Microfluidics in Food Industry: Food Testing & Agriculture

What are the advantages of Microfluidics in Food Industry?

The rapidly growing global population demands more advanced technologies in food processing to produce more functional and safer food.

Emulsion production

In foods, the most common application of microfluidic systems is in the preparation of emulsions. These provide accurate control over droplet size and the shape of internal structures. Microfluidic devices can be used to produce different types of microstructures depending on the final product, adding some characteristics such as texture or dispersion.

Microfluidics for Food Analysis

Food safety analysis is important to control food contamination and quality. Constructing effective methods for fast and accurate food safety sensing on-site is needed. Microfluidic systems can quickly and accurately analyze food samples for contaminants, pathogens, chemical residues, and other quality control parameters, reducing the time required for testing and analysis.

Microfluidics for agriculture

Microfluidics in food industry can be used for precision agriculture, allowing for the precise and controlled delivery of nutrients, fertilizers, and pesticides to crops, minimizing waste, and maximizing crop yields.

On-site soil analysis can also be performed thanks to microfluidics, allowing to rapidly identify soil parameters such as nutrient concentration. This allows for better fertilizer consumption and less unnecessary soil pollution.

Industrial applications

Research applications

Microfluidics to recognize fake honey

Doing PhD with Fluigent 2021: Research on Honey by Daniel Kraus [Jena, Germany]

One example of using Microfluidics in Food Industry:

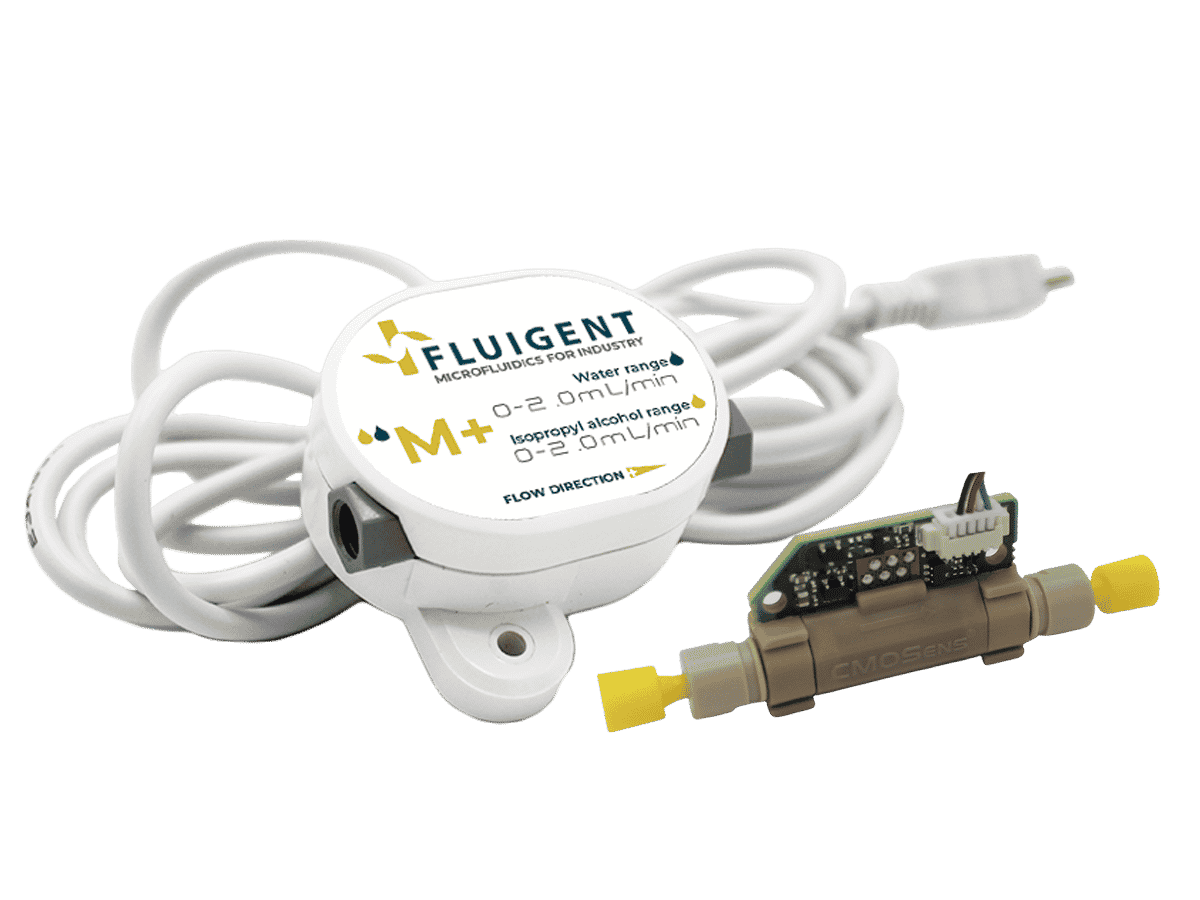

One of our PhD students Daniel is doing his postgraduate research on honey at the Leibniz Institute of Photonic Technology. Using the microfluidic set-up, including microfluidic chip and Fluigent pressure pumps, Daniel can examine the pollens to find out whether the origin of honey is natural or faked.

The high-throughput microfluidic technique enables honey particles to pass with the same velocity through the microfluidic channel, which makes for a better more efficient analysis that goes beyond the state of the art.

Related products

Research field

Industrial field

Expertise & resources

- Advantages of pressure-based microfluidics

Flow control for droplet generation using syringe pumps and pressure-based flow controllers

Read more - Support & Tools

Droplet Size Calculator

Read more - Product presentation videos

DROPLET STARTER package – Make DROPLETS within minutes!

Read more - Droplet and particle generation in microfluidics

Microfluidic Droplet Production Method

Read more - Application notes

Encapsulation of multiple emulsions in a single droplet

Read more - White Papers

Droplet-based Microfluidics

Read more - Array

Raydrop, a universal droplet generator based on a non-embedded co-flow-focusing

Read more - Application notes

Generating a water emulsion in an oil solution using a droplet generator chip

Read more - Array

Robust technology for double emulsion production and focus on microcapsule/microparticle synthesis

Read more

Looking for another market?

From the life sciences to the food industry, many applications require the use of fluids driven at flow rates from nanoliters to milliliters per minute. At such low flows, the success of these applications strongly depends on the level of control and automation of the fluidic operations.

These applications require flow control systems that are adapted for ensuring their success.