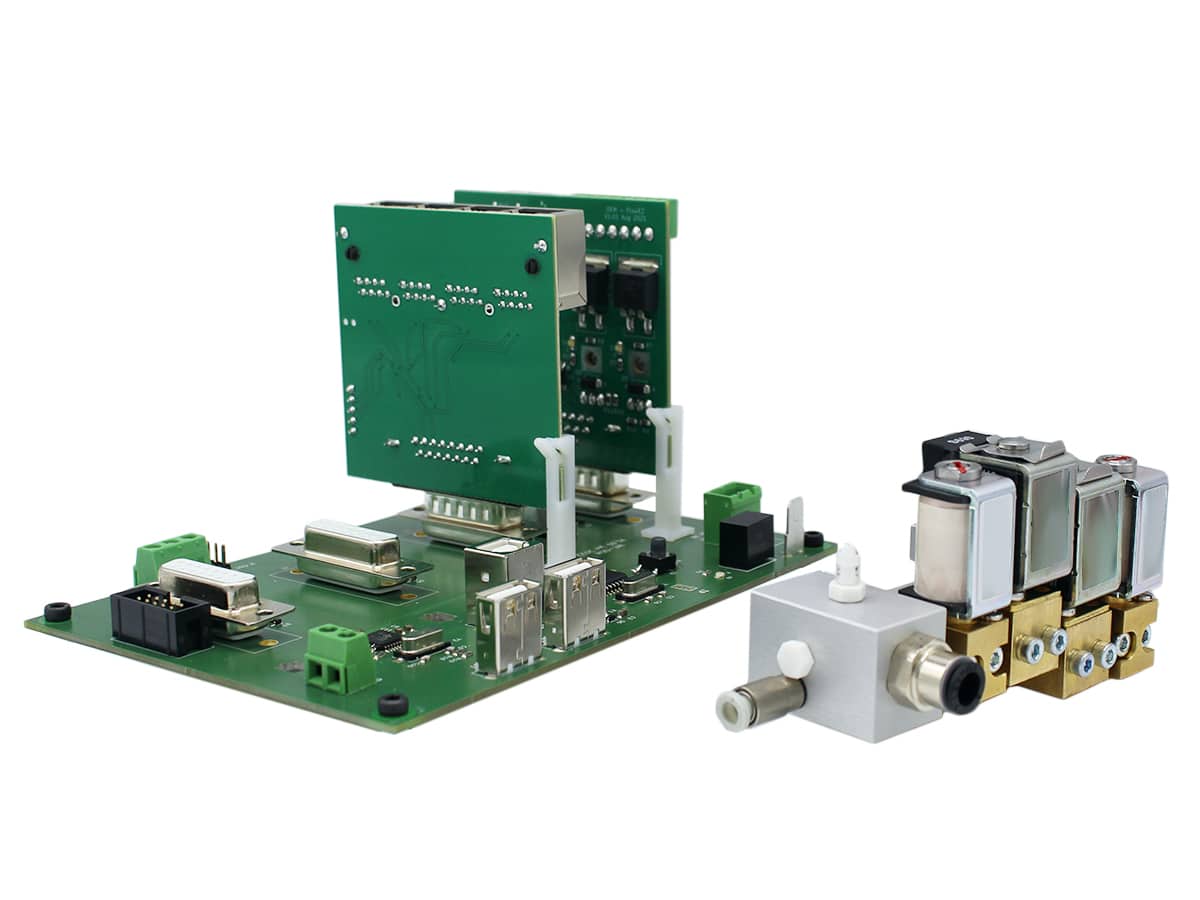

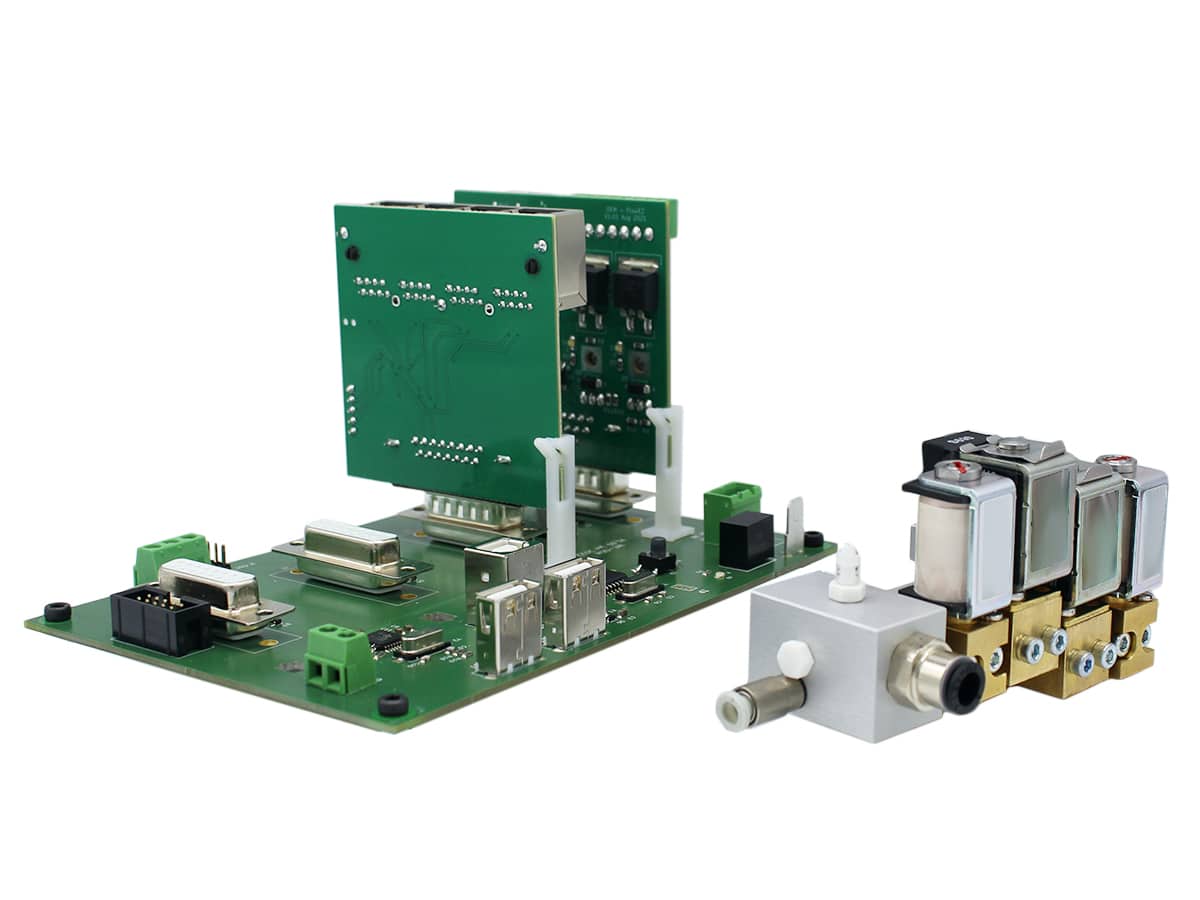

流体压力控制器

了解我们的OEM压力式流量控制器。压力范围为-800 mbar到+7 bar,您可以根据自己的应用选择合适的解决方案,我们将为您量身定制。如果您决定优先考虑系统的紧凑性和响应时间,我们的模块可保证满量程0.1%的压力稳定性和0.25%的精度。

了解我们的OEM压力式流量控制器。压力范围为-800 mbar到+7 bar,您可以根据自己的应用选择合适的解决方案,我们将为您量身定制。如果您决定优先考虑系统的紧凑性和响应时间,我们的模块可保证满量程0.1%的压力稳定性和0.25%的精度。