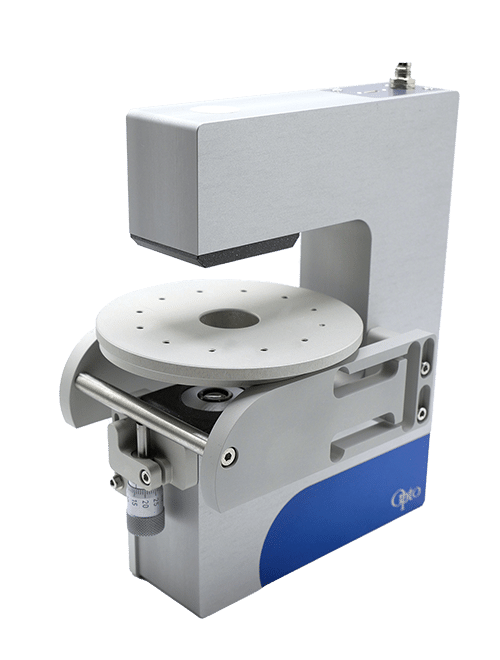

The microfluidic setup was composed of:

Protocols steps

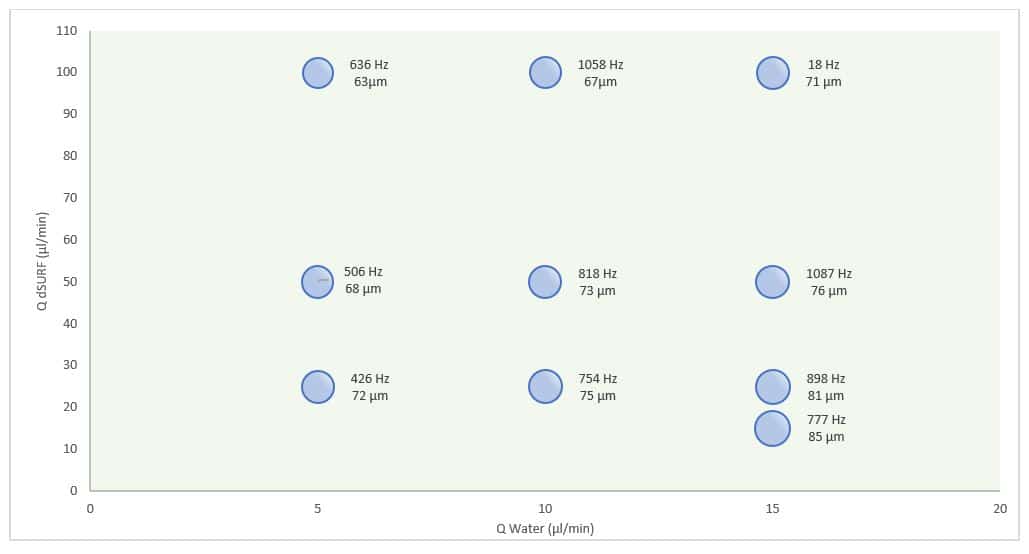

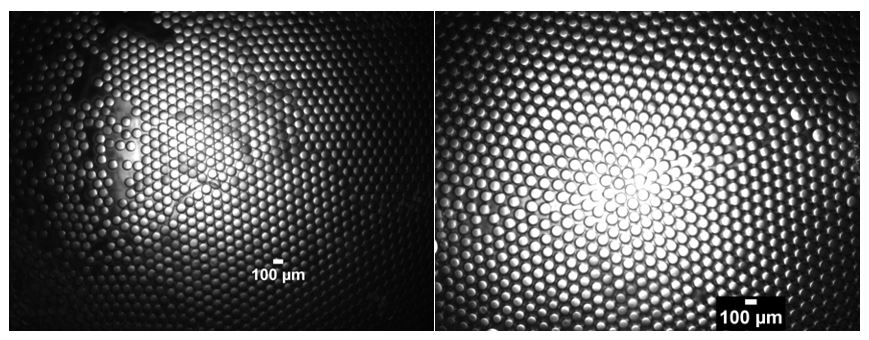

Droplets obtained after generating Water in Fluorocarbon Oil Emulsions

| Continuous phase flowrate (μl/min) | Droplet phase flowrate (μl/min) | Droplet diameter (μm) | Production rate (Hz) |

| 100 | 5 | 63 | 636 |

| 100 | 10 | 67 | 1058 |

| 100 | 15 | 71 | 1334 |

| 50 | 5 | 68 | 506 |

| 50 | 10 | 73 | 818 |

| 50 | 15 | 76 | 1087 |

| 25 | 5 | 72 | 426 |

| 25 | 10 | 75 | 754 |

| 25 | 15 | 81 | 898 |

| 15 | 15 | 85 | 777 |

Conclusion

Fluigent pressure-based flow controller units and a Raydrop microfluidic device were successfully used to generate high-quality, monodisperse water in fluorocarbon oil emulsions. The droplet size was controlled in the range of 63 – 85 μm by adjusting the flow rates of the continuous and dispersed phases. Peak stable droplet production rate was recorded for 71 μm droplets at 1334 Hz. The production techniques developed here can use a wide range of compartmentalization applications such as Drop-Seq and RNA-Seq.

References

- Griffiths AD, Tawfik DS. Miniaturising the laboratory in emulsion droplets. Trends Biotechnol. 2006 Sep;24(9):395-402. doi: 10.1016/j.tibtech.2006.06.009. Epub 2006 Jul 14. PMID: 16843558.

- Song H, Chen DL, Ismagilov RF. Reactions in droplets in microfluidic channels. Angew Chem Int Ed Engl. 2006 Nov 13;45(44):7336-56. doi: 10.1002/anie.200601554. PMID: 17086584; PMCID: PMC1766322.

- Lipinski CA, Lombardo F, Dominy BW, Feeney PJ. Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv Drug Deliv Rev. 2001 Mar 1;46(1-3):3-26. doi: 10.1016/s0169-409x(00)00129-0. PMID: 11259830.