Microfluidic Drug Discovery

Microfluidic automated fluidic workflows as valuable tools for drug discovery

- Increased throughput and reproducibility

- Minimal reagent consumption

- Fast reaction times

- Automated fluidic workflow

Main applications in microfluidic drug discovery

Target selection and validation (drug synthesis)

When developing a drug target, protein structural and affinity studies are needed for target selection and validation, and protein interactions within cells must be studied. Single-cell protein quantitation, protein analysis in nanoliter droplets, and high-sensitivity ligand-binding interactions can be performed using microfluidic devices.

Hit identification and optimization (drug screening)

In microfluidics for drug development, the potential pool size of drug candidates is estimated to be of the order of 1063. Microfluidic drug screening devices, including high-throughput microfluidic multiplexed systems that contain thousands of micrometer chambers, microwell arrays, or microvalves perform high-throughput screening studies with higher sensitivity and shorter reaction times while decreasing reagents volumes and costs.

Preclinical studies (drug evaluation)

In recent years, alternatives to animal experimentation have become a research hotspot. In microfluidic drug discovery, organs-on- chips and organoids are widely used as alternatives as they emulate the architectural and functional complexity of native organs. These systems also enable the exploration of facets of human disease and development that are not accurately recapitulated by animal models.

Resources

Flow Control Performance and Enhanced Automation for Microfluidic Drug Discovery Applications

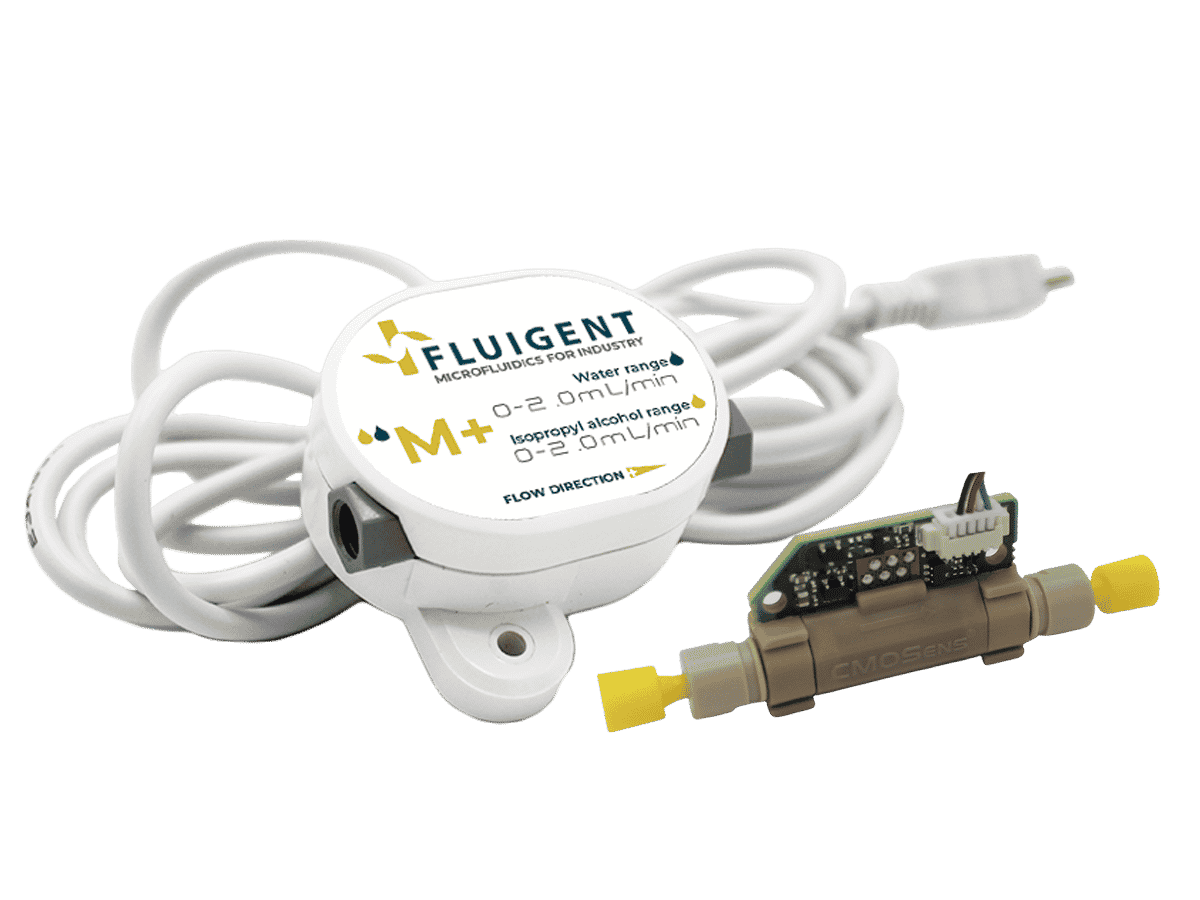

- Drug synthesis and droplet microfluidics: When it comes to droplet or particle generation, having control of the fluid delivery system is important. During droplet or particle production, the flow rate of each phase must remain constant and stable to allow the production of monodisperse droplets.

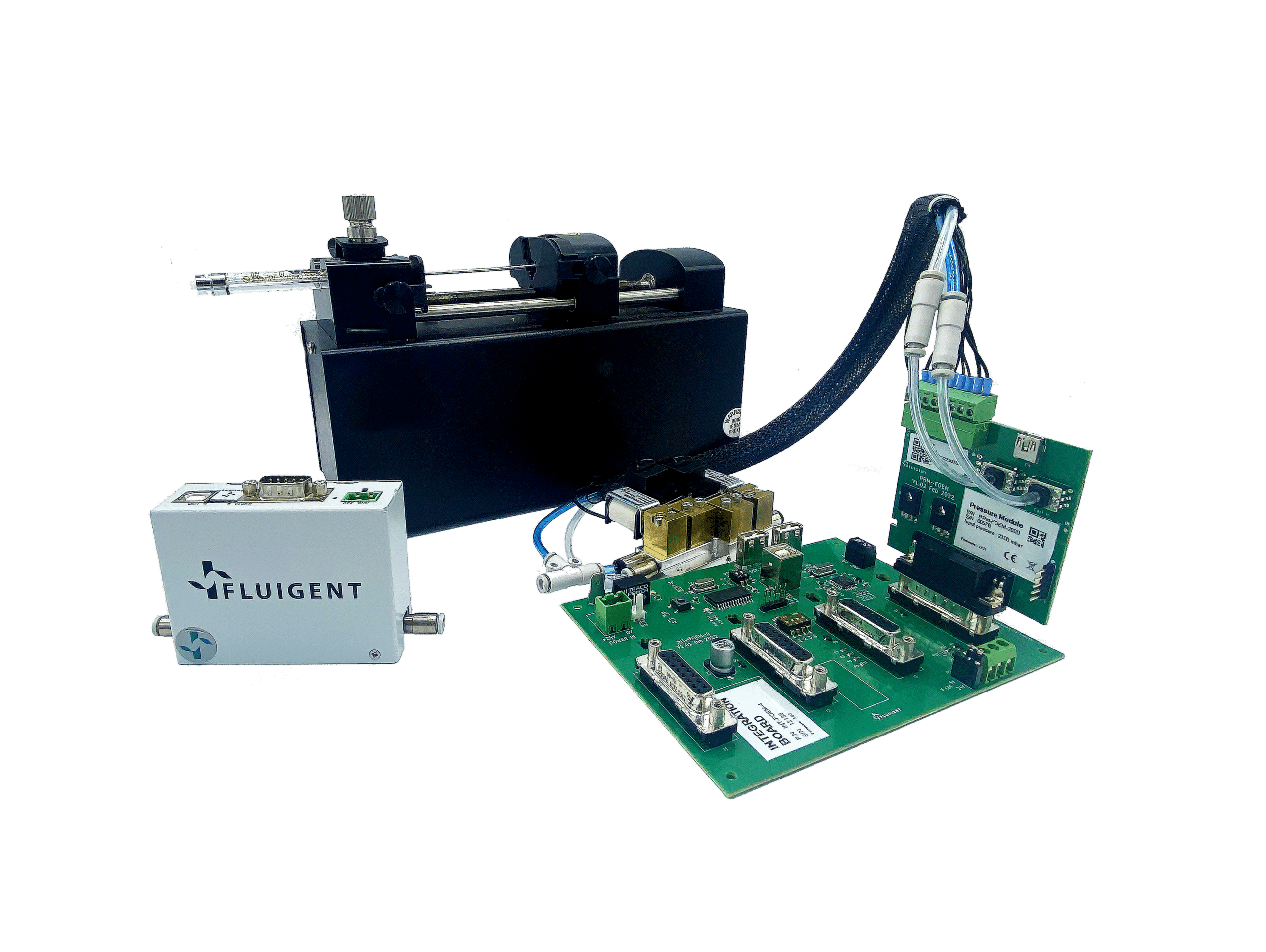

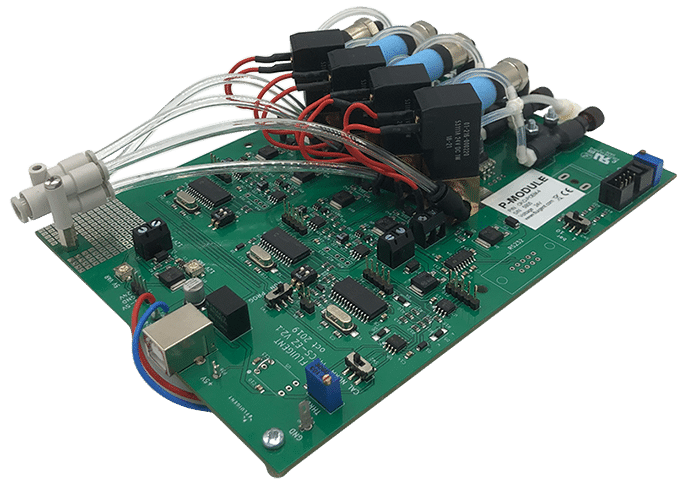

- As experts in fluid control for droplet microfluidics, Fluigent provides droplet generation packages and platforms for researchers. These seamlessly generate micrometer droplets for a wide range of applications. Custom systems are also available to integrate technological and industrial devices.

- Multiplexing for drug screening: More than twenty reagents can be tested simultaneously when performing multiplexing applications on microfluidic devices. In microfluidic drug discovery, automated fluidic workflows are a prerequisite for drug screening. Fluigent developed the Aria to automate multiple fluid deliveries. Reproducibility is improved through complete automation of the fluidic protocol. Fluigent is also able to develop a custom system to fit user specifications and requirements.

- Optimized shear stress and recirculation for organ on a chip studies and cell culture: When performing drug evaluation on 2D/3D cell culture and organs-on-chips, cell culture should be optimized through constant perfusion to enable nutrients/oxygen renewal and by inducing adequate passive stimulation through shear flow as the effect is substantial on cell properties. Sterility on the fluidic path is also a prerequisite. Fluigent develops fluid recirculating systems that perform unidirectional fluid recirculation, ensuring improved and more stable flow rates compared to peristaltic pumps. The system can run for 10 days. Custom systems are also available for microfluidic drug discovery technology integration into industrial devices.

Fluigent Solutions as an Alternative to Syringe Pumps for Better Performance and Automation

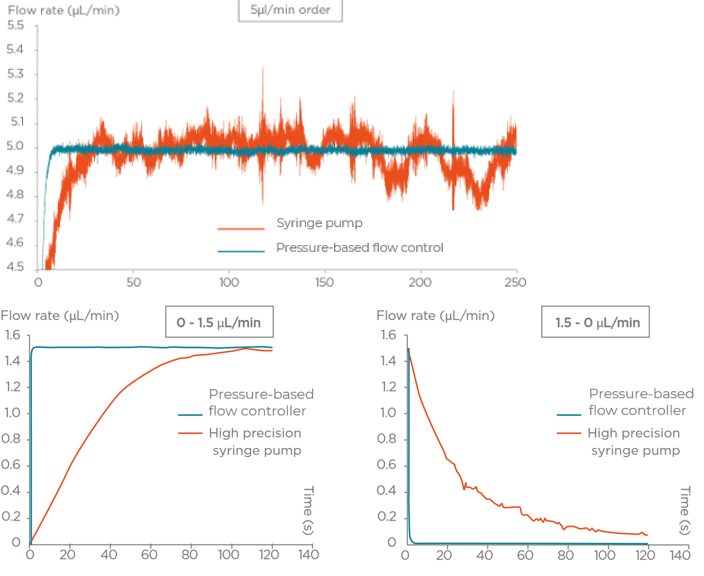

Flow rate stability and responsiveness is critical for the microfluidics for drug development applications. Syringe pumps are commonly used during this process. Depending on the model in use, syringe pumps show limited flow control, and the actual flow rate cannot be monitored. In addition, injection volumes are limited by the syringe, and automation can thus be difficult. An alternative to syringe pumps is pressure-based flow controllers. These show high-precision flow control, fast reaction time, and flow monitoring: parameters which are paramount for microfluidic drug discovery applications.

The benefits of choosing Fluigent for your flow control system:

- Best in class stability: < 0.5% thanks to our field-proven, patented FASTAB™ technology allowing optimal flow control with the robustness required in demanding industrial environments

- Workflow automation becomes straightforward with the Fluigent SDK and software included in the system

- Our engineering team members are experts in microfluidic design, mechanical and software integration, and biology applications

Related resources

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read moreOrgan on a chip Towards the next generation of cell culture platforms

Read more- Microfluidics case studies

OEM Case Study: Microfluidic Drug Screening

Read more - Expert Reviews: Basics of Microfluidics

Key reliability indicators for OEM components to ensure long-term performance of your flow control system

Read more - Expert Reviews: Basics of Microfluidics

Key considerations for fluidic system integration

Read more - Expert Reviews: Basics of Microfluidics

Prostate Organoid Culture in Microbeads

Read more - Expert Reviews: Basics of Microfluidics

Flow control for droplet generation using syringe pumps and pressure-based flow controllers

Read more - Expert Reviews: Basics of Microfluidics

Microfluidic Flow Control: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications

Read more