Choosing the Right Microfluidic Pressure Range

Fluigent offers a line of pressure-based flow controllers with various features, each adapted for specific needs. While the common point shared by all of these products is precise control of pressure for fluid injection, one of the major variations between them is the range of pressure that each system can work with. The most essential consideration in selecting the right micro-scale fluidic pressure range for your specific application is to guarantee proper regulation of the flow rate, which is imperative for achieving optimal results in your microfluidic experiments.

Why is the choice of flow rate important?

In microfluidics, the choice of flow rate is particularly important due to the unique properties of the fluids and the small scale of the systems involved. First, the choice of flow rate range is vital to controlling flow velocity and residence time for efficient fluid manipulation. Another important factor to consider is the level of shear stress on the fluid and any suspended particles or cells within the fluid. As the cells in the human body are constantly subject to shear stress, it is important to be able to control shear stress during microfluidic experiments by adjusting the flow rate. In summary, the flow rate is a critical factor in microfluidic applications that should be carefully selected to ensure accurate and reliable results. This can be achieved with Fluigent microfluidic pressure controllers.

Finding the right pressure range for your microfluidic experiment

In microfluidics, the most physiologically relevant physical quantity is the flow rate, as it determines the transport rate of molecules and the mechanical constraints applied inside the channels of your microfluidic chip. The first step would be to determine the flow-rate range that best suits your application.

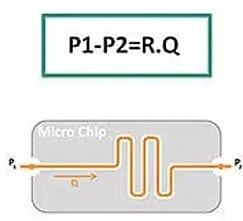

Just like the potential difference in an electrical system, which can be calculated using Ohm’s law once we know the current and electrical resistance values (U=R*I), the pressure can be calculated from the flow-rate and hydrodynamic resistance values: P=R*Q. Depending on your channel geometry and tubing setup, the fluidic resistance will change and determine your pressure values for a given flow rate.

Use our calculator to estimate your chip resistance and determine the microfluidic pressure range you need for your application.

How to calculate flow rate and pressure with the microfluidic calculator?

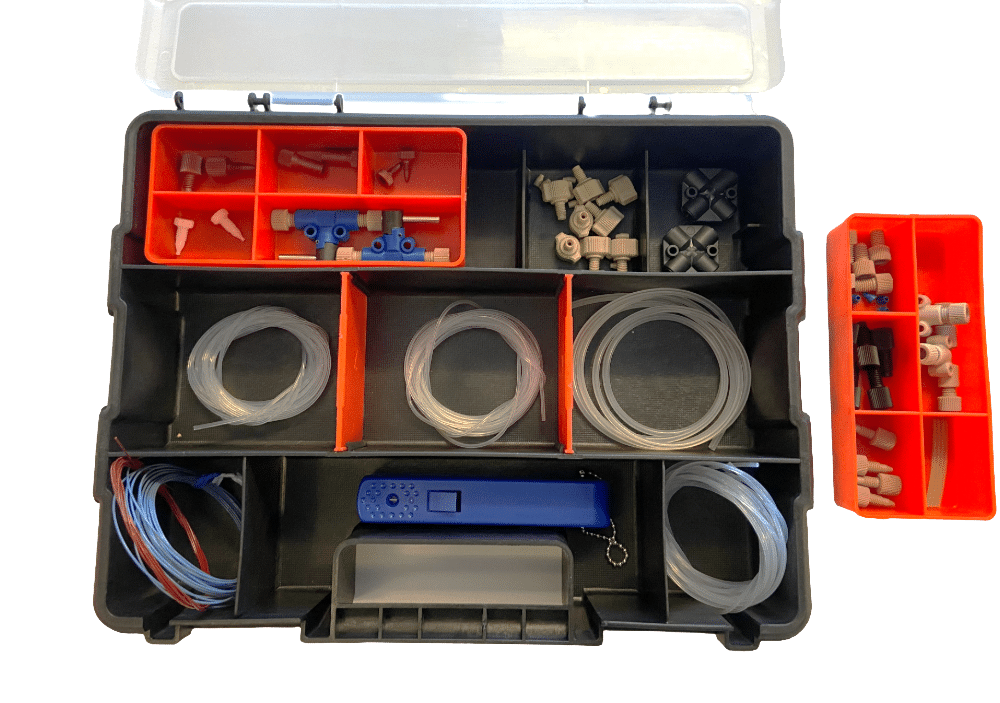

To help users choose the right instrument and the right micro-scale fluidic pressure range, Fluigent has developed a flow rate & pressure calculator that estimates the resistance of most microfluidic setups.

To use the calculator, users must directly input data on:

- Chip geometry: Users will be able to choose between four types of geometry: straight channel, Y network, cross network and H network. If no design matches, the closest of these four will be chosen.

- Chip channel dimensions: Enter the height, length and width of each section of the chip, and the associated resistance is calculated.

- Tubing dimensions: In the same way, the length and diameter of the tubing entering or leaving the chip must be entered to calculate the associated resistances.

- Control types and values: The type of each control can be either a pressure control or a flow rate control. The type of control for each tubing or microchip channel must be filled in, along with their values.

Finally, based on this data, the calculator can recommend a range of microfluidic pressures and flow rates to use. Users can then select the appropriate microfluidic setup for their experiments.

General tips for choosing the right pressure range

- The resolution of our flow controllers is always 0.03% of the full scale. For a 2 bar Flow EZ, one step of incrementation will be 0.6 mbar. To fully benefit from this resolution, we recommend that you work in the middle of the range (between 500 mbar and 1.5 bar in this case).

- If you want to adjust the microfluidic pressure you are working with, you can modify the resistance value of your system by changing your tubing’s dimensions: longer and narrower tubing will result in higher resistance and thus increased pressure. But remember, a narrower structure also means a higher propensity to clogging.

- We usually recommend that you use a microfluidic flow controller with a higher microfluidic flow rate range.

Related resources

- Support & Tools

Pressure & Flow Rate Calculator

Read more - Support & Tools

Shear Stress Calculator

Read more - Support & Tools

Droplet Size Calculator

Read more - Expert Reviews: Basics of Microfluidics

Why Control Shear Stress in Cell Biology?

Read more - Expert Reviews: Basics of Microfluidics

How to choose a microfluidic chip

Read more