Mikrofluidische Lösungen für präzise Flusskontrolle

Fluigent unterstützt Forscher im akademischen Bereich und in der Industrie durch die Bereitstellung von erstklassigen Forschungsinstrumenten und -systemen in Kombination mit einem ausgeprägten Fachwissen im Bereich des Fluidmanagements.

Unsere innovativen, druckbasierten Mikrofluidik-Regler sind mit Lab-on-a-Chip-Geräten und einer Vielzahl von Mikrofluidik-Technologien kompatibel und ermöglichen es Ihnen, sich auf Ihr Wissenschaftliche Mikrofluidik-Anwendungen zu konzentrieren statt auf die Einrichtung.

Mikrofluidischer druckbasierter Flussregler

Fluigent war das erste Unternehmen, das mikrofluidische druckbasierte Flussregler für die Handhabung von Fluiden in der Mikrofluidik eingeführt hat. Druckgesteuerte Flusssteuerungssysteme arbeiten, indem Behälter mit Proben unter Druck gesetzt und zügig in ein mikrofluidisches Gerät injiziert werden.

Unsere Steuerungen, basierend auf der patentierten FASTABTM-Technologie, sichern einen stabilen und pulsationsfreien Fluss, was die Genauigkeit und Reproduzierbarkeit der Experimente verbessert. Die Verwendung von Druck ermöglicht eine schnelle Reaktionszeit und reduziert die Kosten.

Erhältlich in zwei Hauptproduktlinien: die LineUpTM-Serie für einen evolutiven, kompakten und anpassungsfähigen Betrieb und die MFCS-Serie für kundenspezifische und praxiserprobte Erfahrungen.

MFCS

Das MFCS™, oder Microfluidic Flow Control System, ist ein druckbasierter mikrofluidischer Flussregler. Es sind entweder 4 oder 8 Kanäle mit verschiedenen Druckbereichen für mikrofluidische Experimente verfügbar. Das MFCS™ erzeugt eine konstante druckgesteuerte Flussrate, die zuverlässige und wiederholbare Experimente ermöglicht.

Merkmale des MFCS

- Unabhängige Kanäle: Jeder Kanal kann unabhängig gesteuert werden und einen bestimmten Druck oder ein bestimmtes Vakuum zur Handhabung von Flüssigkeiten liefern. Die verfügbaren Druckbereiche reichen von -800 mbar für Vakuumansaugung bis zu 7 bar für Druck.

- Erzielen Sie schnell hervorragende Ergebnisse: Erreichen Sie Ihre Druckziele schnell und starten Sie Ihr Experiment sofort. Die praxiserprobte Technologie ermöglicht es Ihnen, schnell zuverlässige und hervorragende Ergebnisse für Ihre Experimente zu erzielen.

- Zuverlässige und reproduzierbare Ergebnisse: Das MFCS™ vermeidet Kreuzkontaminationen, da es keinen direkten Kontakt zwischen dem Gerät und den Reagenzien gibt. Die pulslose und präzise Steuerung, die durch unsere druckgesteuerte Technologie ermöglicht wird, ist für wiederholbare Ergebnisse bei vielen Anwendungen entscheidend.

- Vollständig anpassbar: Das Design des MFCS™ richtet sich nach Ihren Bedürfnissen. Sie können die Anzahl der Kanäle im Gerät wählen (4 oder 8), wobei jeder Kanal von -800 mbar bis 7 bar reicht. Sie haben ebenfalls die Möglichkeit, eine Druck- oder Vakuumquelle in das Gerät zu integrieren.

LineUP

Unsere LineUp™-Produktreihe ist die nächste Generation von Mikrofluidiksystemen:

- Mit den Flow EZ™- oder Push-Pull-Modulen lassen sich Druck und Vakuum präzise regeln und steuern, die LINK- und LINK COM-Module ermöglichen die Kommunikation mit einem Computer oder einem externen Instrument über TTL-Ports, USB-Kabel oder serielle Schnittstelle.

- Der Adapter wird verwendet, um Flow EZ™-Module mit unterschiedlichen Druckbereichen zu verbinden, ohne dass zusätzliche Druckquellen erforderlich sind. Der P-SWITCH ermöglicht die Vervielfachung der Ausgänge des Systems und der SWITCH EZ steuert Mikrofluidikventile. Das gesamte System ist über eine lokale Steuerung ohne PC-Verbindung steuerbar und kann zusätzlich von der Fluigent-Software überwacht werden, um die Funktionalität zu erweitern und von Automatisierungsvorteilen zu profitieren.

Wählen Sie die Module, die Sie benötigen, und kombinieren Sie sie.

Beispiel einer Anwendung mit FlowEZ und MFCS:

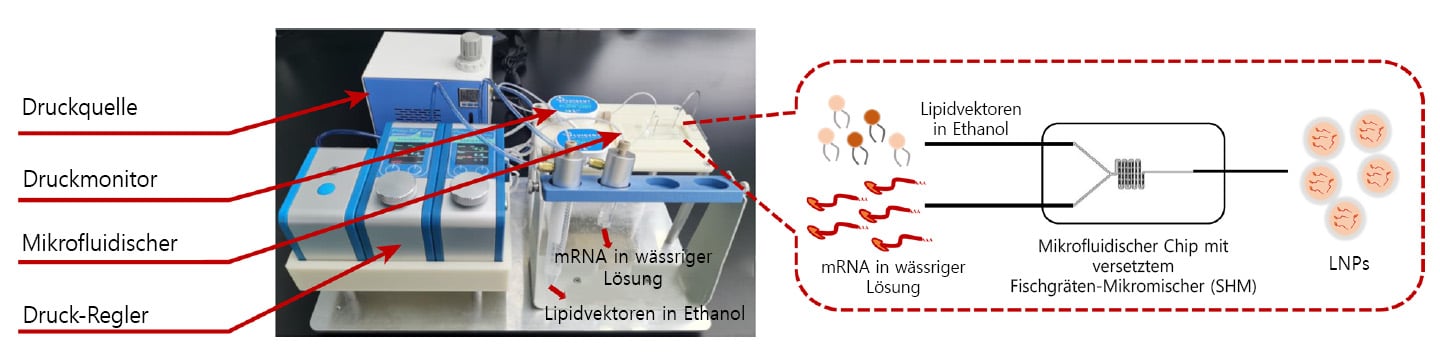

Hongjuan Wei et al. vom Bioinformatikzentrum der AMMS (Peking) ist es gelungen, eine universell integrierte Plattform mit einem entsprechenden Steuerungssystem für die rationelle und bedarfsgerechte Herstellung von mRNA-Produkten zu entwickeln. Unter Verwendung unserer druckgesteuerten Regler (FlowEZ) und Flusssensoren (FlowUnit) wurde ein mRNA-Verkapselungsmodul auf der Basis eines gestaffelten Fischgräten-Mikromischchips in diese Plattform integriert. [1]

mRNA-Kapselungsmodul

Mikrofluidische Sensoren

Die mikrofluidischen Sensoren von Fluigent ermöglichen eine direkte Kontrolle und Überwachung der Flussrate oder eine Erweiterung der Druck-/Vakuummessung im Aufbau und bieten somit eine Lösung für die Messung und/oder Kontrolle von Flussraten für alle fluidischen Anwendungen. Unsere mikrofluidischen Sensoren zeichnen sich durch einen kontrollierten Fluss, eine minimale Verwendung von Reagenzien und Proben, schnelle Analysen, kompakte Bauweise, Systemparallelisierung sowie eine reduzierte Abfallproduktion aus.

Flusssensoren

FLOW UNIT und FLOW UNIT+ sind bidirektionale mikrofluidische Flusssensoren, die für den eigenständigen Einsatz mit dem Line Up™-Controller oder anderen mikrofluidischen Steuerungssystemen wie der MFCS™-Serie unter Verwendung des Flowboard-Hubs kompatibel sind.

Die mikrofluidischen Flusssensoren FLOW UNIT und FLOW UNIT+ sind in mehreren Low-Rate-Bereichen erhältlich.

Merkmale der Flusseinheiten:

- Abstimmen von Messungen für verschiedene Flüssigkeiten: In Verbindung mit einer FLOW UNIT kann ein Skalierungsfaktor zu Ihren Messungen hinzugefügt werden, insbesondere wenn Sie mit Flüssigkeiten arbeiten, für die der Flusssensor nicht spezifisch kalibriert ist. Für organische Lösungen ist bei den FLOW UNIT Modellen S, M+ und L+ eine zweite Kalibrierung mit Isopropylalkohol integriert.

- Messung der Flussrate: Die FLOW UNIT und FLOW UNIT+ ermöglichen schnelle und genaue Messungen von sehr kleinen Flussraten.

- Präzision für verschiedene Flussratenbereiche: Die verschiedenen FLOW UNIT-Modelle bieten eine große Auswahl an Flussbereichen, um Ihren Anforderungen im Bereich von 7nL/min bis 5mL/min optimal gerecht zu werden.

- Überwachung und Steuerung von Experimenten

Drucksensoren

Die PRESSURE UNIT ist ein eigenständiger mikrofluidischer In-Line-Drucksensor für die kontinuierliche Messung des Drucks in einem fluidischen Pfad. Mit unserem mikrofluidischen In-Line-Druckdetektor können Sie den Druck stabil, pulslos und reaktionsschnell überwachen und steuern. Es sind drei verschiedene hochpräzise Drucksensoren erhältlich (S, M und XL), je nach dem Druckbereich, den Sie messen möchten.

Merkmale der Flusseinheiten:

- Breiter Erfassungsbereich: Die PRESSURE UNIT ist ein mikrofluidischer In-Line-Drucksensor, der die genaue Messung von Druck und Vakuum im Bereich von -1000 mbar bis 7 bar ermöglicht. Unser Druckdetektor verfügt über einen breiten Bereich von Messwerten.

- Anzeige in Echtzeit: Überwachen Sie die Druckmessung grafisch mit der OxyGEN-Software von Fluigent. Unsere spezielle Software ermöglicht es dem Benutzer, die Datenerfassung direkt auf einem PC zu steuern.

- Es wird kein Hub benötigt: Schließen Sie den Sensor direkt an einen PC an und profitieren Sie von einer kompakten Lösung für die Druckerfassung. Der mikrofluidische Inline-Drucksensor kann überall (inline) in Ihrem mikrofluidischen Aufbau angeschlossen werden.

- Druckkontrolle: Durch die Kombination eines beliebigen mikrofluidischen Druckdetektors mit unserem Druckkontrollsystem können Anwender eine präzise Druckkontrolle erreichen.

Beispiel für die Anwendung von Flusseinheiten

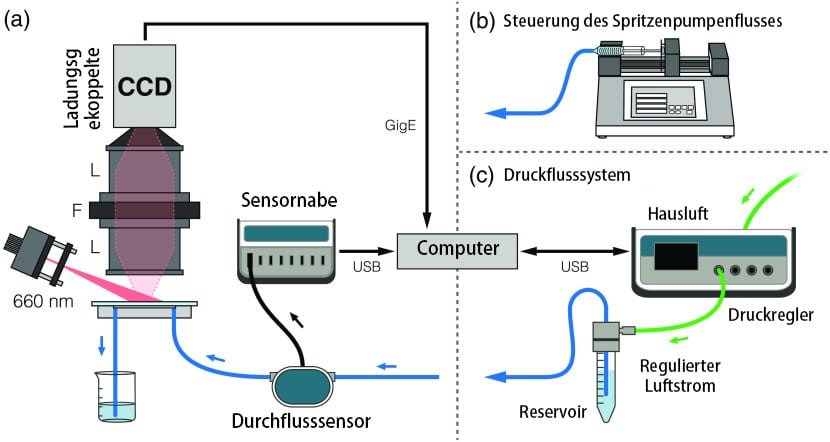

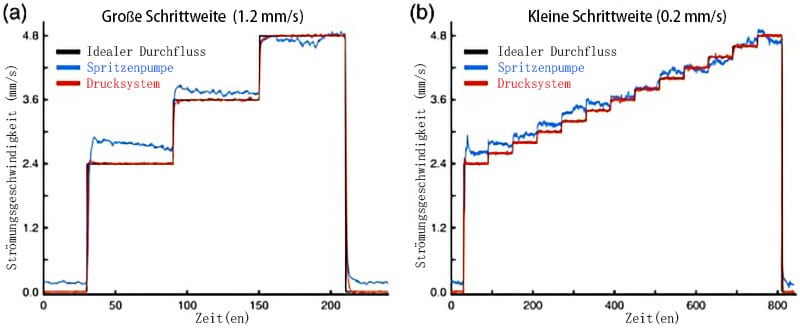

Colin Sullender et al. vom Functional Optical Imaging Laboratory (University of Texas at Austin) gelang es, die Unsicherheit des von einer Spritzenpumpe und unserem druckgesteuerten Flussregler erzeugten Flusses zu quantifizieren. Mit unserem MFCS-EZ-Controller wurde im Vergleich zur Spritzenpumpe ein stabiler und wiederholbarer Fluss erzeugt.

Auf der Grundlage der erzielten Ergebnisse ist der Wechsel von Spritzenpumpensystemen zu unseren druckgesteuerten Reglern ein Schlüsselparameter, um Flussbedingte Fehler zu beseitigen und zuverlässigere Mess- und Bildgebungsverfahren für den Fluss zu entwickeln.

Dieser Ansatz eröffnet neue Möglichkeiten in Bezug auf die genaue Bewertung und den Vergleich von Bildgebungsverfahren (wie auch in dieser Arbeit durch den Vergleich von Laser LSCI und Multi-Exposure Speckle Imaging bewiesen wurde). [2]

Schematische Darstellung des mikrofluidischen Flussmessaufbaus.

Flusssensormessungen für die Spritzenpumpe (blau) und druckgesteuerte (rot) Flusssysteme Vergleich zum idealen vordefinierten Fluss (schwarz)

Mikrofluidische Ventile

Mikrofluidikventile, auch Mikroventile genannt, sind grundlegende Komponenten, die in mikrofluidischen Geräten verwendet werden, um Flüssigkeiten durch verschiedene Ventilanschlüsse zu leiten.

Fluigent Mikrofluidik-Ventile ermöglichen es dem Benutzer, den Fluidikpfad eines jeden Experiments zu komplexisieren. Die Ventile lassen sich leicht in den Aufbau integrieren und in Echtzeit steuern, auch ohne PC.

Unsere mikrofluidischen Ventile bieten einen minimalen Reagenzienverbrauch, senken die Kosten des Experiments und zeichnen sich durch ein geringes Innenvolumen aus. Sie verhindern das Risiko von Kreuzkontaminationen und Biofilmbildung und vermeiden Totvolumen. Ihre optimierten Materialien sorgen für eine hohe Stabilität gegenüber mechanischen Bewegungen und eine hohe chemische Verträglichkeit.

Merkmale der Ventile von Fluigent:

- Kompakte Geräte

- Automatisierungsmöglichkeiten

- Anpassungsfähigkeit und Vielseitigkeit

- Bidirektionaler Fluss

- Geringes internes Volumen

- Schnelle Betätigungszeit

L-SWITCH™ Einspritzventil 6-fach/2-fach

Das L-SWITCH™ ist ein bidirektionales Mikrofluidik-Injektionsventil mit 6 Anschlüssen und 2 Positionen, das für die Handhabung von Flüssigkeiten über verschiedene Ventilanschlüsse verwendet wird. Es ist ideal für eine präzise Volumeninjektion oder für das Umschalten zwischen verschiedenen Flüssigkeiten, da es die Automatisierung der Probeninjektion in Ihrer Flüssigkeitsleitung ermöglicht.

L-SWITCH™ Rezirkulationsventil 6-fach/2-fach

Das L-SWITCH™ Rezirkulationsventil ist ein bidirektionales mikrofluidisches Rezirkulationsventil mit 6 Anschlüssen und 2 Positionen, das zur Handhabung von Flüssigkeiten über verschiedene Ventilanschlüsse verwendet wird. Es ist ideal für die Flüssigkeitsrezirkulation in Zellkulturanwendungen und ermöglicht einen langfristigen unidirektionalen Rezirkulationsfluss.

M-SWITCH™ bidirektionales Ventil mit 11 Anschlüssen und 10 Positionen

Das M-SWITCH™ ist ein mikrofluidisches bidirektionales Ventil mit 11 Ports/10 Positionen für die Injektion oder Auswahl von bis zu 10 verschiedenen Flüssigkeiten oder Chips. Der Fluss im Ventil ist bidirektional. Das Gerät kann als Verteiler oder als Selektor für Multiplexing- oder Demultiplexing-Zwecke verwendet werden.

2-SWITCH™ Probenahmeventil 3-Anschluss/2-Wege

Das 2-SWITCH™ ist ein kompaktes mikrofluidisches 3-Anschluss/2-Wege-Probenahmeventil. Mit Standardanschlüssen kann es in jede mikrofluidische Einrichtung integriert werden. Sein einzigartiges und kompaktes Design ermöglicht es dem Benutzer, 2-SWITCH™-Geräte zu kombinieren, um Platz auf dem Arbeitstisch zu sparen.

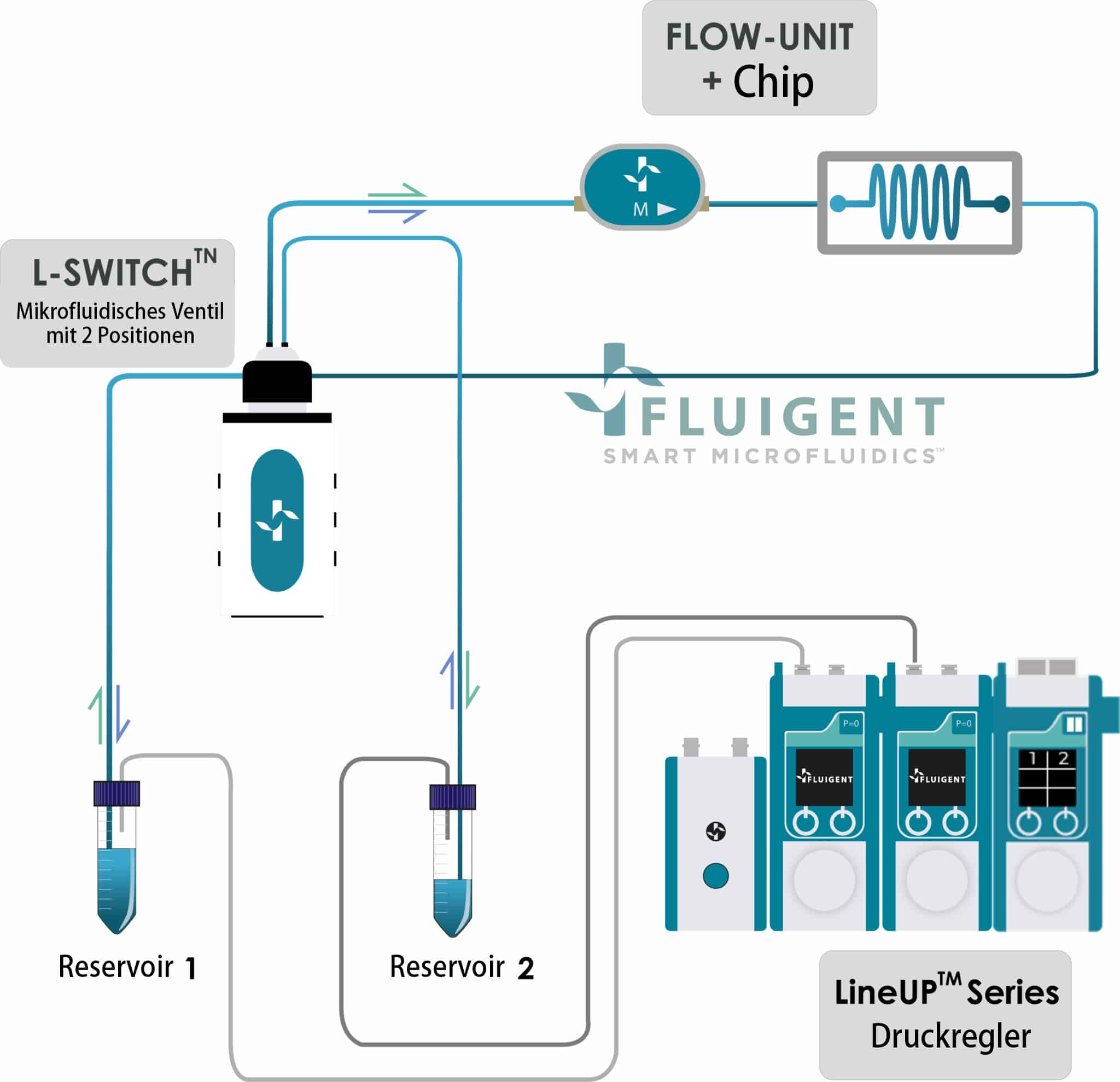

Beispiel für die Anwendung von L-Switch

Die Wahl des richtigen Geräts zur Reproduktion der Strömungsbedingungen, unter denen Zellen in vivo experimentieren, ist von großer Bedeutung, da sie sich auf das Überleben, die Ausbreitung und den Phänotyp der Zellen auswirken und ihre genetische Expression erweitern.

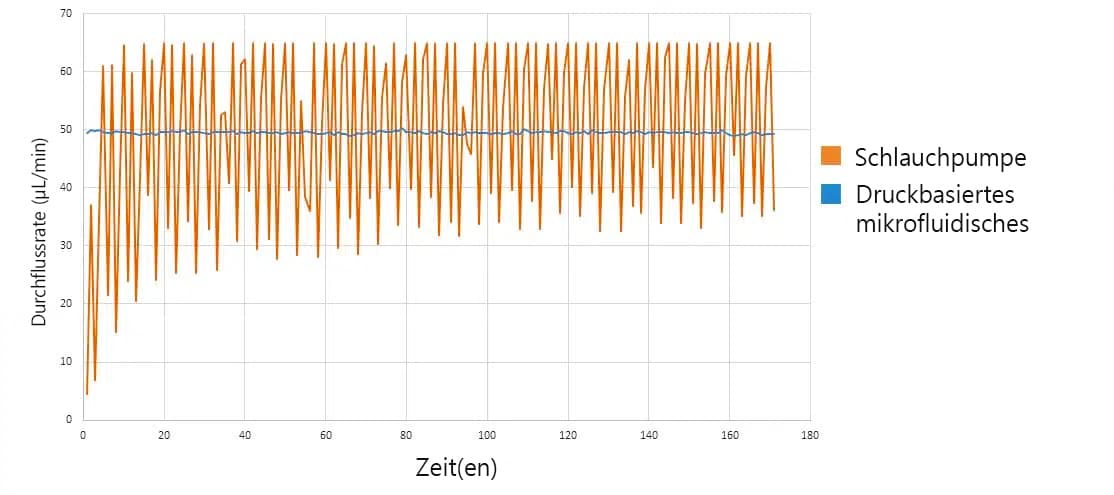

Ein entscheidender Aspekt dieser Technologie ist die Art des verwendeten Perfusionssystems. Unter diesem Gesichtspunkt wurde ein Rezirkulationssystem mit druckbasierten Flussreglern für die Steuerung von Organen auf Chips gebaut und mit klassischen Spritzenpumpen verglichen. Zwei Flow EZ-Geräte wurden an zwei Reservoirs angeschlossen. Die Schläuche führten durch den L-SWITCH (der die Rezirkulation der Medien ermöglicht), eine Flusseinheit und das mikrofluidische Gerät.

Mit dem Flow EZ und dem L-Switch wurde eine stabile Flussrate mit weniger als 2 % Flussschwankung (im Vergleich zu 40 % bei den Spritzenpumpen) beobachtet. Sie förderte das Überleben der Endothelzellen und die Aufrechterhaltung eines physiologischen Phänotyps.

Flussrate als Funktion der Zeit unter Verwendung einer Peristaltikpumpe und eines druckbasierten mikrofluidischen Kontrollsystems.

Referenzen

- Wei, H.; Rong, Z.; Liu, L.; Sang, Y.; Yang, J.; Wang, S. Streamlined and On-Demand Preparation of mRNA Products on a Universal Integrated Platform. Microsyst Nanoeng 2023, 9 (1), 97. https://doi.org/10.1038/s41378-023-00538-8.

- Sullender, C. T.; Santorelli, A.; Richards, L. M.; Mannava, P. K.; Smith, C.; Dunn, A. K. Using Pressure-Driven Flow Systems to Evaluate Laser Speckle Contrast Imaging. J. Biomed. Opt. 2023, 28 (03). https://doi.org/10.1117/1.JBO.28.3.036003.