Easily fits in systems and machines

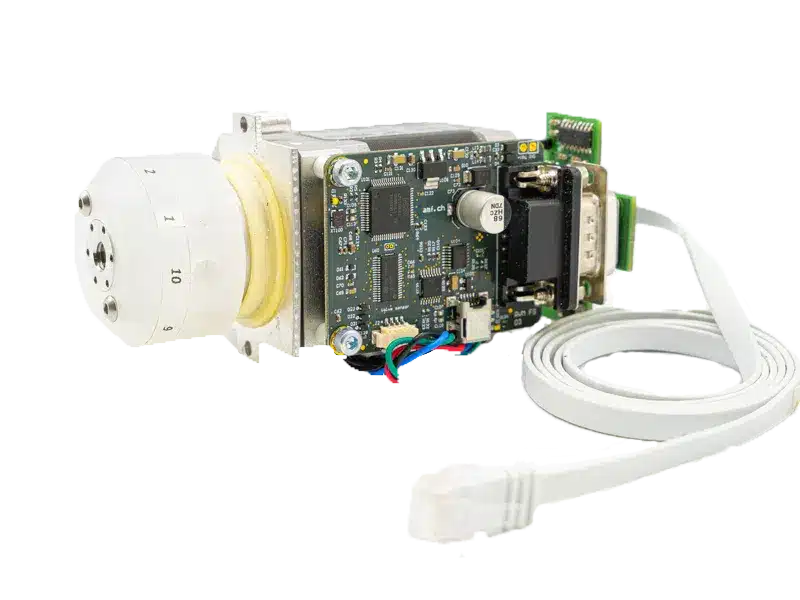

Fluigent M-X

[IVMSW1]Rotary multi-port microfluidic valve for industry

- Compact

Fast

FastActuation and response time

- Accurate

Low internal volume

Automation

AutomationFully automated with in house software or SDK libraries

The OEM Fluigent MX is a bidirectional 11-port / 10-way electric rotary valve for injection or selection of up to 10 different fluids. The flow is bidirectional in the rotary valve. The device can be used as a selector or as a distributor for either multiplexing or demultiplexing purposes.

Specifications

| Internal volume | 4.5 | µL |

| Carryover volume | 2.8 | µL |

| Dead volume | none | |

| Rotation time for 180° | 400 | ms |

| Switching time from Port to Port | > 136 | ms |

| Weight | 590 | g |

| Dimensions | 65 x 55 x 11 | mm |

| Wetted materials | UHMW-PE, PCTFE | |

| Channel diameter | 0.5 | mm |

| Max pressure | 7 | bar |

| Operating temperature | 15-40 (41-104) | °C (°F) |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample | |

| Port communication | RJ45 | |

| Software control | OxyGen, SDK |

M-X References

| Name | Part number | Comment |

|---|---|---|

| Fluigent M-X | IVMSW1 | Rotary multi-port microfluidic valve for industry |

Technical downloads

Fluigent M-X rotary valve features

11-port/10-position

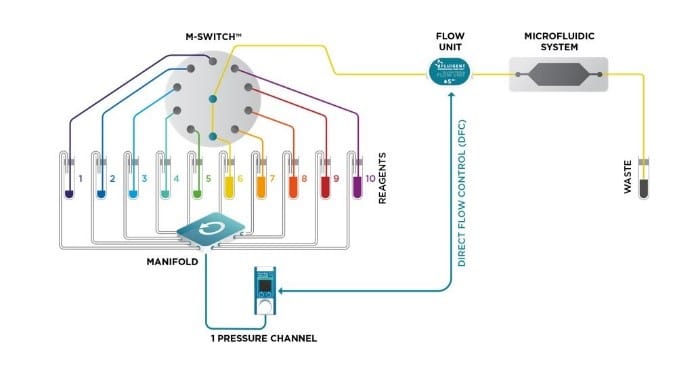

The Fluigent M-X is an 11-port / 10-position electric rotary valve. Any of the peripheral ports (numbered from 1 to 10) can be connected to the central channel, and the fluidic path created is bidirectional. The MX microfluidic electric rotary valve is actuated by a motor that drives a rotor. It can also be used with a manifold to use a single pressure pump to deliver multiple liquids.

Sequential injections

Up to 10 liquids can be sequentially delivered. Each step can be automated using Fluigent software.

Automation

The MX OEM Electric Rotary valve can be controlled by our software for long-term experiments. Create a time-based protocol to set actuation timing of the microfluidic valve(s).

Related applications

Can industrial pressure controllers be used to monitor multiple fluids at different flow rates?

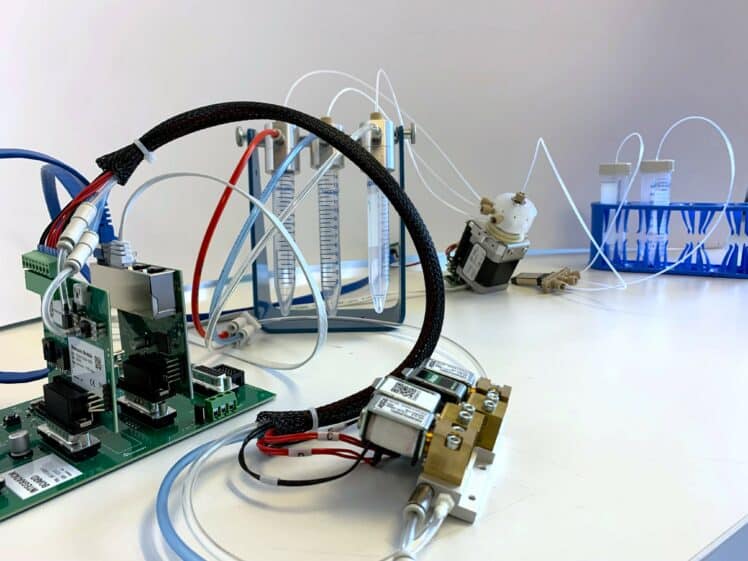

Context

An established company makes wastewater testing systems using syringe pumps. The system draws samples and reagents from multiple reservoirs. The moving seals on the syringe pump break often and cause device failure and wasted reagent.

Solution

Fluigent proposed a 10 port M switch rotary valve powered by a pressure pump which doesn’t use moving seals.

Result

The Fluigent solution eliminated leakage and decreased overall reagent consumption due to a lower internal volume.

How to use the M-X device ?

Example 1: sequential injection of several fluids

In this application example, up to 10 liquids (4 on the schematic) are selected sequentially to be delivered to the chip by the M-X OEM Microfluidic Electric Rotary Valve. The samples at the outlet of the chip may also be sorted by using a bidirectional valve either into a collection tube or to waste. Each step can be automated either by using Fluigent software.

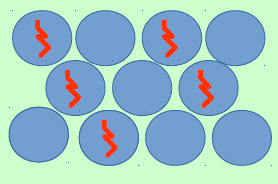

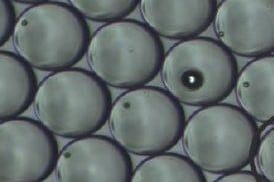

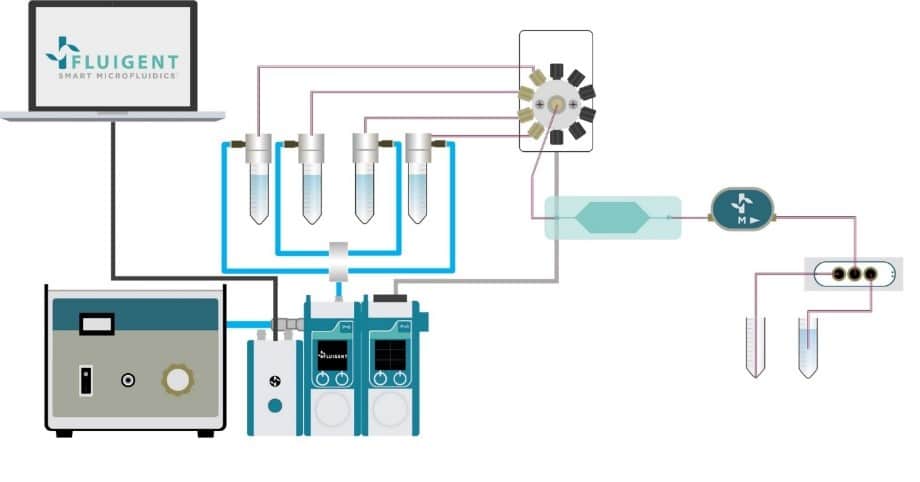

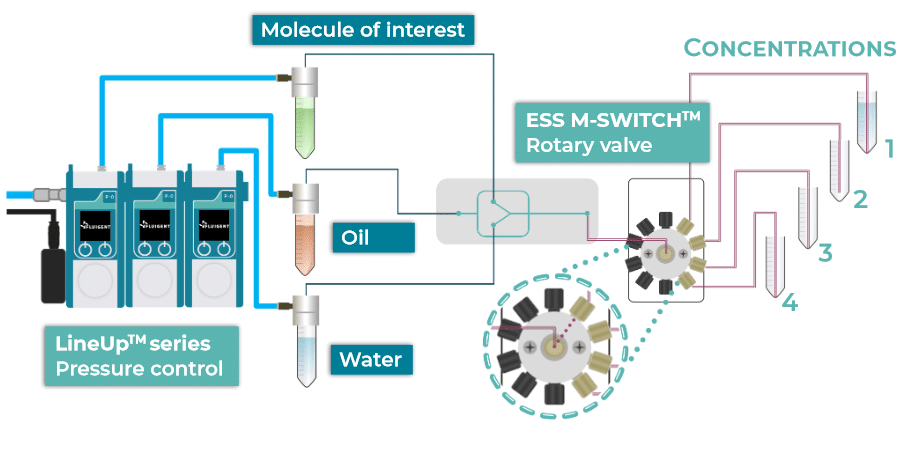

Example 2: Sample generation and collection

In this application example, different concentrations of the molecule of interest are injected into the chip generating water in oil droplets containing various concentrations. The droplets are then sorted at the outlet of the chip using the M-X OEM Microfluidic Electric Rotary Valve on their analyze concentrations. Each step can be automated using Fluigent software.

FAQ

How to add the M-X in my experiment and how to connect it?

To learn how to connect the M-Switch™ on the Switchboard, go to the ESS™ section.

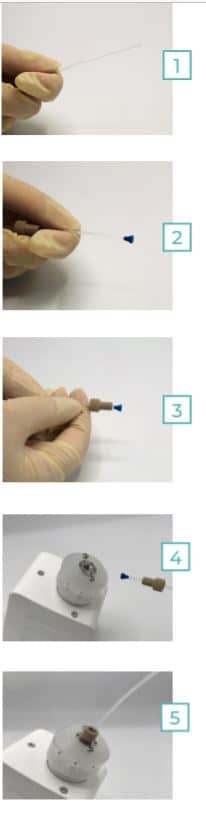

Concerning the tubing connection:

1. Cut the 1/16’’ OD tubing to the desired

length, leaving a square-cut face.

2. Slide the ¼ -28 fitting over the tubing,

with the thread facing outwards. Slip the

ferrule over the tubing, with the tapered

portion of the ferrule facing the fitting.

3. The conectors and ferrules are specifically designed to work together. FLUIGENT

advises you to only use the provided

ferrules together with the provided nuts.

4. Insert the assembly into the receiving

port, and while holding the tubing firmly

against the bottom of the port, tighten

the connector.

5. To check the tightness of your connection, you may pull gently on the tubing

and verify that it remains secure.

How can I clean the M-X after use?

You can clean the M-Switch™ in the same way than the Flow Unit.

Besides, Fluigent strongly advises you to use filtered solutions. Wetted materials are custom PCTFE and UHMW-PE.

How to use tubing with external diameters different from 1/32″?

If one wants to use tubing with external diameters different from 1/32″, a sleeve should be used to adapt to the different size

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 1.0.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 21.0.0.0 or more recent |

Expertises & Resources

-

Fluigent Products Datasheets M-X Technical Specifications Download

-

Microfluidics Case Studies OEM Case Study: Microfluidic Drug Screening Read more

-

Expert Reviews: Basics of Microfluidics Key considerations for fluidic system integration Read more

-

Fluigent Products Datasheets M-SWITCH™ Datasheet Download

-

Microfluidics Case Studies The Hebrew University: Encapsulation and culture in 3D hydrogels for Single cell sequencing Read more