Oil in Water Emulsions

An emulsion is defined as two immiscible liquids wherein droplets of one phase (the dispersed or internal phase) are encapsulated within sheets of another phase (the continuous or external phase) [1]. In oil in water emulsions (O/W), oil droplets are dispersed and encapsulated within the water column. O/W Emulsions are widely used in industrial and R&D environments to manufacture droplets (e.g., for compartmentalization applications), wax beads (e.g., carnauba or cosmetic wax), and polymer beads (e.g., PLGA, styrene, methacrylates, etc.).

Of particular importance is the ability to produce high-quality, monodisperse droplets and the ability to do so reproducibly and at a viable production rate. The combination of pressure-based flow controller units and RayDrop microfluidic devices developed and manufactured by Secoya enable smooth fluid delivery, precision flow rate control, automation, and reproducibility necessary to generate high-quality oil in water emulsions.

Introduction to Oil In Water Emulsions

What are the O/W emulsions?

Oil in water emulsions are conventionally defined as thermodynamically unstable systems which include two immiscible liquids (generally water and oil), in which oil is distributed into the water[1]. Emulsions may divide into two phases over time through creaming, coalescence, flocculation or Ostwald ripening[2].

The preparation method greatly influences the stability of O/W emulsions. Common emulsification techniques have a limited ability to control the size and attached particle layer composition of drops. Formulating drops of controlled size and surface properties is critical for most commercial and technological activities using emulsions. Many physical properties depend on drop size, including coalescence stability, viscosity, thermal and electrical conductivity [1,2]. Stability at rest and under flow (while pouring, pumping or spreading) depends on the interfacial properties and composition.

Generate highly monodisperse emulsions with microfluidics

Microfluidic emulsification methods provide a unique platform to uncover the early stages of emulsion formation. The applied shear stresses work against the interfacial tension to elongate and rupture droplets. High shear stress enhances rupturing and collisions between particles and drops. Fragmented drops recombine when they encounter each other to reduce their interfacial area.

Microfluidic emulsification offers greater control over drop size uniformity. Drop surfaces are tailored by dosing surface active species into the liquids. Another advantage is the potential insights into emulsion formation gained by directly observing drop break-up, film rupture and liquid mixing during drop coalescence in microchannels.

Materials to Generate O/W Emulsions

Reagents

Droplet Phase: Decane

Continuous phase: Water + 2% (wt) Sodium dodecyl sulfate (SDS)

| Reagent | Supplier | Catalogue number | CAS Number |

| Water | Ultrapure 18.2 MΩ – cm | – | 7732-18-5 |

| Decane | Sigma Aldrich | D901 | 124-18-5 |

| Sodium dodecyl sulfate | Sigma Aldrich | 436143 | 151-21-3 |

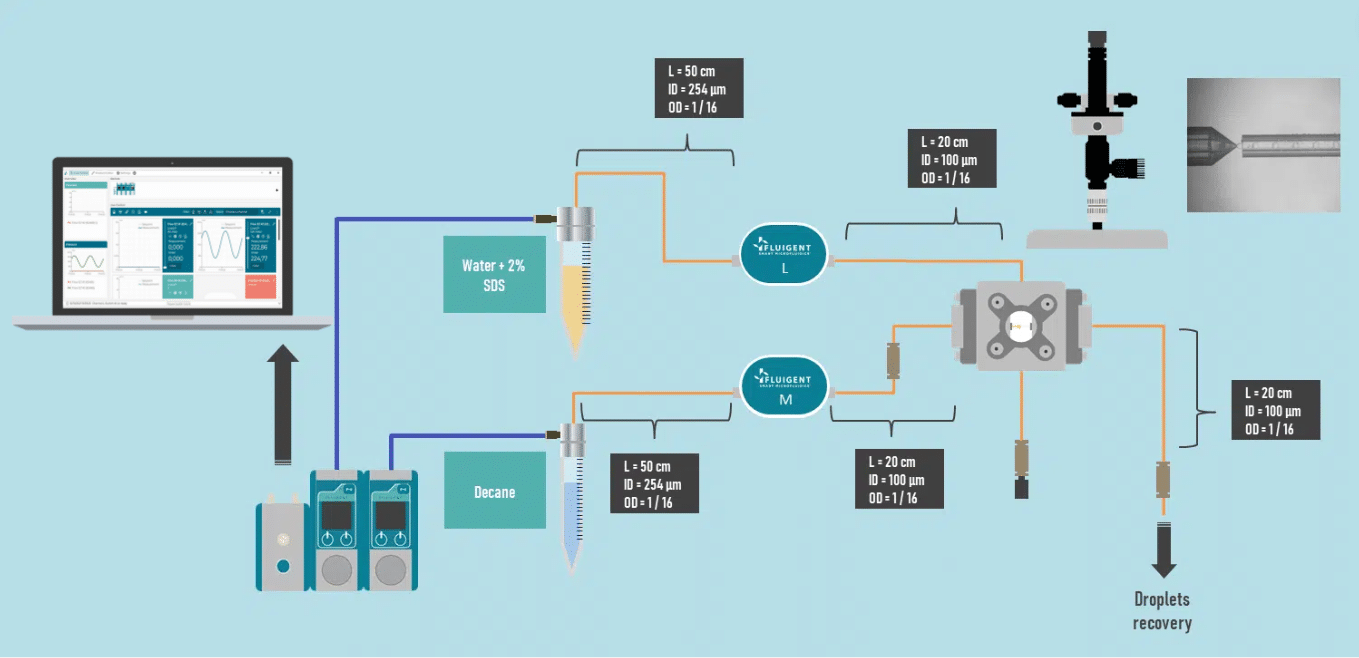

Microfluidic Setup

How to produce an oil in water emulsion

An emulsion is defined as two immiscible liquids wherein droplets of one phase (the dispersed or internal phase) are encapsulated within sheets of another phase (the continuous or external phase) [1]. In oil in water emulsions , oil droplets are dispersed and encapsulated within the water column.

O/W emulsions are widely used in industrial and R&D environments to manufacture droplets (e.g., for compartmentalization applications), wax beads (e.g., carnauba or cosmetic wax), and polymer beads (e.g., PLGA, styrene, methacrylates, etc.). Of particular importance is the ability to produce high-quality, monodisperse droplets and the ability to do so reproducibly and at a viable production rate.

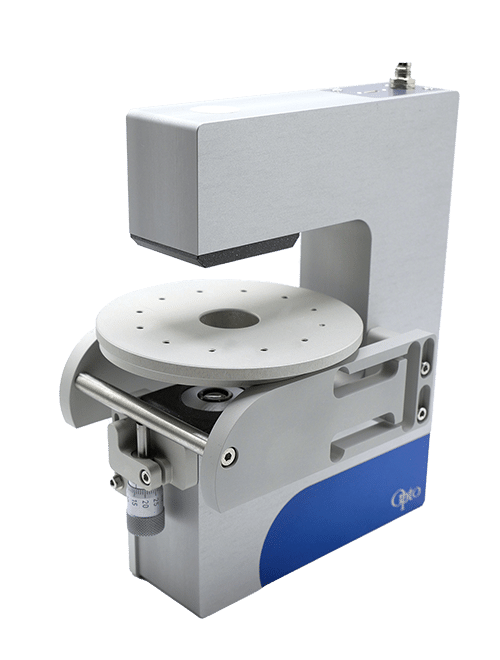

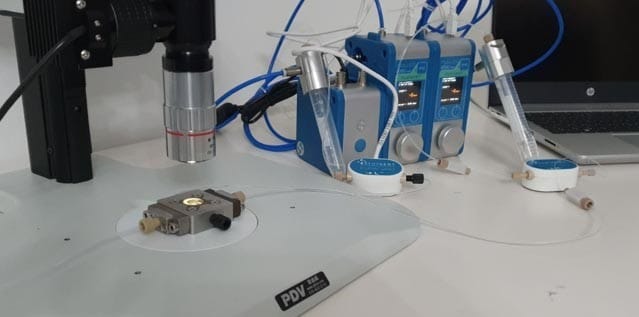

The combination of pressure-based flow controller units and RayDrop microfluidic devices developed and manufactured by Secoya enable smooth fluid delivery, precision flow rate control, automation, and reproducibility necessary to generate high-quality oil in water emulsions.

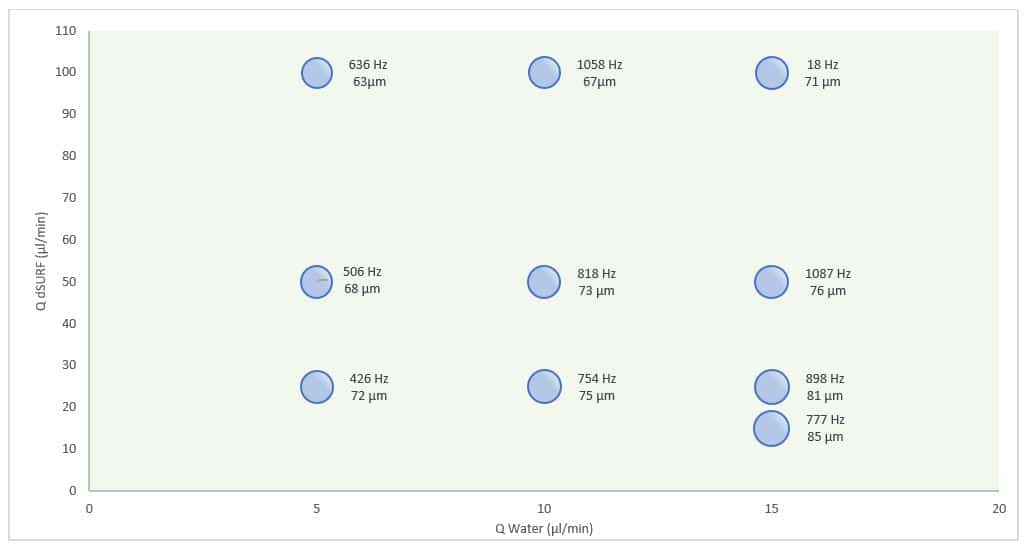

With the use of Fluigent pressure-based flow controller units and the Raydrop microfluidic device (figure 1), we have generated emulsions with control of particle size by adjusting the flow of the continuous phase and the dispersed phase.

Results

| Continuous phase flowrate (μl/min) | Droplet phase flowrate (μl/min) | Droplet diameter (μm) | Production rate (Hz) |

| 100 | 5 | 63 | 637 |

| 100 | 10 | 67 | 1058 |

| 100 | 15 | 73 | 1227 |

| 50 | 5 | 71 | 445 |

| 50 | 10 | 75 | 754 |

| 50 | 15 | 82 | 866 |

| 5 | 5 | 75 | 377 |

| 25 | 10 | 77 | 697 |

| 25 | 15 | 81 | 898 |

| 15 | 15 | 83 | 835 |

Conclusion

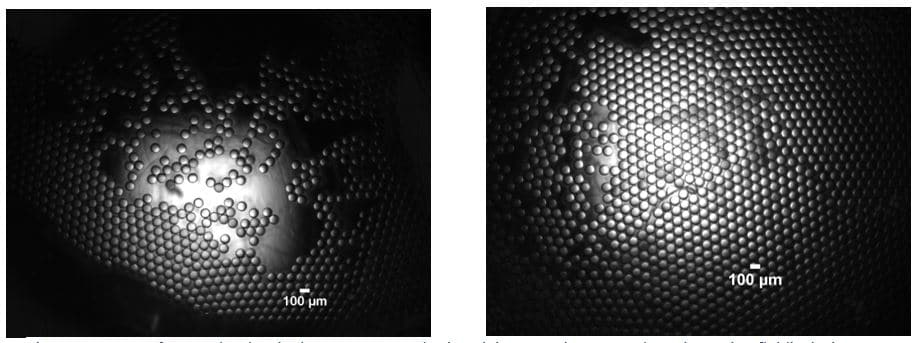

Fluigent pressure-based flow controller units and the Raydrop microfluidic device were successfully used to generate high-quality, monodisperse droplets of decane in water. The droplet size was controlled in the range of 63 – 83 μm by adjusting the continuous and dispersed phase flow rates. Peak stable droplet production rate was recorded for 73 μm droplets at 1227 Hz. The production techniques developed here for oil in water emulsions can be extended to the generation of wax, or polymer beads by adding suitable post-processing steps.