Controlling Flow Rate and Shear Stress with Omi™ to Study Endothelial Cell Response

This Application Note presents a detailed protocol for cultivating a Human Umbilical Vein Endothelial Cells (HUVECs) under flow conditions. The protocol includes chip preparation and cell seeding; once a stable monolayer is established, HUVECs are subjected to controlled unidirectional, laminar flow using the automated Omi organ-on-chip platform. This setup replicates shear stress conditions of 0.23-2.28 dyn/cm² allowing to study the behavior of endothelial cells.

The protocol provides a straightforward model of vascular environments in vitro, demonstrating how organ-on-chip technology allows the study of cellular responses under dynamic flow conditions.

Inside this application note:

- A detailed step-by-step protocol for culturing human umbilical vein endothelial cells (HUVECs) in the BeFlow device

- How to apply unidirectional, laminar flow onto the endothelial monolayer using the Omi™ perfusion platform

- Insights into flow-induced responses including cell alignment, elongation, and proliferation

Role of HUVECs in Organ-on-a-chip Models

Human umbilical vein endothelial cells (HUVECs) are an extensively used model in organ-on-chip applications. They exhibit key characteristics of vascular endothelial cells, including monolayer formation, extracellular matrix production, and response to angiogenic factors (1). They effectively mimic human vascular endothelium. Their in-vitro use provides a valuable tool for studying vascular endothelium interactions. Organ-on-chip (OoC) technology recreates complex human organ microenvironments in vitro, using microfluidic devices to precisely control and manipulate cellular and biochemical conditions.

For discussion on key applications of HUVECs in OOAC models such as angiogenesis assays and shear stress response, download the full application note.

- Vascularized Kidney-on-Chip: create a vascular network within kidney-on-chip models.

- Blood-Brain Barrier Models: form part of the endothelial layer in blood-brain barrier models on chips.

- Lung-on-Chip: simulate the vascular compartment of lung-on-chip models.

How do endothelial cells respond to shear stress?

Shear stress, a force generated by fluid flow, plays a crucial role in the physiology of endothelial cells, which line the interior surface of blood vessels. When applied to endothelial cell cultures, it influences various cellular processes, including alignment, gene expression, and the production of nitric oxide. The dynamic nature of flow conditions simulates the natural environment of blood vessels, allowing researchers to better understand endothelial cell responses in physiological and pathological states (2).

Studies have shown that appropriate shear stress can promote healthy endothelial function, whereas abnormal patterns are linked to vascular diseases. Understanding these effects is vital for developing therapeutic strategies to address cardiovascular issues.

We have written a review explaining why shear stress is an important parameter in the endothelial dynamic cell culture.

Protocol to Form Endothelial Layer in Microfluidic Channel

Materials

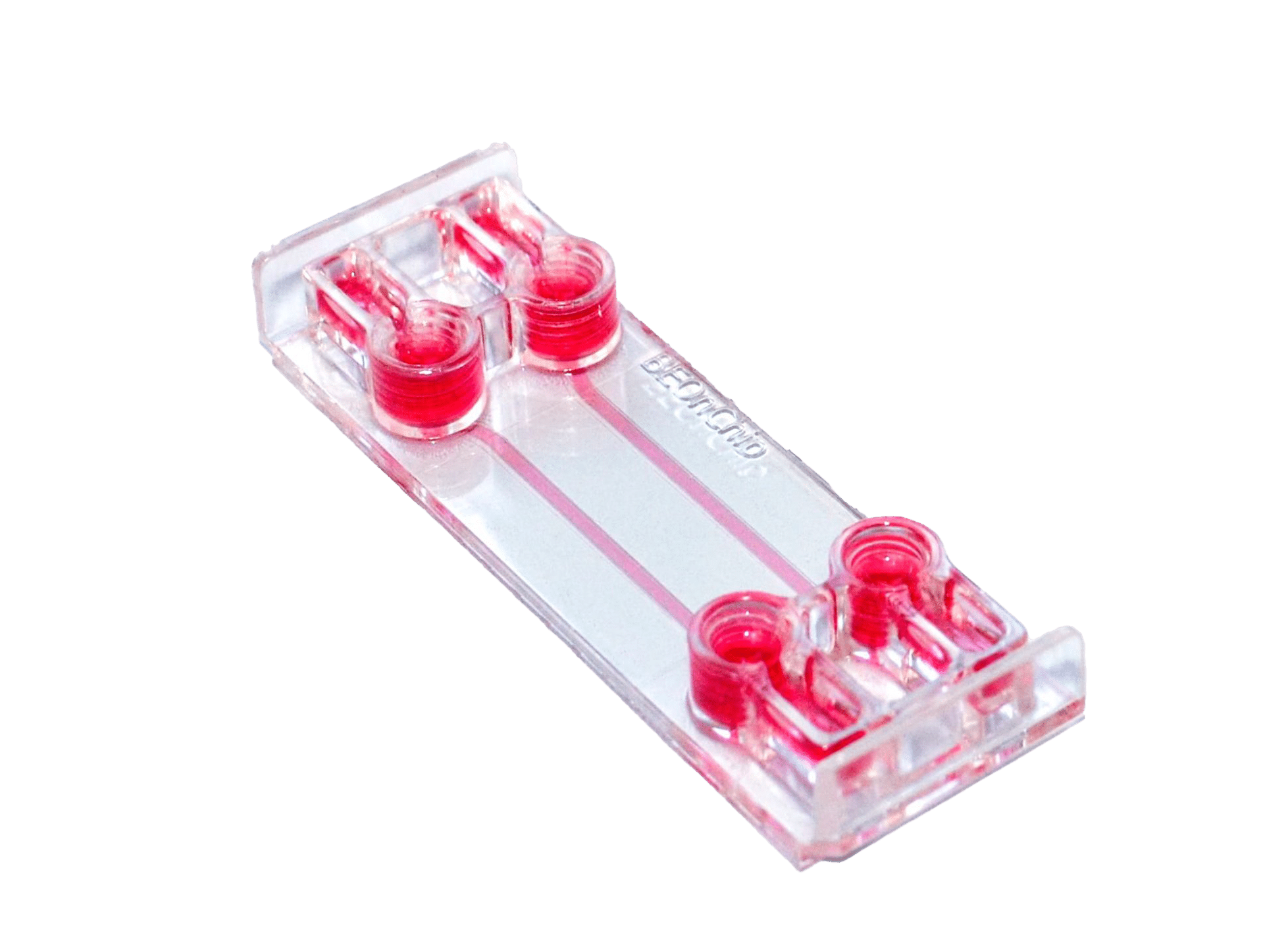

- Microfluidic chip: BeonChip Be-flow [link to product] microfluidic chip (Fig. 1) was used. The channels of the chip are coated with fibronectin protein to enhance cell adhesion. To learn more about coating densities, check PDF file for detailed protocol.

Figure 1: Be-Flow microfluidic chip (BeOnChip)

- Human umbilical vein endothelial cell culture and seeding: Human Umbilical Vein Endothelial Cells (HUVECs) were sourced from (Lonza, Basel, Switzerland). They were cultured in Endothelial Cell Growth Medium-2 at 37 ◦C and 5% CO2 up to 7 passages (Lonza, Basel, Switzerland).

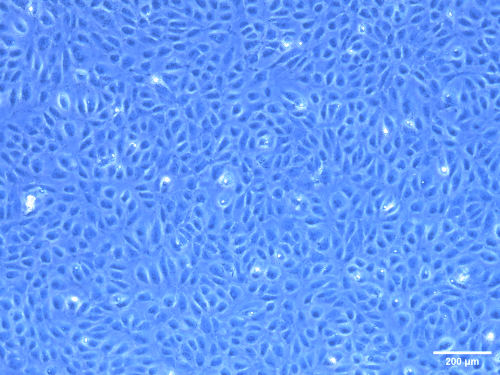

Figure 2: HUVECs Seeded in the Microfluidic Channel Day 0

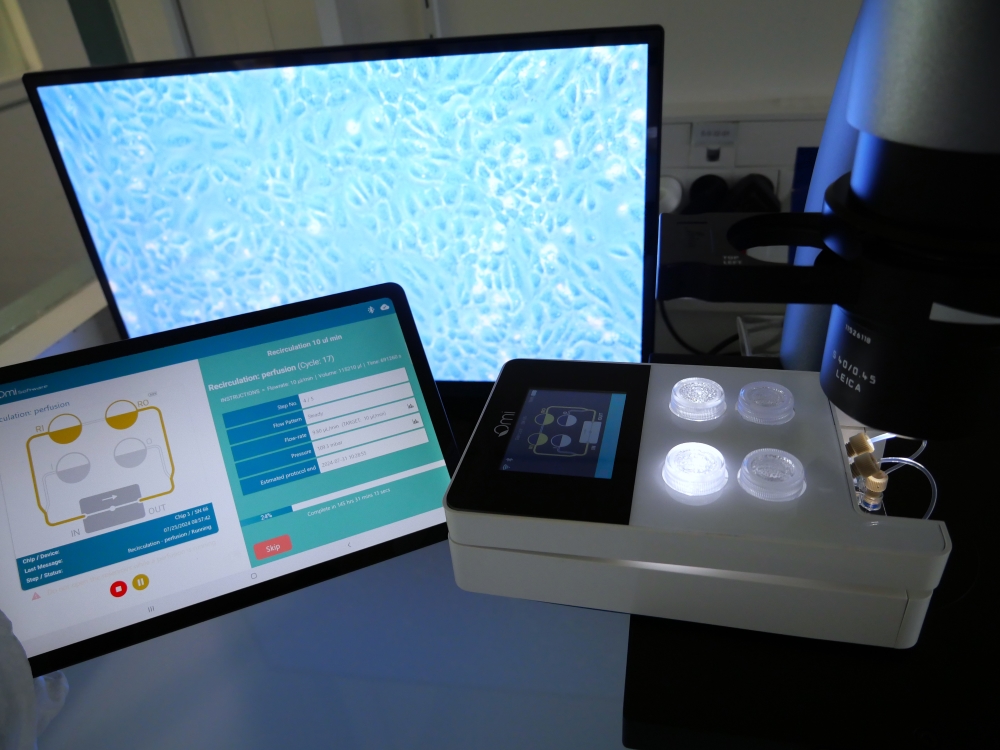

- Omi setup: The Omi is an advanced automated OOC platform designed for precise liquid flow control in organ-on-chip applications. It is highly accurate and versatile and is compatible with a wide range of microfluidic chips, tubing and connectors.

Figure 3: Omi, automated OoC platform.

Endothelial cell culture under shear stress protocol

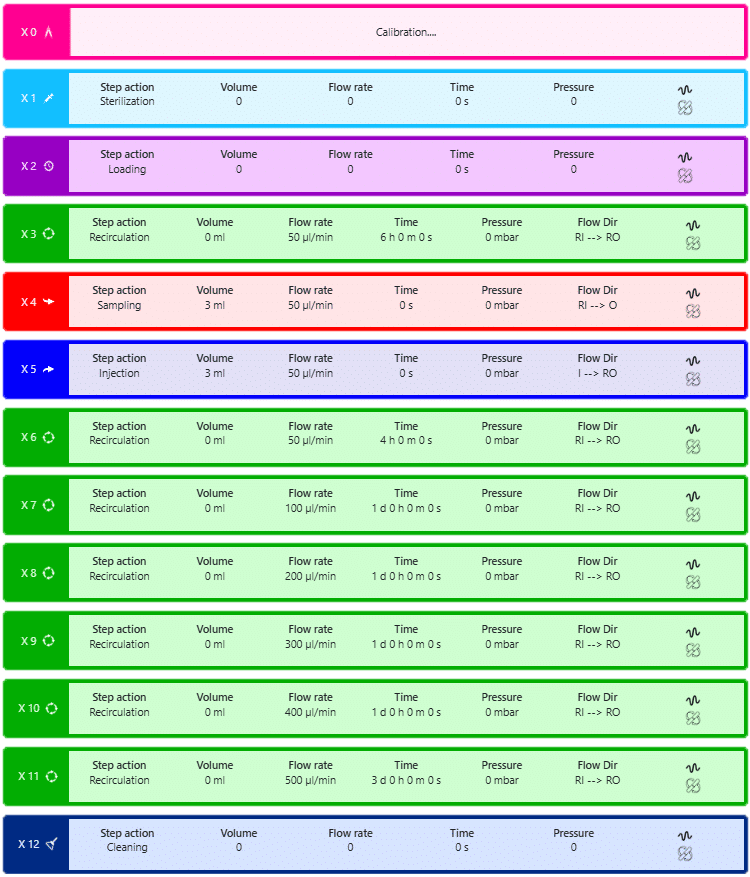

In the application note, we outline the chip preparation, setup, and maintenance of microfluidic cell culture using the Omi™ device with Beonchip’s Be-Flow chip. Key steps include cartridge and adaptor installation, fluidic circuit priming (Loading step), and system sterilization using the built-in Sterilization protocol. Following medium loading, the confluent endothelial monolayer is connected for perfusion.

Once Omi is connected, culture conditions are maintained at 37 °C with 5% CO₂, with medium exchanges performed on days 0*, 3, 5, and 7. Light-microscopy is used to monitor cell morphology, confluence, and alignment throughout the culture period.

*Sampling and Loading steps in the Omi Protocol allow automated medium refreshing over the weekend.

Figure 4: Omi Protocol

Table 1: Set Flow Rate and Equivalent Shear Stress Values Calculated Using Fluigent Calculators

| Flow rate [µL/min] | Shear Stress[dyn/cm²] |

|---|---|

| 50 | 0.23 |

| 100 | 0.46 |

| 200 | 0.91 |

| 300 | 1.37 |

| 400 | 1.82 |

| 500 | 2.28 |

Results: Impact of Flow on HUVECs Growth in the Microfluidic Channel

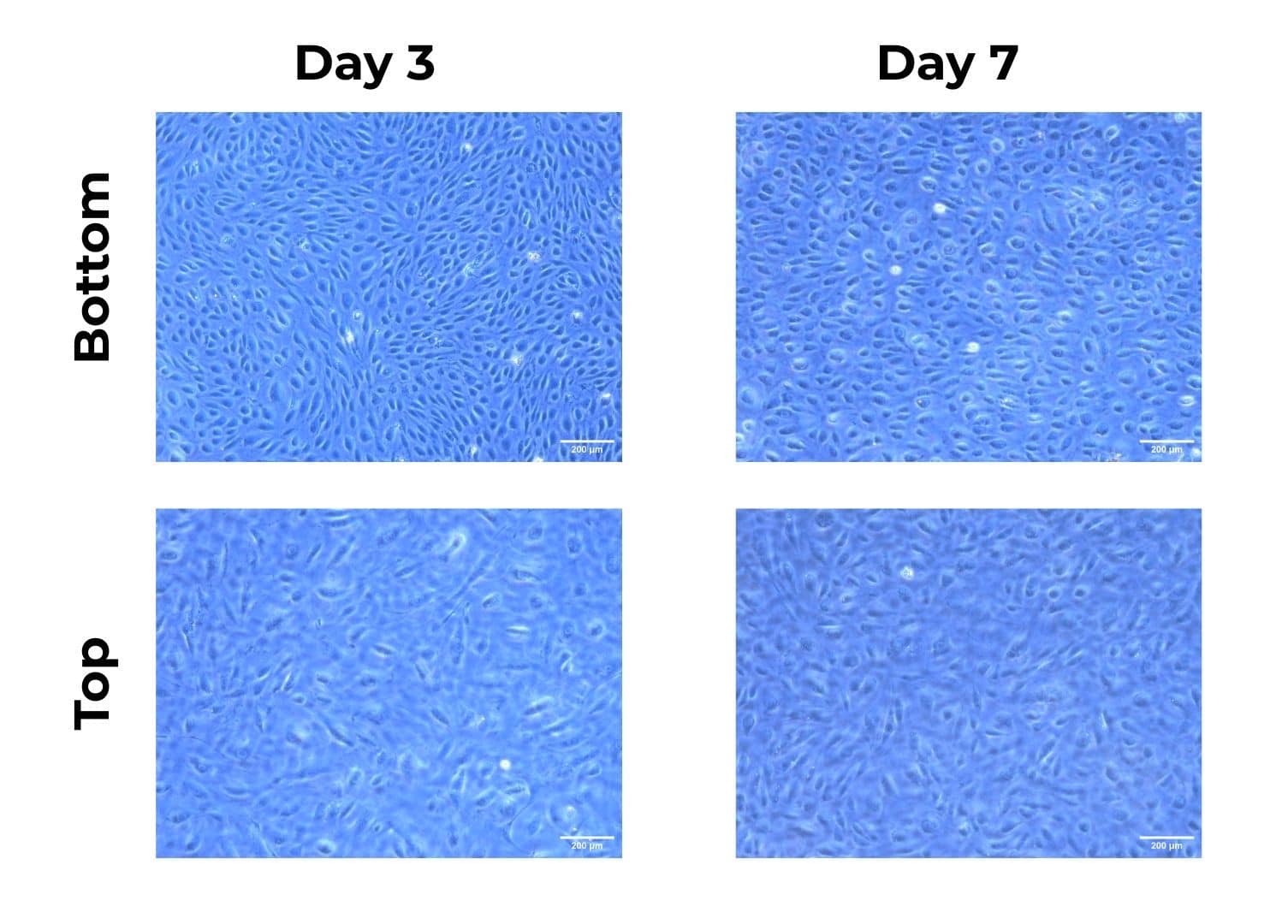

HUVECs cell culture under progressive shear stress was sustained for at least seven days. As shown in Fig. 5, cells maintained healthy morphology, proliferated over time, and exhibited alignment in the direction of flow. Only the bottom layer of the microfluidic chip was coated with fibronectin and seeded with cells. Under static conditions and at low flow rates (e.g., 10 µL/min), colonization of the top channel layer was minimal. In contrast, at a higher flow rate of 300 µL/min (1.37 dyn/cm²), top-layer colonization was first observed on day 3 and reached confluence by day 7 (1.8 dyn/cm²).

Figure 5: Visualization of the Bottom and Top endothelial Layer on the Day 7

Figure 6: HUVECs at Day 3 and Day 5 cultured under shear stress conditions

Conclusion

In conclusion, Omi™ automated perfusion platform demonstrated to model physiological shear stress conditions in vitro using HUVECs cultured in the Beonchip Be-Flow microfluidic device. The system successfully maintained cell viability and monolayer integrity under progressively increasing flow rates. Endothelial cells exhibited flow-induced responses, including elongation, alignment in the flow direction, and top-layer colonization at higher flow rates.

The automated media exchange features, by implementing sampling and injection steps, allowed for unattended operation over weekends or holidays. The cells retained monolayer structure supporting the platform’s suitability for long-term perfusion culture.

Omi™ OOAC Platform for Flow Rate and Shear Rate Control

Omi is an automated platform that helps reproduce the micro physiological behavior of organs inside microfluidic chips. It is compatible with any type of chips to sustain different cell culture types or organ on chip models (Liver, Gut, Skin…).

Expertises & Resources

-

Microfluidic Application Notes Gut-on-Chip Model Development Using OOAC Platform, Omi Read more

-

Microfluidics Case Studies Creating kidney organoids‑vasculature interaction model using Fluigent’s Flow-EZ Read more

-

Microfluidics Case Studies A multiplex microfluidic circuit for blood vessel-on-a-chip perfusion using Fluigent’s FlowEZ Read more

-

Expert Reviews: Basics of Microfluidics Pressure-Controlled Microfluidics in Organ-On-A-Chip Research Read more

-

Microfluidic Application Notes Long-term fluid recirculation system for Organ-on-a-Chip applications Read more

-

Microfluidics Article Reviews Human Blood Brain Barrier (BBB) permeability -on-chip assessment Read more

-

Expert Reviews: Basics of Microfluidics Why Control Shear Stress in Cell Biology? Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

References

- The use of human umbilical vein endothelial cells (HUVECs) as an in vitro model to assess the toxicity of nanoparticles to endothelium: a review, Yi Cao et al, 2017

- Perfusion culture of endothelial cells under shear stress on microporous membrane in a pressure-driven microphysiological system, Shinji Sugiura et al, 2023.