什么是乳剂和液滴

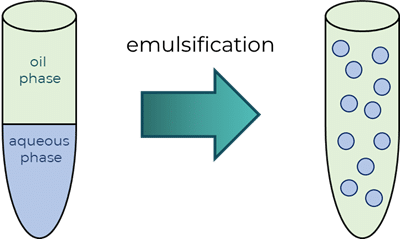

乳剂是一种异质系统,至少由一种不相溶的液体以液滴形式分散在另一种液体中组成。如果不进行乳化,两种液体就会分离,密度较小的相浮于密度较大的相之上。沙拉酱就是常见的乳剂。在由水相(醋)和油相(橄榄油)组成的油醋汁中,如果不进行乳化,这两种相就会分离。通过摇晃油醋汁瓶,醋会分散到油性连续相中,从而形成乳剂。在乳剂中,一种液体(称为分散相)分散在另一种液体(称为连续相)中。

油包水滴液

乳剂的常见应用有哪些?

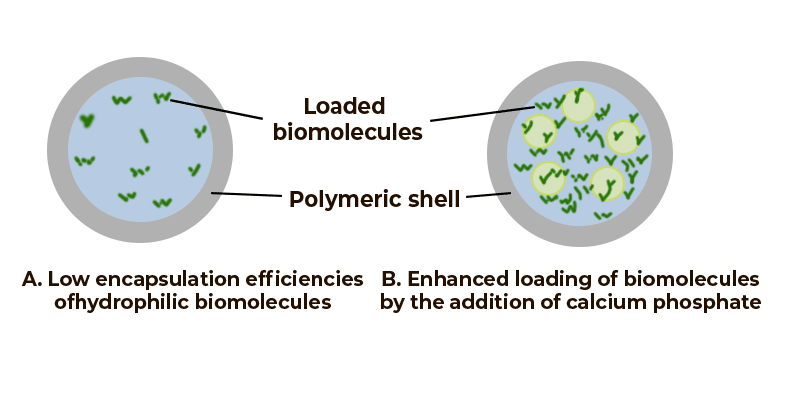

聚合物中的生物分子封装[1]

药剂学:乳剂用于多种医药产品,包括静脉注射、肌肉注射、眼用或口服产品。乳剂也可用作聚合物微粒、脂质纳米粒或微胶囊的模板。例如,后者可以用于药物输送,乳剂本身就是活性药物成分(API),或可作为联合给药的佐剂。

食品工业:作为热力学上稳定的分散剂,乳剂可产生不同大小的液滴,这种独特性质使其适用于食品工业中的多种应用。

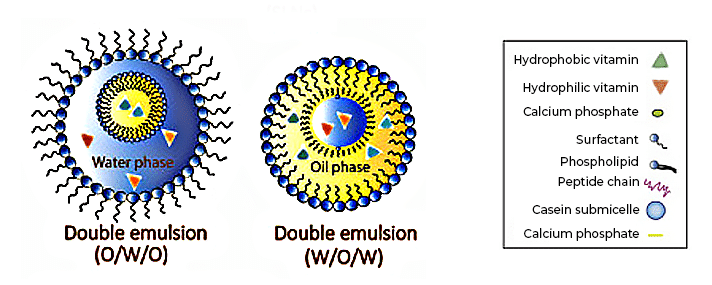

纳米封装作为一种有前景的方法,用于维生素靶向递送和控制释放。[2]

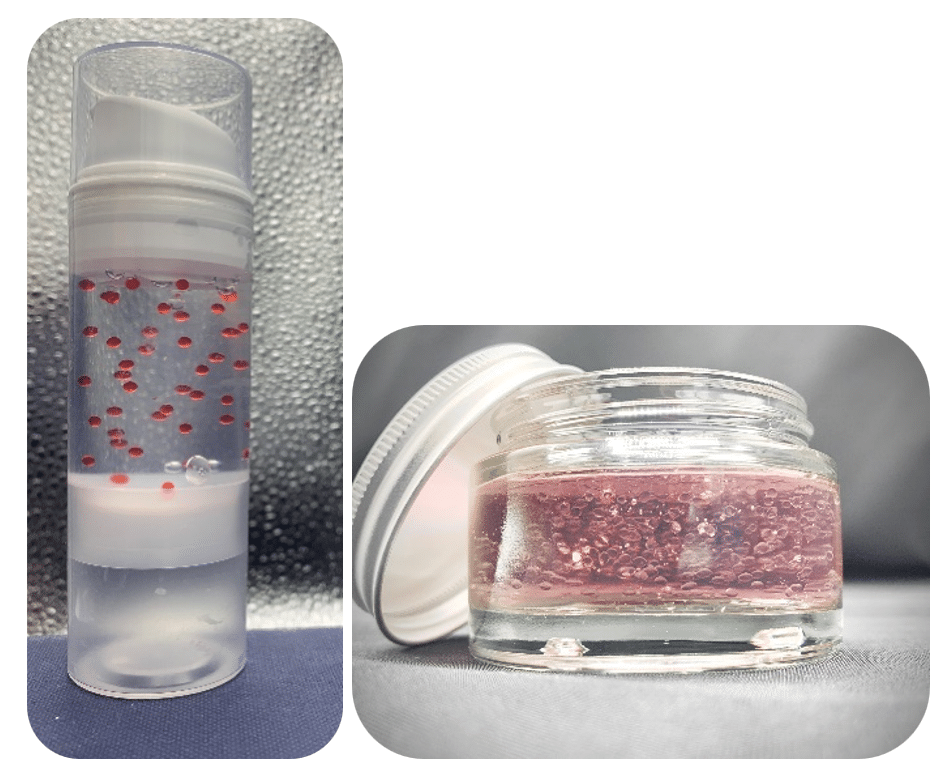

利用微流控技术开发的化妆品产品。

化妆品:化妆品中的乳剂类产品质地细腻、触感光滑,并且能够缓慢且持续地释放活性物质,还可以改善不溶性物质的溶解或增溶。最近,市场上出现了“豪流控”设备,可以生成肉眼可见的乳剂,从而可以开发极具视觉吸引力的独特产品。

为什么要使用液滴微流控技术?

1)传统液滴生成方法的局限性

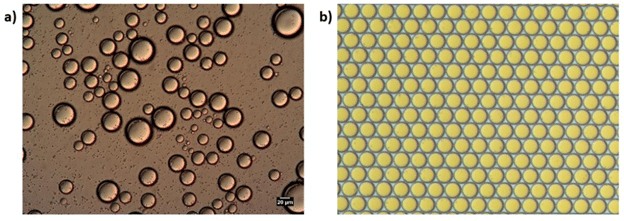

液滴产生的标准方法包括使用高速搅拌机、高压阀均质机、胶体磨等机械设备。液滴破裂通常通过手动/机械搅拌产生的剪切或冲击应力来实现。在这种情况下,整个系统产生的应力通常并不均匀。因此,生成的乳剂大小不一。这在许多应用中可能是一个严重的限制,因为乳剂的稳定性取决于尺寸。

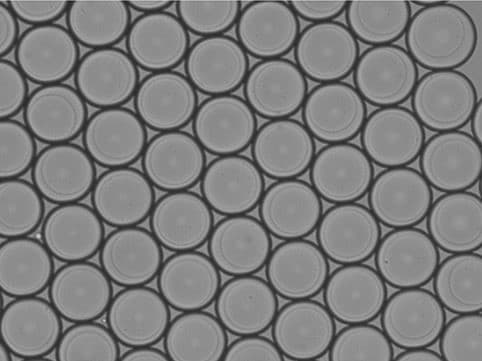

使用a)批量法和b)微流控法生成微乳剂

2)用于控制乳剂的微流控设备

使用微流控系统进行的液滴生产已用于单分散性非常重要的应用。通过微米级大小的通道一次生成一个液滴,从而可以产生出单一分散的液滴。凭借这样的控制水平,以前不可能实现的应用也成为可能,例如数字PCR和液滴内单细胞封装。此外,这种方法产生的浪费较少,对于使用昂贵API(活性药物成分)的应用来说也十分理想。在典型的微流控系统中,微流控芯片通过连接一个或多个流量控制器,以注入其中的流体。液滴尺寸主要取决于微流控通道尺寸、流体特性(粘度)和所使用的流速。

基于微流控的液滴生成和控制支持:

- 高度单分散(尺寸变化<2%)液滴生产,与批量乳化方法相比,频率相对较高

- 高度可再现的复杂结构(多重乳剂、多核乳剂……)

- 单个液滴操控,作为独立皮升规模的生化反应器。

- 生产和生物分析设备的微型化

如何克服液滴芯片材料和表面处理的限制。

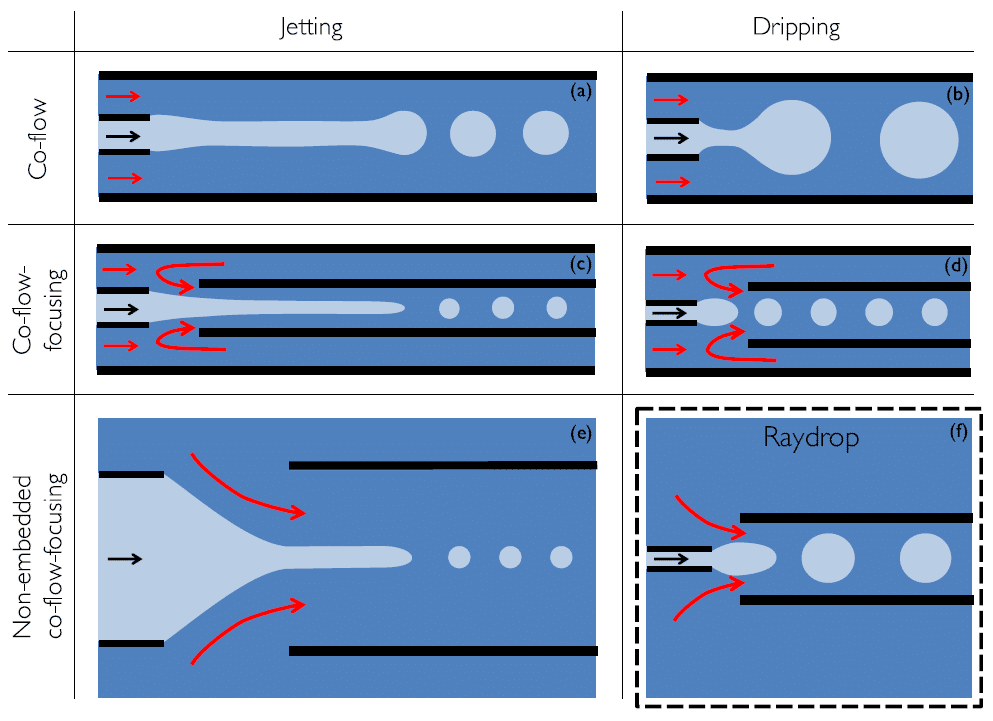

大多数商业微流控液滴生成器依赖于在聚合物或玻璃芯片中实现的平面流动聚焦配置。这种几何形状有很多限制,比如需要特定的涂层,或使用专用的表面活性剂。相比之下,基于玻璃毛细管的液滴生产设备是一大改进,因为分散相永远不会与外毛细管壁接触(a,b)。

实现这些设计(毛细管居中)一直很困难,并且市面上可用的设计在液滴生产方面灵活性较差(直径> 100 µm,生成频率< 1 kHz)。通过将两个圆形毛细管插入方形外部毛细管(c,d)中可以简化居中操作,但相关制造方法限制了大规模生产,并且基于毛细管的高通量液滴生产尚未实现。新的配置提供了一种可行的替代方案,将提取管放置在注射管的前方,并且不采取任何周围的限制措施(e)。然而,该系统仅在射流状态下工作,不能保证液滴单分散性与滴落状态有关。

基于毛细管的可用轴对称液滴生成器设计。

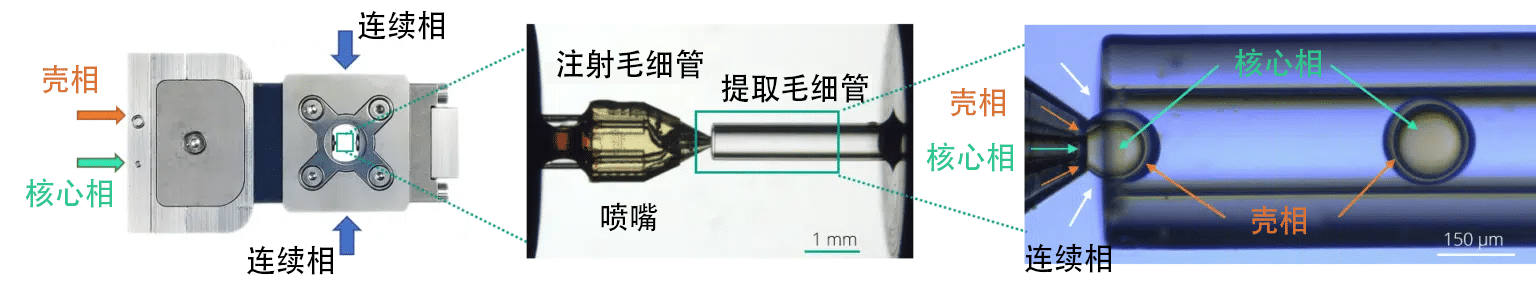

Raydrop:一种非嵌入式共流聚焦微流控液滴发生器

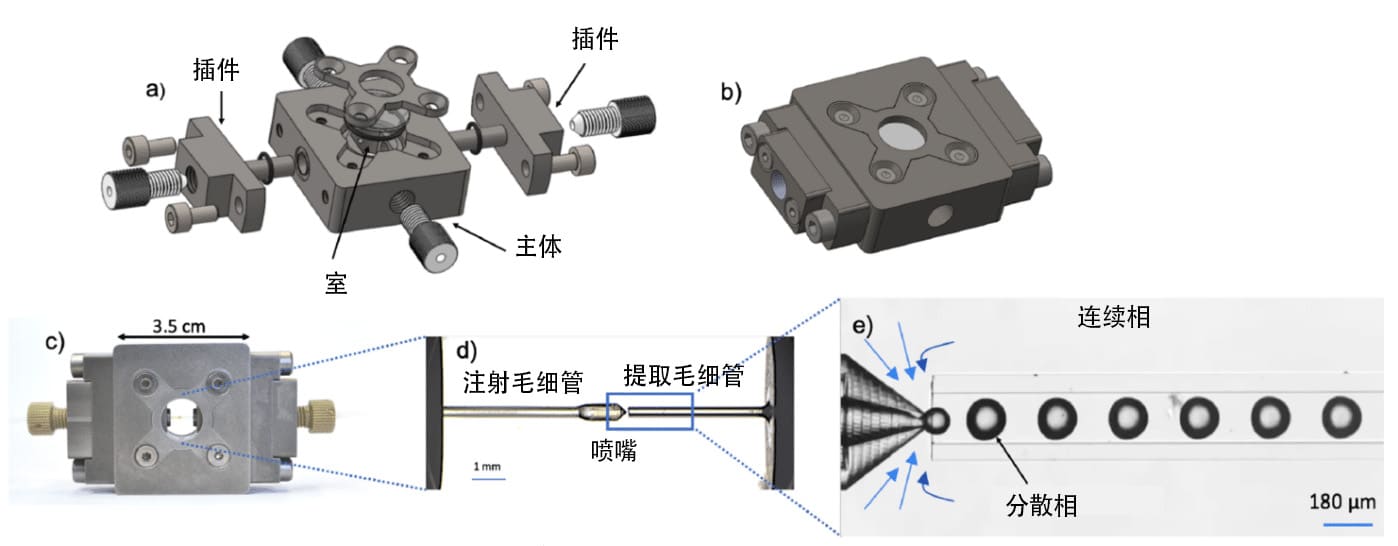

Fluigent和Secoya合作开发了一款新系统,基于前面提到的设计,但有所创新,其中通过使用直径小于提取毛细管的注射毛细管来强制实现滴落状态。这种方法结合了尖端加工和3D打印技术。这种非嵌入式设计展现了共流和流动聚焦的特征,并称之为“非嵌入式共流聚焦”设计。这种配置填补了微流控液滴生成器设计领域中的空白。

a) Raydrop分解图和(b)组装图。(c) Raydrop带有注射和提取玻璃毛细管。(d) 通过顶部窗口放大观察两个毛细管在填充连续相的室内对准的情景。(e) 放大观察基于毛细管的液滴生成区域。

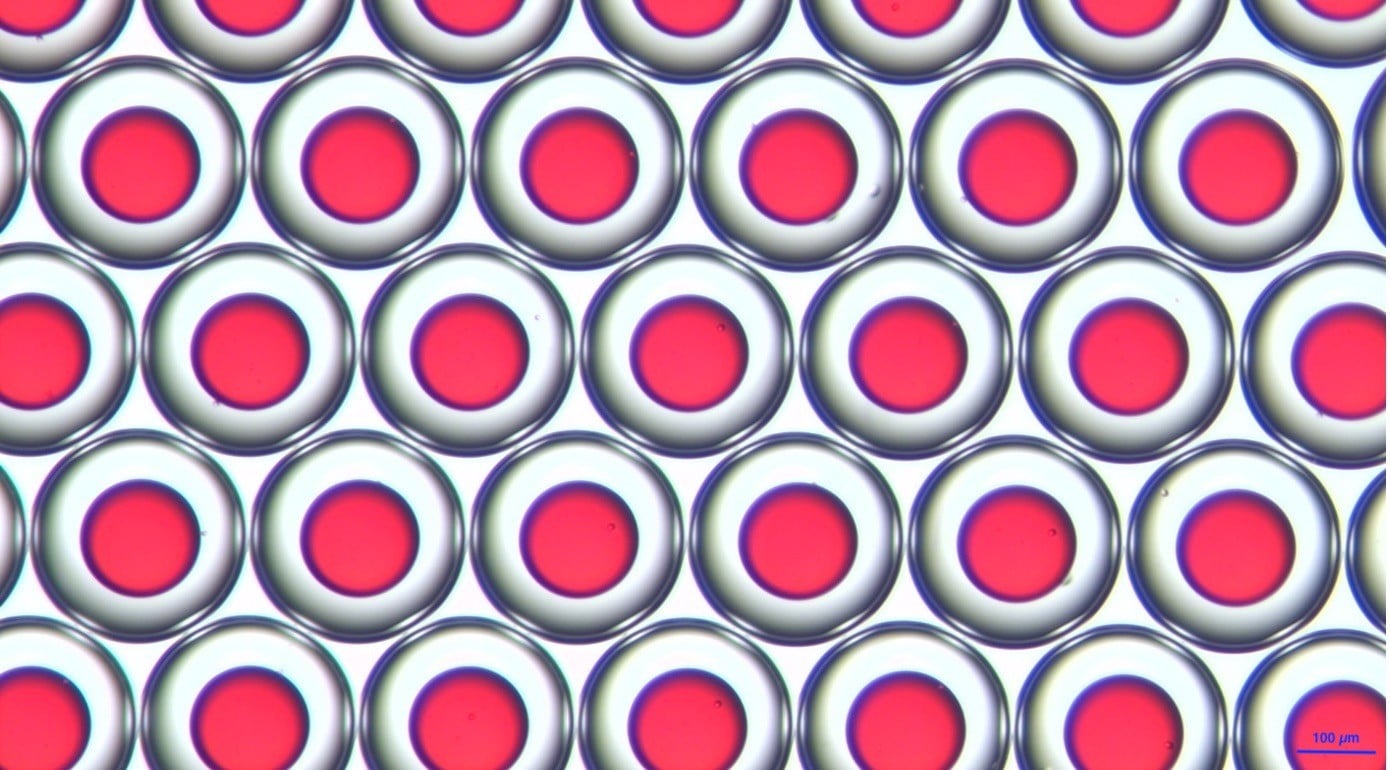

PLGA 微珠示例

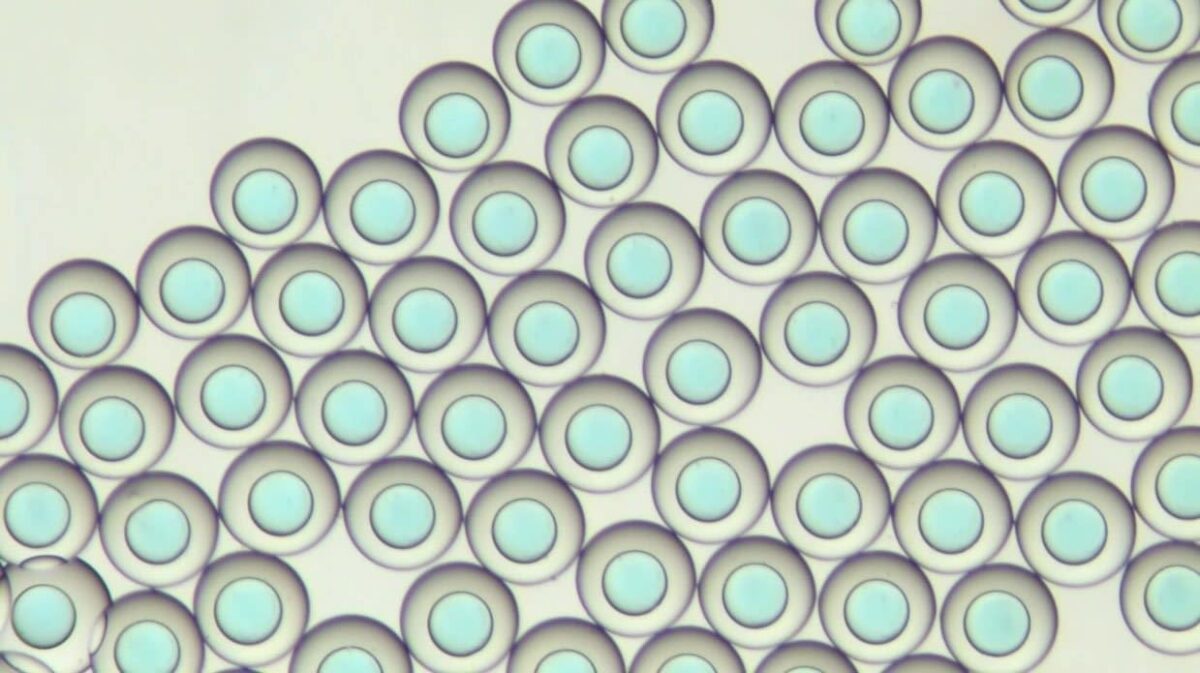

Raydrop是一款商用微流控芯片,操作简单,能够生成非凡单分散性的液滴。

Raydrop®能够生产简单乳剂(水包油和油包水)以及双乳剂(油包水包油或水包油包水),无需涂层处理。

与单一乳剂相比,双乳剂优势众多。双乳剂通常更稳定且不易聚合,并且更易于处理和分析。由于双乳剂能够轻易分散在水连续相中(在生命科学领域的单一乳剂中较少见),因此可以通过自动化细胞分选,例如荧光激活细胞分选(FACS),进行表征和分类。此外,双乳剂是通过固化外壳来生产微胶囊的绝佳模板。

PLGA(左)和壳聚糖(右)微胶囊示例

流速在液滴生成中起什么作用?

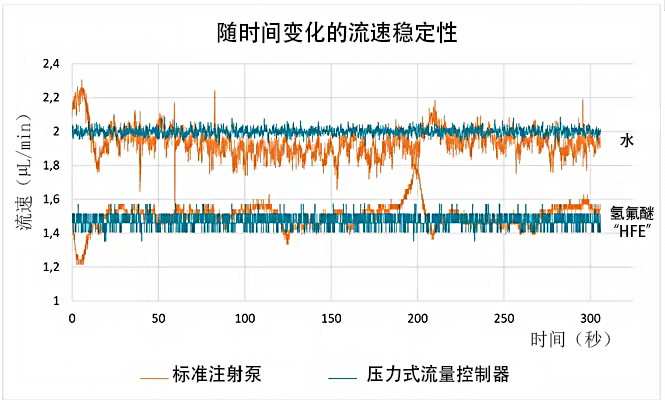

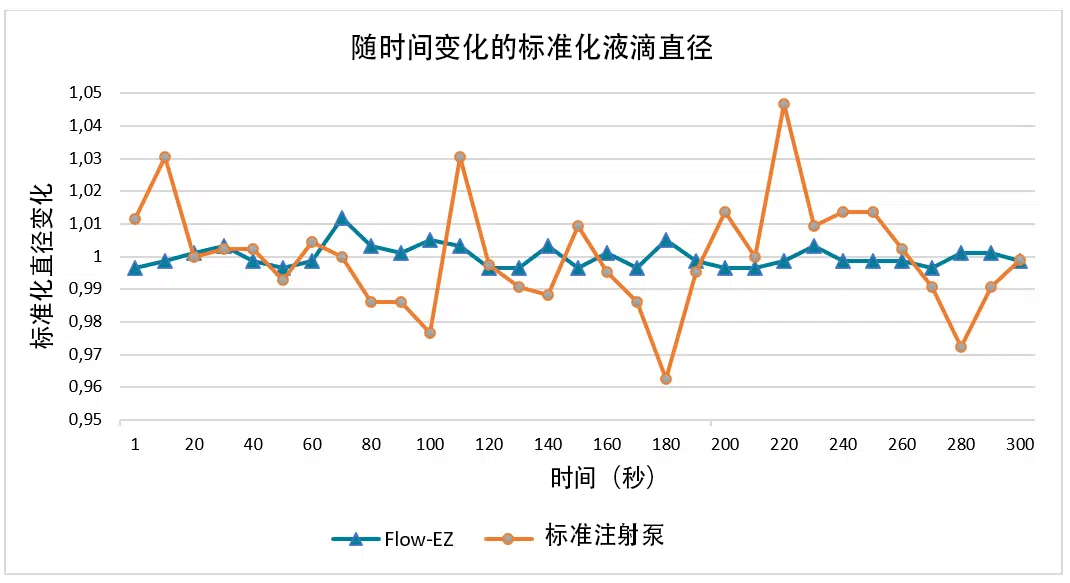

流速稳定性对于获得可重复的反应器体积和可再现的结果至关重要。在微流控实验中,注射泵通常用于产生液滴。根据使用的型号,注射泵的流量控制有限。因此,液滴尺寸(与流速成比例)会受到影响。实际流速无法通过这种设备进行监控。设备上显示的是流速值,但没有给出达到设定流速所需的时间信息。(流量平衡的时间可能会随着微流控的设置而变化,而流速也会随着仪器的不同而波动)。注射泵的替代品是Flow EZ压力式流量控制器。这些表明高精度流量控制、快速反应时间和流量监控可能实现。与注射泵相比,流量更稳定且可重复。

References

- Iqbal, M., Zafar, N., Fessi, H., & Elaissari, A. (2015). Double emulsion solvent evaporation techniques used for drug encapsulation. International Journal of Pharmaceutics. https://doi.org/10.1016/j.ijpharm.2015.10.057

- Katouzian, I., Jafari, S.M., Nano-encapsulation as a promising approach for targeted delivery and controlled release of vitamins, Trends in Food Science & Technology (2016), https://doi: 10.1016/j.tifs.2016.05.002