Flow Expertise for Cell Encapsulation and Single-Cell Analysis

- Higher accuracy

- Higher sensitivity

- Higher encapsulation efficiency

What is cell encapsulation?

Cell encapsulation refers to the technique during which one or several cells are integrated into a three-dimensional extracellular matrix. It was first used in the 1950s to try to create a protective layer around cells to facilitate transplantation processes. Over time, it got recognized as a suitable technique for many more purposes. During this process, cells are carried through a named reagent to then be included in the chosen matrix, which depends on the final use of the encapsulated cells. It has many advantages for various applications such as next-generation sequencing, 3D cell culture, or drug delivery.

Main applications of live cell encapsulation

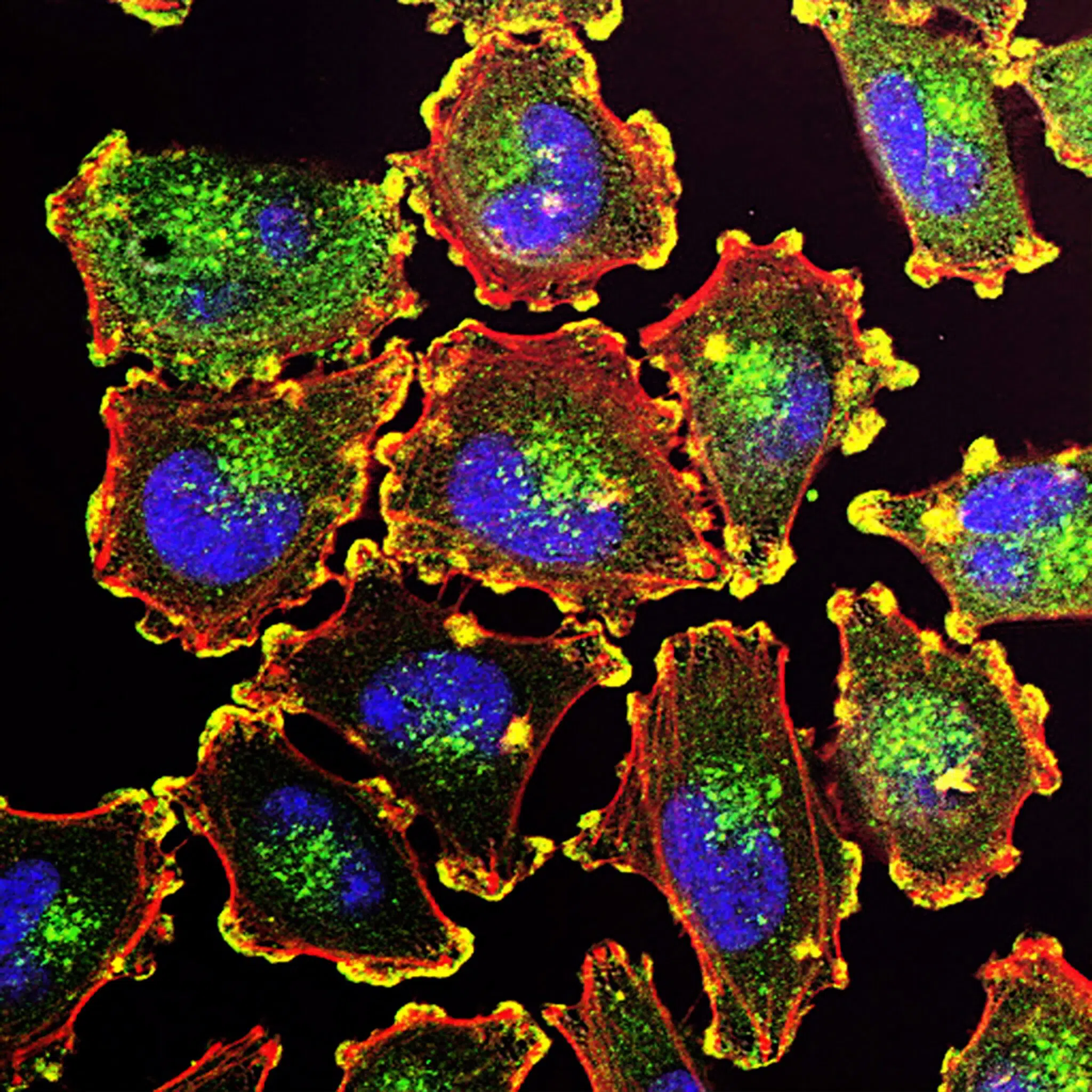

Next-generation sequencing (NGS) for single cell analysis

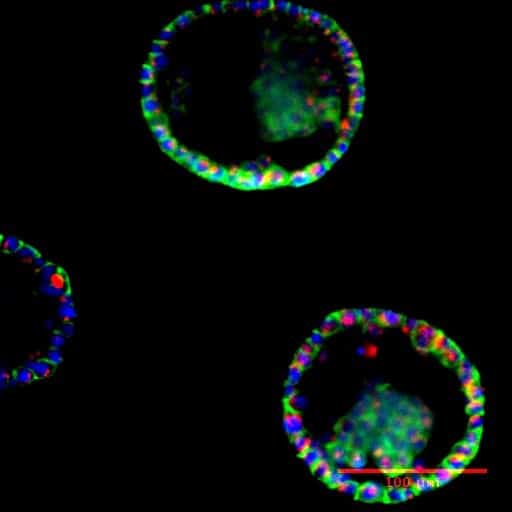

Single-cell RNA sequencing (scRNA-seq) has been crucial in the study of biological heterogeneity and for the characterization of rare cell types. Several techniques exist to obtain single cells for RNA sequencing. The production of highly monodispersed emulsions makes microfluidics an excellent tool for single-cell analysis & cell encapsulation. This provides a substantial increase in throughput, with a reduction in cost. Cells and barcode-containing beads/hydrogels are co-encapsulated in a droplet, allowing one to label all the RNA from each cell with a unique barcode such that after pooling and sequencing, each read is mapped back to its cell of origin.

3D cell culture

In vitro cell culture is a fundamental component of biological production systems and biotechnological research. Using microfluidics permits the development of 3D cell culture models using cell encapsulation. It allows for better replication of native cell microenvironment, which can be particularly adapted for drug screening. Indeed, mimicking the cells’ natural environment allows them to adopt a behavior and a drug response closer to the one in vivo, and therefore to better evaluate the effect of a given molecule on our body. In fact, traditional cell culture methods using petri dishes or culture flasks show limitations, including the difficulty to compartmentalize clones and single cells. The technique allows one to perform single or multiple-cell encapsulation into droplets of pL volume which are generated at a rate of thousands per second.

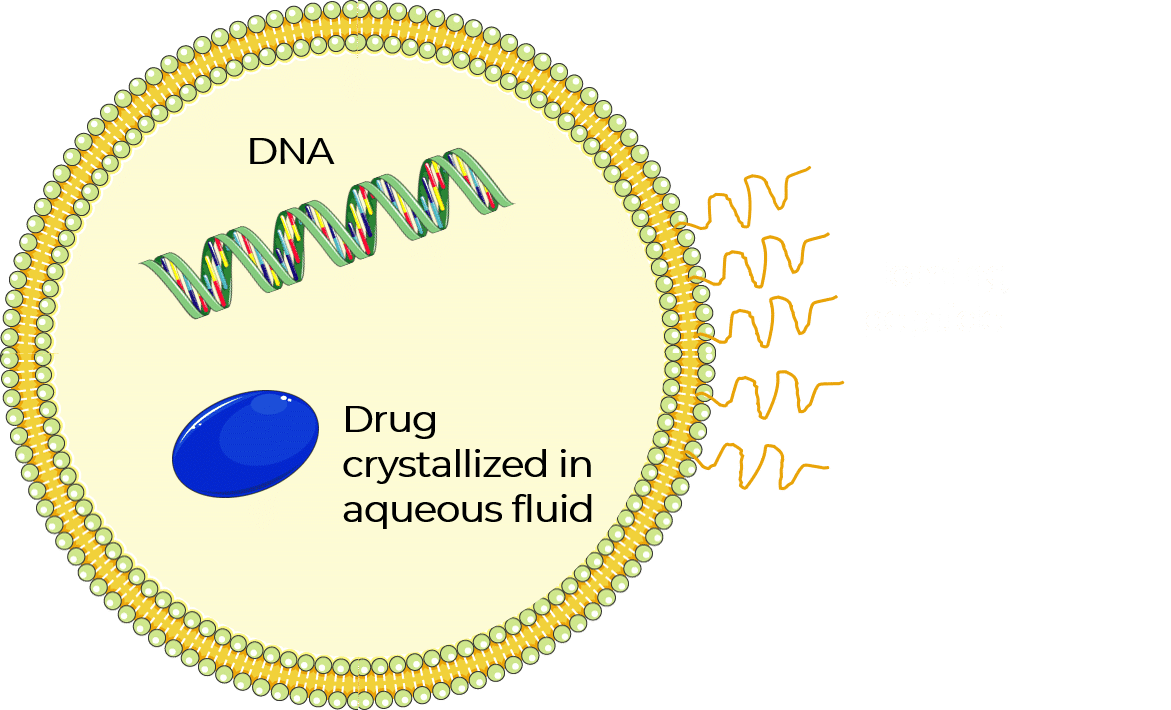

Encapsulation for drug delivery

Micro (and nano) particles for drug delivery bring advantages of: precise dosage, site-specific drug release and delivery, more homogeneous distribution in the physiological environment. Drug delivery applications usually rely on highly monodispersed (<5%) particles for proper efficiency. Microparticles, microspheres, and microcapsules serve as multiunit drug delivery systems that offer numerous advantages based on their structural and functional abilities. Their application is suitable for convenient and tolerable drug administration via several routes. Different sites and biological components can be targeted depending on the size of the particle. Cell encapsulation can also be used in the context of drug delivery as cells allow the release of molecules on a long-term basis, continuously.

Resources

-

Microfluidics Case Studies OEM Case Study: Microfluidic Drug Screening Read more

-

Microfluidics Case Studies The Hebrew University: Encapsulation and culture in 3D hydrogels for Single cell sequencing Read more

-

Microfluidic Application Notes Liposome Nanoparticle Synthesis Read more

-

Microfluidic Application Notes Droplet Sequencing: Drop-Seq method Read more

-

Expert Reviews: Basics of Microfluidics Prostate Organoid Culture in Microbeads Read more

The importance of a stable flow rate for optimized encapsulation of cells

When it comes to droplet or particle generation, having a total control over fluid flow is important. During droplet or particle production the flow rate of each phase must remain constant and stable to allow the production of monodisperse droplet. The ability to precisely control the flow rate of each phase allows one to regulate the size of the droplet and particle generated, the production frequency and the encapsulation efficiency when it comes to cell encapsulation or barcoded bead encapsulation.

In this context there are several systems and methods available to control fluids for droplet and particle generation using microfluidics.

Pressure as the gold standard for microfluidic droplet generation

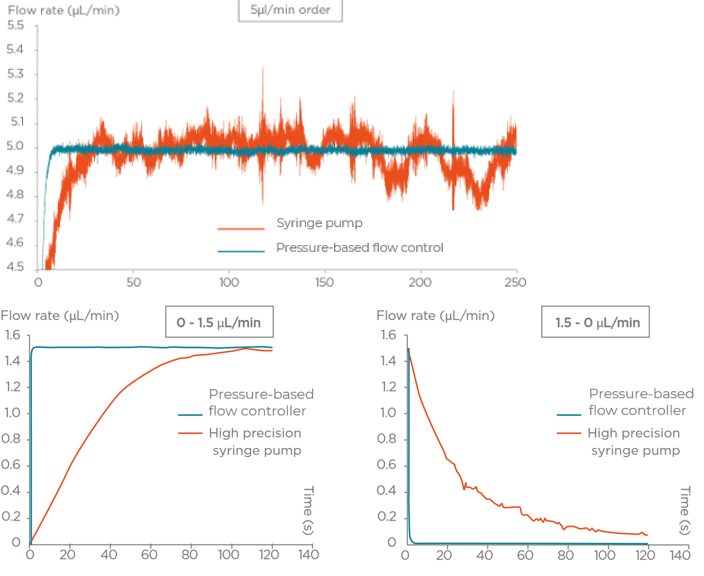

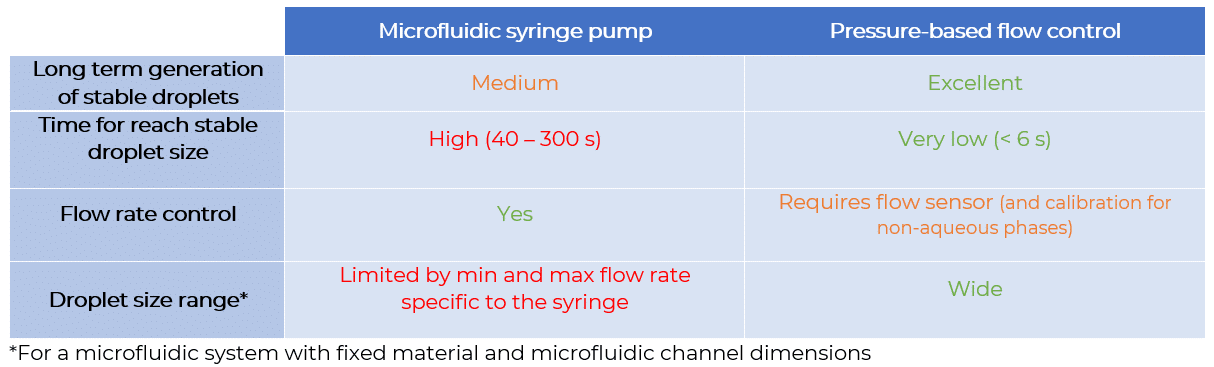

Flow rate stability is critical for having repeatable reactor volumes and reproducible results during cell encapsulation process. Syringe pumps are commonly used for generating droplets. Syringe pumps show limited ability to control flow rates. As a result, the droplet size is affected.

Additionally, the actual flow rate cannot be well controlled with such devices. The flow rate value is displayed on the device, but no information on the time required for reaching a set flow rate is given (the time for flow equilibrium may vary depending on the microfluidic setup. Flow rate can also oscillate.

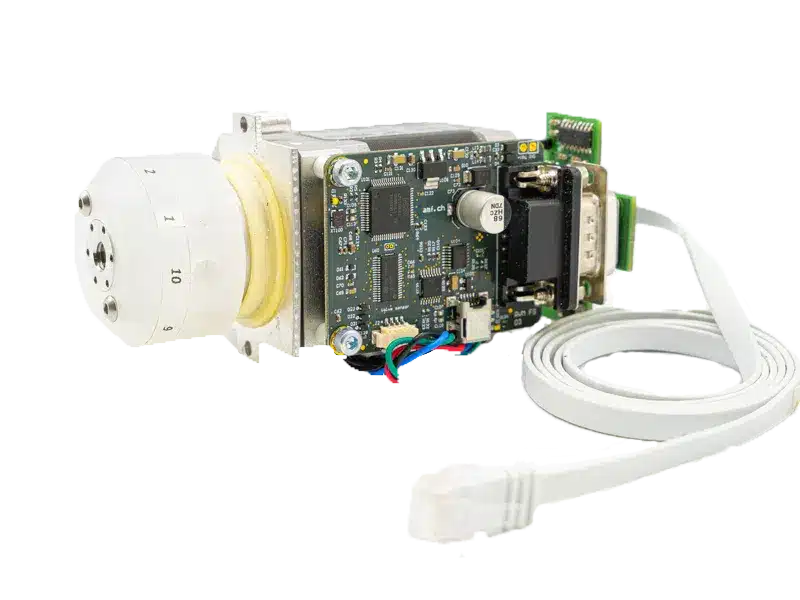

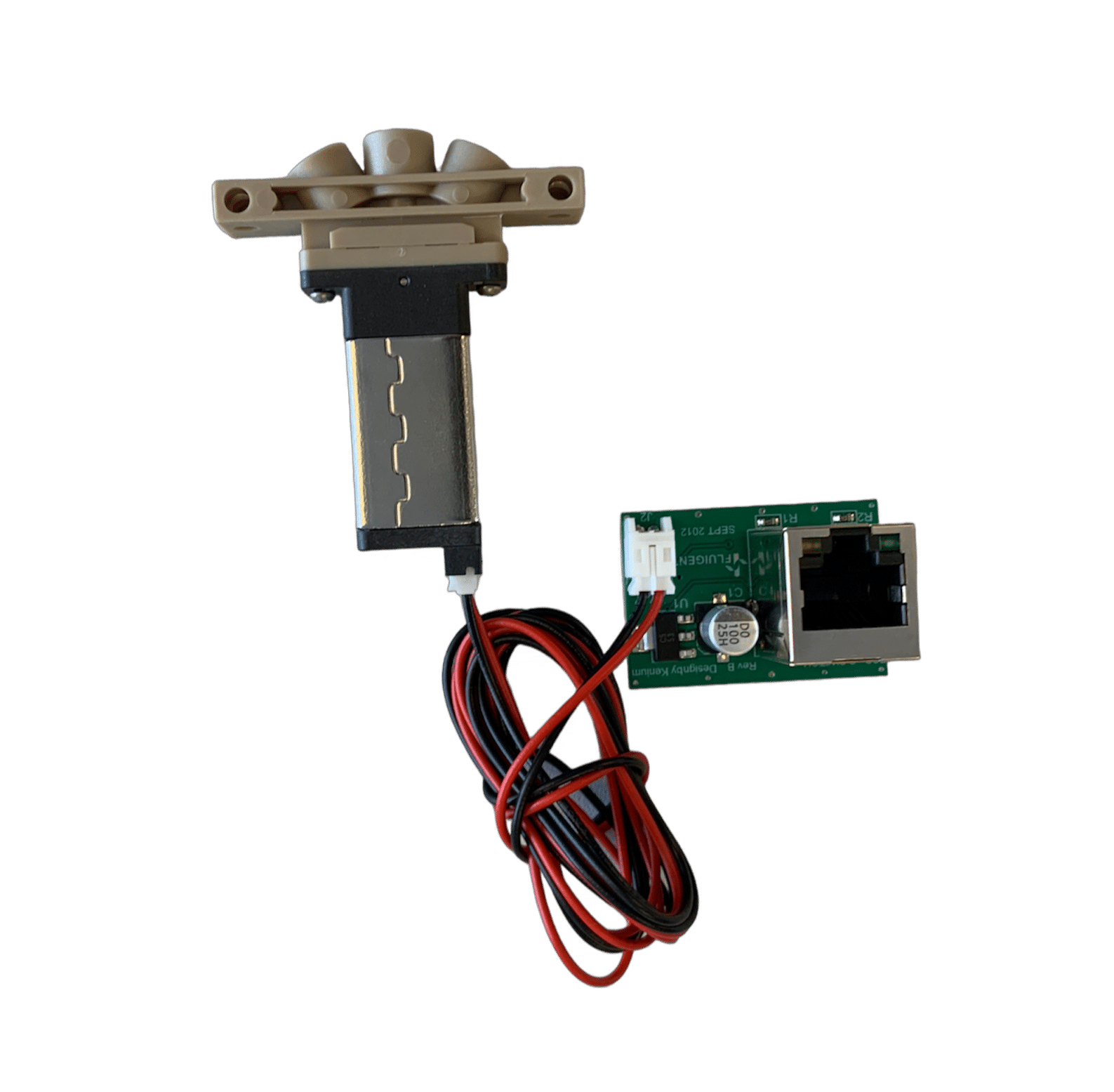

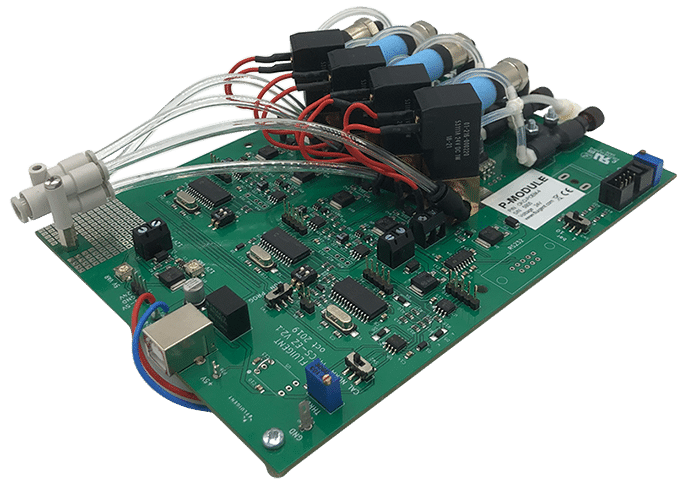

An alternative to syringe pumps is pressure-based flow controllers. These provide high-precision flow control, and fast response times.

Flow control systems and Fluigent added value

We compared the production of water-in-oil emulsions using syringe pumps and pressure-based flow controllers. Using pressure control, the desired droplet size is quickly obtained (< 6 s), and monodisperse droplet generation is ensured over time.

The benefits of choosing Fluigent for your flow control system:

- Best in class stability: 0.1% on the measured value thanks to our field-proven, patented FASTAB™ technology allowing for optimal flow control with the reliability required in demanding industrial environments

- Workflow automation becomes straightforward with Fluigent software

- Our engineering team are experts in microfluidic design, mechanical and software integration as well as biology and application knowledge

Related applications

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read moreMicrofluidics in Water analysis

Read moreMicrofluidics in Food Industry: Food Testing & Agriculture

Read moreMicrofluidics in Life Science

Read moreMicrofluidics for Pharmaceutical Applications

Read more