Pressure & Flow Rate Calculator

In a microfluidic set-up, there are two kinds of flow resistances: external flow resistances (tubing and fittings) and internal flow resistances (microchip design). Together, they determine the pressure needed to achieve the desired flow rate.

Why is flow rate so important in a microfluidic system?

Flow rate is an essential parameter in a microfluidic experiment, if not the most important flow-related parameter. It can be defined as the volume of solution that flows though the cross-section of the channel during one time unit. The flow rate influences the volume of solution needed for the experiment, but also the dynamics of the system, such as diffusion, particle speed, or the flow regime. In addition, the shear stress applied in the system, which has a strong impact on cellular viability and behavior, is directly related to the flow rate.

More generally, controlling the flow rate in a microfluidic system allows biologists to more closely approximate in-vivo conditions, which is critical for organ-on-a-chip experiments in particular.

Fluigent flow meters are designed to allow users to accurately measure the flow rate in a microfluidic system, and to give them the ability to directly control it.

How do I calculate flow rate?

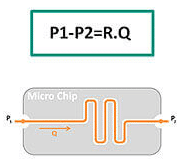

In a microfluidic system, viscous forces predominate over inertial forces, leading to laminar flow behavior and simplification of the Navier-Stockes equations. In this context, the flow rate is directly linked to pressure and flow resistance. The relationship is given by the following formula:

To fully characterize a microfluidic system, it is therefore important to determine the working flow rate range and the associated pressure range. This will help in selecting the most appropriate flow controller model.

Determining the system’s flow resistance is a necessary step to accurately calculate flow rate and pressure. It combines the resistance caused by the tubing and the resistance induced by the microfluidic chip. It is mainly dependent on the liquid viscosity and the tubing and channel geometries.

Our Flow Rate to Pressure Calculator helps users to determine the pressure range and flow rate they need to achieve the best results.

With:

- Mean flow-rate Q

- Pressure drop (change in P)

- Microfluidic resistance R

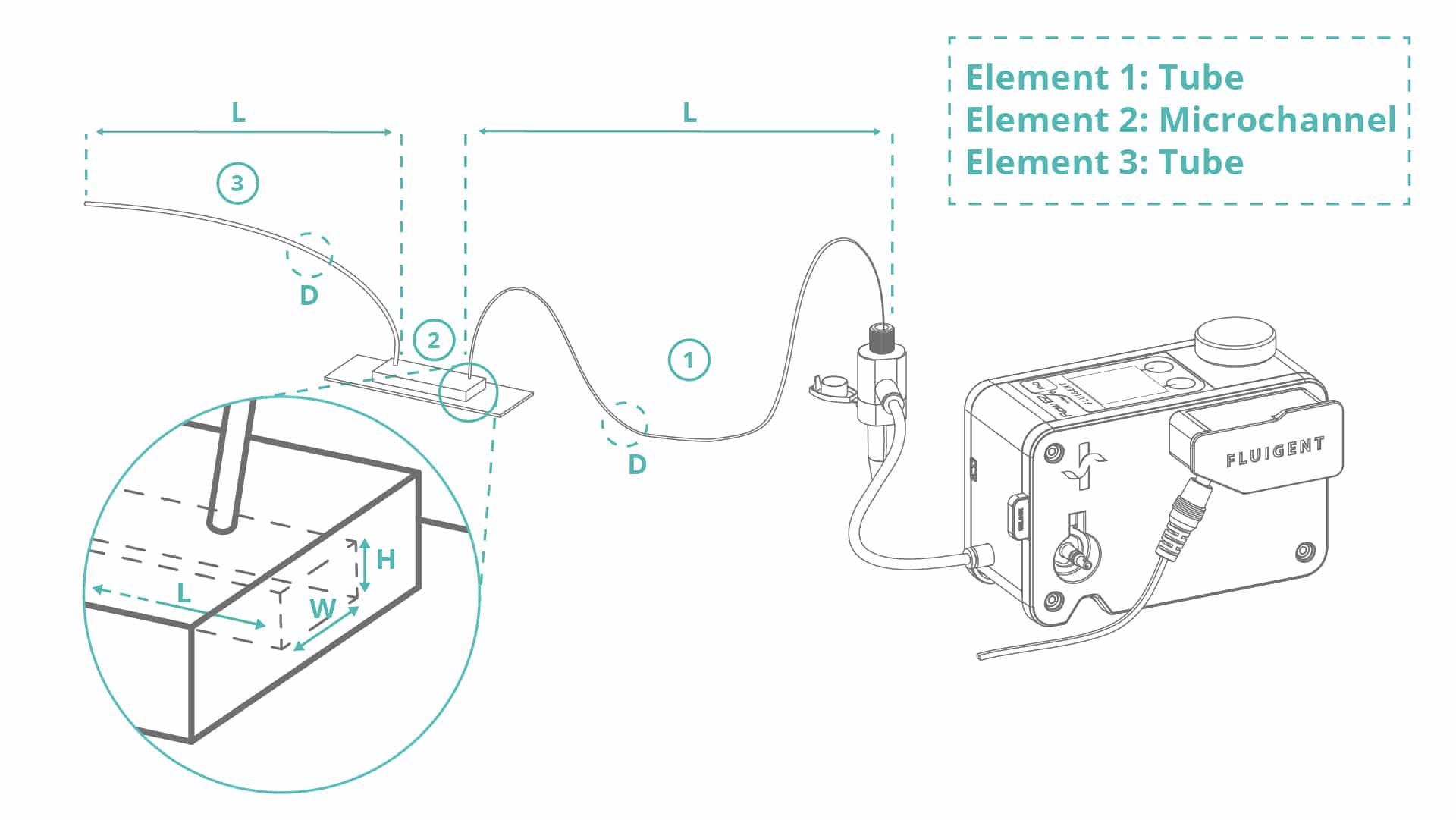

To help our users choose the right instrument, Fluigent has designed a flow rate calculator to estimate the resistance of most microfluidic setups. Users can determine which pressure range to work with and the recommended microfluidic pump by detailing their setup below.

Users must know the geometry of the chip, the type of control applied to the microfluidic experiment, the dimensions of the chip channels, and the dimensions of the tubing and control values. With this data, the Flow Rate to pressure Calculator will recommend a range of pressures and flow rates to work with.

Chip Geometry

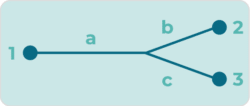

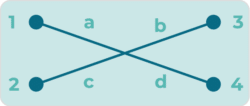

Select the design matching the microfluidic chip used in the experiment. If no chip design is appropriate, please select the closest according to the number of sections.

Straight Channel

Y Network

Cross Network

H Network

Control Type & Unit

Select the type of control applied to the microfluidic experiment, flow rate or pressure, and the units to display the entry and results in. Enter the dynamic viscosity of the fluid used in the microfluidic experiment. Note that the dynamic viscosity of water (at 20°C) is 1 mPa-s.

Straight Channel

Y Network

Cross Network

H Network

Chip Channels Dimensions

Enter the chip channel dimensions in the Flow Rate Calculator. Each microchip design has a different number of sections. Use the channel identification letters (a to e) in the SETUP TYPE panel above to identify each channel section for use in the calculator. The resistance is then calculated for each channel section on the chip.

Channel

Tubing Dimensions

Enter the tubing dimensions and the length of each section. Tubing may be from or to the chip; refer to the introductory image for explanation. Use the flow inlet and outlet identification numbers (from 1 to 4) in the SETUP TYPE panel above to identify the tubing section for use in the calculator. The resistance is then calculated by the Flow Rate Calculator for each tube section in the setup.

Tubing

Control Values

Depending on the control type selected above, enter the pressure or flow rate values for each tubing or microchip channel. The flow rate or the pressure is calculated and displayed. Refer to the SETUP TYPE panel to identify the tubing or microchannel section.

Control

Product Selection

Related Resources

- Expert Reviews: Basics of Microfluidics

Microfluidic Resistance

Read more - Expert Reviews: Basics of Microfluidics

Choosing the Right Microfluidic Pressure Range

Read more - Expert Reviews: Basics of Microfluidics

Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications

Read more - Array

Microfluidic Flow Control Technologies: Strengths and Weaknesses

Read more - Microfluidics Article Reviews

Pressure-driven flow controllers vs. Syringe pumps: A flow precision evaluation for optical blood imaging.

Read more