How to choose a microfluidic chip

This review provides guidelines on how to choose the right microfluidic chip for your application.

What is a microfluidic chip?

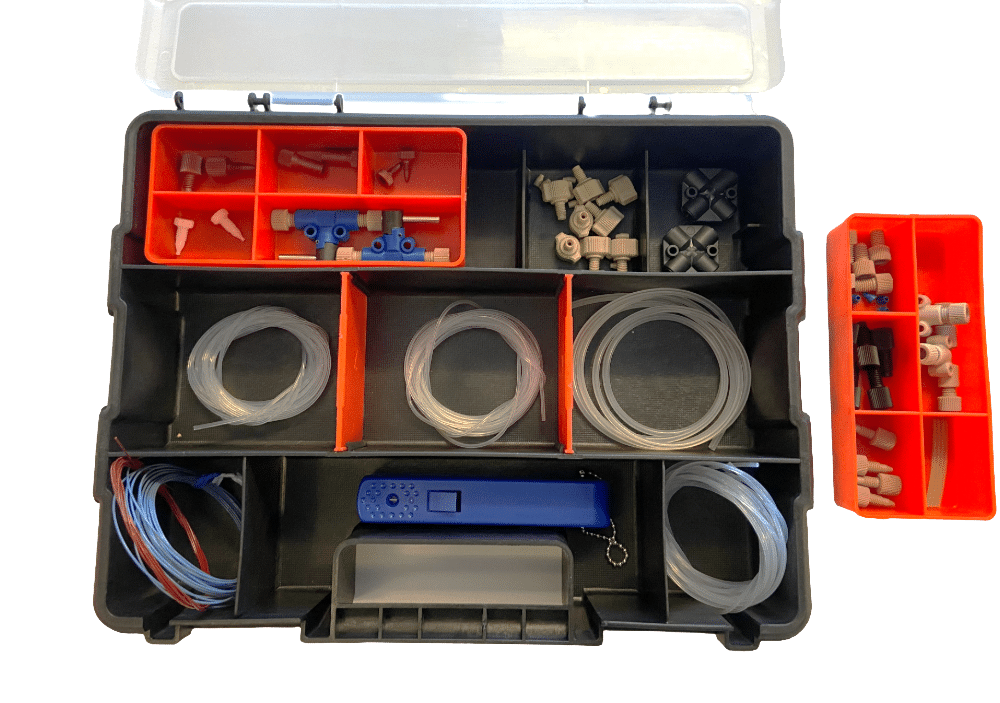

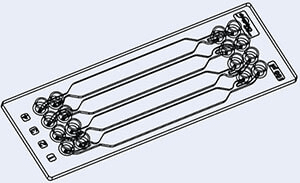

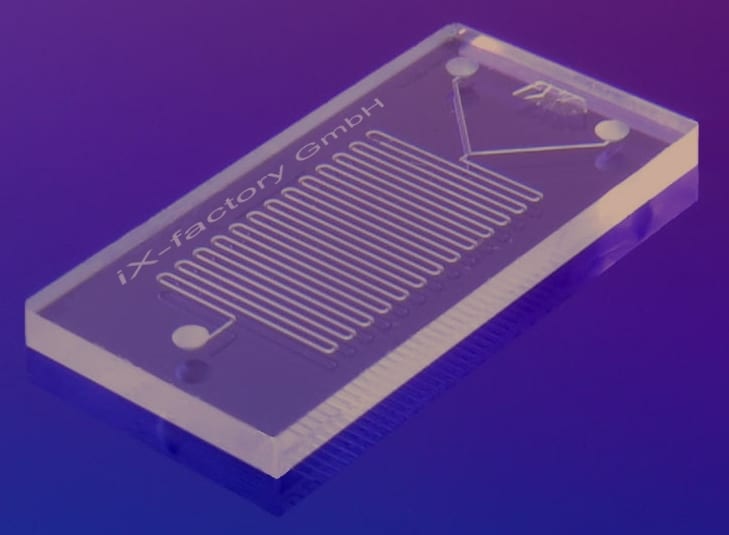

Microfluidic chips are the devices used in microfluidic studies in which micro-channels have been molded or patterned. The micro-channels forming the microfluidic chip are connected together in order to allow fluids to pass though different channels, going from one place to another. This network is connected to the outside environment through inlet and outlet ports. The liquids or gases are injected, managed or removed from the microfluidic chip with passive ways or external active systems (pressure controller, syringe pumps or peristaltic pumps). The channels may have different inner diameters, typically ranging from 5 to 500 µm (read our article about microfluidic tubing), and their network must be specifically designed for the application and the analysis you want to carry out (cell culture and organ-on-a-chip , DNA analysis, lab-on-a-chip, microfluidic droplets. Therefore, microfluidic chips allow the integration of several functions that generally require an entire laboratory in a single micro-sized device.

Why use microfluidics?

Microfluidic devices such as chips have many advantages as they:

- Decrease sample and reagent consumption.

- Portability and flexibility of device design

- Direct coupling to downstream analysis systems

- Increase automation capabilities: multi-step reactions requiring a low level of expertise

- Excellent data quality and substantial parameter control

- Minimize analysis time

Such devices allow applications in many areas such as medicine, biology [1], chemistry and physics. Why should you be attentive when you choose a microfluidic chip? The materials for making microfluidic chips play an important role and should also present the appropriate properties desired by the application.

Material used in microfluidic devices

Most common material used in microfluidics reviewed

Three types of materials are commonly used to create microfluidic chips: silicon, glass and polymers.

Silicon and glass were the original materials first used for microfluidic applications, however as new technological advances occurred, new materials including polymer substrates, composites or paper were used.

For some experiments, a combination of these three chip materials is needed to create the desired microfluidic chip properties. Each material has its specific chemical and physical characteristics. The choice of the material depends on:

- the needs and conditions of your applications.

- the type of solvent, samples, buffers and their polarities

- the design.

- the budget.

Typically, for research purposes, the materials used generally prioritize versatility and performance of the device whereas in commercialization, cost of production, reliability and ease of use are placed above.

Why should you choose a microfluidic chip in silicon?

The first material used in microfluidics was silicon, even though it was quickly replaced by glass and then polymers. Silicon was first selected due to:

- its resistance to organic solvents

- the ease in metal deposition

- superior thermal conductivity

- surface stability

However, a microfluidic chip in silicon is not easy to handle because of its hardness, which doesn’t make it easy to create active microfluidic components such as valves and pumps. Another drawback appears when performing optical detection as silicon shows significant optical opacity.

Combined with a higher price than other materials, silicon microfluidic chips are not widely used in microfluidic studies.

Why should you choose a Microfluidic chip in glass?

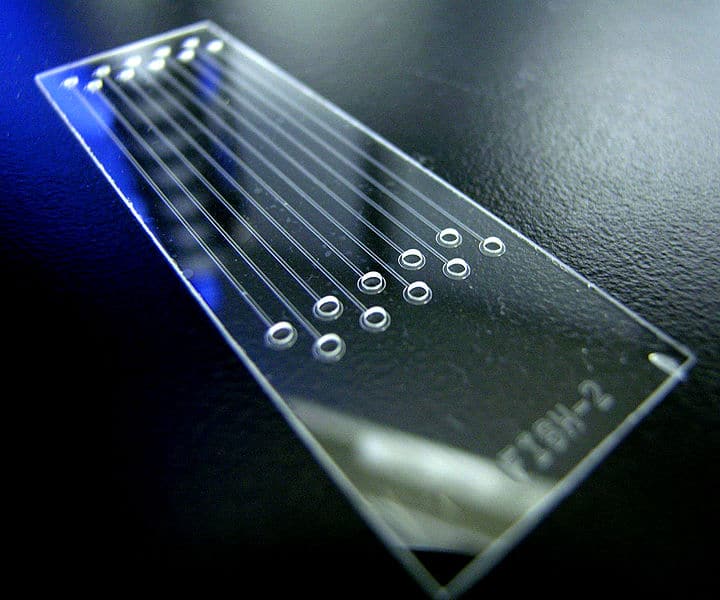

After the initial focus on silicon, glass was used to build microfluidic chips. Optically transparent and electrically insulating, glass is an amorphous material. This material is generally processed with standard photolithography or wet/dry etching methods. Unless special etching techniques are employed, etched glass channels have rounded sidewalls.

Glass shares with silicon the same advantages mentioned above for microfluidics experiments. But one can add:

- Well-defined surface chemistries

- Superior optical transparency

- Excellent high-pressure resistance

- Biocompatibility

- Chemically inert

- Allows for efficient coatings

Glass is compatible with most biological samples.

A microfluidic chip in glass is not permeable to gas and has relatively low non-specific adsorption. Thus, it is compatible with biological samples, but it cannot be used for long-term cell culture.

One major application of glass microfluidic chips is capillary Electrophoresis (CE). This cheaper method is more convenient than standard CE since it’seasier to perform parallel analysis, and it also offers valve-free injection by directly utilizing the electro osmotic flow, which can separate analytes within seconds.

Other typical applications include on-chip reactions droplet formation, solvent extraction and in situ fabrication.

These make it a material of choice for many applications. The main hurdle with this material remains its hardness and its rather high cost, even though prices have been significantly reduced. These limitations are the origin to the development of alternative low-cost chip materials that can be easily fabricated and are compatible for broader biological applications.

Why should you choose a Microfluidic chip in polymers?

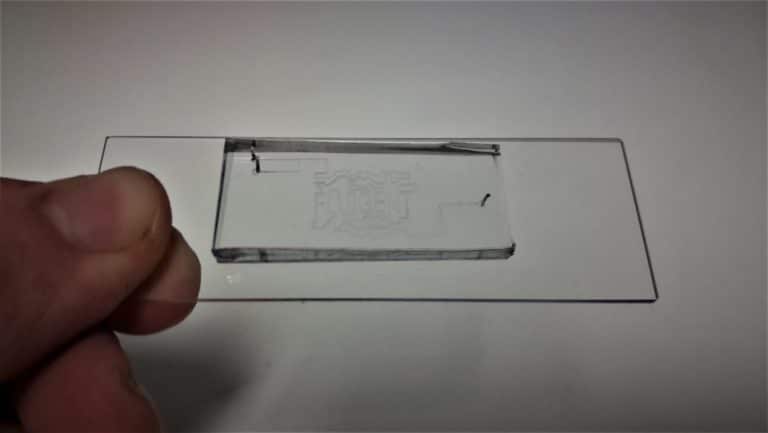

Polymer-based microfluidic chips were introduced several years after silicon/glass chips. The vast variety of polymers grants great flexibility in choosing a suitable material with specific properties.

Polymers are a promising alternative to glass and silicon as they are easy to access, cheaper, robust and require faster fabrication processes. Many polymers can be used to build chips:

- Polystyrene (PS)

- Polycarbonate (PC)

- Polyvinyl chloride (PVC)

- Cyclic Olefin Copolymer (COC)

- Polymethylmethacrylate (PMMA)

- Polydimethylsiloxane (PDMS)

PDMS is the material of choice for fast prototyping microfluidic devices. PDMS chips are commonly used in laboratories, especially in the academic community due to their low cost and ease of fabrication. The main advantages of PDMS microfluidic chips include:

- Oxygen and gas permeability, can be advantageous for oxygen and carbon dioxide transport in cellular studies and long-term experiments

- Optical transparency

- elastomeric properties

- Robustness

- Non toxicity

- Biocompatibility

- Complex microfluidic designs can also be created by stacking multiple layers.

- Relatively low cost

One of the main drawbacks of PDMS chips is its hydrophobic nature. Consequently, introducing aqueous solutions into the microchannels is difficult and hydrophobic analytes can adsorb onto the PDMS surface, thus interfering with analysis. There are now PDMS surface modifications available to avoid issues due to hydrophobicity. Another main issue of PDMS chips is that they are not suitable for high pressure operation as it can alter channel geometry and be prone to leaking at elevated pressure. Bubble formation from passage of gas through PDMS can be problematic.

PDMS is now the most commonly used microchip material.

Key information to keep in mind when choosing a suitable microfluidic chip

- Transparent materials are favored to enable optical observation/analysis

- Materials must be biocompatible for life science applications

- Most of the chips need surface treatment to adapt their surface properties to the application and to limit non-specific adsorption

Polymeric materials for a suitable microfluidic chip

Since its introduction, microfluidics keeps advancing along with technology, and expanding its fields of application. Biological and medical applications are a major focus of current research along with other areas. In terms of materials and functions, while glass and silicon have important uses, polymeric materials have become the material of choice in this field. As described above, they each have their own advantages and disadvantages. Though PDMS is still the more commonly used microfluidic material substrate, new materials and composites presenting interesting features are created in order to make them more adapted to mass production with lower pricing and greater adaptability.

REFERENCES

[1] Beebe, D. J., Mensing, G. A., & Walker, G. M. (2002). Physics and applications of microfluidics in biology. Annual review of biomedical engineering, 4(1), 261-286.

Related Expertises

- Interviews & Testimonials

Panel Discussion & Interviews – Microfluidics & Organ-On-Chips

Read more - Expert Reviews: Basics of Microfluidics

Mastering Microfluidic Chips: An In-Depth Definition

Read more - Expert Reviews: Basics of Microfluidics

What is the history of microfluidics?

Read more

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more- Expert Reviews: Basics of Microfluidics

Choosing the Right Microfluidic Pressure Range

Read more

White paper: Organ on Chip

Read more- Expert Reviews: Basics of Microfluidics

Microfabrication of Microfluidic Chips: Materials and Methods

Read more - Expert Reviews: Basics of Microfluidics

Application of microfluidic chip technology

Read more