High monodispersity (CV < 2%)

Microfluidic Double Emulsion Device

[ORDRPDE]RayDrop Double Emulsion

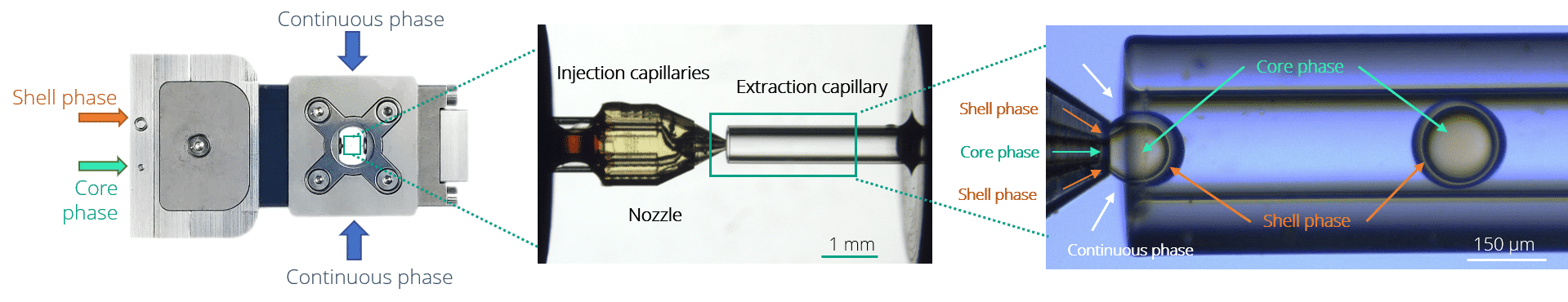

The RayDrop is a microfluidic double emulsion device composed of three main, fully removable parts: two inserts on each side,a center section containing a nozzle, and an outlet capillary. There are 5 standard microfluidic connections, two on the box for the continuous phase and three others: one on each insert for the core shell phase entry,and one on the collecting emulsion outlet. The droplets are produced by controlling the squeezing of the droplet phase locally generated by the continuous phase at the entrance of the collection capillary.

The RayDrop specific design allows for multiple liquid type emulsification within the same device with no coating needed. The device can create both single and complex emulsions.

- Reproducible

- Flexible

Multiple applications

- Easy

One device, coating-free

Features of the Double Emulsion Generator

A unique device

Perform double emulsions in one single device.

A flexible device

Droplet size from 25 µm to 450µm outer diameter.

Frequency of up to 5 000 Hz.

Water-in-oil-in-water (w/o/w) and oil-in-water-in-oil (o/w/o) within the same device.

User-friendly

Exchangeable nozzles that are easy to disassemble and clean with clear water. microscope visualization and the ability to connect with standard tubing and nuts.

Surface coating not required

As opposed to standard double emulsion microfluidic chips, the Raydrop does not require any surface coating steps. The double emulsion device also does not require any surfactant for droplet generation.

Related applications

Description of the double emulsion microfluidic chip

Most commercially available and lab-made droplet generators are based on a flow-focusing technology implemented in rectangular microchannels fabricated by lithography and made of polydimethylsiloxane (PDMS), polymers or glass. However, this planar configuration has many limitations due to the contact between the walls of the microchannels and both phases at the junction, requiring laborious and often ephemeral wettability treatments of these walls. On the contrary, due to their axisymmetric configuration, glass capillary systems do not have this drawback since the dispersed phase is never in contact with the walls of the outer capillary.

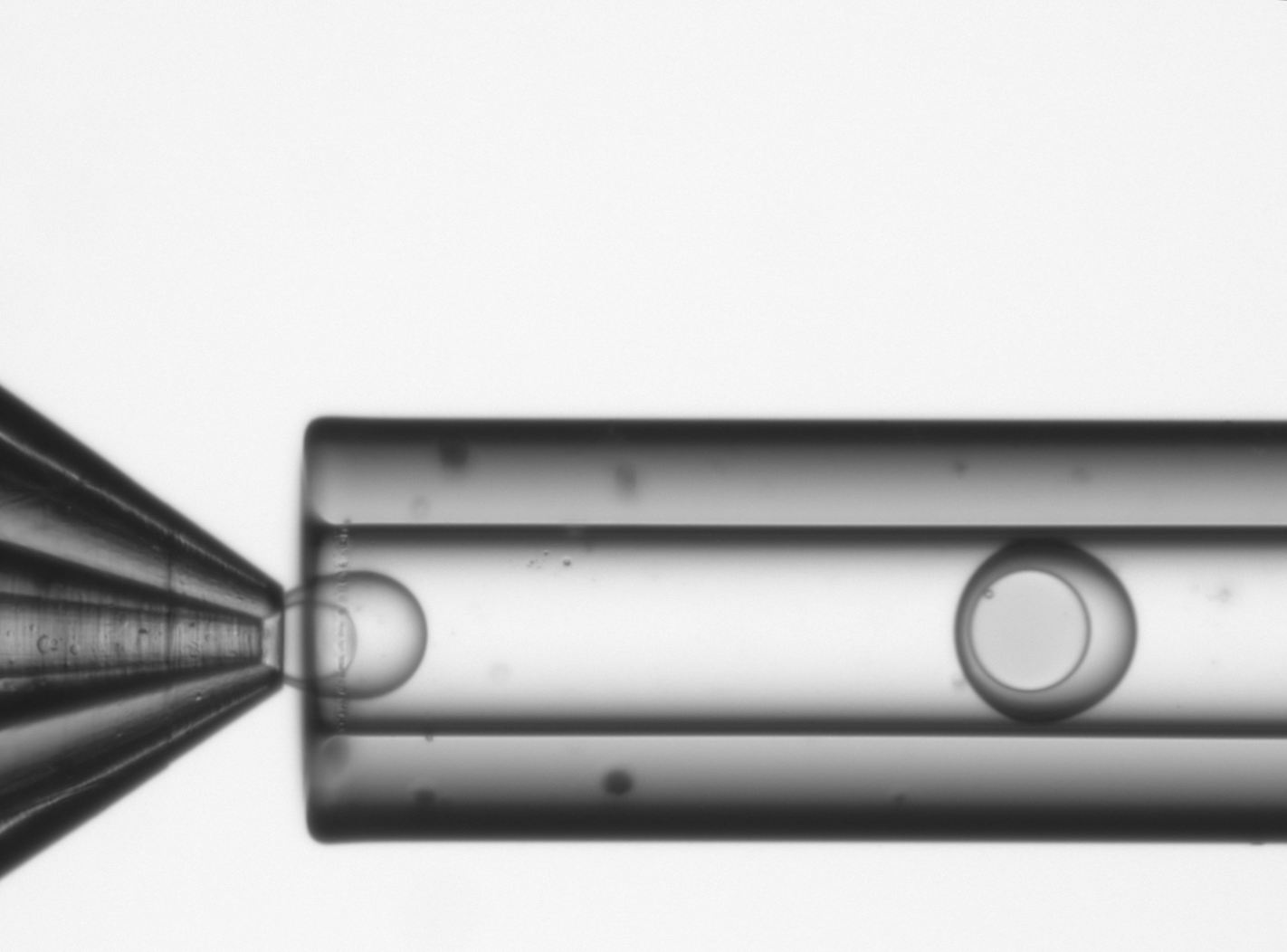

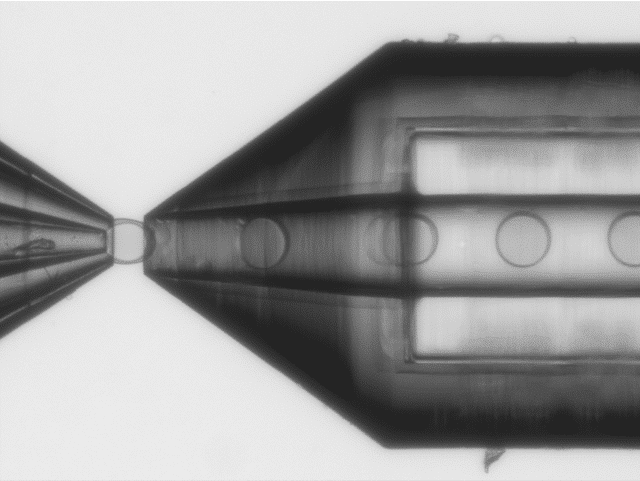

Therefore, The RayDrop double emulsion device relies on the alignment of two glass capillaries inside a pressurized chamber. A 3D-printed micro-nozzle is additionally connected at the tip of the injection capillary, enforcing the dripping of small droplets. This non-embedded design presents both the characteristics of a co-flow (axisymmetric geometry) and a flow-focusing (dramatic local accelerations of the continuous phase), and is thereby called non-embedded co-flow-focusing.

TheRayDrop double emulsion chip can be used for many applications from encapsulation of active pharmaceutical ingredients to cell and fragrance encapsulation in polymer microcapsules.

The design is known as a “technological breakthrough” due to the following:

- Its ability to enable high-throughput generation of monodisperse droplets for a wide variety of fluids, due to the continuous phase not being confined before entering the extraction capillary, and allowing for the flushing of viscous continuous phases.

- The double emulsion device is “plug-and-play” because of its standard connections and the possibility to easily assemble and disassemble all parts for cleaning.

In the context of a growing demand of controlled droplets in many areas, the Raydrop double emulsion device emerges as a robust and versatile solution, easily implementable in both laboratories with little experience and microfluidic facilities.

The RayDrop Double emulsion is available in three different standard configurations (Core Nozzle size-Shell Nozzle size-Extraction capillary size):

30 µm – 70 µm – 150µm

60 µm -120 µm – 300 µm

90 µm -160 µm -450 µm

As all capillaries from the RayDrop double emulsion device are easily exchangeable, users can change either the nozzle capillary or the collecting capillary with another nozzle or capillary size.

It can also be tuned to target different droplet size by changing capillaries size and nozzle configuration:

Small droplet configuration: 30µm-70µm-90µmThis two-nozzle configuration allows the device to decrease double emulsion size down to 50 µm.

The versatility of the RayDrop double emulsion device allows for proper operation, independently of the wetting properties of the materials in contact with the fluids, and independently of the physicochemical properties of these fluids (interfacial tension, viscosity, density, miscibility).

It additionally indicates that tuning the diameters of the nozzle tip and/or the extraction capillary enables it to cover a wide range of droplet diameters with any given fluid, a feature unachievable with other single devices.

Check out our webinar to learn more about the RayDrop double emulsion device

Raydrop, a universal droplet generator based on a non embedded co flow focusing

Most commercial microfluidic droplet generators rely on the planar flow-focusing configuration implemented in polymer or glass chips. The planar geometry, however, suffers from many limitations and drawbacks, such as the need of specific coatings or the use of dedicated surfactants, depending on the fluids in play.

On the contrary, and thanks to their axisymmetric geometry, glass capillary-based droplet generators are a priori not fluid-dependent. Nevertheless, they have never reached the market because their assembly requires art-dependent and not scalable fabrication techniques.

In the context of a growing demand of controlled droplets in many areas, discover the Raydrop that emerges as a very robust and versatile solution easily implementable in laboratories with little experience and facilities in microfluidics.

What you will learn:

- Introduction to droplet-based microfluidics

- Current method & technologies present on the market droplet & emulsion production

- Understand the advantages & challenges of droplet-based microfluidics

- Discover a new method for droplet and emulsion production

Webinar recording – Double emulsion production made easy: a reliable device

Are you working in academia or industry in the field of cosmetic, food, pharma, or chemical process? If you are looking for solutions and methods to improve and gain performance in generating the right double-emulsion for your needs, this online workshop may be of benefit to you. Until now, generating double emulsions has been a challenge as existing technologies suffer from various limitations (low reproducibility, …).

Overview

Whereas double emulsion is a promising method for many applications, technologies to make double emulsion such as batch methods are all suffering from various limitations (low reproducibility, big size distribution…)

Microfluidics which consist of precisely control fluids at micrometric scale is a promising technology for making double emulsion. However, this technology requires microfluidic chips and devices made of specific materials ( mostly hydrophobic such as PDMS or hydrophilic such as Glass ). Physical properties of the materials remains a big limitation for double emulsion because allow generating simple emulsion (w/o, o/w) but it’s become almost impossible to reach double emulsion (w/o/w or o/w/o) without using a chemical coating on the chip which has a lifetime and is not robust enough for long term production.

During this webinar, we are going to present the only device available on the market which allows to easily produce double emulsion with any kind of solution without chemical surface treatments needed.

Speakers:

Webinar recording – Master the production of Double Emulsions

Are you working in academia or industry in the field of cosmetic, food, pharma, or chemical process? If you are looking for solutions and methods to improve and gain performance in generating the right double-emulsion for your needs, this online workshop may benefit you. Until now, generating double emulsions has been a challenge as existing technologies suffer from various limitations (low reproducibility, need for multiple surface coatings, big size distribution, etc.).

This replay features the highlights and key takeaways from the 4 sessions. It covers:

- Presentation of double emulsion generation using Raydrop

- Live demonstration on how to make double emulsions

- The most asked questions & answers from 4 sessions

Specifications

| Device characteristics | Co-Flow focusing design |

| Droplet type | water in oil in water and oil in water in oil |

| Double emulsion size | Shell: 50 to 140 µm Core: 20 to 120 µm |

| Generation rate | 5 000 Hz (measured for the smallest double emulsion size) – can go higher under specific conditions |

| Nozzle type | Methalcrylate resin |

| Nozzle size | Core: 30 µm ID Shell: 70 µm ID |

| Inlet and outlet capillary | 150 µm ID |

| External dimensions | L*l*h = 92,5 mm * 52 mm * 13,5 mm |

| Weight | 405 |

| Operating pressure | 0 – 5 bar |

| Burst pressure | 10 bar |

| Wetted material: continuous phase | PEEK, FEP, glass, stainless steel, polyimide, Kalrez (seal), methalcrylate resin or glass (nozzle) |

| Wetted laterial: dispersed phase | PEEK, FEP, glass, methalcrylate resin or glass (nozzle) |

| Internal volume | 600µL |

| PN | Product name | Capillary sizes | Nozzle type |

| ORDRPDE-30-70-150 | Complete Raydrop | 30µm-70µm-150µm | Methacrylate Resin |

| O-DE-RDRPC04-EUP | Complete Raydrop | 30µm-70µm-90µm | Methacrylate Resin |

| O-SP-DNI3070-CO | Double nozzle insert | 30µm-70µm | Methacrylate Resin |

| ORDRPSNO-90 | Simple nozzle insert | 90µm | Methalcrylate resin |

| ORDRPSNO-60 | Simple nozzle insert | 60µm | Methacrylate Resin |

| ORDRPCOL-150 | Collecting capillary insert | 150µm | Glass |