Designed for parallelization

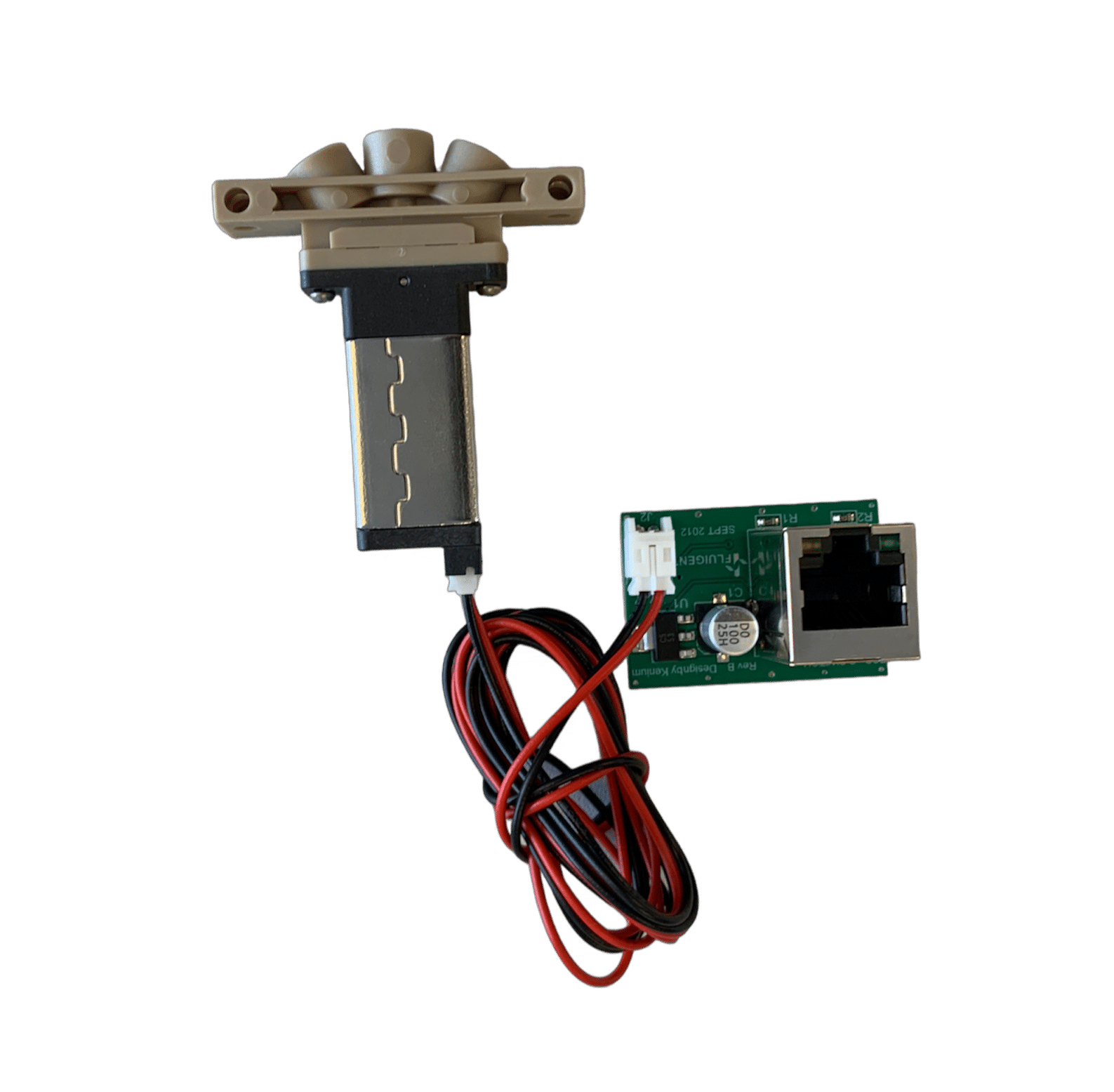

Fluigent 2-X

IV2SWBK13-port/2-way bidirectional valve for industry

- Compact

Fast

FastActuation and response time

- Accurate

Low internal volume

Automation

AutomationFully automated with in house software or SDK libraries

The 2-X is a compact 3-port/2-way microfluidic valve. Using standard fittings, it can be integrated into any fluidic system.

Specifications

| Internal volume | 59 | µL |

| Dead volume | none | |

| Switching time | 3 | ms |

| Weight | 36 | g |

| Dimensions | 56.4 x 46 x 11 | mm |

| Wetted materials | PEEK, EPDM or FFKM (on demand) | |

| Channel diameter | 1.2 | mm |

| Max pressure | -1 to 2 | bar |

| Operating temperature | 0-50 (32-122) | °C (°F) |

| Liquid compatibility | Resistant to neutral and aggressive liquids | |

| Port communication | RJ45 | |

| Software control | OxyGen, SDK |

2-X References

| Name | Part number | Comment |

|---|---|---|

| Fluigent 2-X | IV2SWBK1 | 3-port/2-way bidirectional valve |

| 2-X kit | CTQKITSW2 | Tubing and fitting dedicated for the 2-X |

Technical downloads

Fluigent 2-X valves features

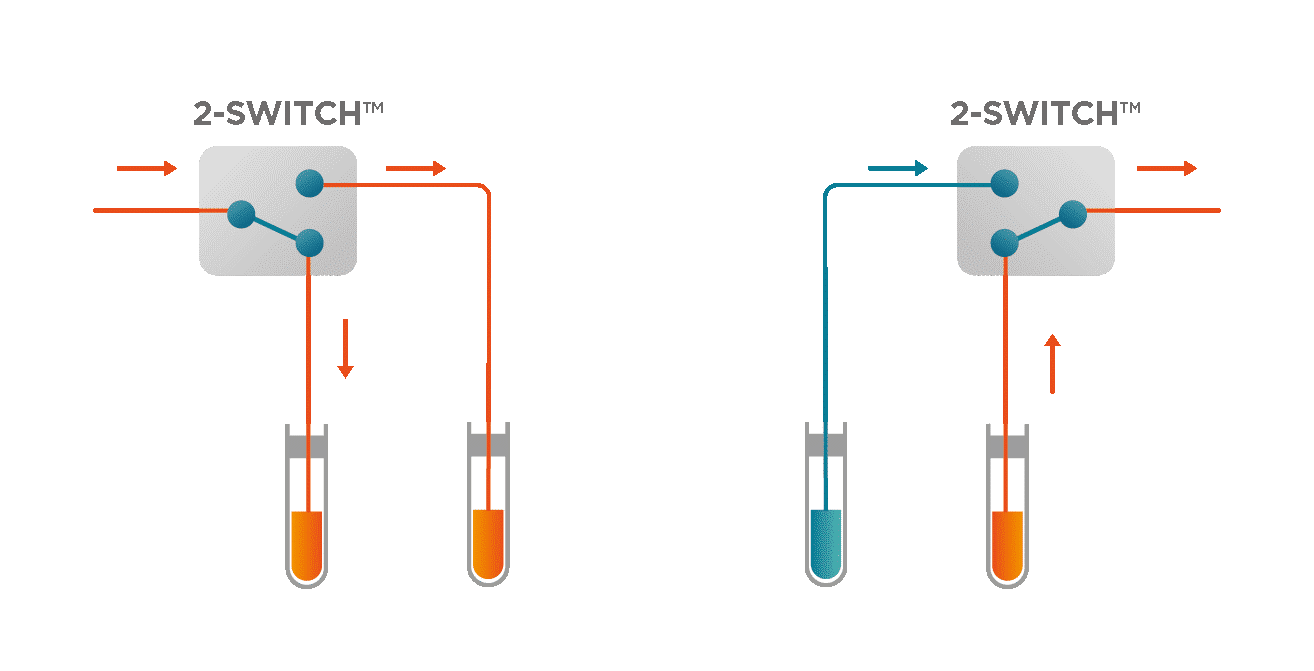

Fluid switching and sampling

The 2-X can be used for fluid switching or sampling depending on the direction of flow. When 2 liquids are coming into the valve, select which to deliver to your device. Alternately, one liquid can be driven into selected parts of a setup for sampling/sorting.

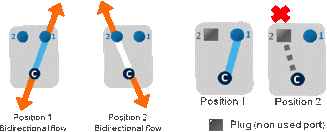

ON/OFF flow

The 2-X is a versatile device that can be very easily adapted into an on/off valve (2-port / 2-position) by connecting a plug to one port (other than the common port).

Time-based automation

The valve can be controlled by using Fluigent software for long-term operations. Create a time-based protocol to set actuation timing of the valve(s).

Suited for many applications

Its versatility makes it ideal for applications where fluid sorting, switching or periodic sampling is required such as fluid sorting.

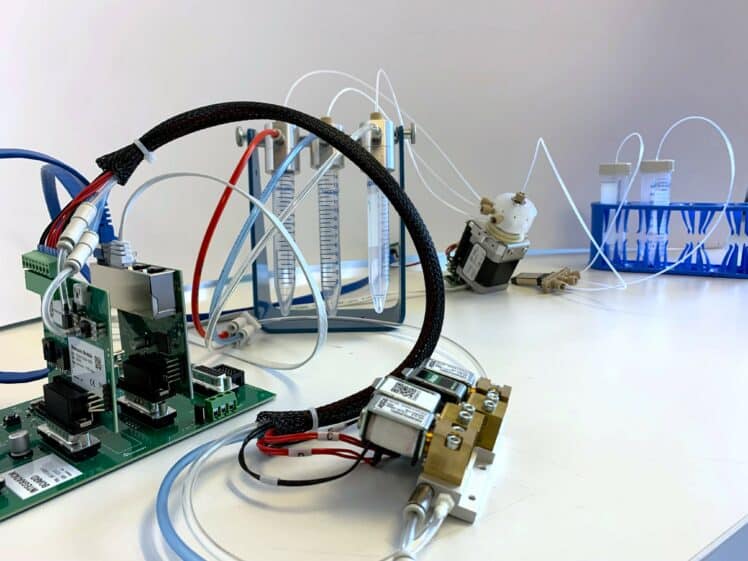

Parallelize and combine valves

The specific design of the valve allows one to combine several together with a minimum of space requirement. Added to the automation software, one can easily create multiple fluidic paths.

Related applications

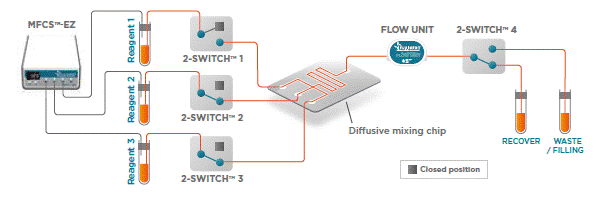

How to use the 2-X valve?

The diagram shows an example of how to use the 2-X devices.

At the upstream of the microfluidic device, 2-X are used for each inlet as on/off switches. In order to choose which reagent will be injected into the mixing chip.

At the downstream of the chip, 2-X is used as a 2-way switch to easily sort the exiting flow and recover only the sample that you want.

All the 2-X can be automated so that the selection of reagents and the outlet sorting are fully synchronized. This kind of fluidic diagram can be very useful for chemical mixing reactions, stoichiometry, and viscosity studies.

FAQ

How to add the 2-X in my experience and how to connect it?

- Cut the 1/16’’ OD tubing to the desired length, leaving a square-cut face.

- Slide the nut over the tubing with the nut thread facing the tubing end being connected.

- Slip the ferrule over the tubing, with the tapered portion of the ferrule facing the nut.

- Insert the assembly into the receiving port, and while holding the tubing firmly against the bottom of the port, tighten the nut finger tight.

- To check the tightness of your connection, you may pull gently on the tubing: it must stay fitted in the ferrule and nut.

Warning: The 2-SWITCH™ device can only be connected with 1/16’’ OD tubing.

How can I clean the 2-X after use?

You can clean the 2-X in the same way than the Flow Unit.

Besides, Fluigent strongly advises you to use filtered solutions. Wetted material is Teflon® only.

How can I make a junction between a 2-X and tubing with external diameters different from 1/16″?

The 2-Xcan only be connected with 1/16’’ OD tubing and the provided fittings. There is a wide variety of materials and internal diameters available with 1/16’’ tubing to suit your application. However, if you have constraints on your fluidic set-up that force you to use tubing of other external diameters than 1/16’’, a wide range of adaptors and unions are available from the fittings suppliers, to make a junction between your specific tubing and the 2-SWITCH™ tubing.

Warning: Please note that sleeves cannot be used directly in the 2-X fluidic ports (risks of trapping the smaller tubing and possible non-tight connection).

With a fluidic “ON/OFF” switch configuration, should I fill with liquid the plugged path inside the 2-X before screwing the plug?

If you are planning to use a 2-X as a fluidic on/off switch, you will need to plug either port #1 or port #2 on the 2-X. For example, if you plug port #2, when in Position 2 the common port will be connected to the plug inside the 2-X. As there is still some internal volume inside the 2-X (12µL per position), it is better to fill the 2-X in Position 2 with distilled water before connecting the plug to close the position. This way, during the experiment when the valve is actuated in Position 2 to close a path, there will be no air bubble and a minimal liquid displacement in the Position 2, as it will have already been filled with liquid.

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 21.0.0.0 or more recent |