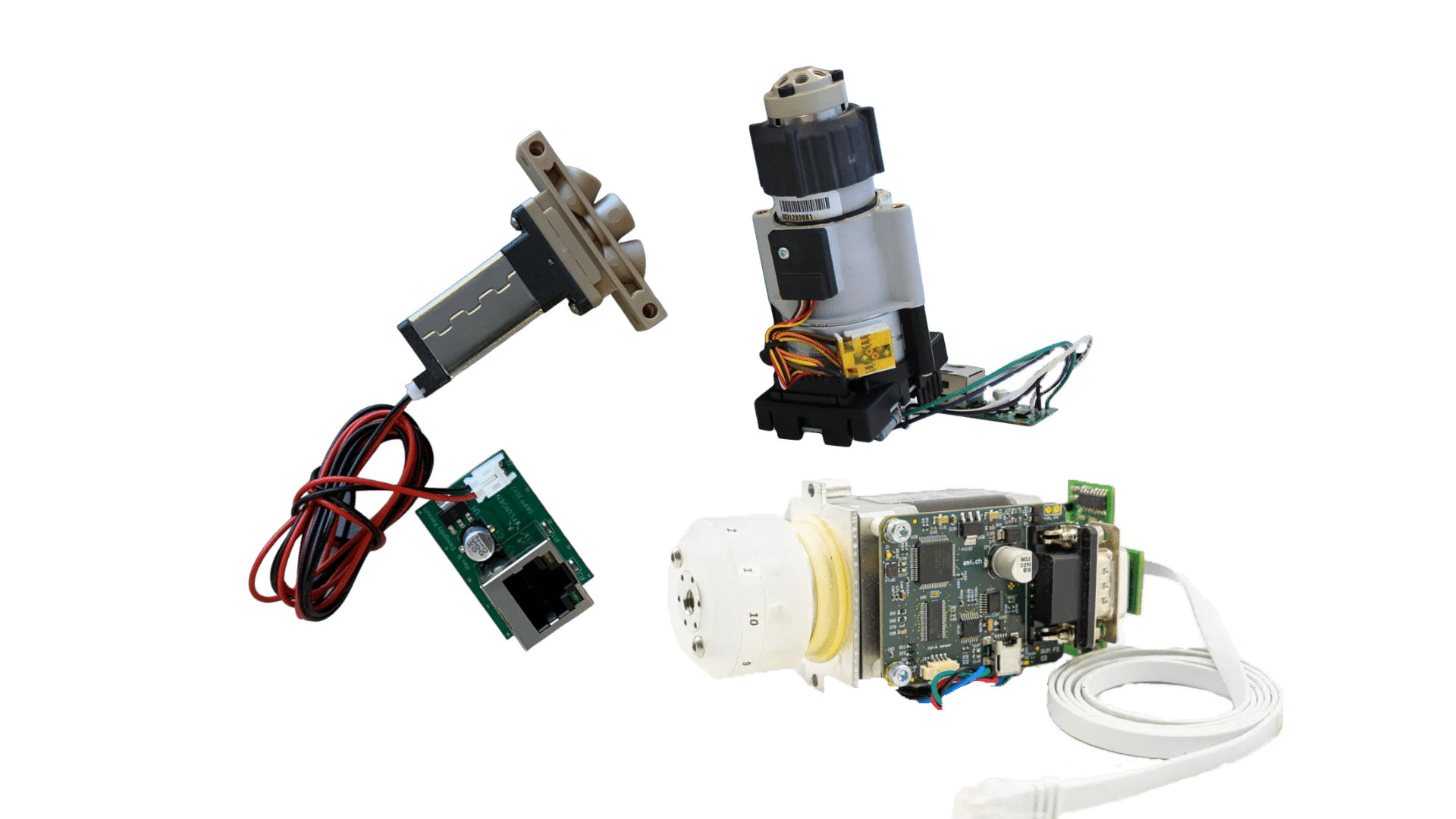

OEM微流控组件

Fluigent产品系列包含OEM微流控组件,以便客户能够构建完整的微流控系统。我们所有的可集成模块都适合微流控应用。借助我们的OEM微流控组件,我们可以自动化和监控复杂微流控系统中的流体管理。

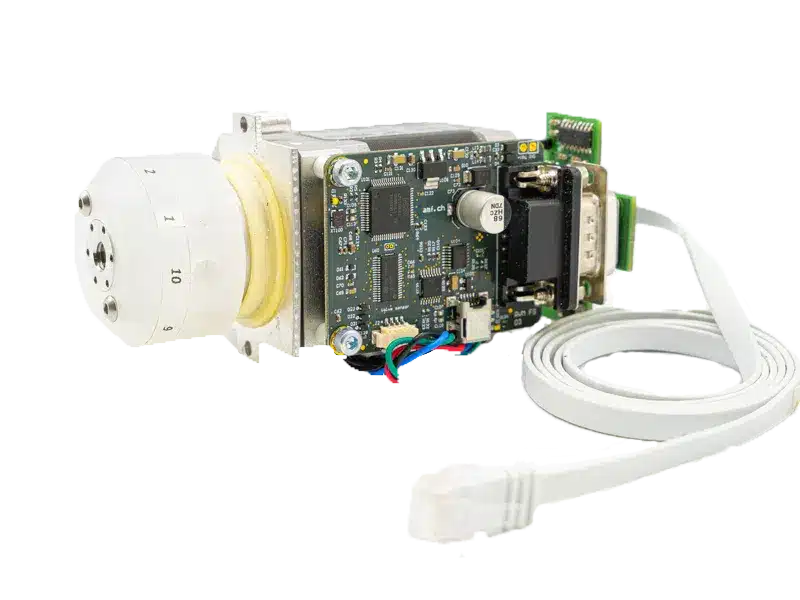

Fluigent M-X

[IVMSW1]

工业用旋转多端口微流控阀

- 外形紧凑 : 可轻松安装在系统和机器中

- 快速 : 启动和响应时间短

- 精确 : 内部体积低

- 自动化 : 可使用内部软件或SDK库实现完全自动化

OEM Fluigent MX是一款十位十一通双向电动旋转阀,用于注射或选择最多10种不同的流体。流体在旋转阀中双向流动。该设备可用作选择器或分配器,用于复用或解复用用途。

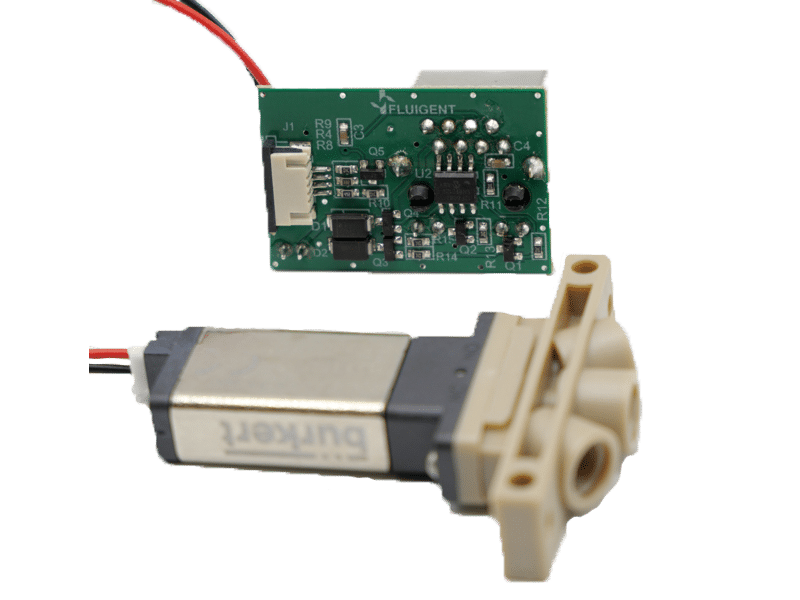

Fluigent L-X

[IVLSW1]

工业用样本注射和再循环微流控阀

- 外形紧凑 : 专为系统集成设计

- 快速 : 启动和响应时间短

- 精确 : 内部体积低

- 自动化 : 可使用内部软件或SDK库实现完全自动化

L-X OEM两位六通阀是一款双向微流控阀,专为细胞培养应用中的精确样本注射或流体再循环而设计。

Fluigent 2-X

IV2SWBK1

工业用两位三通双向阀

- 外形紧凑 : 专为并行化设计

- 快速 : 启动和响应时间短

- 精确 : 内部体积低

- 自动化 : 可使用内部软件或SDK库实现完全自动化

2-X是一款紧凑型两位三通微流控阀。使用标准配件,可以集成到任何流控系统中。

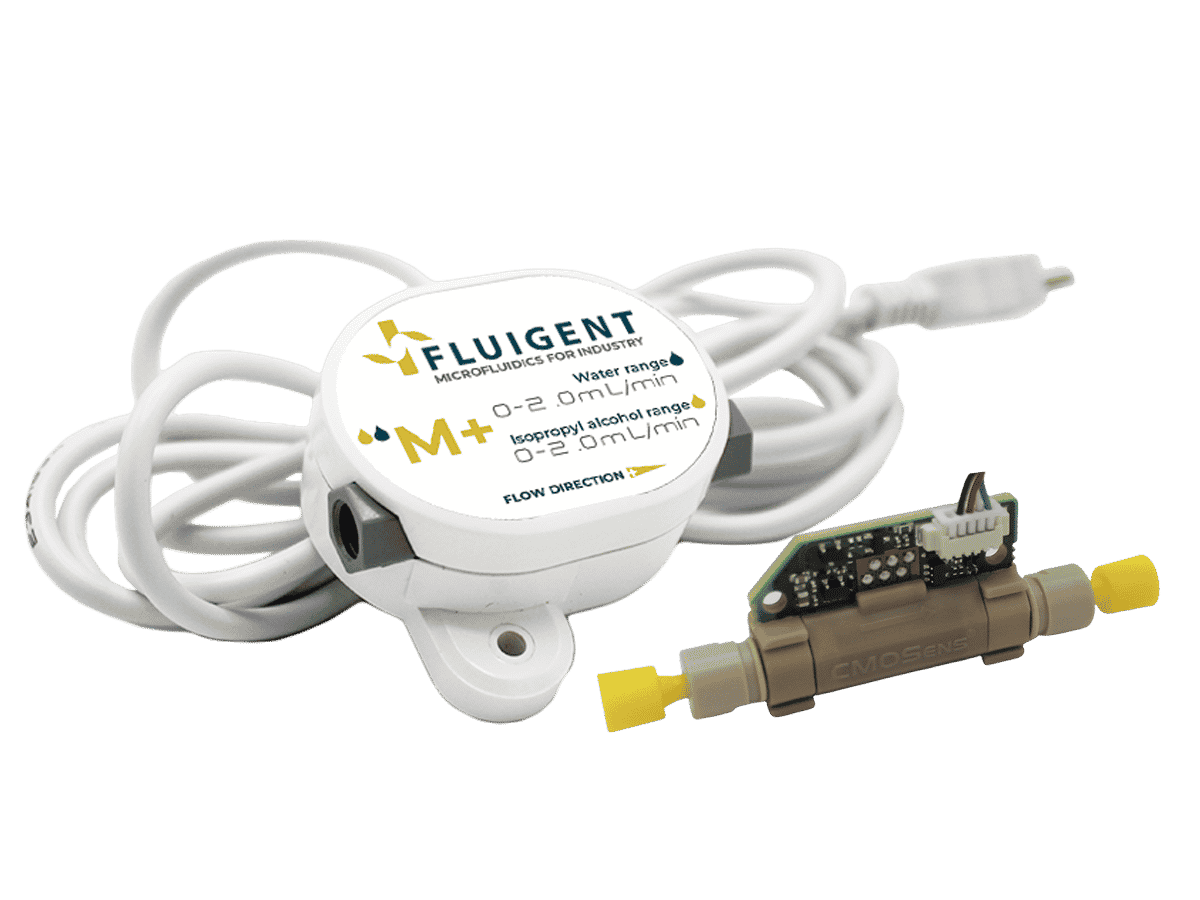

FS系列

[IFSXX]

微流控OEM流量传感器

- 响应时间短 : 压力式直接流速控制

- 稳定性高 : 优异的可靠性和长期稳定性

- 可靠 : 经过行业验证的技术

- 简洁直观 : 易于使用的系统

我们的微流控OEM流量传感器FS系列专用于流速控制和监控。当与Fluigent压力控制器组合使用时,允许进行基于压力的流量控制。双向动态流体流速能够精确测量0–1.5 µL/min到最高40 mL/min。

Fluigent RX

[ISRX21]

OEM微流控压力源

- 外形紧凑 : 适合工业和研究用途

- 易于使用 : 标准连接

- 适配性强 : 在有无电脑的情况下均可使用

RX OEM微流控压力源支持无缝集成到工业系统中或用作独立压力源,以便为微流控压力控制器提供压力源。该组件非常适合实验室环境和操作台。

该组件封装在坚固的钢制外壳内,可向一个或多个压力控制模块(如PX系列或其他需要压缩空气来操作的仪器)供应干燥且经过过滤的空气,压力最高可达2500 mbar。