Designed with microfluidic specifications, droplet microfluidic software plug-in for droplet measurement & frequency measurement

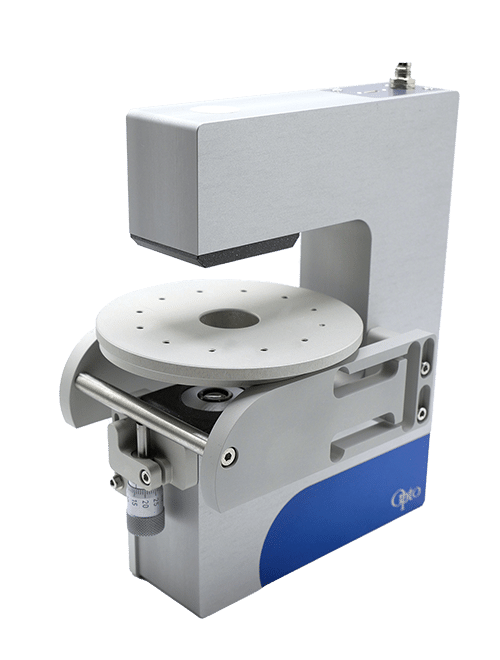

Digital High-speed Microscope

O-HSM-01A microscope designed for microfluidics

A plug-and-play solution for visualizing microfluidic experiments. Opto’s compact high-speed microscope is suited for high-speed applications such as process monitoring in microfluidic droplet generation or for other fast-moving particle tracking, flow cytometry, and general microfluidics. The microscope connectsvia a USB 3.1 cable to a PC, where the user can visualize their microfluidic device with the OptoViewer Software

- Dedicated to microfluidics

- Ready to use

All-in-one digital microscope with integrated software

- Ultra Compact

Save previous lab bench space

- Cost-effective

Best performance / price ratio

Download the documents

Features of Opto High-Speed Camera

Plug & Play solution

The high-speed microscope comes ready to use. It connects to a PC via a USB 3.1 cable. The device includes a fast camera with fixed optic parameters, allowing for highly reproducible results.

Ultra-compact & robust

With dimensions of only W140 x L193 x H40, the high-speed microscope is one of the most compact units available. It allows users to save bench space.

Microscopy for microfluidics

The digital camera and optics are optimized to fit with microfluidic applications. With 5X magnification, fast image acquisition of up to 1000 fps, high resolution (360LP/mm), and high contrast transmission though brightfield transmitted light (4000K), the microscope can track droplets and other fast-moving particles in microfluidic systems. The large FoV of (1.3 x 0.84 mm) and the working distance of 13 mm allow users to work with many types of microfluidic setups.

Optimized Microfluidic software

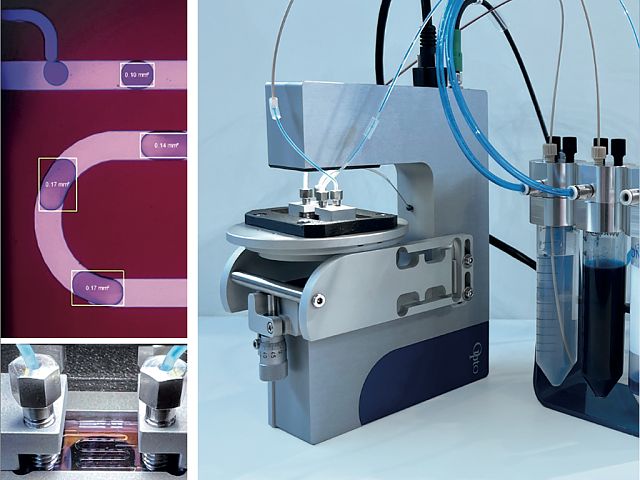

The OptoViewer software allows for visualization, photography, and video recording. The software offers many features including adjustable imaging settings (exposure time, framerate, gain, and more) and annotations, which are ideal for microfluidic experiments. In addition, the integrated droplet plug-in allows for live microfluidic droplet measurement and counting.

Related applications

High-speed microscope for microfluidics: “Track Droplet” software plugin

The OptoViewer software features a “Track Droplets” plugin. Thisallows for droplet/particle analysis. Single cells or microfluidic droplets can be automatically detected, tracked, velocity measured, and volume determined or read out inline. All statistics are displayed and can be saved.

- Droplet count

- Droplet per second

- Average droplet size

Combine with Fluigent Pressure – Flow Controllers for the most reliable results

In microfluidic devices, droplet size and generation rate are directly linked to the flow rates of the liquid solution phases . Fluigent pressure controllers provide highly stable flow rates (0.1% CV pressure, < 5% of measured flow rate value) with excellent response times (< 1s), producing highly homogenous droplets or particles for long periods of time.

Microscopy for droplet microfluidics

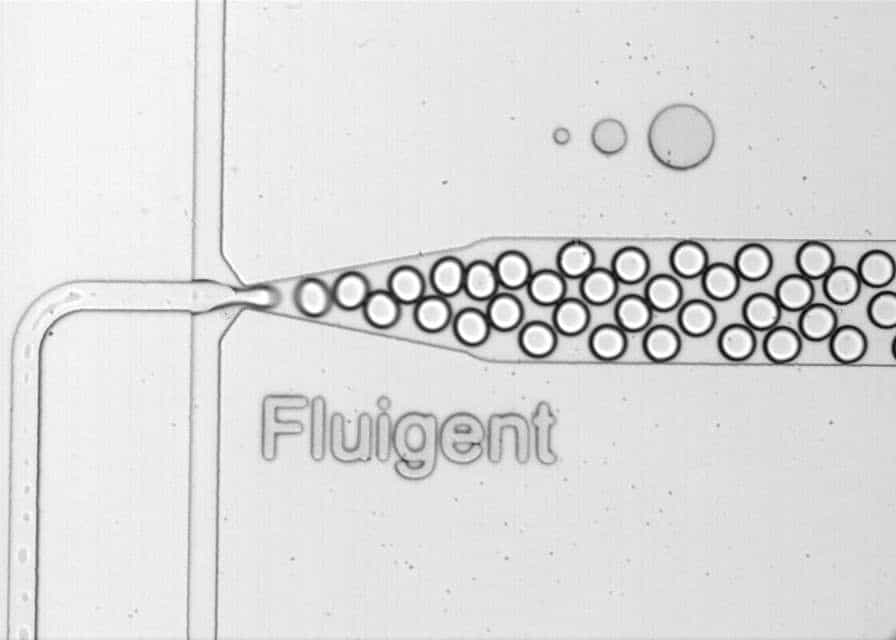

Water-in-oil and oil-in-water emulsion production

An emulsion refers to a mixture of two liquids that are normally unable to mix. It consists of small droplets of one liquid suspended within another liquid. Specifically, in oil-in-water (O/W) emulsions, tiny droplets of oil are dispersed and enclosed within the continuous water phase. In water in oil (W/O) emulsions, small droplets of water are dispersed within the continuous oil phase.

These emulsion techniques, O/W and W/O are extensively utilized in various OEM and research settings to create droplets, hydrogel beads, polymer beads, or wax beads.

Fluigent has published several application notes on this topic, introducing cutting-edge technology that involves the use of a high-speed microscope. This tool enables researchers to observe the production of high-quality monodispersed droplets.

Figure 1: Water-in-oil droplets generated by Fluigent controllers and chips, visualized through the microscope.

Read our application notes:

Double emulsion production

In addition to its use in single-emulsion experiments, our fast microscope for microfluidics can also be utilized in setups involving double emulsions. The creation of double emulsions hold great promise in various academic and industrial fields. Examples include fragrance manufacturing in the cosmetics industry, food applications, drug delivery in pharmaceutics, and more.

The application note “Double Emulsion Generation” introduces Fluigent’s Double Emulsion Production Pack: a comprehensive system equipped with a microscope. This system enables the production of monodisperse double emulsions. It features the RayDrop, developed and manufactured by Secoya, to facilitate one-step production of double emulsions using a single device.

Figure 2: System setup for double emulsions

Read our application note:

Microparticles Synthesis

Fluigent technology enables the production of highly monodispersed microparticles or microcapsules. Several materials are used depending on the final application, including alginates, PLGA, or agarose microparticles. To achieve a high level of uniformity, the RayDrop is utilized as part of a microfluidic setup that includes the digital high-speed microscope.

Figure 3: System for PLGA microparticle production.

See our application notes for microparticles production:

“I see great potential for our collaboration. As Opto, we can support FLUIGENT in optics, microscopy, automation, and software. Our small and compact microscopy solutions are perfect for the combination with microfluidics (compact, cost-efficient, scalable, high quality made in Germany).

The greatest benefit for the users is our free AI- based Software. It enables the recognition and tracking of objects like particles or droplets. This input is further used to control the pump. This is what makes our common package unique.”

Daniel Kraus | Product Manager Biophotonics at Opto GmbH | Project Manager at SpectroNet

Specifications Microscope

| Magnification | 5X |

| FoV [mm] | 1.3 x 0.84 |

| Resolution [LP|mm] | 360 |

| Working Distance WD [mm] | 13 |

| Object Space Resolution [μm/Pixel] | 0.7 |

| Depth of Field DoF [mm] | 0.008 |

| Sensor | IMX392LQR-C| 2.35 MP | Colour | 166 fps* *At maximum resolution. By reducing pixels area, fps can go up to ~1000fps |

| Dimensions [mm] | W140 x L193 x H40 |

| Weight [g] | 1400 |

| Interface | USB3.1 Gen 1 Type C |

| Illumination | Transmitted light | white| 4000K |

| Control Software | OptoViewer 2.0 |

| Certifications | CE / RoHS / WEEE-Reg.-No. DE 68564667 |

Markus Riedi, CEO Opto GmbH