마이크로유체칩: 작동 원리 및 올바른 칩 선택 방법

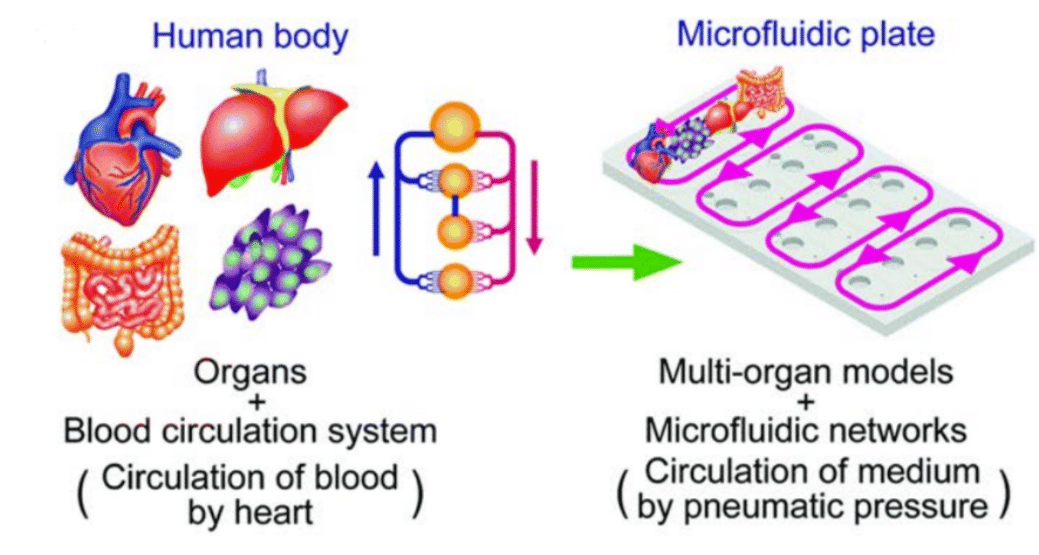

마이크로유체칩(Microfluidic chips)—랩온어칩(Lab-on-a-chip) 또는 바이오칩(Biochips)이라고도 불리는—은 설계된 마이크로채널(보통 5–500 µm 너비)을 통해 소량의 유체를 정밀하게 조작할 수 있는 소형 장치입니다. 이러한 칩은 세포 배양, 드롭렛 생성, 랩온어칩 분석, 오가논어칩 플랫폼과 같은 다양한 응용 분야에서 널리 사용되고 있습니다. 칩 제작에 사용되는 재료는 성능과 호환성에 큰 영향을 미치므로, 칩을 선택하거나 설계할 때 용도를 고려하는 것이 매우 중요합니다.

본 문서에서는 마이크로유체칩의 미세가공 공정과 특정 응용 분야에 적합한 칩을 선택하는 방법에 대해 알아보겠습니다.

목차:

마이크로유체칩의 미세가공

랩온어칩 기술에서 핵심적인 역할을 하는 이 칩들은 실리콘, 유리 또는 PDMS(Polydimethylsiloxane)와 같은 폴리머와 같은 다양한 소재로 제작됩니다. 사용되는 재료에 따라 제조 공정 또한 달라집니다.

다음 내용의 대부분은 Aryasomayajula 등이 집필한 『 Spinger Handbook of Nanotechnology)』(“Microfluidic Devices and Their Applications”)과 Ren 등이 작성한 논문 “Materials for Microfluidic Chip Fabrication)”[1]에서 발췌하였습니다.

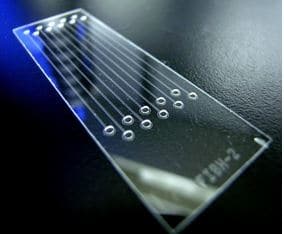

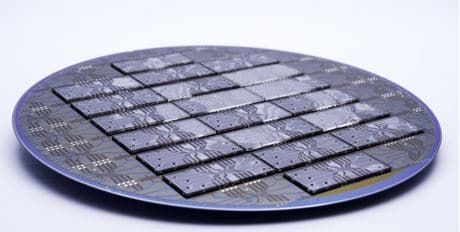

1. 실리콘 또는 유리 마이크로유체칩

- MEMS(Micro-Electro-Mechanical Systems) 기술이 도입되면서 개발된 최초 세대의 마이크로유체용 소재입니다.

- 유리 : 투명하며 비활성이고, 높은 열 및 화학 내성을 가집니다.

- 실리콘 : 불투명하지만 포토리소그래피를 통해 마이크로 미터 수준의 정밀한 구조 제작이 가능합니다.

- 두 소재 모두 고해상도의 채널을 제작할 수 있으며, 높은 재현성을 바탕으로 마이크로 미터 이하의 채널 크기를 구현할 수 있어 캐필러리 전기영동(CE), 드롭렛 생성, 칩 내 반응 등에 이상적입니다.

🛠️ 제작 방법

- 실리콘 :

벌크 마이크로머신가공(Bulk micromachining), 표면 마이크로머신가공(Surface micromachining), 식각(Etching) 및 증착(Deposition) 기술을 이용한 매설 채널(Buried channels) 등의 방법으로 제작됩니다. - 유리 :

주로 습식/건식 식각(Wet/dry etching) 및 기계적 가공 공정을 통해 제작됩니다.

⚠️ 한계점

- 비용이 비싸며 전문 장비와 유해 화학물질이 필요합니다.

- 기체 투과성이 없으며, 내구도가 약하고 세포 배양에는 부적합합니다.

✅ 요약

실리콘과 유리는 고온에서도 높은 정밀도와 안정성을 제공하는 매우 강성이 큰 소재입니다. 하지만 제조 비용이 높고 생물학적 응용이나 대량 생산에는 한계가 있어, 폴리머와 같은 대체 소재들이 점점 더 각광받고 있습니다.

2. 폴리머 마이크로유체칩

- 실리콘/유리 이후에 도입된 폴리머는 경제적이고 유연하며 쉽게 접근할 수 있는 대안입니다.

- 프로토타이핑 및 대량 생산 모두에 적합한데, 이는 사용되는 폴리머 종류에 따라 달라집니다.

🛠️ 폴리머의 종류와 응용 분야

🧼 엘라스토머 (예: PDMS)

- 유연성이 뛰어나며 소프트 리소그래피를 통한 신속한 프로토타이핑에 이상적입니다.

- 주로 학술 연구에서 널리 사용됩니다.

- 한계점 : 친수성 부족(소수성), 재현도 낮음, 압력 저항성 약함, 대량 생산에는 부적합

🔍 열가소성 플라스틱 (예: PMMA, COC, PC)

- 투명하고 생체적합성, 저비용

- 열성형 또는 사출 성형을 통한 대량 생산에 적합

- PDMS보다 화학 내성이 우수하지만 기체 투과성이 낮아 장기 세포 배양에는 부적합

🔥 열경화성 수지 (예: TPE) )

- 열이나 용매에 강하게 구조가 유지됨

- 사출 성형으로 제작되어 높은 정밀도 제공

- 상대적으로 비용이 높아 사용 빈도는 낮음

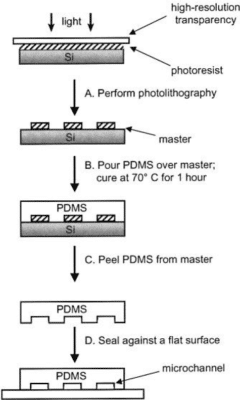

그림 1 :

(A) 포토마스크(고해상도 투명 디자인 포함)를 통해 노출된 감광성 수지를 패터닝하여 몰드 마스터를 제작합니다.

(B) 마스터 위에 액체 PDMS를 붓고 70°C에서 1시간 동안 경화시킵니다.

(C) 경화된 PDMS 복제물을 마스터에서 벗겨내고, (D) 평탄면에 밀봉하여 채널을 완전히 밀폐합니다.

전체 공정에는 약 24시간이 소요됩니다 [2].

✅ 요약

폴리머, 특히 PDMS는 프로토타이핑에, 열가소성 플라스틱은 산업용으로 널리 사용되고 있습니다. 저렴한 비용, 가공 용이성, 다양한 응용 분야에 걸친 유연성 덕분에 현재 마이크로유체 분야에서 가장 선호되는 소재입니다.

3. 종이 기반 마이크로유체칩

- 종이는 다공질이며 셀룰로오스 기반으로, 모세관 작용을 통해 자연스럽게 액체를 흡수합니다.

- 채널 형성은 소수성 패터닝을 통해 이루어지며, 액체는 친수성 영역을 따라 이동하도록 유도됩니다.

- 외부 펌프 없이도 유체가 수동적으로 흐르므로 간단한 시스템으로 충분합니다.

🛠️ 제작 방법

✅ 저비용, 간단한 공정 – 휴대용 진단 장치 제작에 이상적

일반적인 제작 기법:

- 왁스 인쇄 (가장 일반적)

- 잉크젯 인쇄

- 플렉소그래피

- 스크린 인쇄

- 포토리소그래피

- 종이 절단

왁스 인쇄 : 패턴을 생성한 후 가열하여 왁스를 녹여 소수성 경계를 만들고, 이를 통해 유체 흐름을 유도합니다.

⚠️ 한계점

- 최소 채널 너비 가~200 µm 로 정밀한 가공은 어려움. (PDMS/유리는 ~20 µm까지 가능)

- 표면 장력이 낮은 액체에서는 유체 제어가 어려움

- 외부 압력 기반 시스템 또는 펌프와 호환되지 않음

- 아직까지는 고급 마이크로유체 응용이 제한적임

✅ 왜 종이를 사용하는가?

- 초저비용, 일회용, 제작이 매우 용이함

- 현장진단(POCT) 및 개인 맞춤형 진단에 적합

- 외부 전원이나 장비가 필요하지 않음

4. 하이드로젤 마이크로유체칩

- 하이드로젤은 친수성, 다공질 구조를 가진 생체적합성 3차원 폴리머 네트워크(천연 또는 합성)로, 물을 90% 이상 흡수 할 수 있습니다.

- 세포 포집, 생물학적 조직 환경 모방, 제어된 3D 미세환경 구현에 이상적이며, 주요 종류로는 아가로스 , 매트리겔 , PEG-DA , 알지네이트 , 키틴 등이 있습니다.

왜 하이드로젤을 마이크로유체 기술에 사용하는가?

✅ 생체적합성 – 세포 생존과 조직 기능 유지에 유리

✅ 투과성 – 영양소, 약물, 신호 분자의 확산 가능

✅ 투명성 – 현미경 및 이미징 관찰에 최적

✅ 생체모방 환경 – 실제와 유사한 3D 세포 배양 및 농도 기울기 생성 가능

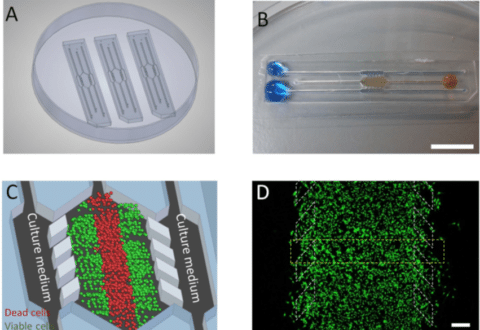

그림 2 :

(A) petri dish 안에 위치한 3개의 마이크로소자. 중앙에는 배양 챔버(확대도 C), 주변에 6개의 채널이 구성되어 있음.

(B) 한 소자의 중앙 채널에서 노란색 콜라겐 하이드로젤이 중심 배양실로 흐르고 있으며, 양측 채널에서는 파란색 물이 펌프를 통해 흐름.

(C) 양측 채널을 통해 배양액이 흐름.

(D) 형광 염료를 이용한 세포 모니터링 [3].

🛠️ 제작 방법

하이드로젤을 마이크로유체칩에 통합하는 다양한 방법이 존재하며[4], 대표적으로 다음과 같은 기술들이 사용됩니다:

- 소프트 리소그래피 (Soft Lithography)

- PDMS 또는 포토레지스트로 만든 몰드 사용

- 액상 젤을 붓고 경화 후 박리하여 구조 형성

- 2D 및 층상 구조의 준-3D 하이드로젤 구조 제작 가능

- 광중합 (Photopolymerization)

- UV 조사를 이용해 고해상도 구조 형성

- 세 가지 방식: 균일 조사, 마스크 기반 프린팅, 직접 조사

- 정밀한 3D 미세구조 구현 가능

- 국소 통합 / 동축 유동 (Local Integration / Co-laminar Flow)

- 미세채널 내에서 서로 다른 겔을 나란히 흐르게 하여 적층 구조 형성

- 현장 경화(in-situ solidification)로 복합 구조 안정화

- 동적인 다층 구조 구현에 유용

- 일회용 템플릿 (Sacrificial Templates)

- 3D 생분해성 템플릿 위에 젤 코팅 후 템플릿 용해 → 채널 형성

- 혈관 모방 구조나 조직 스캐폴드 제작에 활용 가능

⚠️ 한계점

- 진정한 3D 구조의 기하학적 정밀 제어는 복잡함

- 경화 및 생체적합성을 위한 젤 성분의 최적화 필요

- 일부 젤은 기계적 강도가 낮거나 배치 간 변동성이 큼 (예: 마트리겔)

올바른 칩 선택하기

- 목적 파악 : 드롭렛 생성, 세포 분석, DNA 분석 등 사용 목적을 명확히 해야 합니다.

- 채널 설계 매칭 : 유동 조건에 따라 직선형, Y형, 교차형 또는 H형 네트워크 등을 선택합니다.

1. 응용 목적에 맞는 칩 소재 선택

- 실리콘 : 화학적으로 안정적이고 열 전도성이 우수하지만 불투명하며 취약합니다.

- 유리 : 투명하고 비활성이며 생체적합성과 고압 저항성이 뛰어납니다. 광학 분석에 적합하지만 가공비가 높습니다.

- 폴리머 (PDMS, PMMA, COC, PS, PC) :

PDMS :

연구에서 널리 사용됨 – 생체적합성, 기체 투과성, 유연성, 간단한 프로토타이핑 가능, 하지만 소수성이며 고압에는 부적합.

열가소성 플라스틱 :

자가형광 낮음, 광학적 특성이 우수하며 사출 성형을 통한 대량 생산에 적합.

2. 정밀한 유체 설계

- 채널 종류 선택 : 유동 요구사항에 따라 직선형, Y형, 교차형, H형 네트워크 등을 선택합니다.

- 유동 저항 및 전단력 계산 :

칩 및 튜빙의 기하학적 구조를 기반으로 이상적인 압력 및 유속 범위를 계산하는 도구 활용.

3. 적절한 압력/유속 설정

- 중간 수준의 압력 사용 : 예를 들어, 2 bar 시스템에서는 0.5–1.5 bar 범위 사용이 해상도 향상에 유리합니다.

- 튜빙 길이 및 지름 조절 : 저항 미세 조정 가능하지만, 막힘 방지 필요.

4. 막힘 방지 및 전단력 제어

- 좁은 채널은 막힘 위험 증가 : 중간 크기의 채널 선택 권장.

- 전단력 관리 : 특히 민감한 세포에는 압력 조절을 통해 전단력을 최소화해야 함.

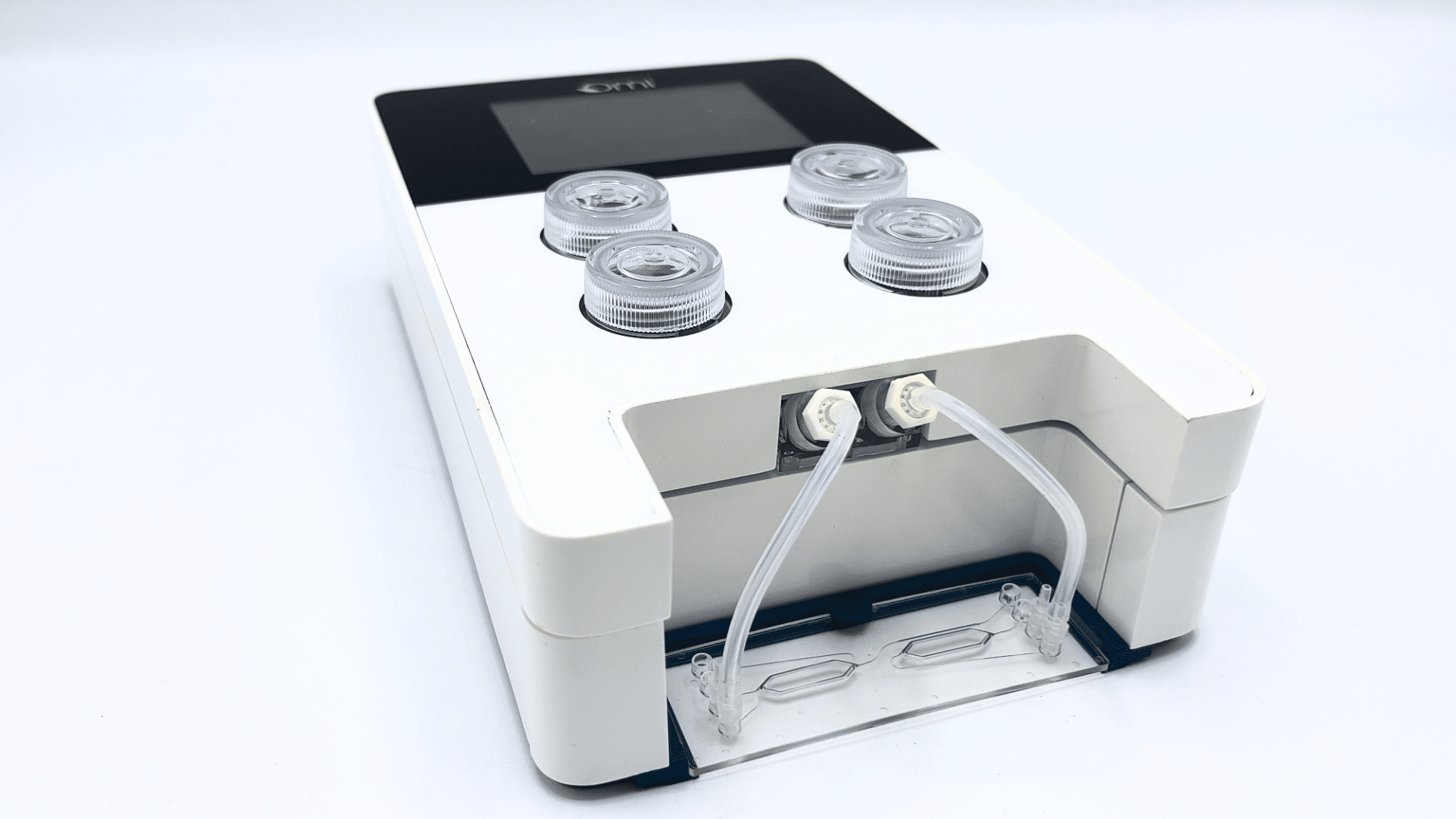

5. 시스템 호환성 확보

- 칩, 튜빙, 펌프/컨트롤러, 코팅, 검출기 간 호환성 확인

- Fluigent 또는 기타 시스템 사용 시 , 즉시 사용 가능한 통합형 솔루션 선호.

요약 표

| 단계 | 주요 포커스 |

|---|---|

| 응용 분야 정의 | 분석 타입 결정 (예: 세포, DNA, 드롭렛, 오가논어칩) |

| 소재 및 제작 선택 | 광학 투명성, 압력 내성, 비용 균형 고려 |

| 마이크로채널 + 튜빙 설계 | 유동/저항 목표에 맞는 형상 및 크기 선택 |

| 유속/압력 계산 및 최적화 | 계산 도구 활용, 중간 시스템 조건 유지 |

| 시스템 통합 가능성 확인 | 물리적 및 기능적 호환성 보장 |

유용한 도구 및 자료

- 계산 도구 : 압력 및 유속 계산기, 전단력 계산기, 드롭렛 크기 예측기

- 소재 가이드 : PDMS, 유리, 폴리머, 실리콘의 장단점 비교

- 코팅 및 표면 처리 : 소수성/친수성 균형 조절 및 비특이적 흡착 감소에 활용

결론

최적의 마이크로유체 칩을 선택하기 위해서는 초기부터 다음과 같은 순서로 접근해야 합니다:

응용 분야 → 소재 선택 → 설계 → 유체 제어 → 시스템 호환성

계산 도구와 검증된 가이드라인을 활용하여 복잡성이나 과도한 비용 없이 효율적이고 정밀하며 신뢰성 있는 칩을 구현하세요.

참고문헌:

- Ren, K., Zhou, J. & Wu, H. Materials for microfluidic chip fabrication. Acc. Chem. Res. 46, 2396–2406 (2013).

- McDonald, J. C. & Whitesides, G. M. Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 35, 491–499 (2002).

- Ayuso, J. M. et al. Development and characterization of a microfluidic model of the tumour microenvironment. Sci. Rep. 6, 1–16 (2016).

- Zhang, X., Li, L. & Luo, C. Gel integration for microfluidic applications. Lab Chip 16, 1757–1776 (2016).