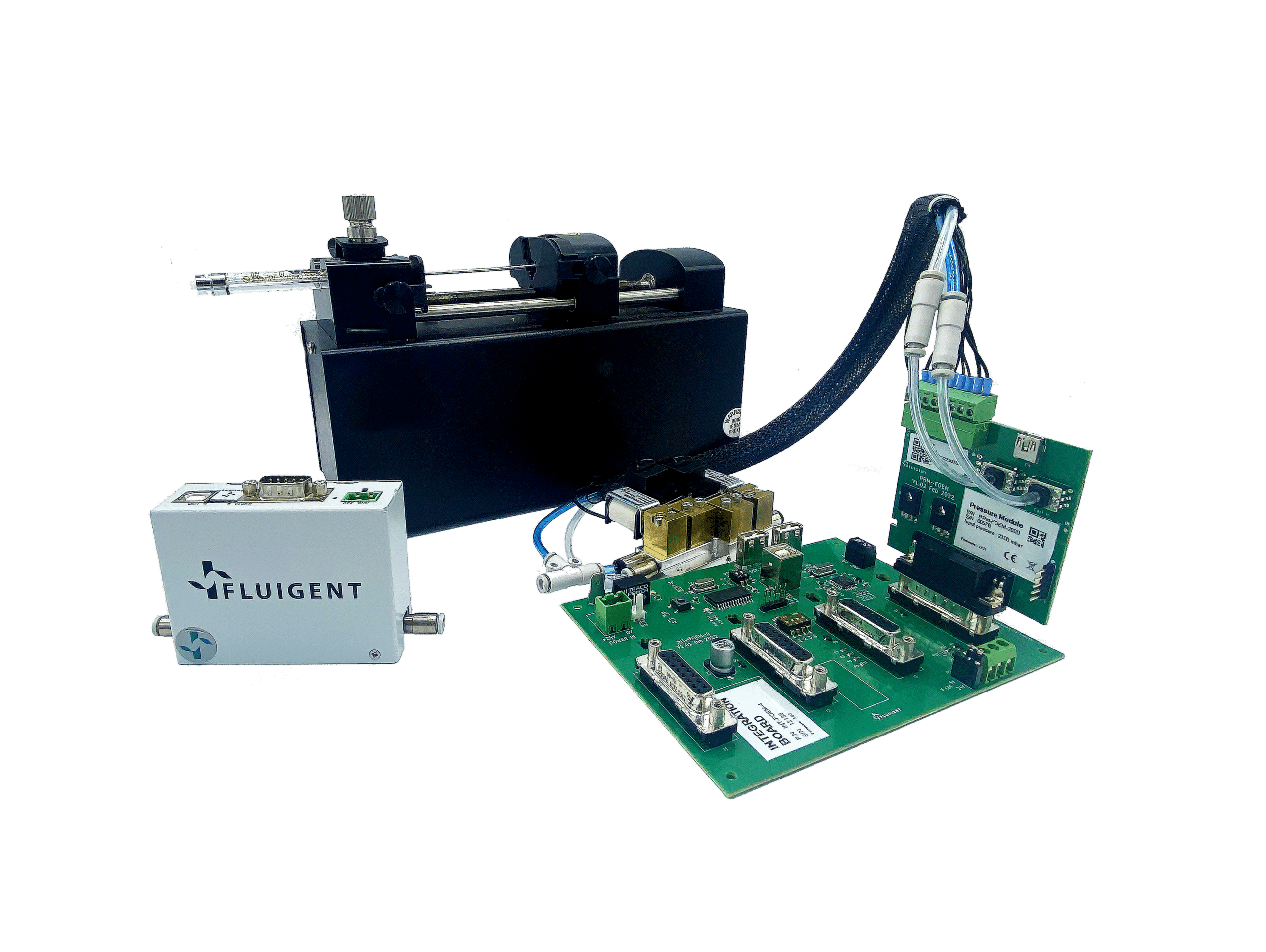

Key reliability indicators for OEM components to ensure long-term performance of your flow control system

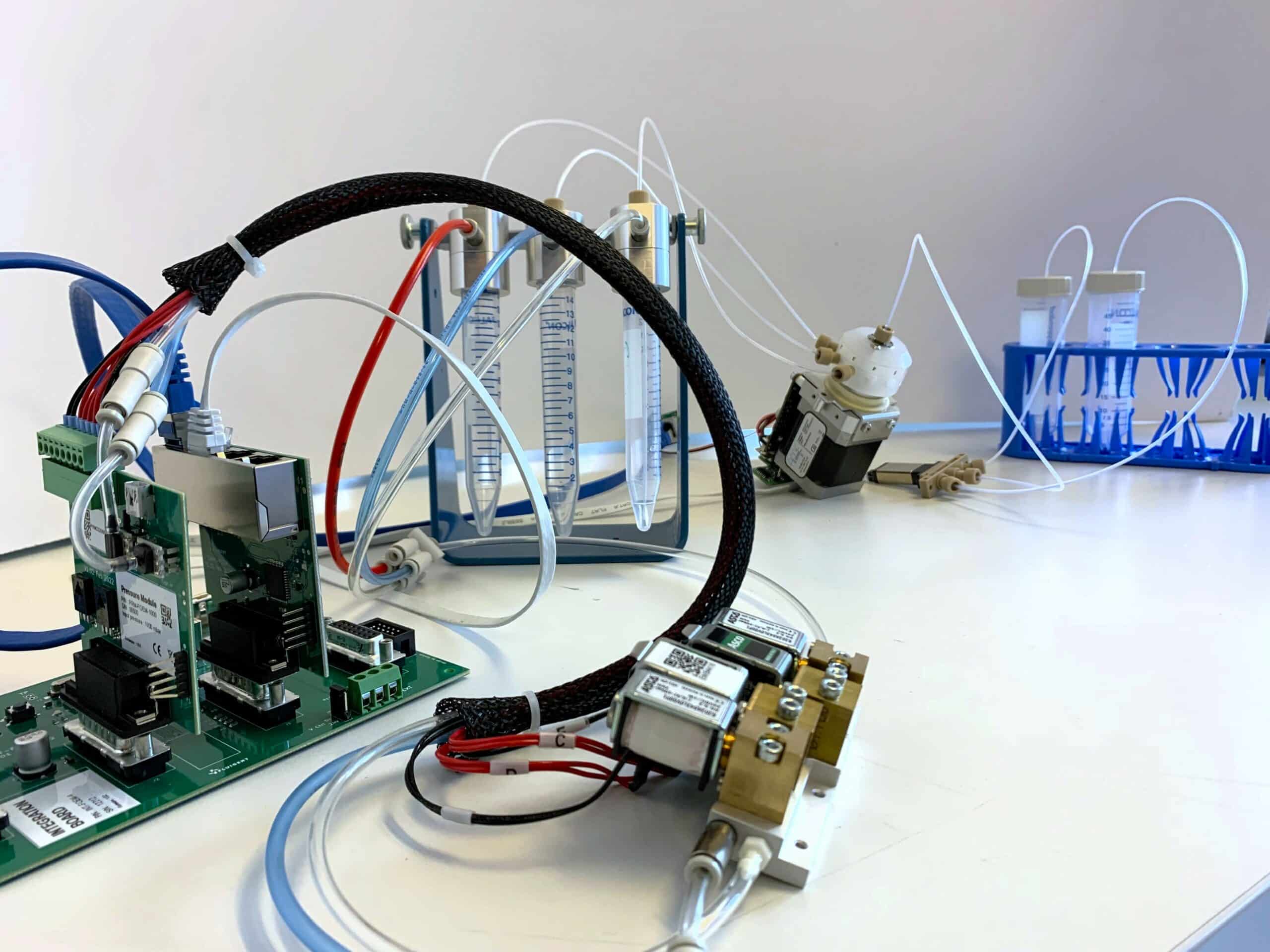

When designing complex laboratory automation systems or devices, OEM liquid handling components that are integrated should be reliable and operate smoothly for many years. If the designed system is intended to work for applications such as drug screening or, molecular diagnostics, the consequence of poor performance of liquid handling components can lead to unreliable results. It ultimately affects your company’s reputation as well as your customer confidence. Selecting the right OEM components for your system is important for ensuring reliable and long-term performance.

In this short blog, we review the most important aspects and reliability indicators for OEM components to consider when selecting your fluid handling OEM components.

Checklist of reliability indicators for OEM components to ensure long-term dependability

As system integration experts, we know that many factors can impact system performance. A system’s reliability can be determined by the assembly procedure, as well as by its weakest component. This determines the mean time before failure (MTBF). Following are some important considerations when selecting OEM flow controllers and other liquid handling components:

- Partner with company with high quality standards. Look for companies that work under quality standards such as ISO 9001, and have successfully completed external audits

- Today, companies must consider pollution and environmental challenges when developing a product. Work with companies that comply with CE, RoHS and others

- Partner with companies capable of providing components and systems with additional certifications such as UL, IP65, or EMC to support you through all system development phases

- Look for companies with proven track record in the OEM industry

In-depth review of key reliability indicators for OEM components

It is difficult to select a microfluidic flow controller or other liquid handling components based on specification datasheets alone, as minor specification differences will be hard to detect. In addition, specifications are still a variable as some suppliers will simply give them based on sub-components, while some suppliers will determine specifications based on «real life» conditions. After a few months or even years of use, performance can be impacted by this choice, ultimately affecting system reliability and brand image. In addition to our previous checklist, one should emphasize on the following reliability indicators for OEM components when choosing a supplier:

Regulatory compliance

For some applications, it is required that your OEM components meet regulatory requirements such as ISO 9001. Even if such certificates are not mandatory for your application, fully audited verification of regulatory compliance can ensure higher reliability. In fact, they require testing, monitoring, maintenance, control, and documentation for all processes and protocols that are part of the product development and life cycle. In addition, ISO certificates need to be renewed every three years, ensuring high-quality standards in the long run. Liquid handling flow controllers and other fluid handling OEM components that are certified will meet international quality standards and ensure a robust and consistent performance.

Product calibration and pre-testing

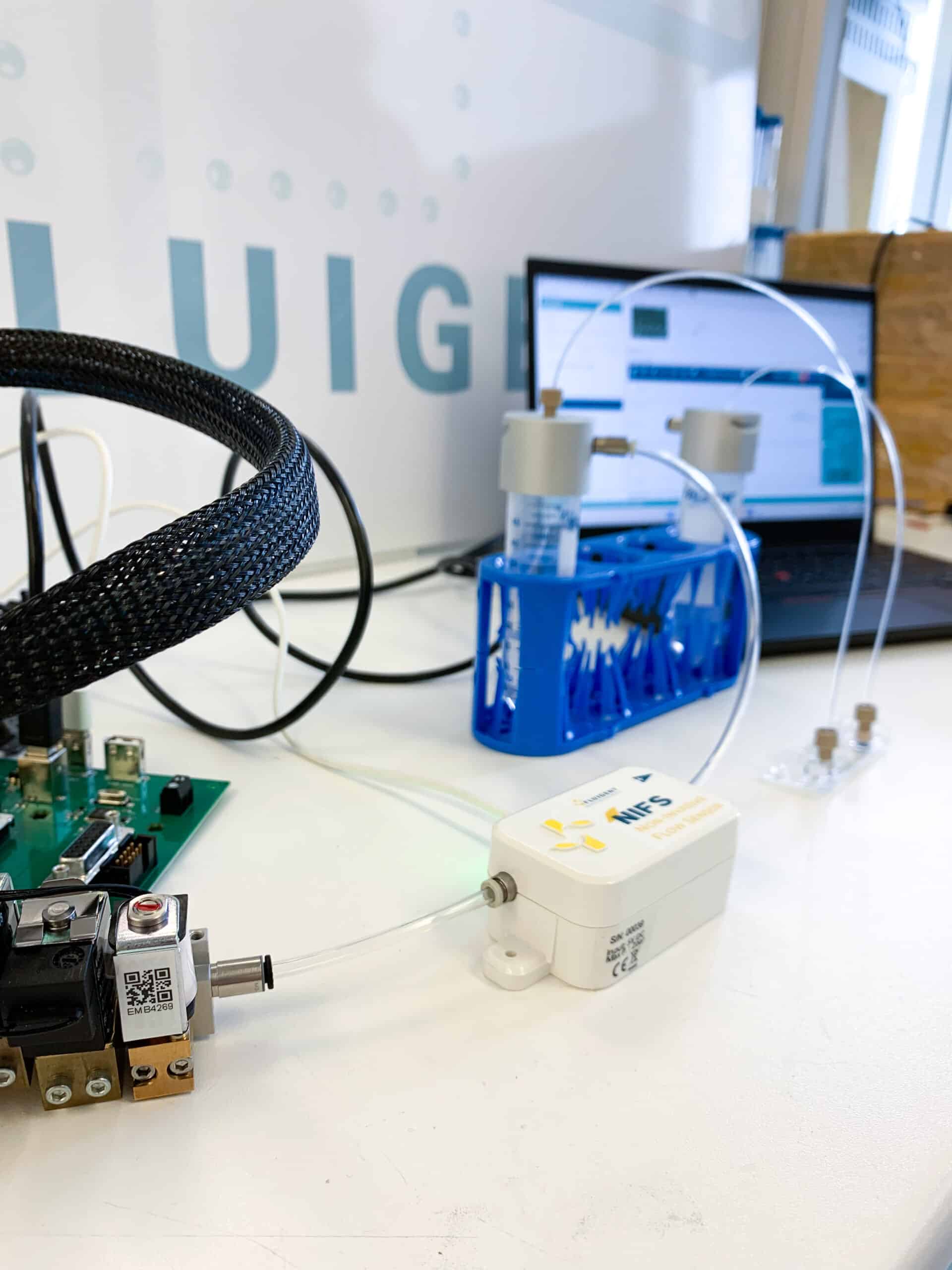

At Fluigent, we believe the performance of your liquid handling system is critical for your application. Precision and accuracy depend on the flow controller itself as well as the other components connected to your system. For ensuring performance, product calibration; validation; and documentation using documented testing systems should be a standard and are reliability indicators for OEM components.

Fluigent can provide customized flow controllers to meet specific requirements (for instance, using pressure controllers, it is possible to have requirements on pressure drop, pressure stability, or gas consumption). A reliable OEM supplier will perform several tests on the customized system and will deliver documentation. A good OEM supplier will accept making post-production adjustments for optimizing your system. You can have a higher trust level for OEM suppliers willing to be fully transparent on testing results.

Expertise in liquid handling – service and maintenance

Long-term performance will also depend on how the products are used. Knowing how to protect and maintain pumps will increase your system’s lifetime. What gas and liquids are compatible with your system? When using biological liquids such as media, PBS, or high viscosity liquids such as blood, what are the cleaning protocols? What should I do to avoid any clogging inside my system? If using pressure-based flow control, how do I ensure I will not experience any backflow? All these questions and many other reliability indicators for OEM components should appear when developing your system. A strong OEM partner should take time to answer all your questions, help you in upgrading and maintaining your system, and communicate efficiently with you to provide long-term customer care.

Related Resources

- Expert Reviews: Basics of Microfluidics

What is the history of microfluidics?

Read more - Expert Reviews: Basics of Microfluidics

Microfluidics overview: History and Definition

Read more 5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more- Array

Microfluidic Flow Control Technologies: Strengths and Weaknesses

Read more Microfluidic Drug Discovery

Read more

Contamination-free Liquid Handling System

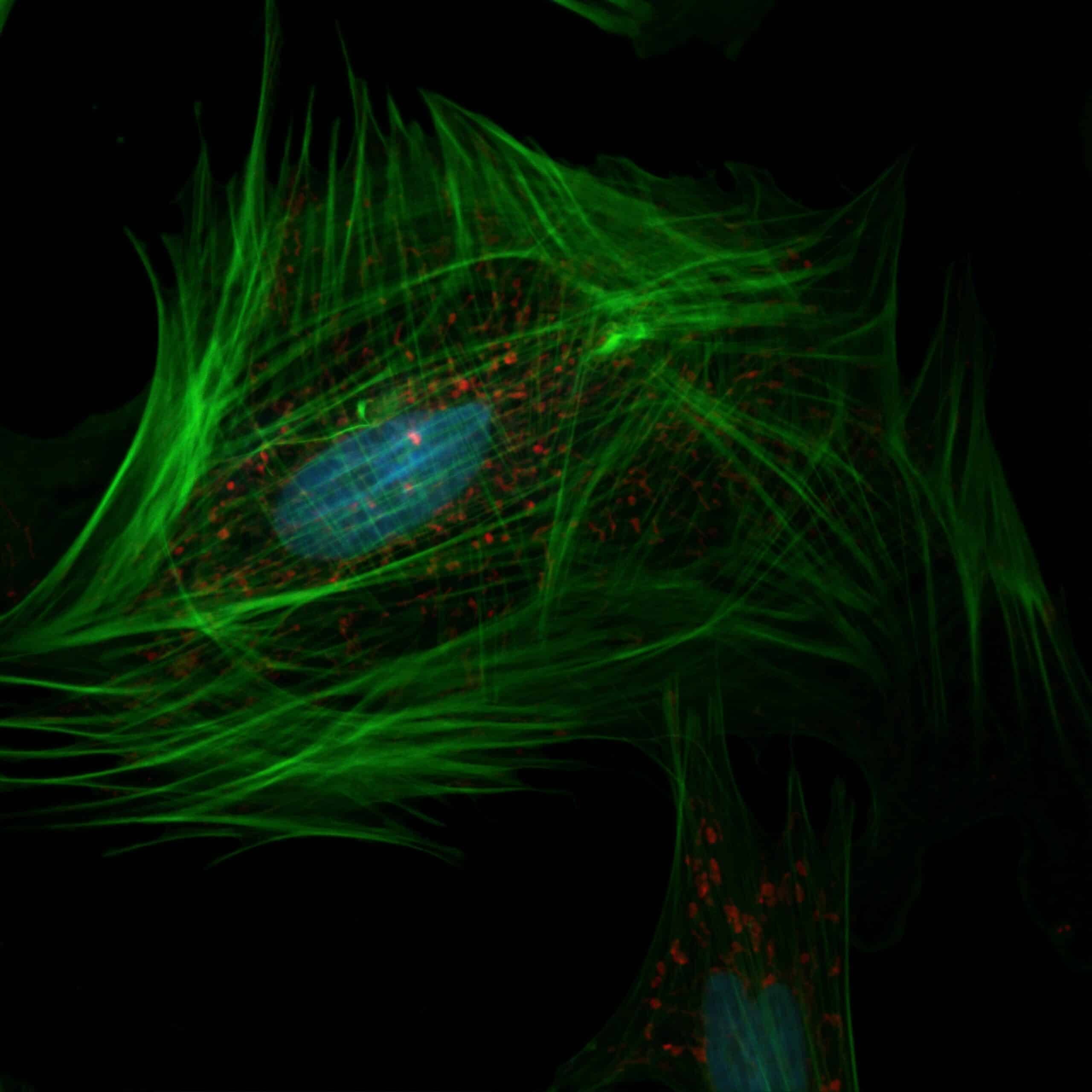

Read moreLocalization microscopy and flow control for multiplexing

Read more- Expert Reviews: Basics of Microfluidics

Key considerations for fluidic system integration

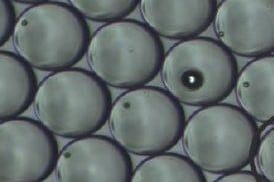

Read more Flow Expertise for Cell Encapsulation and Single-Cell Analysis

Read moreValve Automation with the F-OEM for Microfluidic Applications

Read more