微流控知识

听听我们的客户怎么说

“得益于Fluigent的专业知识,我们能够彻底改变微流控方案的规模,从一个博士生实验发展到任何人都可以使用的完全自动化、并行化的工作流程。Fluigent不仅在这一转变过程中通过他们的创新思维和多学科技能给予我们支持,其客户服务和响应速度也是一流的!”

匿名客户

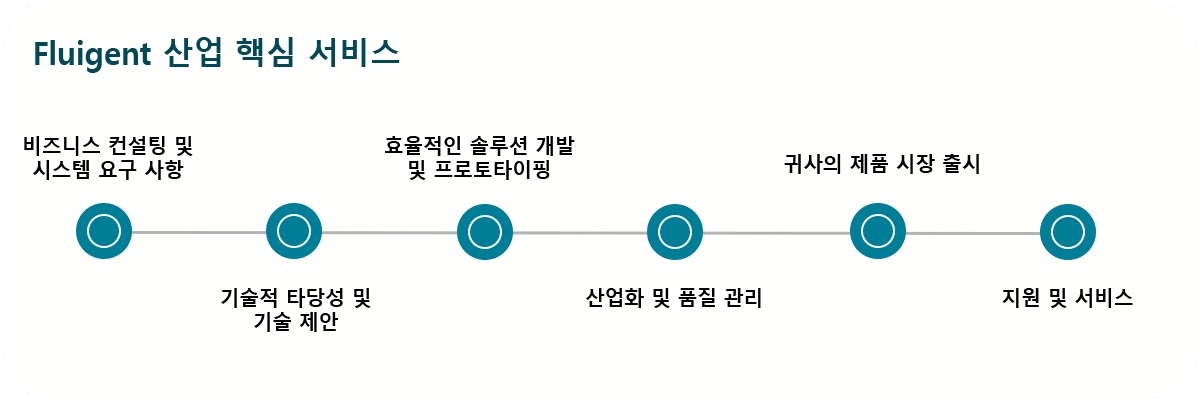

从开发到商业化

每个系统都有自身独特的规格。Fluigent提供灵活的定制微流控设备开发服务,以实现您心中所想的系统。我们的核心服务包括提供完整的OEM微流控服务,将您的解决方案推向市场,同时确保高质量标准和满意度。

1.业务咨询与系统要求

Fluigent会与所有用户一起讨论微流控产品开发的业务模式和技术规格。

2.技术可行性与技术审查

一旦明确了您的需求和技术规格,我们的研发团队将依托最先进的模块和独特的创新技术组合,为您的应用推荐最经济高效的解决方案。

3.高效解决方案开发与原型制作

一旦规格和要求确定,研发项目团队将致力于开发您的定制微流控解决方案。在整个开发过程中,我们将不断向您更新关于项目总体进展的最新情况。我们非常重视透明度这一核心价值。我们将把OEM微流控定制系统原型发送给您进行测试和验证。

4.工业化与质量管理

验证后,研发部门会将您的原型转交到我们的生产部门。通过ISO 9001证书要求的培训、生产文件、台架测试和其他质量评估,我们交付具有高度可再现性能的标准系统。

5.产品上市/支持与服务

我们的合作关系并不会因为您的产品商业化而结束。我们制造并运送定制微流控设备后,Fluigent还将提供一流的团队培训和备件订单支持服务。

OEM微流控定制系统:Fluigent独特的技术组合

Fluigent 拥有15年以上的经验,作为第一家使用压力驱动微流控中流体的公司,可应对流体稳定性和无菌性挑战。得益于持续的创新过程,我们通过开发尖端技术解决当前的限制,目前已拥有20多项专利。通过将我们的技术集成到您的定制微流控设备中,Fluigent 将增强您的应用性能,并确保您在竞争中占据优势。

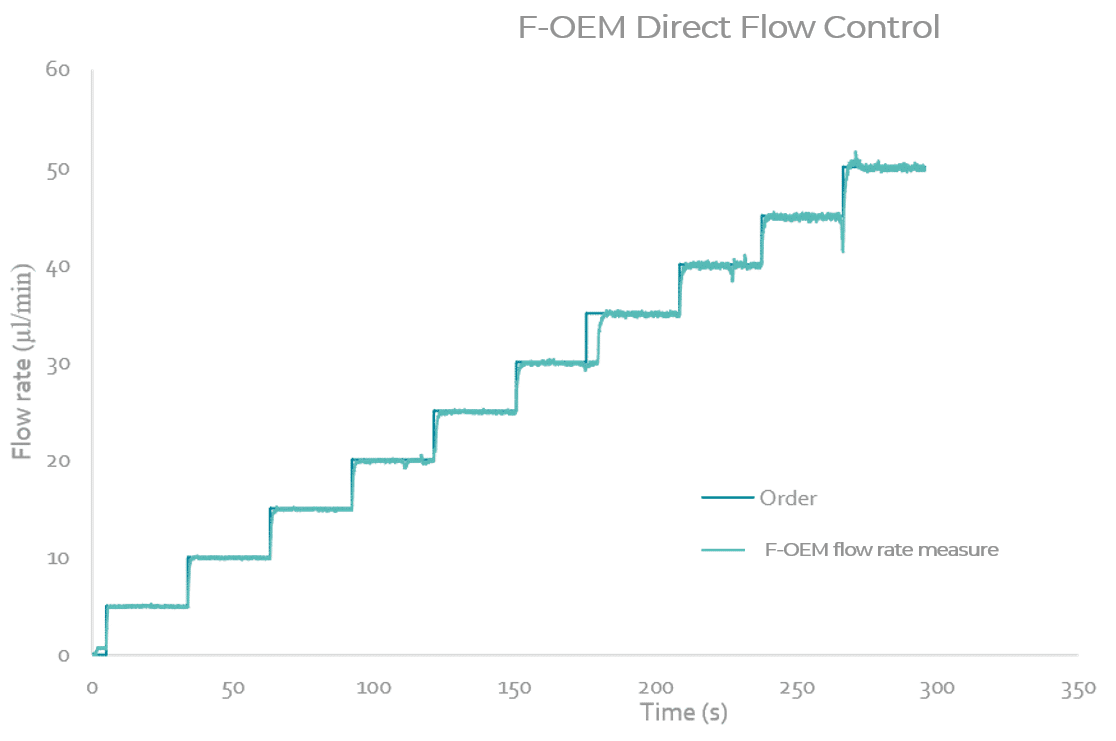

DFC流速控制算法

自学习算法支持实时压力/流速监控和控制

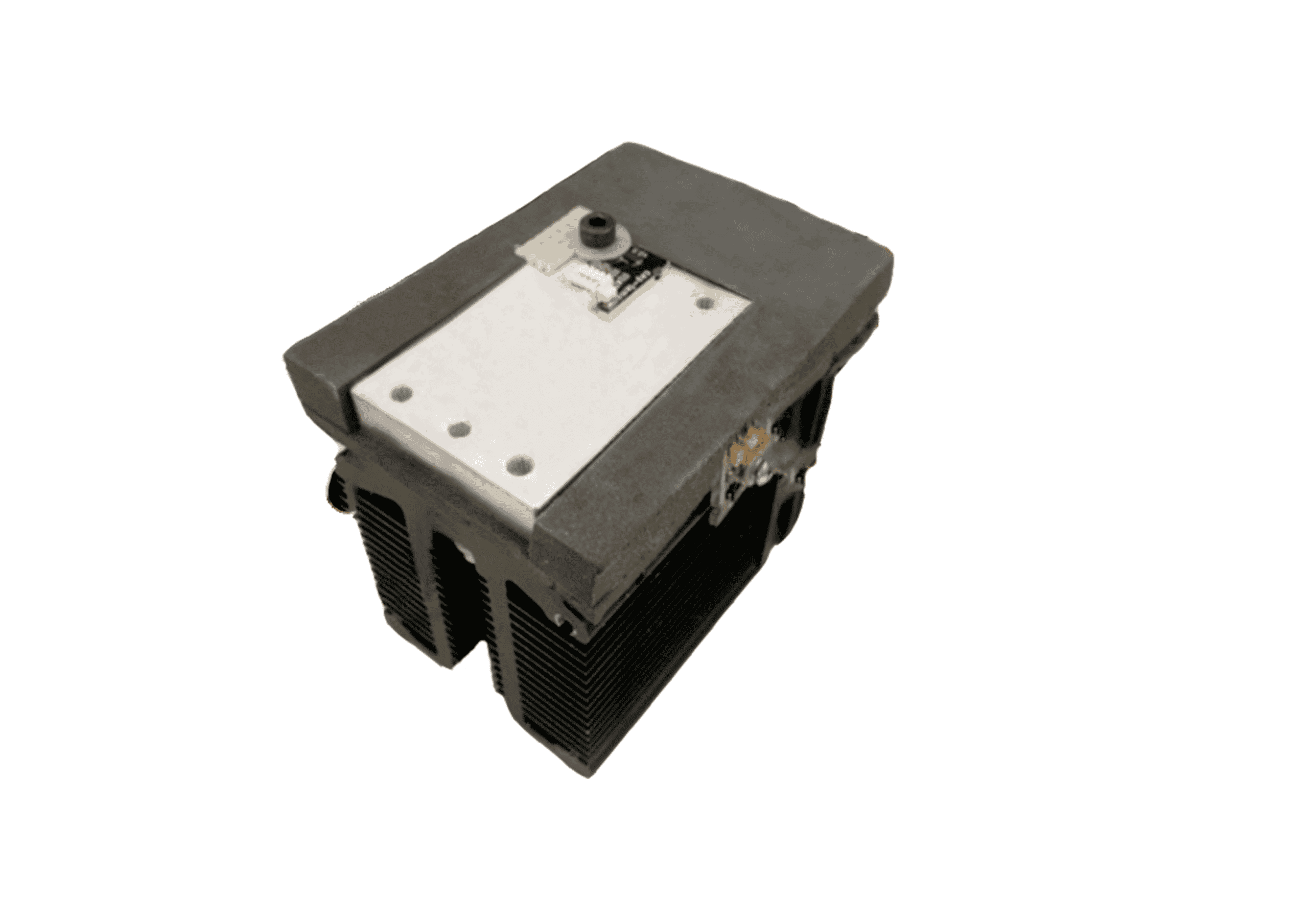

微型泵算法

微型泵中的Fluigent算法可实现紧凑的压力供应和控制

流体混合器

生物旋涡混合器。轨道运动,质量补偿振动

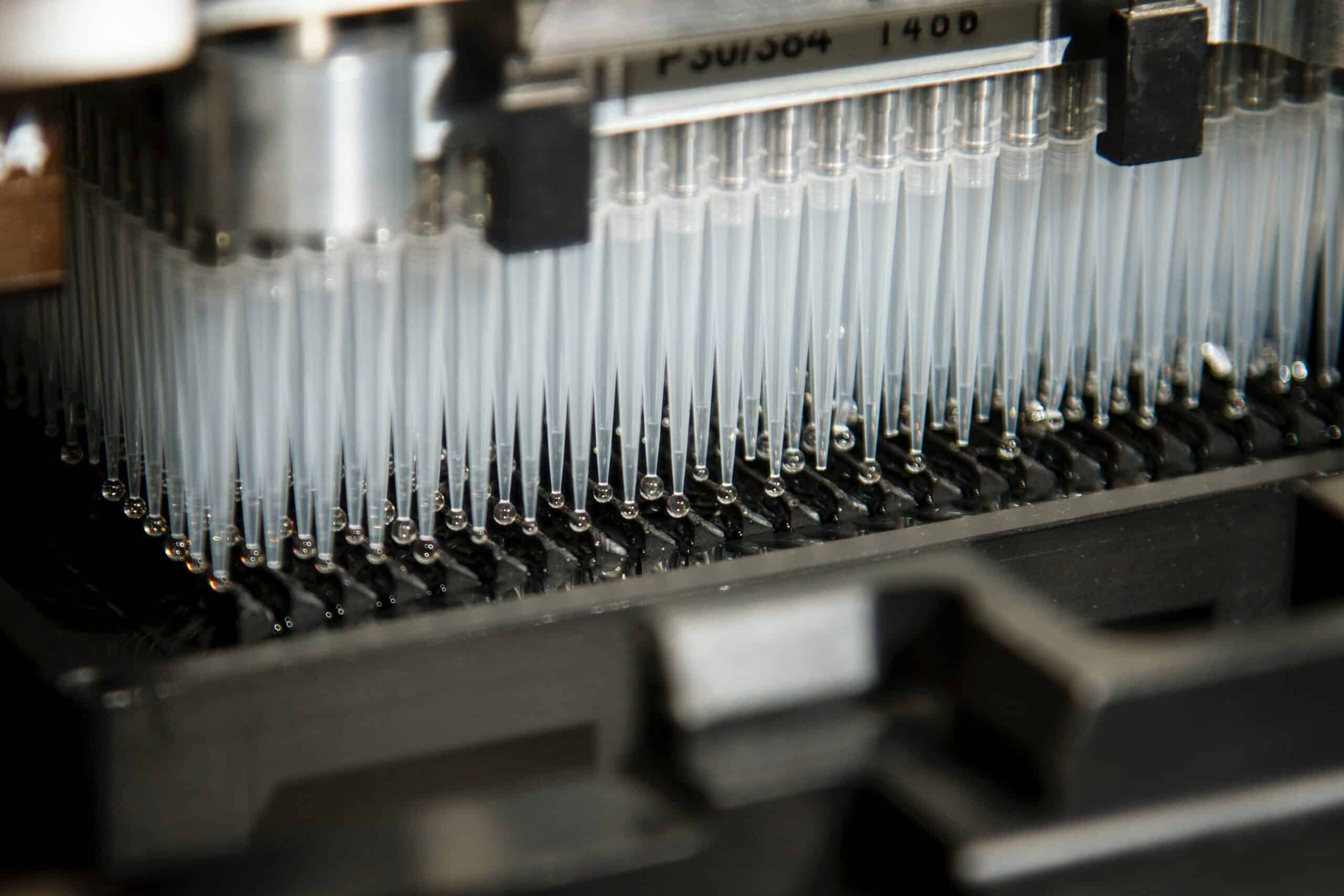

机器人移液

用于微孔板中流体取样的三轴(x/y/z)机器人平台

温度管理

用于加热和冷却的温度模块

还有很多…

定制软件开发

我们为您的定制微流控设备提供基于知名最终用户软件OxyGEN以及SDK库的定制软件。我们开发和设计您的用户界面,并创建专用方案,以最佳方式满足您的应用需求。此外,我们可以在您的微流控产品开发过程中与第三方设备的软件进行交互,以实现跨设备通信,并保证最佳效率和用户友好性。

OEM客户案例研究

每个客户情况不同,都面临着特定的挑战,我们特别注意解决这些问题。在客户案例研究中,了解我们客户的故事以及我们与之建立的关系。

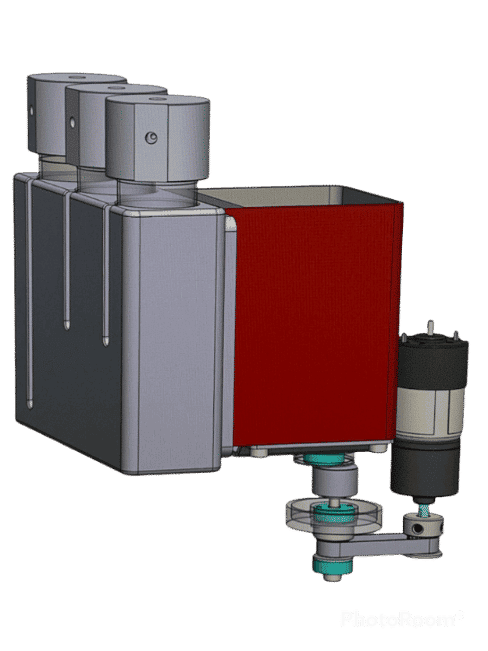

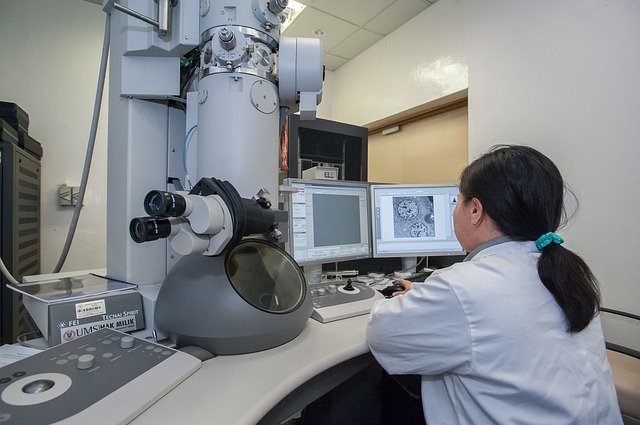

背景

一个领先的电子显微镜研究小组希望在其标准成像平台中添加自动采样系统,作为提供给客户的增值功能。由于我们在工程实际和制造OEM微流控定制系统方面拥有丰富经验,Fluigent接受邀请开发这个补充模块。

解决方案

Fluigent在定制微流控和流体处理硬件和软件方面的专业知识,为所有用户实验提供技术支持。

结果

该采样系统可在长时间的成像实验中自动输送样品量,同时保持样品处于冷藏状态。不久之后,附加功能也将集成到客户端软件中,这样用户便可以在一个地方充分利用整个平台的功能。

背景

这家公司在研究微流控技术后,为寻找一种流体处理解决方案,联系了Fluigent。

解决方案

当客户专注于开发其生物学领域专有技术时,Fluigent的团队已经成功完成了从流体系统到仪器设计的开发,创建了围绕芯片所需的组件。

结果

这一结果使用户能够同时使用多个微流控设备,而无需大量的预先培训,从而提供精准医疗的体外诊断测试。