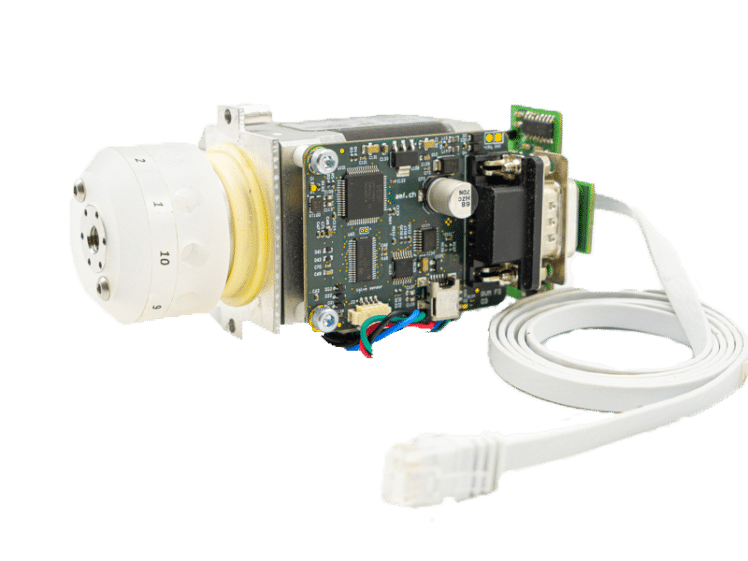

Designed for system integration

Fluigent L-X

[IVLSW1]Sample injection and recirculation microfluidic valve for industry

- Compact

Fast

FastActuation and response time

- Accurate

Low internal volume

Automation

AutomationFully automated with in house software or SDK libraries

The L-X OEM 6 port 2 position valve is a bidirectional microfluidic valve designed for precise sample injection or fluid recirculation in cell culture applications.

Specifications

| Internal volume | 660 | µL |

| Dead volume | none | |

| Switching time | 100 | ms |

| Weight | 475 | g |

| Dimensions | 7x9x15 | mm |

| Wetted materials | PEEK | |

| Max pressure | 7 | bar |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample | |

| Port communication | RJ45 | |

| Software control | OxyGen, SDK |

L-X References

| Name | Part number | Comment |

|---|---|---|

| Fluigent L-X | IVLSW1 | Sample injection and recirculation microfluidic valve for industry |

Technical downloads

Fluigent L-X valve features

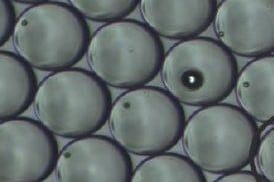

Precise fluid injection

Several sample loops are available, from 5 µL to 100 µL.

Fluigent software for automation

The L-X microfluidic valve can be controlled by Fluigent software for long-term experiments. Create a time-based protocol to set actuation timing of the valve(s).

A versatile valve

The OEM 6 port 2 position valve can be operated using pressure up to 7 bar (100 psi), and the wetted material is PEEK, a highly chemically and biocompatible material.

Minimized liquid waste

Low port-to-port volume of 660 nL.

Related applications

Fluigent pressure-based flow controllers VS Peristaltic pump

| Fluigent pressure-based flow controllers | Peristaltic pumps | |

| Flow stability | High (<1% variation) | Low (>20% variation) |

| Response time | High | Medium |

| Pressure control | Yes | No |

| Price | Medium-High | Low |

| Implementation | Requires pressure sources | Easy |

How to use the L-X device ?

Working principle

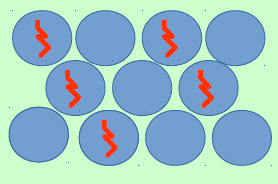

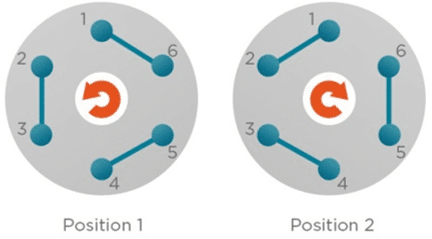

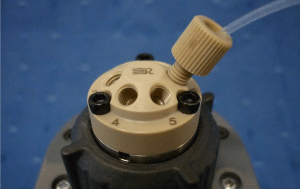

Peripheral valve ports (numbered from 1 to 6) can alternatively be connected to the right or the left channels. The L-X OEM microfluidic valve is actuated by a motor that drives a rotor – where the fluidic path is engraved – against a stator – containing the fluidic paths.

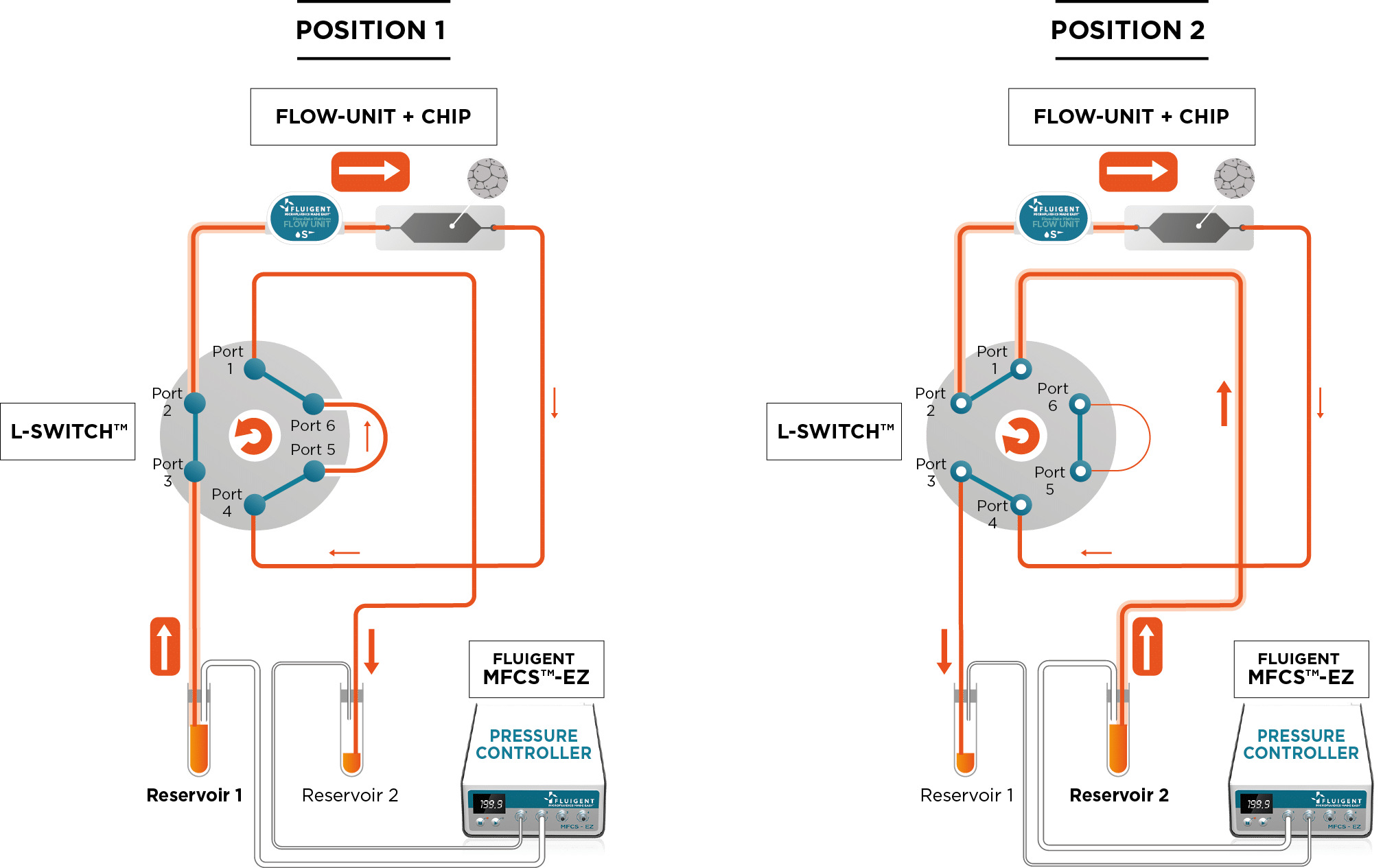

Fluid recirculation

The L-X 6 port 2 position valve can be used as a useful cell culture tool: a small volume of buffer can be recirculated within a closed loop into the chip for several hours or days. Combined with our pressure-based flow controllers, it can achieve a highly stable flow rate, allowing to better mimic flow-induced shear stress experienced by cells in vivo.

The figure shows the working principle: fluid is injected from reservoir 1 to reservoir 2 and passes through the L-X. When reservoir 1 is almost empty, fluid is injected from reservoir 2 to reservoir 1, and the port positions of the L-X are switched so that fluid is injected on the same direction, which is usually required for cell culture under flow.

FAQ

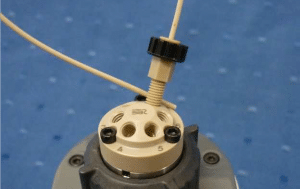

How to add the L-X in my experiment and how to connect it?

- Connect the L-X to the SWITCH EZ port

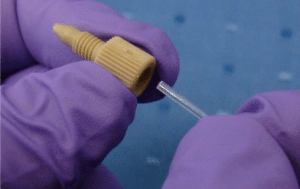

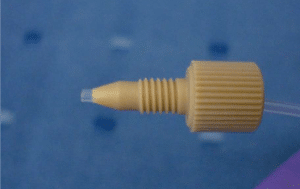

- Cut the 1/16’’ OD tubing to the desired length, leaving a square-cut face.

- Insert the tubing into a nut until it passes 1.5 – 3mm.

- Insert into a port of L-X, twist until it is tightened. You can pull gently the tubing to verify that it is securely connected to the port.

How to connect a sample loop to the L-SWITCHTM?

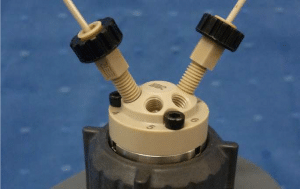

How to connect a sample loop to the L-X?

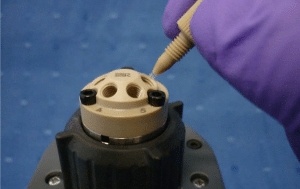

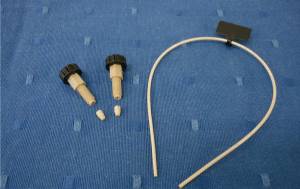

- In order to connect a sample loop to the L-SWITCH™, you will need two nuts and two ferrules, in addition to the sample loop itself (nuts and ferrules are provided with the sample loop).

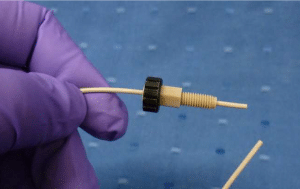

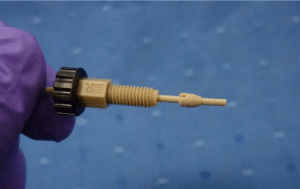

- Pass one end of the sample loop through a nut.

- Add a ferrule

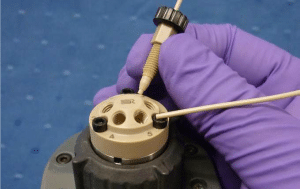

- Hold the set together and insert it into a port of the L-SWITCH™ (for example, port 1 here).

- Twist until the set is tightened. You can pull gently the sample loop to verify that it is securely connected.

- Repeat these steps for the other end of the sample loop to connect it to another port of the L-SWITCH™ (for example port 4 here).

How can I clean the L-X after use?

You can clean the L-Switch™ in the same way than the Flow Unit.

Besides, Fluigent strongly advises you to use filtered solutions. Wetted materials are PEEK only.

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 21.0.0.0 or more recent |

Expertises & Resources

-

Fluigent Products Datasheets L-X Technical Specifications Download

-

Expert Reviews: Basics of Microfluidics Key considerations for fluidic system integration Read more

-

Fluigent Products Datasheets L-SWITCH™ Datasheet Download

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more