Fits industrial and research use

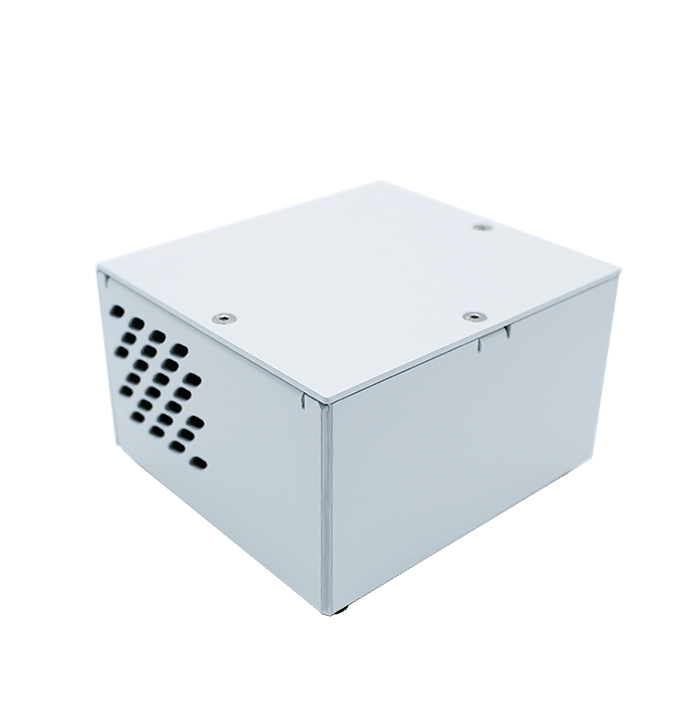

Fluigent RX

[ISRX21]OEM Microfluidic Pressure Source

- Compact

- Easy to use

Standard connections

- AdaptableUse with or without a PC

The RX OEM Microfluidic Pressure Source is designed to be seamlessly integrated into industrial systems or used as a standalone pressure source to supply microfluidic pressure controllers. Ideal for a lab environment and benchtop.

Packaged in a robust steel enclosure, it provides dried and filtered air at up to 2500 mbar for one or multiple pressure control module(s) such as the PX-series or other instruments which need compressed air to operate.

Specifications

| Minimum pressure | 500 | mbar |

| Maximum pressure | 2500 | mbar |

| Free flow (flow rate at 0 mbar output) | 0.8 | L/min |

| Flow rate at 2000 mbar | 5.6 | L/min |

| Dimensions | 106 x 96.5 x 61.5 | mm |

| Weight | 823 | g |

| Air quality | Dried and filtered |

RX and bundles

| Product Name | Pressure range in mbar | Product number |

|---|---|---|

| Rx Pressure source, compatible with F-OEM | 500 to 2500 | E-AC-RX1-2500 |

| Rx Pressure source, compatible with PX and P-OEM | 500 to 2500 | ISRX21 |

| RX + PX 1 bar | RX: 500 to 2500 PX: 0 to 1000 | ISPXRX11 |

| RX + PX 2 bar | RX: 500 to 2500 PX: 0 to 2000 | ISPXRX21 |

| RX Connection Kit | IPCKPX1 | |

| RX Power kit | IPPKPX1 |

Technical downloads

Features of our RX OEM Microfluidic Pressure Source

Compact and versatile

With a rectangular footprint of only 106 x 96.5 x 61.5 mm (4.17”x 3,8”x2.4”), the RX OEM microfluidic pressure source is a convenient compact, and reliable pressure source, packaged in a powder-coated steel enclosure. It can be mounted in any position or orientation as long as the fan intake is not obstructed, and the unit is secured to a stable point or surface.

Condensation-proof and filtered air

The RX OEM microfluidic pressure source has a built-in air filter and drying components. It will filter and reduce the humidity of the room air to prevent condensation. The drying component is designed to perform at room temperature. For more details on air supply conditions required for your setup please contact us.

Designed for Industrial Integration

This pressure source is a combination of hardware and software to provide pre-regulated compressed air for optimal performance, lifetime, and reliability. The user can either use the pre-programmed pressure points for a simple operation or use the RS232 interface for custom pressure targets and integration into any programming language which supports a serial connection.

- DIN rail mounting plate on demand

- Low noise, will not disturb a conversation

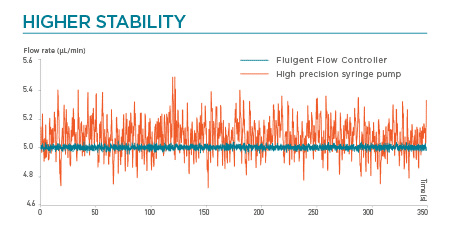

Combine with a PX to ensure pulse-free liquid flow

Pulse-free flow is critical for generating high quality and repeatable results. The PX OEM Microfluidic Pressure Source integrates an algorithm which allows any pressure based instrument to obtain a precise pulse-free flow.

Related applications

Can industrial pressure controllers be used to monitor multiple fluids at different flow rates?

Context

This start-up distributes an innovative vaccine development platform that uses pressure based microfluidics. Not all users have compressed air available on site.

Solution

The RX OEM microfluidic

pressure source is proposed as an option with the platform as an external component.

Result

Availability of air is no longer a roadblock, users enjoy the reliability of RX due to its optimal performance and drying functionality.

| PX Series | Up to 4 PX at 1 bar |

| 2 PX at 2 bar for low flow | |

| PX at 2 bar for high flow | |

| P-OEM Module | Up to 4 channels |

| Depends on total air consumption: channel count, pressure and reservoir sizes for an acceptable response time |

Expertise & ressources

-

Expert Reviews: Basics of Microfluidics Key reliability indicators for OEM components to ensure long-term performance of your flow control system Read more

-

Expert Reviews: Basics of Microfluidics Key considerations for fluidic system integration Read more

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more