Multiple emulsion droplet generation

In this Application Note, we demonstrate how to encapsulate multiple aqueous droplets (called “core”) into a single oil shell. Multiple core-containing emulsions were generated using two RayDrop developed and manufactured by Secoya (a capillary based microfluidic device equipped with a 3D printed injection nozzle) placed in series onto our RayDrop platform. The number of cores contained inside a droplet can be tuned by varying the flow rate of the core phase.

Introduction to multiple emulsion

Traditionally, batch methods are used to produce emulsions in industry. The use of bulk mixing allows one to produce large quantities of emulsions but to the detriment of quality. The particle size distribution in a bulk mixer is large leading to numerous particles sizes and a low encapsulation rate of Active Pharmaceutical Ingredient (API) or double emulsion production (core-shell particles)1. Batch methods make the control of multiple emulsions more complex, i.e. the encapsulation of a precise number of droplets of liquid A in a droplet of liquid B.

The use of microfluidics provides monodispersed emulsions with high control over both the size and structure can be obtained2. Microfluidic tools are also used to create emulsions of varying compositions. It is possible to produce water–in-oil–in-water (W/O/W) emulsions or oil–in-water–in-oil (O/W/O) emulsions. A microfluidic device developed by Secoya Technologies – called the RayDrop – allows one to easily produce highly controlled emulsions. Examples of applications in single and double emulsion can be found on our website.

Following the work of Li, E. Q. et al 3, the experts of Secoya Technologies demonstrate the ability to produce multiple emulsions using the RayDrop. These multiple emulsions are precursors in the creation of solid microcapsules used for triggered release1. These multicompartmental microspheres are also of interest to co-encapsulate incompatible solutions (which would react if they were in contact)4.

In this Application Note, aqueous droplets are obtained using the combination of two RayDrop devices placed in series. The influence of the fluidic parameters on the number of cores contained in the oil shell is underlined in this application note.

Experimental procedure

Reagents

Core phase:

- 2% Tween20 (Sigma-Aldrich) in water

Shell phase:

- Mineral oil light containing 2% ABIL EM 90 (Evonik) and 0.08% Bromocresol Purple (Sigma-Aldrich).

Continuous phase:

- Solution of 70% wt glycerol (>99.5%, Sigma-Aldrich) in water with 2% Tween20 (Sigma-Aldrich)

RayDrop platform setup

The production of droplets is performed with the RayDrop platform.

It is a fully integrated system comprising all the components needed to produce simple and double emulsions. This platform is divided into three parts: mechanics, fluidics and optics:

Mechanics

It is composed of a displacement stage (in x,y,z) allowing focus adjustment and the correct positioning of the RayDrop observation window.

Fluidics

Three Flow-EZ pressure-based flow controllers with the required tubing and valves and connected to pressurized reservoirs perform the automated fluidic injection. Emulsions are generated in the RayDrop. (a filter placed after each reservoir prevents impurities from reaching the RayDrop).

Optics

A color USB 3.0 camera with a LED source is connected to a computer to observe the droplet formation in live, control the stability of the emulsion and measure the size of droplets core and shell.

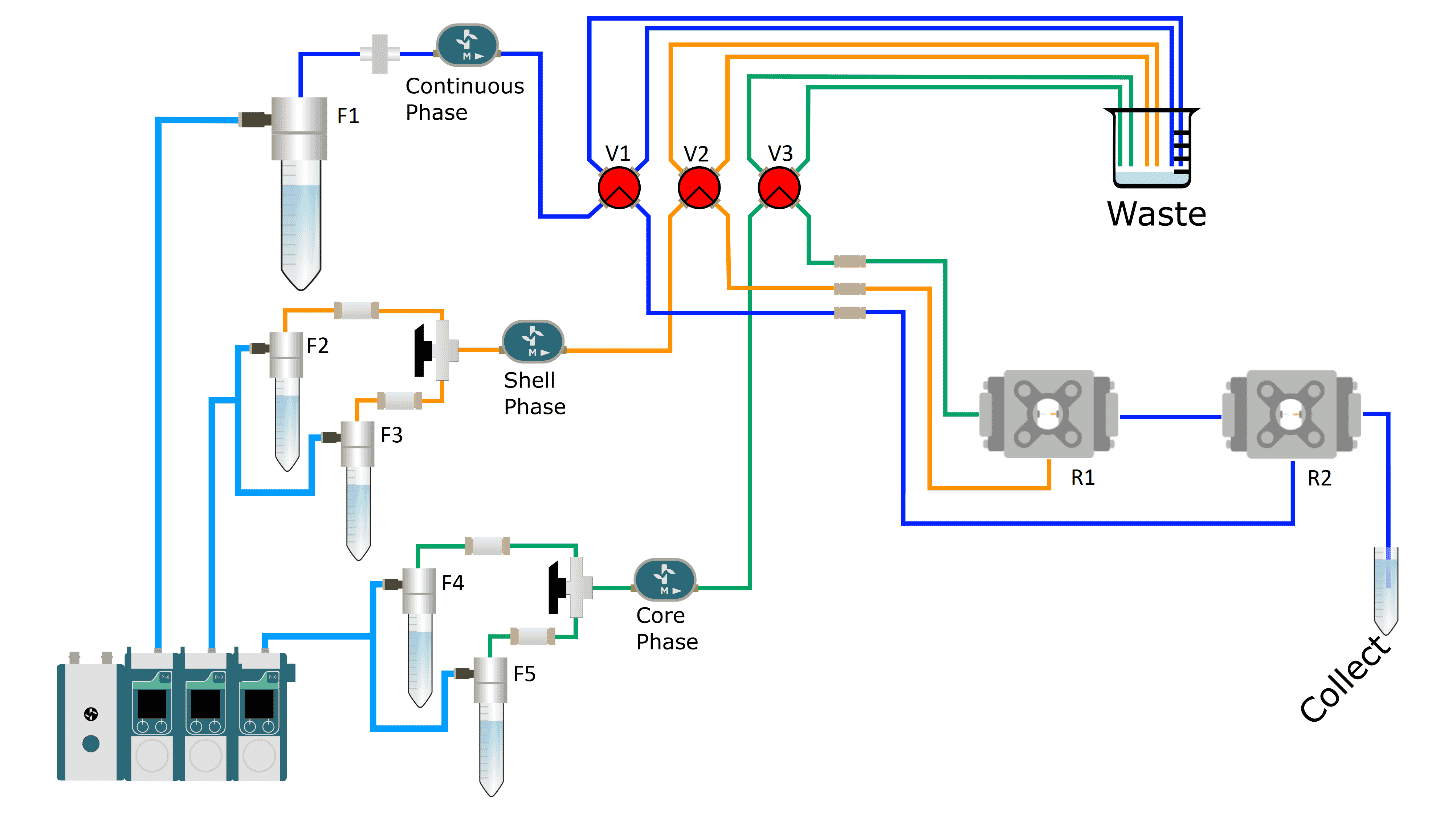

The experimental setup used for multiple emulsion generation is schematically represented in Figure 2. Here, a second RayDrop (R2) is placed next to the first RayDrop (R1).

Fluid reservoirs

| Reservoir | Volume (mL) | Phase | Composition |

| F1 | 50 | Continuous | 70% glycerol + 30 water + 2% Tween 20 |

| F2 | 25 | Shell (priming & cleaning) | Not used in this application note |

| F3 | 25 | Shell | Mineral oil light + 2% ABIL 90 + 0.08% Bromocresol |

| F4 | 25 | Core (priming & cleaning) | Not used in this application note |

| F5 | 25 | Core | Water + 2% Tween 20 |

RayDrop design

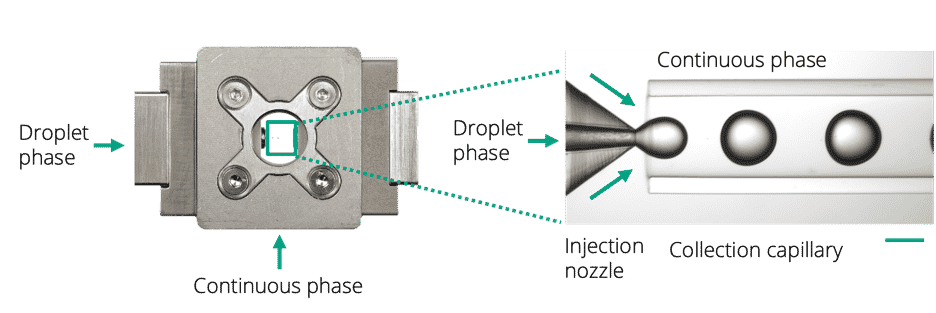

The RayDrop is a microfluidic droplet generator based on the alignment of two glass capillaries: the first one is terminated by a 3D printed nozzle and injects the droplet phase in the second one. At the junction of both capillaries, the continuous phase filling the cavity pinches the jet of droplet phase, leading to the formation of droplets with a high monodispersity.

In this case, two RayDrop are placed in series. The first is placed on the platform as usual and the second is added after, as shown in Figure 2. To control the formation of droplets inside the second RayDrop, an additional camera and an additional LED light source are used.

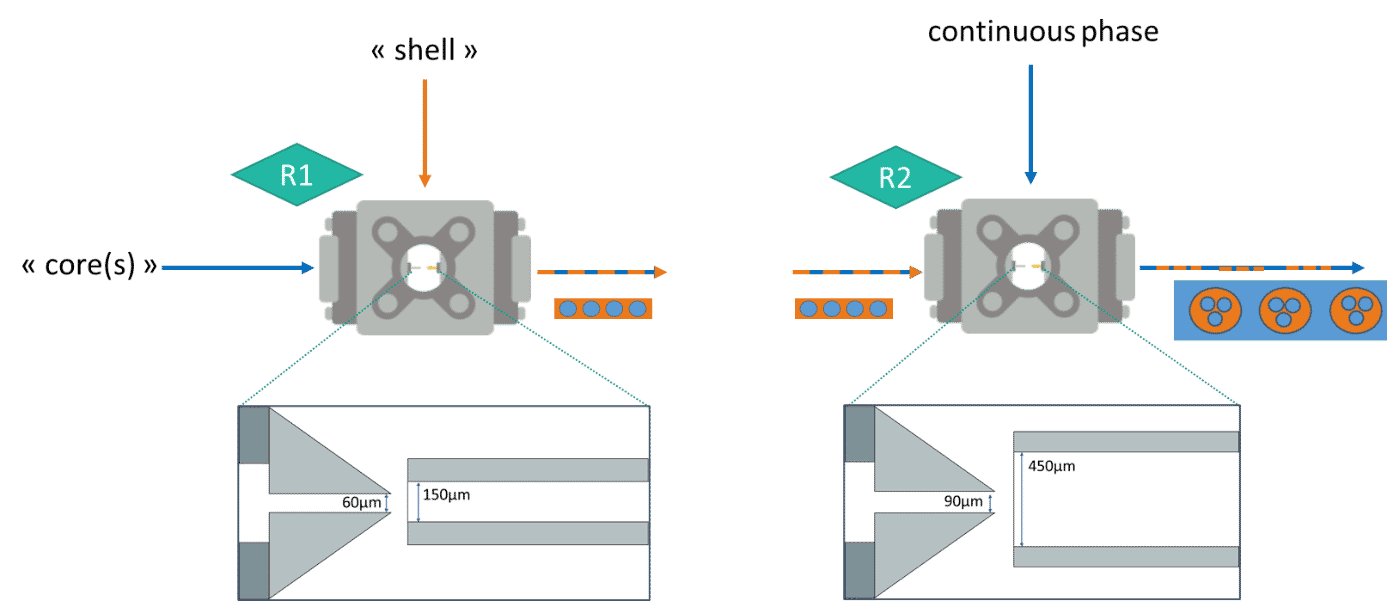

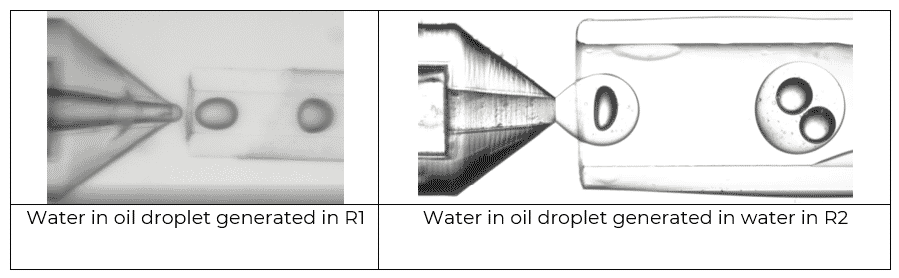

Droplets formed in RayDrop 1 (R1) are transported as the “shell” phase (see Figure 4) in RayDrop 2 (R2). Here, the “shell” phase is pinched by the continuous phase, leading to the formation of a shell droplet encapsulating multiple core droplets.

Nozzle information

The range of droplet sizes formed depends on the dimension of both the injection nozzle and collection capillary. The dimensions used for this application note are reported below.

| Part | RayDrop | Nozzle size (µm) | Collection capillary size (µm) |

| Inner diameter | 1 | 60 | 150 |

| Inner diameter | 2 | 90 | 450 |

Multiple emulsion generation

Oily double emulsions with multiple cores are formed. To generate droplets, the protocol below can be followed:

1. Set the valve V2 on the reservoir F3 containing the shell phase

2. Set the valve V3 on the reservoir F5 containing the core phase

3. Fill RayDrop R1 with the shell phase solution (refer to the user guide for more details about how to fill the RayDrop)

4. Fill RayDrop R2 with the continuous phase solution

5. Connect the two filled RayDrop together with a tubing

6. Carefully set the continuous phase to a low flow rate (for example, Qcontinuous= 40µl/min) and check that there is no backflow in the first RayDrop.

7. Set the shell phase to a low flow rate (for example Qshell= 7µl/min with Qshell<Qcontinuous) to create a simple emulsion oil in water visible in the second RayDrop.

8. Set the core phase to a low flow rate (for example Qcore= 1µl/min) to generate simple emulsions in R1 which leads to the generation of multiple emulsions in R2.

9. The single encapsulated multiple emulsions are now produced. The dripping mode provides a high stability for droplet formation. Droplets show high monodispersity. It is possible to vary the flow rates in order to change the size of the emulsion as well as the number of cores (see the following section for more details).

Results

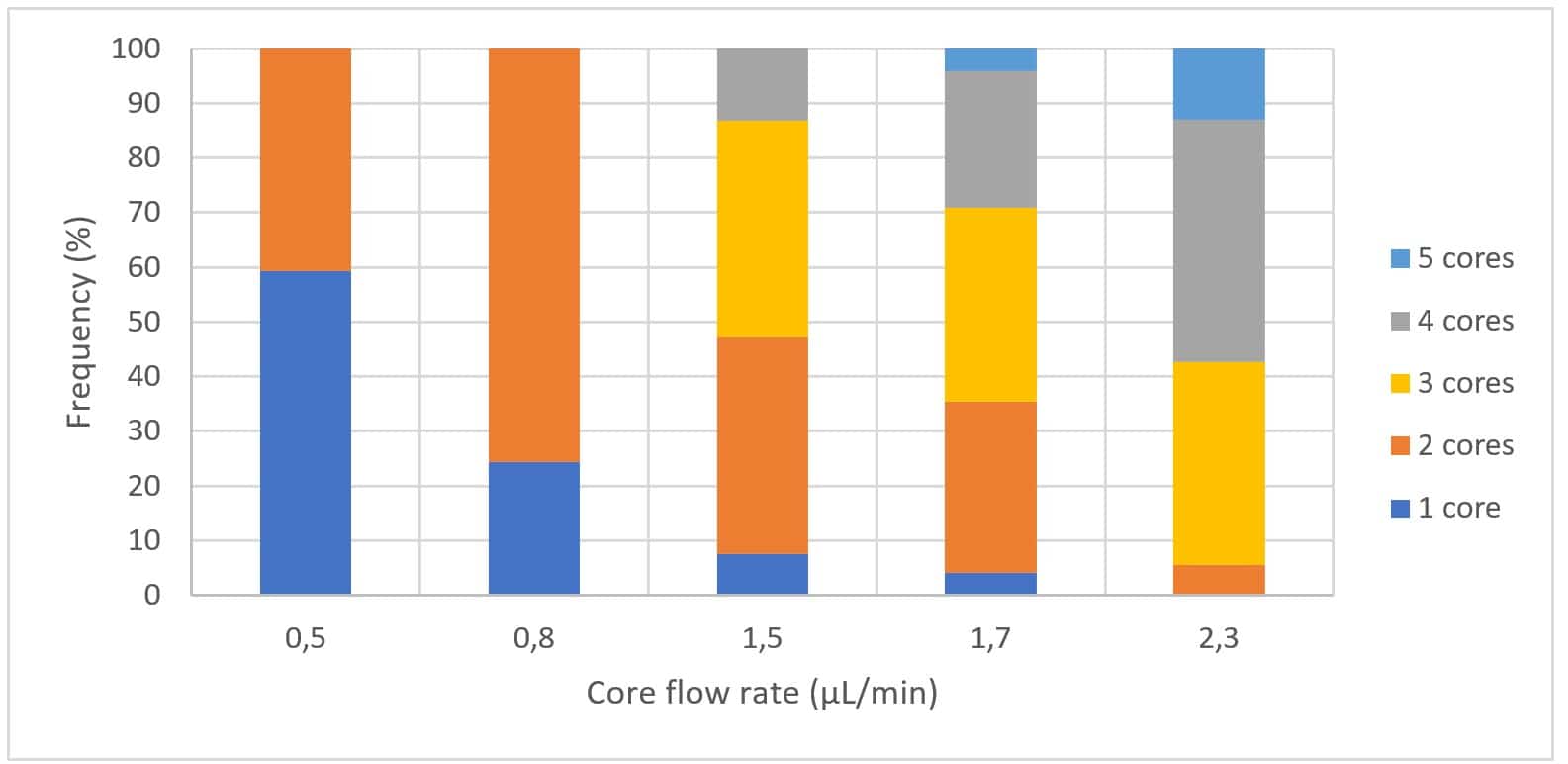

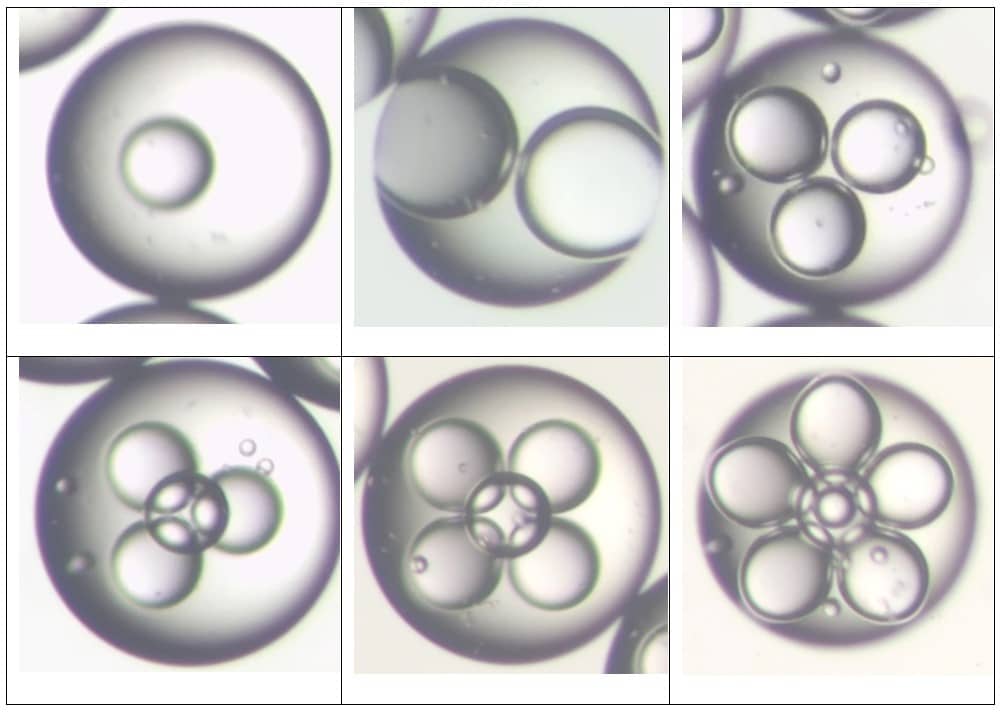

The number of cores in a single droplet depends on the flow rate of the core phase.

During the formation of the multiple emulsions in RayDrop R2, the flow rates of the shell and of the continuous phases are kept fixed. Thus, only the flow rate of the core phase is changed. By increasing the core flow rate, the number of encapsulated core droplets increases. For a core flow rate of 0.5µl/min, most droplets contain one core while for a core flow rate of 2.3µl/min, most droplets contain four cores.

Conclusion & Perspectives

We have shown the feasibility of producing multiple emulsions in a single shell using two RayDrop devices placed in series and integrated onto the RayDrop platform. We further demonstrate how to tune the number of cores in a droplet by varying the flow rate of the core phase.Using a Double Emulsion RayDrop, several type of emulsions containing multiple cores could be produced. For example, using a Double emulsion RayDrop as RayDrop R1 would allow one to obtain multiple double emulsions inside a single droplet

References

[1] Vladisavljević, G., al Nuumani, R. & Nabavi, S. Microfluidic Production of Multiple Emulsions. Micromachines (Basel) 8, 75 (2017).

[2] Lee, T. Y., Choi, T. M., Shim, T. S., Frijns, R. A. M. & Kim, S.-H. Microfluidic production of multiple emulsions and functional microcapsules. Lab on a Chip 16, 3415–3440 (2016).

[3] Li, E. Q., Zhang, J. M. & Thoroddsen, S. T. Simple and inexpensive microfluidic devices for the generation of monodisperse multiple emulsions. Journal of Micromechanics and Microengineering 24, 015019 (2014).

[4] Wang, W. et al. Controllable microfluidic production of multicomponent multiple emulsions. Lab on a Chip11, 1587 (2011).