All-in-one pressure controller and supply powered by battery or line voltage.

- Customize your own

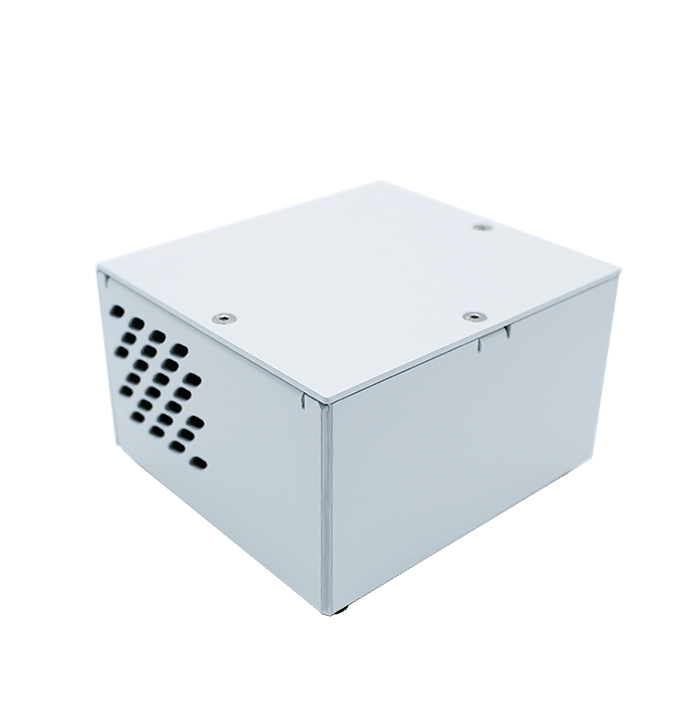

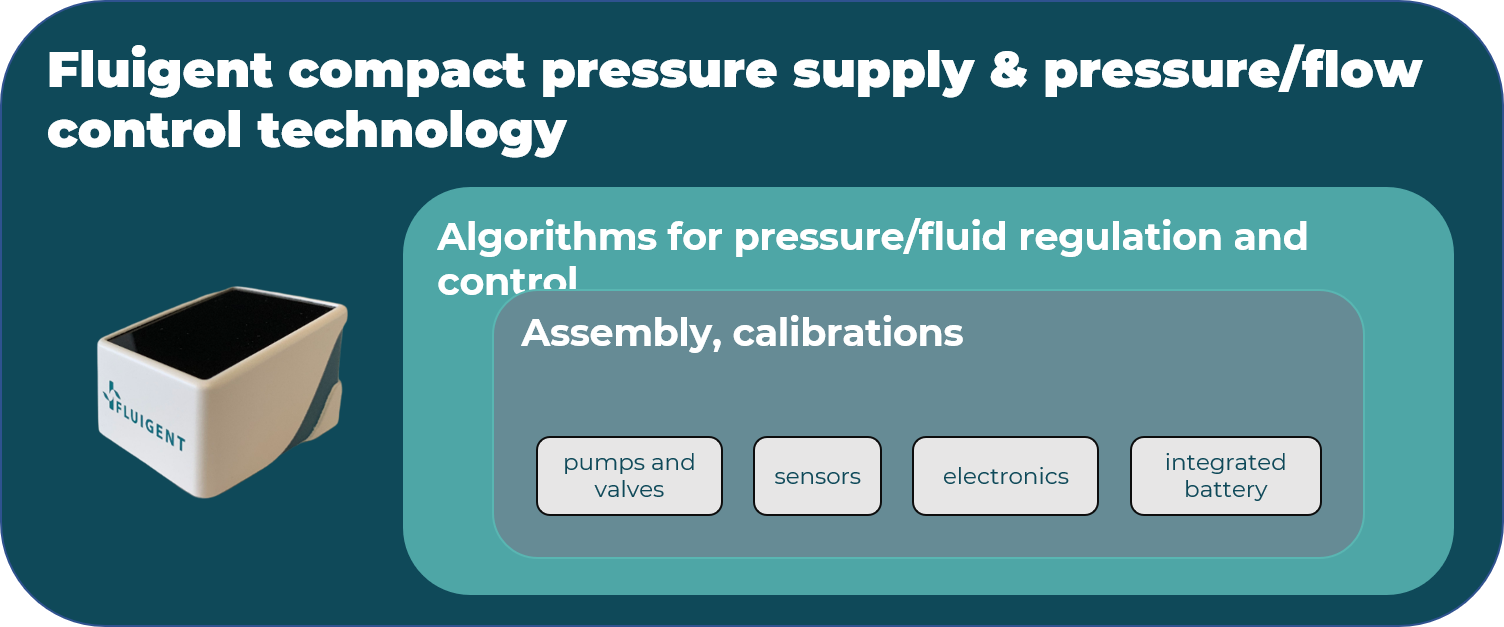

(Patent pending) compact all-in-one pressure supply & pressure/flow control

Free Standing:

Free Standing: Light and compact:

Light and compact:Weighing in less than 170 g and with a volume of 140 cm3

Unmatched performance:

Unmatched performance:Excellent stability and response time thanks to Fluigent pressure and liquid handling expertise

- Silent operation:

(< 20 dB)

Fluigent has developed (patent pending) an all-in-one, free standing, compact, integrated pressure-based control with an internal pressure supply technology. It offers excellent performance. is well-suited technology for applications that require mobile or compact fluidic control devices, including point of care (PoC) diagnostic and testing, or for water and soil on-site analysis. This technology combines electronic and pneumatic elements engineered together with well established Fluigent regulation algorithms and knowledge.

This technology can be integrated in any custom project.

Benefit from the best performance and Fluigent expertise for your project.

Technology description

Fluigent’s most compact and miniaturized pressure-based liquid handling technology

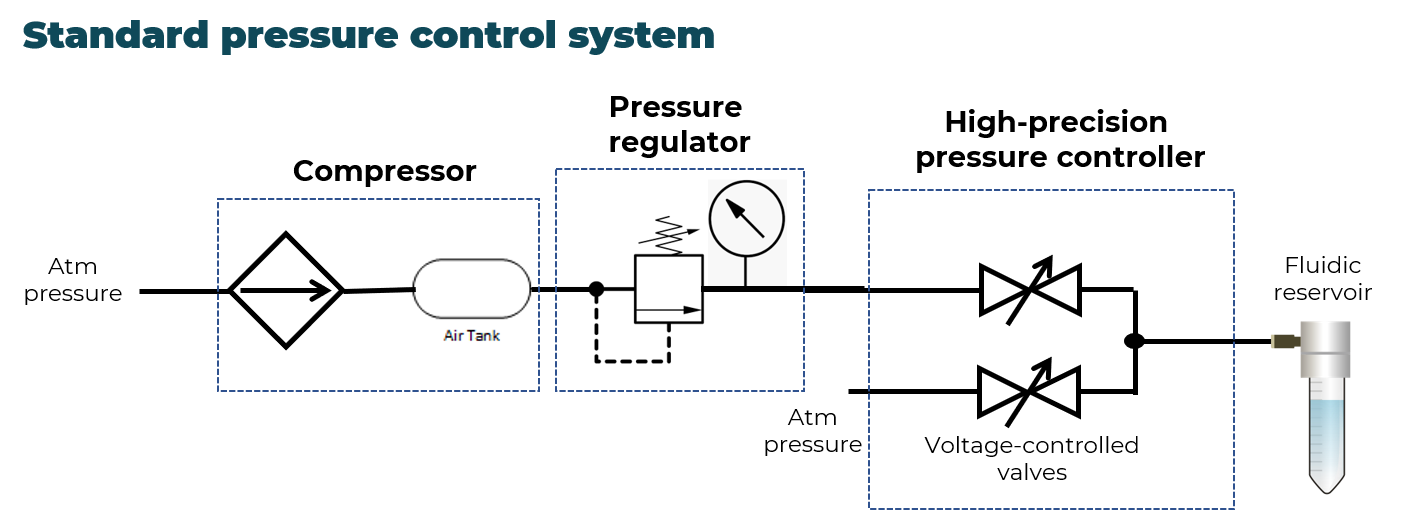

It is well established that pressure-based flow control offers unequaled flow stability and response times. Most pressure controllers require a pressure source which is regulated.

Although an external pressure supply allows working over large pressure ranges (generally up to 7 bar) and high gas flow rates, it can be cumbersome, and integration into a device is challenging. Point of care devices needing a small footprint can have engineering challenges.

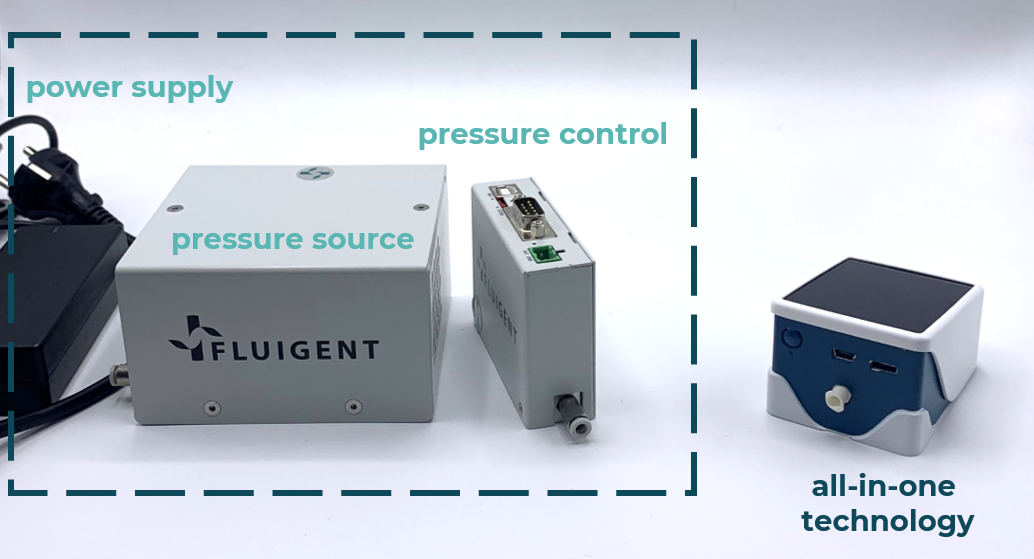

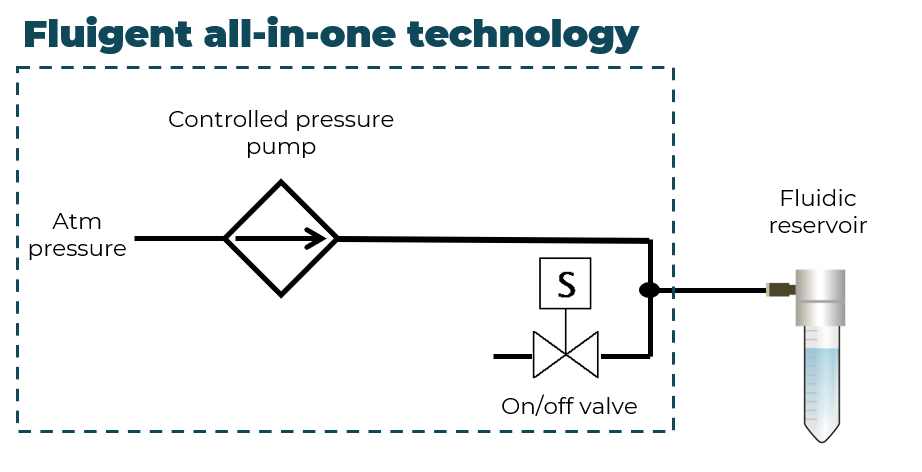

Fig 1: (left) A pressure supply and pressure controller vs our new technology (right) Fluigent engineered technology

Fluigent has developed a pressure-based technology that offers an integrated pressure supply and control (positive and negative pressure) in a light (< 170 g) and compact format (L*l*H = 7*5*4). The technology consists of a uniquely engineered assembly of electronics, sensors integrated with a micropump, and pneumatics to provide high performance.

Fig 2: (left) Pneumatic schematic of a standard fluidic system using pressure to move fluids (right) Pneumatic schematic of Fluigent new technology

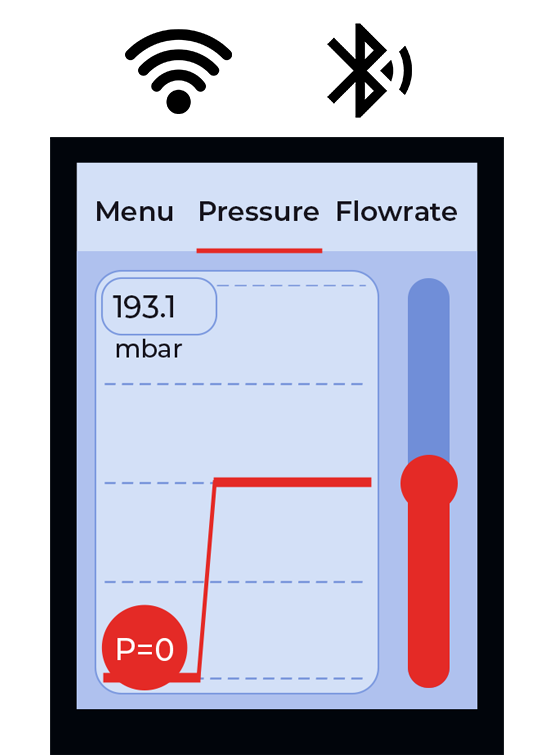

Portable or connected

The technology is powered by an embedded rechargeable battery to facilitate portability. It can support a wide range of connections (Wi-Fi, BLE, IoT, USB, industrial bus), and embedded protocols. For point-of-care applications, a touch screen can be developed based on your needs. A flow sensor can directly be connected to the engineered device.

Fluigent expertise equals performance

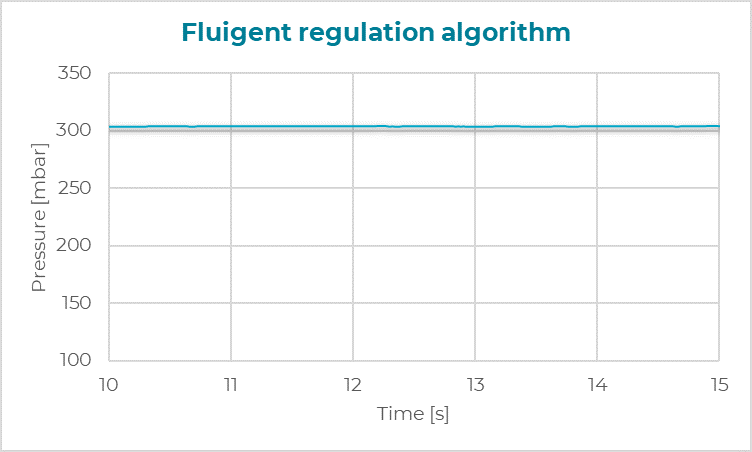

Unmatched pressure and flow stability

Fluigent’s i (patent pending) powerful pressure regulation algorithm is based on physical equations and self-learning routines that offer several benefits:

- No overshoot/undershoot, allowing for an immediate highly accurate and stable flow

- Useful over a wide pressure or vacuum range (up to 600 mbar, -400 mbar vacuum, standalone pressure/vacuum regulation capability)

- Adapts to any reservoir size

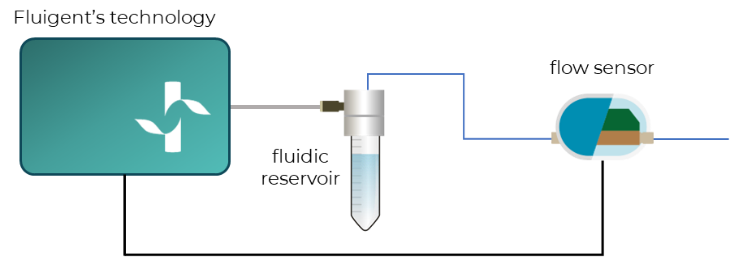

By directly connecting a flow rate sensor, it is possible to monitor or control flow rate in real time. The algorithm includes a continuous optimization of the parameters that allow it to adapt to the interactions between microfluidic channels in complex situations.

Fig 4: Fluigent’s technology connected with a flow rate sensor for pressure-based flow control

Stop & Go, pressure/vacuum capabilities

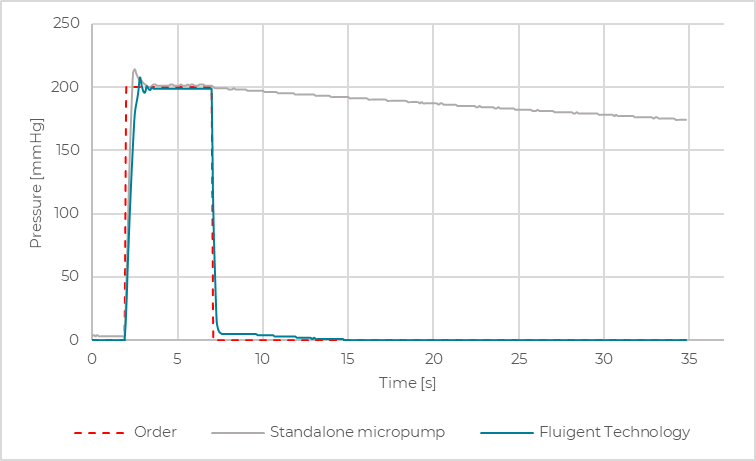

When using a gas micropump alone, pressure drops are very slow, as shown in Fig. 5 that compares Fluigent solution with a standalone gas micropump. In fact, it is possible to observe that the micropump will take more than a minute to reach zero pressure.

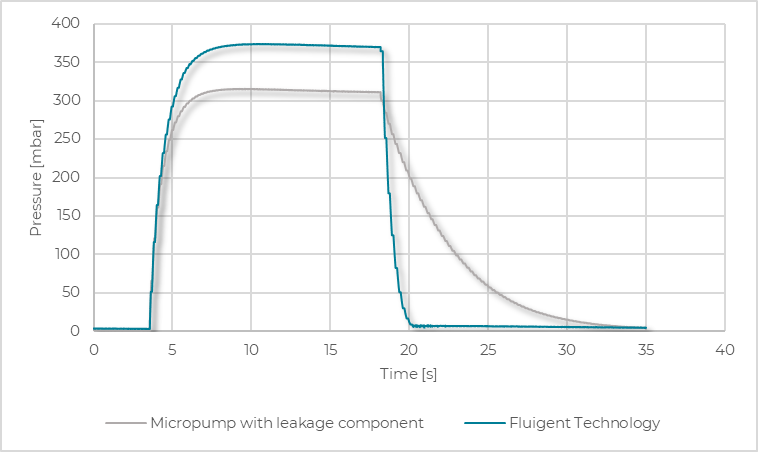

Using a pressure leakage or a valve in complement to the pump is a way to circumvent this limitation. With the addition of a pressure leakage component, the pressure drop now takes about 5 seconds (see Fig. 6). However, adding such leakage components influence the overall performance: the maximum pressure that can be reached has now decreased of about 15% (from 375 mbar to 310 mbar illustrated in the graph Fig. 6).

To ensure excellent response time while guaranteeing the best performance, Fluigent developed a technology that makes use of proportional valves. Using this engineered solution, pressure drop takes less than a second, and the maximum pressure reachable has not deteriorated (see graph). This allows to perform operations that require fast response time, or require fast change between applied positive pressure and vacuum.

Comparing with standard pressure control

| Compact pressure/flow control technology | Standard pressure controllers (e.g. Fluigent PX, P-OEM, F-OEM) | |

|---|---|---|

| Compactness | – All in one micropump for pressure source and control – Optimized footprint | Need to be connected to an external pressure source and power supply |

| Pressure/flow stability | Excellent (~0,3% on the measured value) | Excellent (< 0,1% on the measured value) |

| Pressure response time | Excellent (a few seconds) | Excellent (a few seconds) |

| Gas flow rate | Up to 2 L/min depending on the model. Examples: – 2 L/min using a 0-200 mbar pressure range – 750 mL/min using 0-380 mbar pressure range 150 mL/min using 0-800 mbar pressure range | Up to 3.5 L/min depending on the model Examples: – 3.5 L/min using Fluigent F-OEM 0-7000 mbar – 800 mL/min using Fluigent F-OEM 0-1000 mbar – 550 mL/min using Fluigent PX 0-1000 mbar |

| Pressure range | – Pressure: Up to 600 mbar (for a single pump) – Vacuum: Up to -400 mbar | – Pressure: Up to 7 bar – Vacuum: Up to -800 mbar |

| Lifespan | ~ 5 000 h (maintenance can be performed) | Lifetime |

Related Applications

Emerging point of care applications make use of more complex fluidic operations and require compact systems. Our technology is an excellent fit for such applications as it is fully connected and provides excellent fluidic performance while being compact.

- Life Sciences – Point of Care testing and diagnostics:

Point of Care (PoC) testing allows one to diagnose diseases at or near the patient site. Point of care tests such as blood analysis, glucose monitoring, infectious disease testing, cholesterol testing, or cardiac markers are marketed1. A new generation of point of care diagnostic devices has been recently developed for providing higher sensitivity diagnostics, such as nucleic acid amplification tests. These often require more bulky equipment as the internal technology is more advanced.

- Environmental – water and soil analysis:

Continuous monitoring of water resources such as freshwater, seawater, and, in particular, wastewater and drinking water, for human and animal consumption, is essential2. Conventional water monitoring is based on laboratory instruments that are generally sophisticated and expensive. As the equipment is not easily portable, samples can be compromised during travel. As an alternative, microfluidic-based portable devices have been developed for on-site analysis. Our engineered systems tackle these limitations by bringing a cost-effective solution with a highly reduced footprint.

- Other Industrial applications:

Complex pressure and flow distribution can be eliminated as the unit can be placed at the location where pressure, vacuum, or flow control is needed.

References

1. Sachdeva, S., Davis, R. W. & Saha, A. K. Microfluidic Point-of-Care Testing: Commercial Landscape and Future Directions. Front. Bioeng. Biotechnol. 8, 1–14 (2021).

2. Janire, S., Raquel, C.-C., R_oisín, M. O. & Lourdes, Basabe-Desmonts Fernando, B.-L. Microfluidics and materials for smart water monitoring: A review. 1186, (2021).

Websites: