Liquid Stirring Solutions

Fluid agitation is a common step in many microfluidic applications. During sample preparation, it allows for the dissolution, mixing, or dispersing of reagents. Continuous stirring is required during specific experiments to maintain mass transfer, emulsion, or suspension in heterogeneous mixtures. Fluigent provides a variety of solutions to meet your liquid stirring specifications.

This technology can be integrated in any custom project. Benefit from the best performance and Fluigent expertise for your project.

- Tailor-made: different types of motion, intensities of stress, volumes handled

- Compatible with temperature control: stirring and heating/cooling modules are easily combined

- Versatile: can be integrated into Fluigent’s protocols and communicate with other microfluidic setup modules

Liquid/liquid dispersion modules: technology description

Fluigent has developed fluid agitation solutions based on several different technologies. The stirring module can be coupled to a temperature control module, as both require a platform to which the reservoirs are attached. Since control of these components is integrated into the software, Fluigent systems allow the user to manipulate certain parameters. For example, three different speeds can be implemented, allowing for different modes of liquid stirring with the same module.

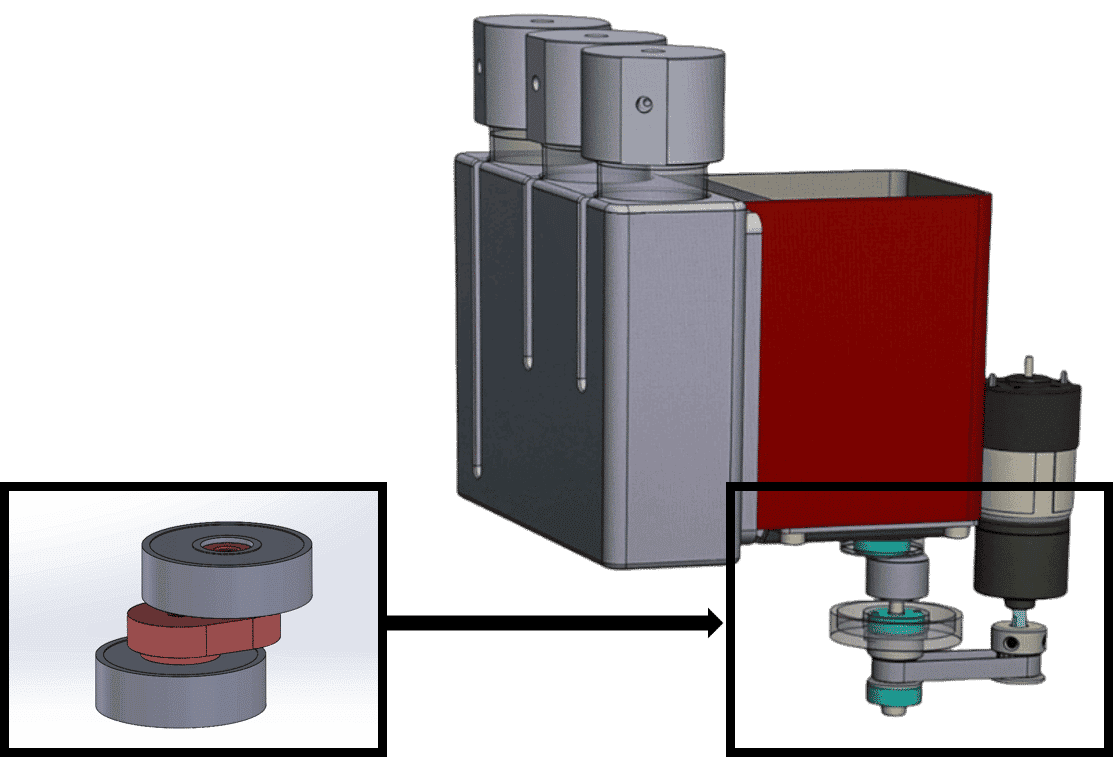

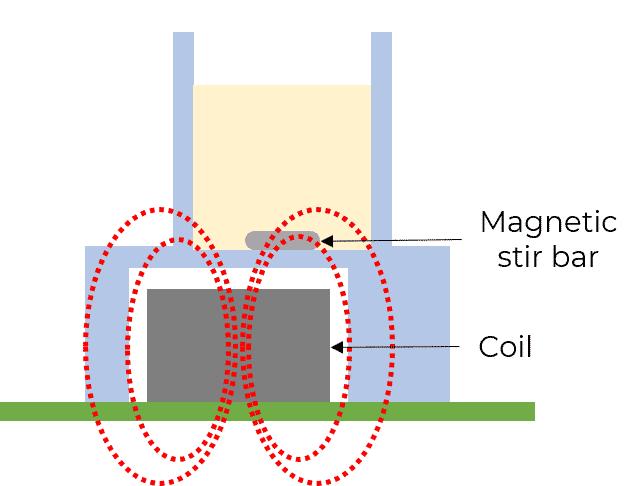

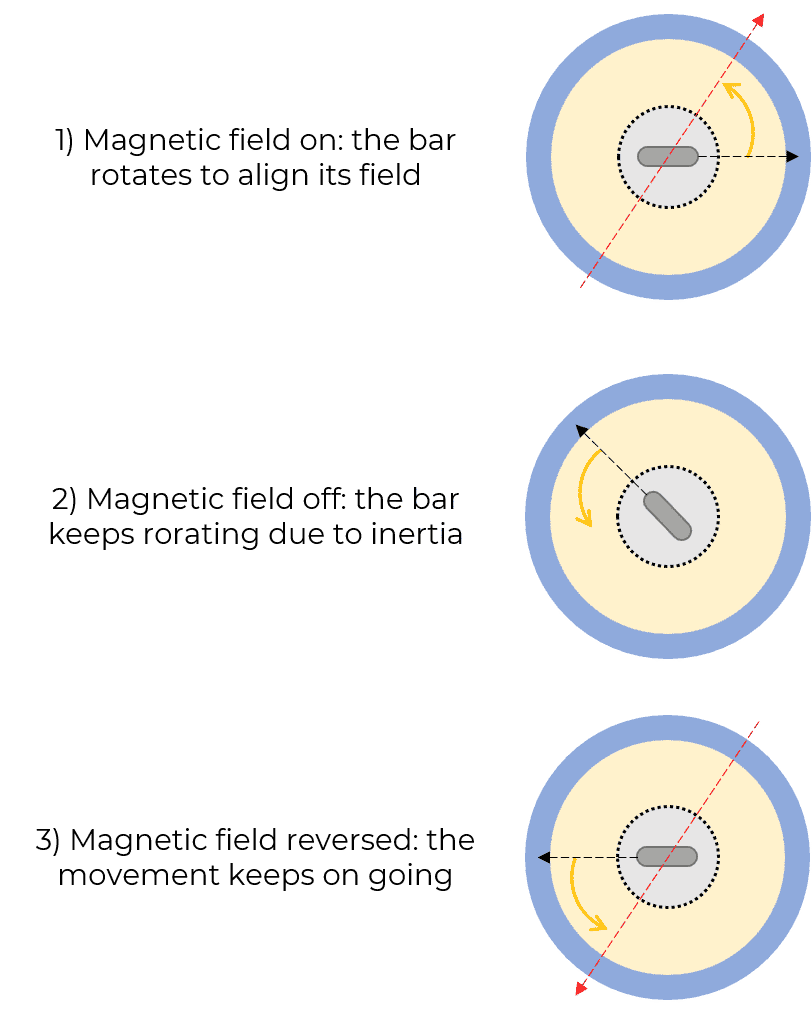

Magnetic induction stirrer: a motor-less agitation method

The technology designed by Fluigent works similarly to standard magnetic stirrers generally used in chemistry applications, and consists of two elements: a magnetic stir bar (immersed in the fluid) and a coil (placed under the container, off-center). When AC current flows through the coil, the magnetic field is alternately generated, turned off, and inverted, causing the stir bar to vibrate or spin and stirring the liquid in the sample. By adjusting the current, this method can provide gentle to strong agitation. This magnetic induction stirrer presents a number of advantages over traditional motorized magnetic stirrers: it does not generate heat that may interfere with temperature-sensitive experiments and it is quiet and compact, making it readily adaptable to the small volumes used in microfluidics. It is the preferred technology to integrate fluid stirring into a very compact system.

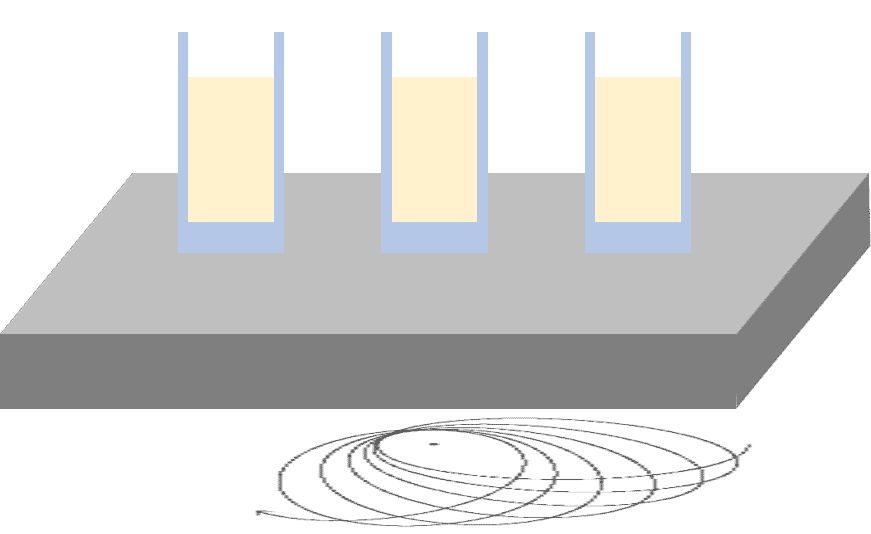

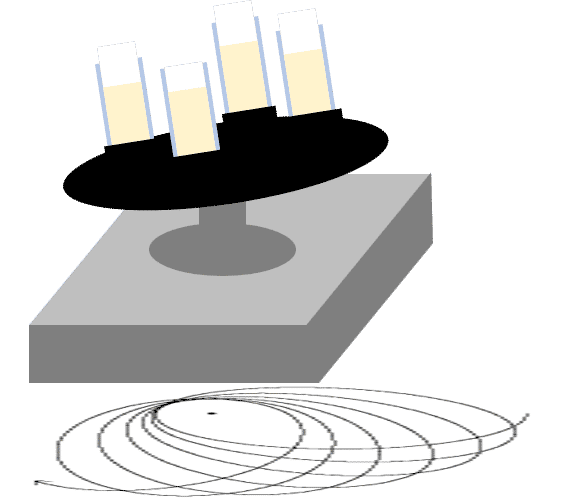

Orbital shaker: a stable platform for consistent vial-to-vial homogeneity

Fluigent has also developed contactless fluid agitation technologies. Orbital shakers usually consist of a large plate that provides soft orbital motion in a horizontal plane. However, the movement can be implemented differently so that the platform oscillates with any desired trajectory. Unlike the magnetic stirrer, this solution is non-intrusive and can consistently handle multiple reservoirs with the same device. The benefits of the orbital shaker compared to other shakers like the platform shaker or the vortexer are that it generates no vibrations, produces less heat, and is able to aerate the samples and evenly distribute cells. This technology has been developed for customers who do not need much capacity but require external sterile liquid stirring that avoids sedimentation and cell damage. The platform is also optimized to integrate temperature control.

Vortex mixer: a solution for intense shear stress

The vortex mixer is similar to the orbital shaker in terms of its motion. The differences are orbital diameter, agitation frequency range and means of contact. While the orbital shaker usually has a larger diameter and a lower frequency, the vortex mixer typically has a smaller diameter and a higher frequency. As a result, vortex mixers allow for more intense liquid stirring. In addition, vials are placed on a plate on an orbital shaker, whereas the vortexer has a cup-shaped, slightly off-center rubber piece vertically attached to the motor drive shaft that transmits its rotary movement to the vial or the foam rack with several tubes attached to it. This creates a vortex in the liquid.

Comparison between liquid agitation technologies

Each method has its own advantages that make it more appropriate for certain applications. Here are some variables that may be taken into account when choosing the best liquid stirring solution for your project: [1]

| Magnetic stirrer | Orbital plate | Vortex mixer | |

| Agitation level | Locally gentle to intense shear | Intermediate-level stress | Most intense overall stress |

| Frequency range (rpm) | 60-1400 | 60-300 | 500-3200 |

| Invasiveness | Invasive but the stir bar is coated (PTFE) to be chemically inert | Non invasive | Non invasive |

| Durability | No moving external parts subject to breaking or wearing out | Motorized mechanical device | Motorized mechanical device |

| Noise level | Quiet | Noisy | Noisy |

| Volume | Compact, useful for small volumes due to the size of the bar and the absence of a motor | Plate of adjustable size that can fit multiple reservoirs | Rack of adjustable size that can fit multiple reservoirs |

| Used for | Low-viscosity laboratory mixing | Homogeneous distribution of cells and nutrients throughout the flask | Vigorous mixing, resuspension of samples |

Microfluidic applications related to liquid/liquid dispersion

Drug production

Homogeneous mixing is a prerequisite in biopharmaceutical manufacturing operations like drug production. These operations are performed in stirred vessels that use magnetic stirrers because they are gentle enough to prevent protein damage despite the shear stress they can cause. Magnetic stirring can also be used to produce drug nanosuspensions to enhance their dissolution rate and improve safety for the patient. [2][3]

Cell culture

The cultivation of mammalian cells in suspension is essential for protein synthesis in clinical and pharmaceutical research. The traditional cultivation method uses spinner flasks, but they require substantial effort to clean and sterilize. Another approach is to agitate Erlenmeyer flasks or a multiwell plate on an orbital shaker. This method allows for superior cell growth, high reproducibility in performance, good cell viability, low cost, and easy cleaning and handling of the bottles, making it a viable liquid stirring solution for the culture of mammalian cells in suspension. [4][5]

DNA extraction for PCR

Many applications of DNA technology, such as detection of fungal pathogens by PCR, require extraction methods that isolate uncontaminated DNA suitable for amplifications. Several methods are available to achieve this, and most of them have a reagent mixing step that uses a vortex mixer for maximum efficiency. [6][7]

Related products

Expertise and resources

References

[1] G. Bai, J. S. Bee, J. G. Biddlecombe, Q. Chen, W. T. Leach, “Computational fluid dynamics (CFD) insights into agitation stress methods in biopharmaceutical development”, International Journal of Pharmaceutics, 2012

[2] T. Ladner, S. Odenwald, K. Kerls, G. Zieres, A. Boillon, J. Boeuf, “CFD Supported Investigation of Shear Induced by Bottom-Mounted Magnetic Stirrer in Monoclonal Antibody Formulation”, Pharmaceutical Research, 2018

[3] P. Kocbek, S. Baumgartner, J. Kristl, “Preparation and evalutation of nanosuspensions for enhancing the dissolution of poorly soluble drugs”, International Journal of Pharmaceutics, 2006

[4] M. Micheletti, T. Barrett, S. D. Doig, F. Baganz, M. S. Levy, J. M. Woodley, G. J. Lye, “Fluid mixing in shaken bioreactors: Implications for scale-up predictions from microlitre-scale microbial and mammalian cell cultures”, Chemical Engineering Science, 2006

[5] N. Muller, P. Girard, D. L. Hacker, M. Jordan, F. M. Wurm, “Orbital Shaker Technology for the Cultivation of Mammalian Cells in Suspension”, Biotechnology and Bioengineering, 2005

[6] J. C. Colosi, B. A. Schaal, “Tissue grinding with ball bearings and vortex mixer for DNA extraction”, Nucleic Acids research, 1993

[7] D. N. Fredricks, C. Smith, A. Meier, “Comparison of Six DNA Methods for Recovery of Fungal DNA as Assessed by Quantitative PCR”, Journal of Clinical Microbiology, 2005