Reusable glass herringbone mixer

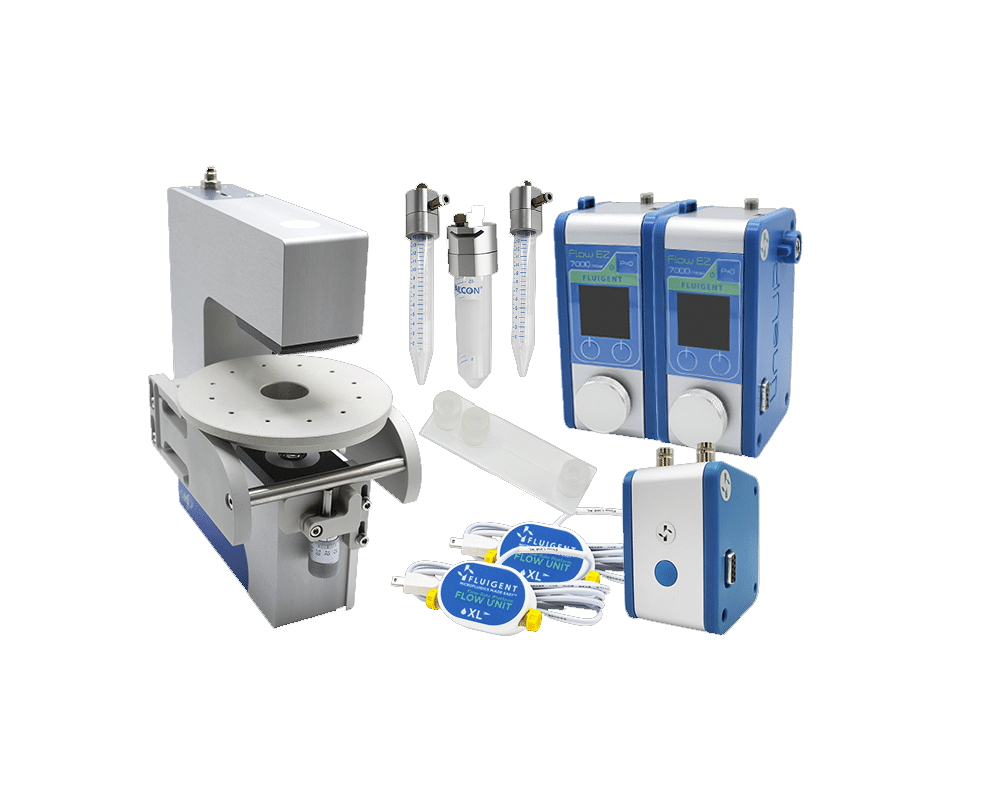

Liposome Production Pack

[O-MIX-LIPO-PCK]Complete system for producing liposomes reproducibly over the size range from 40 nm to 150 nm

Liposomes are nano-spherical lipid vesicles. These structures hold promise for delivering therapeutic agents due to their biocompatibility, and ability to encapsulate various types of drugs and nucleic acids. Microfluidics revolutionizes liposome production by providing precise control over mixing organic and water phases on-chip. This enables reproducible outcomes in liposomal size, polydispersity, morphology, and lamellarity, ensuring high-quality lipid-based nanoparticles.

The Fluigent Liposome Production Pack is a reliable and complete system for long-term production, with the ability to vary the particle size over the range from 40 to 150 nm. This includes Fluigent’s LineUP microfluidic pumps and Little Things Factory (GmbH)'s staggered herringbone mixer, a reusable glass microfluidic chip.

- Cost effective

- Easy to use

Ready-to-use system with complete protocol

- Versatile

Adjustable liposome size

- High precision

< 0.2 PdI

Features of the Pack

Complete System

Provides all the components needed to start generating liposomes with high monodispersity and stability.

Engineered Solution

Designed with right pressure controllers, microfluidic chip, and accessories to give you the greatest possible flexibility in terms of particle size and generation rate.

Dedicated Protocol

A complete method is provided to assist you in setting up and starting your experiments.

Customization

We can adapt the package to meet your needs (particle size, generation rate).

Why use microfluidics for liposome synthesis?

The physical characteristics of liposomes (size, polydispersity index (PDI), lamellarity) depend not only on the lipid composition but also on the method of preparation. Traditional methods like thin-film hydration and extrusion have been commonly used, though they come with limitations. These can be time-consuming processes with high batch-to-batch variation, making them less suitable in drug development. The emergence of microfluidics in the last decade has advanced the field by offering a more efficient and precise approach to liposome synthesis. These include control of fluid dynamics, high control of flow ratios, contributing to uniform size, minimal variation, and reproducibility of the size of the liposomes generated.6

| Manufacturing Method | Advantages | Disadvantages |

|---|---|---|

| Film hydration | – Established method – Understood method | – High consumption of organic solvents – High PDI – Lack of reproducibility Need for additional downsizing step – Difficulties in scaling-up |

| Solvent injection | – Simple and fast – Scale-up possibility | – Exposure to organic solvent – High PDI – Stability problems |

| Extrusion | – Uniform and homogenous formulation | – Possible clogging of the membrane pores – Difficulties in scale-up |

| Microfluidics | – High encapsulation rate – Control of the liposome size – Homogeneous size distribution – Ability to control temperature | – Highly dependent on the instrument – May require some expertise for manufacturing microfluidic chip |

Microfluidics staggered herringbone mixer for liposome production: Efficient, sustainable, and cost-effective

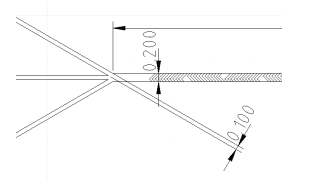

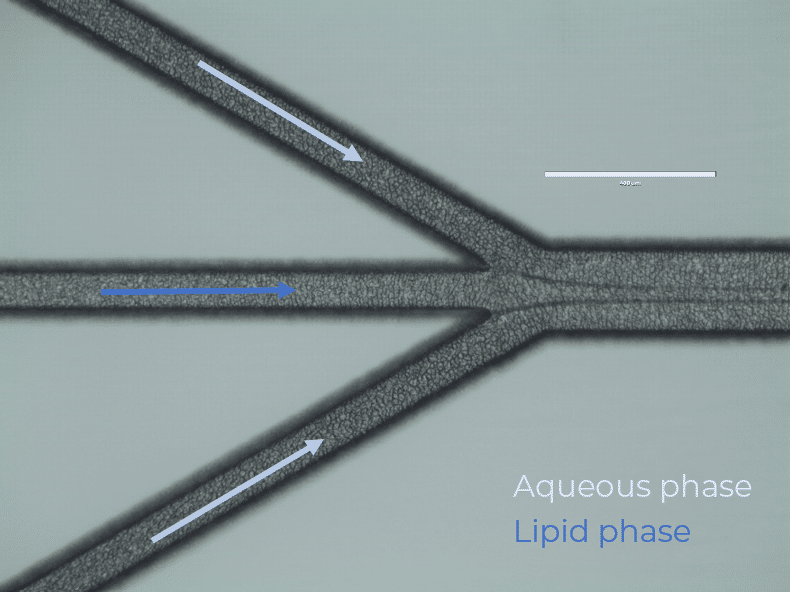

The Little Things Factory (GmbH) staggered herringbone mixer includes an Inlet, mixing section, and outlet. The inlets of the device are shaped in a flow-focusing design, which permits instant visualization and easy control of the aqueous and lipid phases before mixing. After, the mixing section is formed by 30 half-cycles including 6 herringbone structures each.

The herringbone structures induce rotational flow, causing the two phases to wrap around each other with alternating orientations between each half-cycle. This process results in a flow profile characterized by a decreasing diffusion length between the streams. This facilitates rapid mixing and promotes the lipids to self-assemble into liposomes. By tuning the lipid concentration, flow rate ratio, and total flow rate, the size and monodispersity of the liposomes are efficiently controlled.7

Manufactured in glass, the chip can be easily connected to the microfluidic setup with standard 1/4-28 UNF threaded ports. The chip can be cleaned and reused.

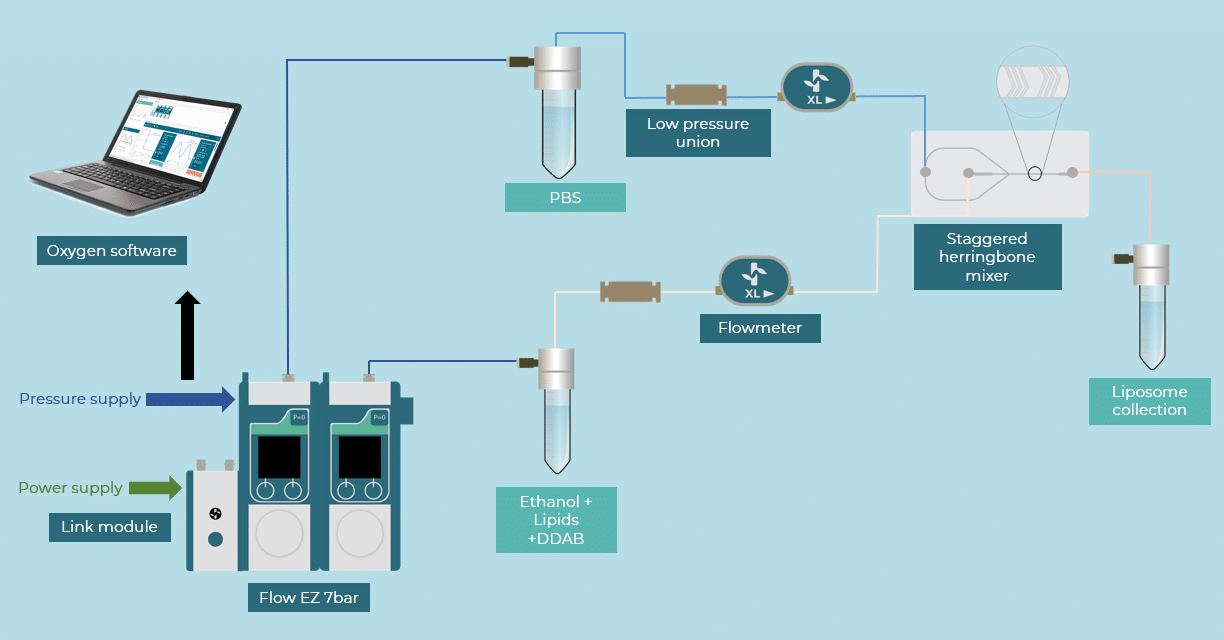

Liposome generation set-up

Figure 1: Liposome production set-up.

Case Study: How to produce drug-loaded liposomes for ovarian cancer treatment studies

See our case study, based on the paper published in Scientific Reports (2024) from the Ca’Foscari University of Venice. This describes the production of amiodarone-loaded liposomes with precise control over size and drug content obtained using the Flow EZ and the glass herringbone mixer.

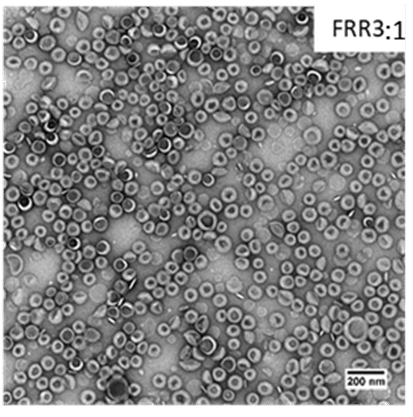

Figure 2: TEM image of the obtained liposomes for FRR 3:1 (at TFR = 1 mL/min, the flow rate was 750 µL/min for the aqueous phase and 250 µL/min for the organic phase).8

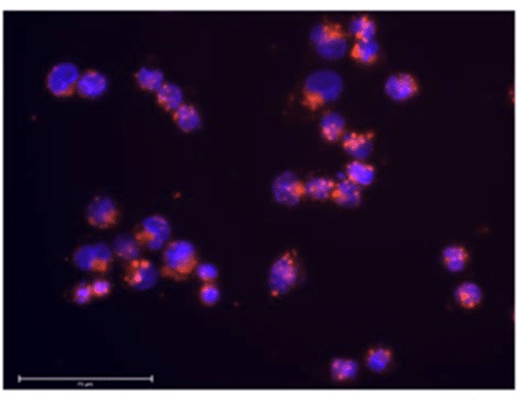

Figure 3: Liposome internalization by cells.8

Specifications

| LineUp Flow EZ pressure controller (7000 mbar) x2 |

| LineUp LINK Module (software control) x1 |

| FLOW UNIT XL (x2) |

| P-CAP series 15 mL (x2) |

| P-CAP series 50 mL (x1) |

| OxyGEN Software |

| Digital High-speed Opto Microscope (optional) |

| Staggered herringbone mixer chip |

Microfluidic Chip Specifications

| Herringbone micromixer chip | Little Things Factory – T29 |

| Material | Borofloat®33 |

| Dimension | 75 x 25 x 2 ± 0.3 mm |

| Total volume | 3.0 µL |

| Mixer volume | 0.47 µL |

| Mixer length | 28.7 mm |

| Channel depth | 0.08 – 0.11 mm |

| Channel width | 0.1 – 0.5 mm |

Liposome Production

| Lipid phase | Lipids in organic solvent (depending on the application). In the User Guide, absolute ethanol, lipids (40 mg/mL), and Dimethyldioctadecylammonium (DDAB – 10mg/mL) were used. |

| Aqueous phase | Phosphate-buffered saline (PBS) (pH 7.2) |

| Particle size range* | 40 nm to 150 nm |

| Polydispersity* | From 10% to 20% |

* Depending on FRR (download the Liposome production pack User Guide for more information).

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Imaging

| OptoViewer Software |

| Batch Method | Fluigent microfluidic method | |

| Particle size distribution | Low | High |

| Reproducibility | Low | High |

| Live particle size control | No | Precise |

| Range of particle size | Limited size range | Wide size range |

| Continuous (in line) production | No | Yes |